Polymer on:

[Wikipedia]

[Google]

[Amazon]

A polymer (; Greek '' poly-'', "many" + ''

A polymer (; Greek '' poly-'', "many" + ''

A polymer (; Greek '' poly-'', "many" + ''

A polymer (; Greek '' poly-'', "many" + ''-mer

{{Short pages monitor

The structure of a polymeric material can be described at different length scales, from the sub-nm length scale up to the macroscopic one. There is in fact a hierarchy of structures, in which each stage provides the foundations for the next one.

The starting point for the description of the structure of a polymer is the identity of its constituent monomers. Next, the

An important microstructural feature of a polymer is its architecture and shape, which relates to the way branch points lead to a deviation from a simple linear chain. A branched polymer molecule is composed of a main chain with one or more substituent side chains or branches. Types of branched polymers include star polymers, comb polymers,

An important microstructural feature of a polymer is its architecture and shape, which relates to the way branch points lead to a deviation from a simple linear chain. A branched polymer molecule is composed of a main chain with one or more substituent side chains or branches. Types of branched polymers include star polymers, comb polymers,

The bulk properties of a polymer are those most often of end-use interest. These are the properties that dictate how the polymer actually behaves on a macroscopic scale.

The bulk properties of a polymer are those most often of end-use interest. These are the properties that dictate how the polymer actually behaves on a macroscopic scale.

In general, polymeric mixtures are far less miscible than mixtures of

In general, polymeric mixtures are far less miscible than mixtures of

How to Analyze Polymers Using X-ray DiffractionPolymer Chemistry Hypertext, Educational resourceIntroduction to Polymers

{{Portal bar, Science, Chemistry, Numismatics, Electronics, Algae, Money Polymer chemistry Soft matter Materials science

microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymers ...

essentially describes the arrangement of these monomers within the polymer at the scale of a single chain. The microstructure determines the possibility for the polymer to form phases with different arrangements, for example through crystallization, the glass transition or microphase separation.

These features play a major role in determining the physical and chemical properties of a polymer.

Monomers and repeat units

The identity of the repeat units (monomer residues, also known as "mers") comprising a polymer is its first and most important attribute. Polymer nomenclature is generally based upon the type of monomer residues comprising the polymer. A polymer which contains only a single type ofrepeat unit

In polymer chemistry, a repeat unit or repeating unit (or mer) is a part of a polymer whose repetition would produce the complete polymer chain (except for the end-groups) by linking the repeat units together successively along the chain, like the ...

is known as a homopolymer, while a polymer containing two or more types of repeat units is known as a copolymer. A terpolymer is a copolymer which contains three types of repeat units.

Polystyrene is composed only of styrene

Styrene () is an organic compound with the chemical formula C6H5CH=CH2. This derivative of benzene is a colorless oily liquid, although aged samples can appear yellowish. The compound evaporates easily and has a sweet smell, although high concen ...

-based repeat units, and is classified as a homopolymer. Polyethylene terephthalate, even though produced from two different monomers ( ethylene glycol and terephthalic acid), is usually regarded as a homopolymer because only one type of repeat unit is formed. Ethylene-vinyl acetate contains more than one variety of repeat unit and is a copolymer. Some biological polymers are composed of a variety of different but structurally related monomer residues; for example, polynucleotide

A polynucleotide molecule is a biopolymer composed of 13 or more nucleotide monomers covalently bonded in a chain. DNA (deoxyribonucleic acid) and RNA (ribonucleic acid) are examples of polynucleotides with distinct biological function. The pre ...

s such as DNA are composed of four types of nucleotide

Nucleotides are organic molecules consisting of a nucleoside and a phosphate. They serve as monomeric units of the nucleic acid polymers – deoxyribonucleic acid (DNA) and ribonucleic acid (RNA), both of which are essential biomolecule ...

subunits.

:

A polymer containing ionizable subunits (e.g., pendant carboxylic groups) is known as a polyelectrolyte

Polyelectrolytes are polymers whose repeating units bear an electrolyte group. Polycations and polyanions are polyelectrolytes. These groups dissociate in aqueous solutions (water), making the polymers charged. Polyelectrolyte properties are ...

or ionomer, when the fraction of ionizable units is large or small respectively.

Microstructure

The microstructure of a polymer (sometimes called configuration) relates to the physical arrangement of monomer residues along the backbone of the chain. These are the elements of polymer structure that require the breaking of a covalent bond in order to change. Various polymer structures can be produced depending on the monomers and reaction conditions: A polymer may consist of linear macromolecules containing each only one unbranched chain. In the case of unbranched polyethylene, this chain is a long-chain ''n''-alkane. There are also branched macromolecules with a main chain and side chains, in the case of polyethylene the side chains would be alkyl groups. In particular unbranched macromolecules can be in the solid state semi-crystalline, crystalline chain sections highlighted red in the figure below. While branched and unbranched polymers are usually thermoplastics, many elastomers have a wide-meshed cross-linking between the "main chains". Close-meshed crosslinking, on the other hand, leads to thermosets. Cross-links and branches are shown as red dots in the figures. Highly branched polymers are amorphous and the molecules in the solid interact randomly. :Polymer architecture

polymer brush

A polymer brush is the name given to a surface coating consisting of polymers tethered to a surface. The brush may be either in a solvated state, where the tethered polymer layer consists of polymer and solvent, or in a melt state, where the teth ...

es, dendronized polymers, ladder polymer

In chemistry, a ladder polymer is a type of double stranded polymer with the connectivity of a ladder. In a typical one-dimensional polymer, e.g. polyethylene and polysiloxanes, the monomers form two bonds, giving a chain. In a ladder polymer the ...

s, and dendrimer

Dendrimers are highly ordered, branched polymeric molecules. Synonymous terms for dendrimer include arborols and cascade molecules. Typically, dendrimers are symmetric about the core, and often adopt a spherical three-dimensional morphology. The ...

s. There exist also two-dimensional polymers (2DP) which are composed of topologically planar repeat units. A polymer's architecture affects many of its physical properties including solution viscosity, melt viscosity, solubility in various solvents, glass-transition temperature and the size of individual polymer coils in solution. A variety of techniques may be employed for the synthesis of a polymeric material with a range of architectures, for example living polymerization

In polymer chemistry, living polymerization is a form of chain growth polymerization where the ability of a growing polymer chain to terminate has been removed. This can be accomplished in a variety of ways. Chain termination and chain transfer ...

.

Chain length

A common means of expressing the length of a chain is the degree of polymerization, which quantifies the number of monomers incorporated into the chain.Rubinstein, p. 3 As with other molecules, a polymer's size may also be expressed in terms of molecular weight. Since synthetic polymerization techniques typically yield a statistical distribution of chain lengths, the molecular weight is expressed in terms of weighted averages. The number-average molecular weight (''M''n) and weight-average molecular weight (''M''w) are most commonly reported.Rubinstein, pp. 23–24 The ratio of these two values (''M''w / ''M''n) is thedispersity

In chemistry, the dispersity is a measure of the heterogeneity of sizes of molecules or particles in a mixture. A collection of objects is called uniform if the objects have the same size, shape, or mass. A sample of objects that have an inconsi ...

(''Đ''), which is commonly used to express the width of the molecular weight distribution.

The physical properties of polymer strongly depend on the length (or equivalently, the molecular weight) of the polymer chain.Rubinstein, p. 5 One important example of the physical consequences of the molecular weight is the scaling of the viscosity (resistance to flow) in the melt. The influence of the weight-average molecular weight () on the melt viscosity () depends on whether the polymer is above or below the onset of entanglements. Below the entanglement molecular weight, , whereas above the entanglement molecular weight, . In the latter case, increasing the polymer chain length 10-fold would increase the viscosity over 1000 times. Increasing chain length furthermore tends to decrease chain mobility, increase strength and toughness, and increase the glass-transition temperature (Tg). This is a result of the increase in chain interactions such as van der Waals attractions and entanglements that come with increased chain length. These interactions tend to fix the individual chains more strongly in position and resist deformations and matrix breakup, both at higher stresses and higher temperatures.

Monomer arrangement in copolymers

Copolymers are classified either as statistical copolymers, alternating copolymers, block copolymers, graft copolymers or gradient copolymers. In the schematic figure below, Ⓐ and Ⓑ symbolize the tworepeat unit

In polymer chemistry, a repeat unit or repeating unit (or mer) is a part of a polymer whose repetition would produce the complete polymer chain (except for the end-groups) by linking the repeat units together successively along the chain, like the ...

s.

:

*Alternating copolymers possess two regularly alternating monomer residues:Painter, p. 14 . An example is the equimolar copolymer of styrene

Styrene () is an organic compound with the chemical formula C6H5CH=CH2. This derivative of benzene is a colorless oily liquid, although aged samples can appear yellowish. The compound evaporates easily and has a sweet smell, although high concen ...

and maleic anhydride

Maleic anhydride is an organic compound with the formula C2H2(CO)2O. It is the acid anhydride of maleic acid. It is a colorless or white solid with an acrid odor. It is produced industrially on a large scale for applications in coatings and pol ...

formed by free-radical chain-growth polymerization.Rudin p.18-20 A step-growth copolymer such as Nylon 66

Nylon 66 (loosely written nylon 6-6, nylon 6/6, nylon 6,6, or nylon 6:6) is a type of polyamide or nylon. It, and nylon 6, are the two most common for textile and plastic industries. Nylon 66 is made of two monomers each containing 6 carbon atoms, ...

can also be considered a strictly alternating copolymer of diamine and diacid residues, but is often described as a homopolymer with the dimeric residue of one amine and one acid as a repeat unit.Cowie p.104

*Periodic copolymers have more than two species of monomer units in a regular sequence.

*Statistical copolymers have monomer residues arranged according to a statistical rule. A statistical copolymer in which the probability of finding a particular type of monomer residue at a particular point in the chain is independent of the types of surrounding monomer residue may be referred to as a truly random copolymer.Painter, p. 15 For example, the chain-growth copolymer of vinyl chloride and vinyl acetate

Vinyl acetate is an organic compound with the formula CH3CO2CH=CH2. This colorless liquid is the precursor to polyvinyl acetate and ethene-vinyl acetate copolymers, important industrial polymers.

Production

The worldwide production capacity of v ...

is random.

*Block copolymers have long sequences of different monomer units. Polymers with two or three blocks of two distinct chemical species (e.g., A and B) are called diblock copolymers and triblock copolymers, respectively. Polymers with three blocks, each of a different chemical species (e.g., A, B, and C) are termed triblock terpolymers.

*Graft or grafted copolymers contain side chains or branches whose repeat units have a different composition or configuration than the main chain. The branches are added on to a preformed main chain macromolecule.

Monomers within a copolymer may be organized along the backbone in a variety of ways. A copolymer containing a controlled arrangement of monomers is called a sequence-controlled polymer. Alternating, periodic and block copolymers are simple examples of sequence-controlled polymers.

Tacticity

Tacticity describes the relative stereochemistry ofchiral

Chirality is a property of asymmetry important in several branches of science. The word ''chirality'' is derived from the Greek (''kheir''), "hand", a familiar chiral object.

An object or a system is ''chiral'' if it is distinguishable from i ...

centers in neighboring structural units within a macromolecule. There are three types of tacticity: isotactic (all substituents on the same side), atactic

Tacticity (from el, τακτικός, taktikos, "relating to arrangement or order") is the relative stereochemistry of adjacent chiral centers within a macromolecule. The practical significance of tacticity rests on the effects on the physical p ...

(random placement of substituents), and syndiotactic

Tacticity (from el, τακτικός, taktikos, "relating to arrangement or order") is the relative stereochemistry of adjacent chiral centers within a macromolecule. The practical significance of tacticity rests on the effects on the physical p ...

(alternating placement of substituents).

:

Morphology

Polymer morphology generally describes the arrangement and microscale ordering of polymer chains in space. The macroscopic physical properties of a polymer are related to the interactions between the polymer chains. * Disordered polymers: In the solid state, atactic polymers, polymers with a high degree of branching and random copolymers form amorphous (i.e. glassy structures).Bernd Tieke: ''Makromolekulare Chemie.'' 3. Auflage, Wiley-VCH, Weinheim 2014, S. 295f (in German). In melt and solution, polymers tend to form a constantly changing "statistical cluster", see freely-jointed-chain model. In the solid state, the respective conformations of the molecules are frozen. Hooking and entanglement of chain molecules lead to a "mechanical bond" between the chains.Intermolecular

An intermolecular force (IMF) (or secondary force) is the force that mediates interaction between molecules, including the electromagnetic forces of attraction

or repulsion which act between atoms and other types of neighbouring particles, e.g. a ...

and intramolecular attractive forces only occur at sites where molecule segments are close enough to each other. The irregular structures of the molecules prevent a narrower arrangement.

* Linear polymers with periodic structure, low branching and stereoregularity (e. g. not atactic) have a semi-crystalline structure in the solid state. In simple polymers (such as polyethylene), the chains are present in the crystal in zigzag conformation. Several zigzag conformations form dense chain packs, called crystallites or lamellae. The lamellae are much thinner than the polymers are long (often about 10 nm). Wolfgang Kaiser: ''Kunststoffchemie für Ingenieure.'' 3. Auflage, Carl Hanser, München 2011, S. 84. They are formed by more or less regular folding of one or more molecular chains. Amorphous structures exist between the lamellae. Individual molecules can lead to entanglements between the lamellae and can also be involved in the formation of two (or more) lamellae (chains than called tie molecules). Several lamellae form a superstructure, a spherulite

In petrology, spherulites () are small, rounded bodies that commonly occur in vitreous igneous rocks. They are often visible in specimens of obsidian, pitchstone, and rhyolite as globules about the size of millet seed or rice grain, with a dul ...

, often with a diameter in the range of 0.05 to 1 mm.

:The type and arrangement of (functional) residues of the repeat units effects or determines the crystallinity and strength of the secondary valence bonds. In isotactic polypropylene, the molecules form a helix. Like the zigzag conformation, such helices allow a dense chain packing. Particularly strong intermolecular interactions occur when the residues of the repeating units allow the formation of hydrogen bonds, as in the case of ''p''-aramid. The formation of strong intramolecular associations may produce diverse folded states of single linear chains with distinct circuit topology

The circuit topology of a folded linear polymer refers to the arrangement of its intra-molecular contacts. Examples of linear polymers with intra-molecular contacts are nucleic acids and proteins. Proteins fold via formation of contacts of variou ...

. Crystallinity and superstructure are always dependent on the conditions of their formation, see also: crystallization of polymers. Compared to amorphous structures, semi-crystalline structures lead to a higher stiffness, density, melting temperature and higher resistance of a polymer.

* Cross-linked polymers: Wide-meshed cross-linked polymers are elastomers and cannot be molten (unlike thermoplastics); heating cross-linked polymers only leads to decomposition. Thermoplastic elastomer

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. ...

s, on the other hand, are reversibly "physically crosslinked" and can be molten. Block copolymers in which a hard segment of the polymer has a tendency to crystallize and a soft segment has an amorphous structure are one type of thermoplastic elastomers: the hard segments ensure wide-meshed, physical crosslinking.

Crystallinity

When applied to polymers, the term ''crystalline'' has a somewhat ambiguous usage. In some cases, the term ''crystalline'' finds identical usage to that used in conventional crystallography. For example, the structure of a crystalline protein or polynucleotide, such as a sample prepared for x-ray crystallography, may be defined in terms of a conventional unit cell composed of one or more polymer molecules with cell dimensions of hundreds of angstroms or more. A synthetic polymer may be loosely described as crystalline if it contains regions of three-dimensional ordering on atomic (rather than macromolecular) length scales, usually arising from intramolecular folding or stacking of adjacent chains. Synthetic polymers may consist of both crystalline and amorphous regions; the degree of crystallinity may be expressed in terms of a weight fraction or volume fraction of crystalline material. Few synthetic polymers are entirely crystalline. The crystallinity of polymers is characterized by their degree of crystallinity, ranging from zero for a completely non-crystalline polymer to one for a theoretical completely crystalline polymer. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers. Polymers with a degree of crystallinity approaching zero or one will tend to be transparent, while polymers with intermediate degrees of crystallinity will tend to be opaque due to light scattering by crystalline or glassy regions. For many polymers, crystallinity may also be associated with decreased transparency.Chain conformation

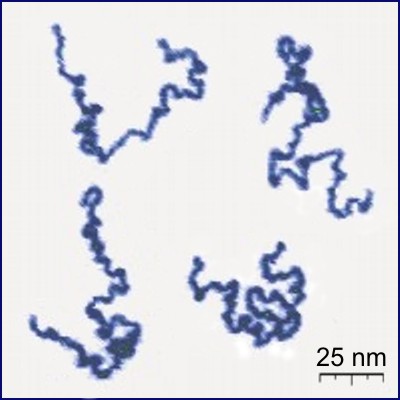

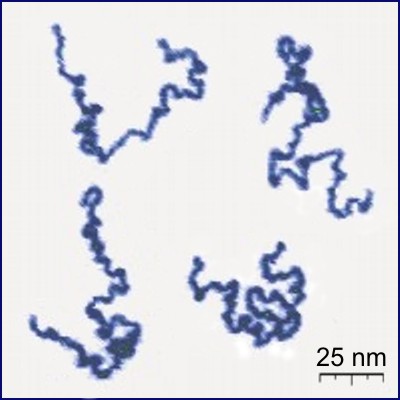

The space occupied by a polymer molecule is generally expressed in terms ofradius of gyration ''Radius of gyration'' or gyradius of a body about the axis of rotation is defined as the radial distance to a point which would have a moment of inertia the same as the body's actual distribution of mass, if the total mass of the body were concentr ...

, which is an average distance from the center of mass of the chain to the chain itself. Alternatively, it may be expressed in terms of pervaded volume, which is the volume spanned by the polymer chain and scales with the cube of the radius of gyration.

The simplest theoretical models for polymers in the molten, amorphous state are ideal chain

Ideal may refer to:

Philosophy

* Ideal (ethics), values that one actively pursues as goals

* Platonic ideal, a philosophical idea of trueness of form, associated with Plato

Mathematics

* Ideal (ring theory), special subsets of a ring considered ...

s.

Properties

Polymer properties depend of their structure and they are divided into classes according to their physical bases. Many physical and chemical properties describe how a polymer behaves as a continuous macroscopic material. They are classified as bulk properties, or intensive properties according to thermodynamics.Mechanical properties

The bulk properties of a polymer are those most often of end-use interest. These are the properties that dictate how the polymer actually behaves on a macroscopic scale.

The bulk properties of a polymer are those most often of end-use interest. These are the properties that dictate how the polymer actually behaves on a macroscopic scale.

Tensile strength

The tensile strength of a material quantifies how much elongating stress the material will endure before failure. This is very important in applications that rely upon a polymer's physical strength or durability. For example, a rubber band with a higher tensile strength will hold a greater weight before snapping. In general, tensile strength increases with polymer chain length and crosslinking of polymer chains.Young's modulus of elasticity

Young's modulus quantifies the elasticity of the polymer. It is defined, for smallstrain

Strain may refer to:

Science and technology

* Strain (biology), variants of plants, viruses or bacteria; or an inbred animal used for experimental purposes

* Strain (chemistry), a chemical stress of a molecule

* Strain (injury), an injury to a mu ...

s, as the ratio of rate of change of stress to strain. Like tensile strength, this is highly relevant in polymer applications involving the physical properties of polymers, such as rubber bands. The modulus is strongly dependent on temperature. Viscoelasticity describes a complex time-dependent elastic response, which will exhibit hysteresis in the stress-strain curve when the load is removed. Dynamic mechanical analysis or DMA measures this complex modulus by oscillating the load and measuring the resulting strain as a function of time.

Transport properties

Transport properties such as diffusivity describe how rapidly molecules move through the polymer matrix. These are very important in many applications of polymers for films and membranes. The movement of individual macromolecules occurs by a process called reptation in which each chain molecule is constrained by entanglements with neighboring chains to move within a virtual tube. The theory of reptation can explain polymer molecule dynamics and viscoelasticity.Phase behavior

Crystallization and melting

Depending on their chemical structures, polymers may be either semi-crystalline or amorphous. Semi-crystalline polymers can undergo crystallization and melting transitions, whereas amorphous polymers do not. In polymers, crystallization and melting do not suggest solid-liquid phase transitions, as in the case of water or other molecular fluids. Instead, crystallization and melting refer to the phase transitions between two solid states (''i.e.'', semi-crystalline and amorphous). Crystallization occurs above the glass-transition temperature (''T''g) and below the melting temperature (''T''m).Glass transition

All polymers (amorphous or semi-crystalline) go through glass transitions. The glass-transition temperature (''T''g) is a crucial physical parameter for polymer manufacturing, processing, and use. Below ''T''g, molecular motions are frozen and polymers are brittle and glassy. Above ''T''g, molecular motions are activated and polymers are rubbery and viscous. The glass-transition temperature may be engineered by altering the degree of branching or crosslinking in the polymer or by the addition ofplasticizer

A plasticizer ( UK: plasticiser) is a substance that is added to a material to make it softer and more flexible, to increase its plasticity, to decrease its viscosity, and/or to decrease friction during its handling in manufacture.

Plasticiz ...

s.

Whereas crystallization and melting are first-order phase transitions, the glass transition is not. The glass transition shares features of second-order phase transitions (such as discontinuity in the heat capacity, as shown in the figure), but it is generally not considered a thermodynamic transition between equilibrium states.

Mixing behavior

small molecule

Within the fields of molecular biology and pharmacology, a small molecule or micromolecule is a low molecular weight (≤ 1000 daltons) organic compound that may regulate a biological process, with a size on the order of 1 nm. Many drugs ...

materials. This effect results from the fact that the driving force for mixing is usually entropy, not interaction energy. In other words, miscible materials usually form a solution not because their interaction with each other is more favorable than their self-interaction, but because of an increase in entropy and hence free energy associated with increasing the amount of volume available to each component. This increase in entropy scales with the number of particles (or moles) being mixed. Since polymeric molecules are much larger and hence generally have much higher specific volumes than small molecules, the number of molecules involved in a polymeric mixture is far smaller than the number in a small molecule mixture of equal volume. The energetics of mixing, on the other hand, is comparable on a per volume basis for polymeric and small molecule mixtures. This tends to increase the free energy of mixing for polymer solutions and thereby making solvation less favorable, and thereby making the availability of concentrated solutions of polymers far rarer than those of small molecules.

Furthermore, the phase behavior of polymer solutions and mixtures is more complex than that of small molecule mixtures. Whereas most small molecule solutions exhibit only an upper critical solution temperature

The upper critical solution temperature (UCST) or upper consolute temperature is the critical temperature above which the components of a mixture are miscible in all proportions. The word ''upper'' indicates that the UCST is an upper bound to a tem ...

phase transition (UCST), at which phase separation occurs with cooling, polymer mixtures commonly exhibit a lower critical solution temperature phase transition (LCST), at which phase separation occurs with heating.

In dilute solutions, the properties of the polymer are characterized by the interaction between the solvent and the polymer. In a good solvent, the polymer appears swollen and occupies a large volume. In this scenario, intermolecular forces between the solvent and monomer subunits dominate over intramolecular interactions. In a bad solvent or poor solvent, intramolecular forces dominate and the chain contracts. In the theta solvent, or the state of the polymer solution where the value of the second virial coefficient becomes 0, the intermolecular polymer-solvent repulsion balances exactly the intramolecular monomer-monomer attraction. Under the theta condition (also called the Flory condition), the polymer behaves like an ideal random coil

In polymer chemistry, a random coil is a conformation of polymers where the monomer subunits are oriented randomly while still being bonded to adjacent units. It is not one specific shape, but a statistical distribution of shapes for all the ch ...

. The transition between the states is known as a coil–globule transition.

Inclusion of plasticizers

Inclusion of plasticizers tends to lower Tg and increase polymer flexibility. Addition of the plasticizer will also modify dependence of the glass-transition temperature Tg on the cooling rate. The mobility of the chain can further change if the molecules of plasticizer give rise to hydrogen bonding formation. Plasticizers are generally small molecules that are chemically similar to the polymer and create gaps between polymer chains for greater mobility and fewer interchain interactions. A good example of the action of plasticizers is related to polyvinylchlorides or PVCs. A uPVC, or unplasticized polyvinylchloride, is used for things such as pipes. A pipe has no plasticizers in it, because it needs to remain strong and heat-resistant. Plasticized PVC is used in clothing for a flexible quality. Plasticizers are also put in some types of cling film to make the polymer more flexible.Chemical properties

The attractive forces between polymer chains play a large part in determining the polymer’s properties. Because polymer chains are so long, they have many such interchain interactions per molecule, amplifying the effect of these interactions on the polymer properties in comparison to attractions between conventional molecules. Different side groups on the polymer can lend the polymer toionic bonding

Ionic bonding is a type of chemical bonding that involves the electrostatic attraction between oppositely charged ions, or between two atoms with sharply different electronegativities, and is the primary interaction occurring in ionic compounds ...

or hydrogen bonding

In chemistry, a hydrogen bond (or H-bond) is a primarily electrostatic force of attraction between a hydrogen (H) atom which is covalently bound to a more electronegative "donor" atom or group (Dn), and another electronegative atom bearing a l ...

between its own chains. These stronger forces typically result in higher tensile strength and higher crystalline melting points.

The intermolecular forces in polymers can be affected by dipole

In physics, a dipole () is an electromagnetic phenomenon which occurs in two ways:

*An electric dipole deals with the separation of the positive and negative electric charges found in any electromagnetic system. A simple example of this system ...

s in the monomer units. Polymers containing amide or carbonyl

In organic chemistry, a carbonyl group is a functional group composed of a carbon atom double-bonded to an oxygen atom: C=O. It is common to several classes of organic compounds, as part of many larger functional groups. A compound containi ...

groups can form hydrogen bonds between adjacent chains; the partially positively charged hydrogen atoms in N-H groups of one chain are strongly attracted to the partially negatively charged oxygen atoms in C=O groups on another. These strong hydrogen bonds, for example, result in the high tensile strength and melting point of polymers containing urethane or urea linkages. Polyesters have dipole-dipole bonding between the oxygen atoms in C=O groups and the hydrogen atoms in H-C groups. Dipole bonding is not as strong as hydrogen bonding, so a polyester's melting point and strength are lower than Kevlar

Kevlar (para-aramid) is a strong, heat-resistant synthetic fiber, related to other aramids such as Nomex and Technora. Developed by Stephanie Kwolek at DuPont in 1965, the high-strength material was first used commercially in the early 1970s a ...

's ( Twaron), but polyesters have greater flexibility. Polymers with non-polar units such as polyethylene interact only through weak Van der Waals forces. As a result, they typically have lower melting temperatures than other polymers.

When a polymer is dispersed or dissolved in a liquid, such as in commercial products like paints and glues, the chemical properties and molecular interactions influence how the solution flows and can even lead to self-assembly

Self-assembly is a process in which a disordered system of pre-existing components forms an organized structure or pattern as a consequence of specific, local interactions among the components themselves, without external direction. When the ...

of the polymer into complex structures. When a polymer is applied as a coating, the chemical properties will influence the adhesion of the coating and how it interacts with external materials, such as superhydrophobic

Ultrahydrophobic (or superhydrophobic) surfaces are highly hydrophobic, i.e., extremely difficult to wet. The contact angles of a water droplet on an ultrahydrophobic material exceed 150°. This is also referred to as the lotus effect, after the ...

polymer coatings leading to water resistance. Overall the chemical properties of a polymer are important elements for designing new polymeric material products.

Optical properties

Polymers such as PMMA and HEMA:MMA are used as matrices in the gain medium of solid-state dye lasers, also known as solid-state dye-doped polymer lasers. These polymers have a high surface quality and are also highly transparent so that the laser properties are dominated by thelaser dye

Laser dyes are dyes used as laser medium in a dye laser. Laser dyes include the coumarins and the rhodamines. Coumarin dyes emit in the green region of the spectrum, whereas rhodamine dyes are used for emission in the yellow-red. The color emi ...

used to dope the polymer matrix. These type of lasers, that also belong to the class of organic laser

Organic lasers use an organic (carbon based) material as the gain medium. The first organic laser was the liquid dye laser. These lasers use laser dye solutions as their gain media.

Organic lasers are inherently tunable and when configured as o ...

s, are known to yield very narrow linewidths which is useful for spectroscopy and analytical applications. An important optical parameter in the polymer used in laser applications is the change in refractive index with temperature

also known as dn/dT. For the polymers mentioned here the (dn/dT) ~ −1.4 × 10−4 in units of K−1 in the 297 ≤ T ≤ 337 K range.

Electrical properties

Most conventional polymers such as polyethylene are electrical insulators, but the development of polymers containing π-conjugated bonds has led to a wealth of polymer-based semiconductors, such aspolythiophene

Polythiophenes (PTs) are polymerized thiophenes, a sulfur heterocycle. The parent PT is an insoluble colored solid with the formula (C4H2S)n. The rings are linked through the 2- and 5-positions. Poly(alkylthiophene)s have alkyl substituents at ...

s. This has led to many applications in the field of organic electronics.

Applications

Nowadays, synthetic polymers are used in almost all walks of life. Modern society would look very different without them. The spreading of polymer use is connected to their unique properties: low density, low cost, good thermal/electrical insulation properties, high resistance to corrosion, low-energy demanding polymer manufacture and facile processing into final products. For a given application, the properties of a polymer can be tuned or enhanced by combination with other materials, as in composites. Their application allows to save energy (lighter cars and planes, thermally insulated buildings), protect food and drinking water (packaging), save land and lower use of fertilizers (synthetic fibres), preserve other materials (coatings), protect and save lifes (hygiene, medical applications). A representative, non-exhaustive list of applications is given below. * Clothing, sportswear and accessories: polyester andPVC clothing

PVC clothing is shiny clothing made from the plastic polyvinyl chloride (PVC). PVC plastic is often called "vinyl" and this type of clothing is commonly known as "vinyl clothing". PVC is sometimes confused with the similarly shiny patent le ...

, spandex

Spandex, Lycra, or elastane is a synthetic fiber known for its exceptional elasticity. It is a polyether-polyurea copolymer that was invented in 1958 by chemist Joseph Shivers at DuPont's Benger Laboratory in Waynesboro, Virginia, US.

The g ...

, sport shoes, wetsuit

A wetsuit is a garment worn to provide thermal protection while wet. It is usually made of foamed neoprene, and is worn by surfers, divers, windsurfers, canoeists, and others engaged in water sports and other activities in or on water. It ...

s, footballs and billiard balls

A billiard ball is a small, hard ball used in cue sports, such as carom billiards, pool, and snooker. The number, type, diameter, color, and pattern of the balls differ depending upon the specific game being played. Various particular ball pro ...

, ski

A ski is a narrow strip of semi-rigid material worn underfoot to glide over snow. Substantially longer than wide and characteristically employed in pairs, skis are attached to ski boots with ski bindings, with either a free, lockable, or partia ...

s and snowboards, rackets, parachutes, sails, tents and shelters.

* Electronic and photonic technologies: organic field effect transistors

The field-effect transistor (FET) is a type of transistor that uses an electric field to control the flow of current in a semiconductor. FETs (JFETs or MOSFETs) are devices with three terminals: ''source'', ''gate'', and ''drain''. FETs control ...

(OFET), light emitting diodes

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (cor ...

(OLED) and solar cells, television components, compact discs (CD), photoresist

A photoresist (also known simply as a resist) is a light-sensitive material used in several processes, such as photolithography and photoengraving, to form a patterned coating on a surface. This process is crucial in the electronic industry.

...

s, holography

Holography is a technique that enables a wavefront to be recorded and later re-constructed. Holography is best known as a method of generating real three-dimensional images, but it also has a wide range of other applications. In principle, i ...

.

* Packaging and containers: films, bottles

A bottle is a narrow-necked container made of an impermeable material (such as glass, plastic or aluminium) in various shapes and sizes that stores and transports liquids. Its mouth, at the bottling line, can be sealed with an internal stop ...

, food packaging, barrels.

* Insulation: electrical

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described ...

and thermal insulation, spray foams.

* Construction and structural applications: garden furniture

Garden furniture, also called patio furniture or outdoor furniture, is a type of furniture specifically designed for outdoor use. It is typically made of weather-resistant materials such as aluminium which is rust-proof.

History

The oldes ...

, PVC windows, flooring, sealing, pipes

Pipe(s), PIPE(S) or piping may refer to:

Objects

* Pipe (fluid conveyance), a hollow cylinder following certain dimension rules

** Piping, the use of pipes in industry

* Smoking pipe

** Tobacco pipe

* Half-pipe and quarter pipe, semi-circula ...

.

* Paints, glues and lubricants: varnish, adhesives, dispersants, anti-graffiti coating

An anti-graffiti coating is a coating that prevents graffiti paint from bonding to surfaces.

Cleaning graffiti off buildings costs billions of dollars annually. Many cities have started anti-graffiti programs but vandalism is still a problem. Comp ...

s, antifouling coatings, non-stick surface

A non-stick surface is engineered to reduce the ability of other materials to stick to it. Non-stick cookware is a common application, where the non-stick coating allows food to brown without sticking to the pan. Non-stick is often used to refer ...

s, lubricants.

* Car parts: tires, bumpers, windshields, windscreen wipers, fuel tank

A fuel tank (also called a petrol tank or gas tank) is a safe container for flammable fluids. Though any storage tank for fuel may be so called, the term is typically applied to part of an engine system in which the fuel is stored and propelle ...

s, car seat

A car seat is the seat used in automobiles. Most car seats are made from inexpensive but durable material in order to withstand prolonged use. The most common material is polyester.

Bucket seat and bench seat

A bucket seat is a separate ...

s.

* Household items: bucket

A bucket is typically a watertight, vertical cylinder or truncated cone or square, with an open top and a flat bottom, attached to a semicircular carrying handle called the ''bail''.

A bucket is usually an open-top container. In contrast, a ...

s, kitchenware, toys (e.g., construction set

A construction set is a set of standardized pieces that allow for the construction of a variety of different models. The pieces avoid the lead-time of manufacturing custom pieces, and of requiring special training or design time to constr ...

s and Rubik's cube).

* Medical applications: blood bag, syringes, rubber glove

A rubber glove is a glove made out of natural rubber or Synthetic rubber. The term ‘rubber’ refers to durable, waterproof and elastic material made from natural or synthetic latex. Rubber gloves can be unsupported (rubber only) or supported ( ...

s, surgical suture, contact lenses, prosthesis, controlled drug delivery and release, matrices for cell growth.

* Personal hygiene and healthcare: diapers using superabsorbent polymer

A superabsorbent polymer (SAP) (also called slush powder) is a water-absorbing hydrophilic homopolymers or copolymers that can absorb and retain extremely large amounts of a liquid relative to its own mass.

Water-absorbing polymers, which are cla ...

s, toothbrushes, cosmetics, shampoo, condoms.

* Security: personal protective equipment, bulletproof vests, space suit

A space suit or spacesuit is a garment worn to keep a human alive in the harsh environment of outer space, vacuum and temperature extremes. Space suits are often worn inside spacecraft as a safety precaution in case of loss of cabin pressure, ...

s, ropes.

* Separation technologies: synthetic membrane

An artificial membrane, or synthetic membrane, is a synthetically created membrane which is usually intended for separation purposes in laboratory or in industry. Synthetic membranes have been successfully used for small and large-scale industrial ...

s, fuel cell membranes, filtration, ion-exchange resin

An ion-exchange resin or ion-exchange polymer is a resin or polymer that acts as a medium for ion exchange. It is an insoluble matrix (or support structure) normally in the form of small (0.25–1.43 mm radius) microbeads, usually white or ye ...

s.

* Money: polymer banknote

Polymer banknotes are banknotes made from a synthetic polymer such as biaxially oriented polypropylene (BOPP). Such notes incorporate many security features not available in paper banknotes, including the use of metameric inks. Polymer banknote ...

s and payment card

Payment cards are part of a payment system issued by financial institutions, such as a bank, to a customer that enables its owner (the cardholder) to access the funds in the customer's designated bank accounts, or through a credit account and ...

s.

* 3D printing.

Standardized nomenclature

There are multiple conventions for naming polymer substances. Many commonly used polymers, such as those found in consumer products, are referred to by a common or trivial name. The trivial name is assigned based on historical precedent or popular usage rather than a standardized naming convention. Both theAmerican Chemical Society

The American Chemical Society (ACS) is a scientific society based in the United States that supports scientific inquiry in the field of chemistry. Founded in 1876 at New York University, the ACS currently has more than 155,000 members at all ...

(ACS) and IUPAC

The International Union of Pure and Applied Chemistry (IUPAC ) is an international federation of National Adhering Organizations working for the advancement of the chemical sciences, especially by developing nomenclature and terminology. It is ...

have proposed standardized naming conventions; the ACS and IUPAC conventions are similar but not identical. Examples of the differences between the various naming conventions are given in the table below:

In both standardized conventions, the polymers' names are intended to reflect the monomer(s) from which they are synthesized (source based nomenclature) rather than the precise nature of the repeating subunit. For example, the polymer synthesized from the simple alkene ethene

Ethylene (IUPAC name: ethene) is a hydrocarbon which has the formula or . It is a colourless, flammable gas with a faint "sweet and musky" odour when pure. It is the simplest alkene (a hydrocarbon with carbon-carbon double bonds).

Ethylene i ...

is called polyethene, retaining the ''-ene'' suffix even though the double bond is removed during the polymerization process:

:→

:However, IUPAC structure based nomenclature is based on naming of the preferred constitutional repeating unit.

Characterization

Polymer characterization spans many techniques for determining the chemical composition, molecular weight distribution, and physical properties. Select common techniques include the following: *Size-exclusion chromatography

Size-exclusion chromatography (SEC), also known as molecular sieve chromatography, is a chromatographic method in which molecules in solution are separated by their size, and in some cases molecular weight. It is usually applied to large molecules ...

(also called gel permeation chromatography Gel permeation chromatography (GPC) is a type of size-exclusion chromatography (SEC), that separates analytes on the basis of size, typically in organic solvents. The technique is often used for the analysis of polymers. As a technique, SEC was fi ...

), sometimes coupled with static light scattering

Static light scattering is a technique in physical chemistry that measures the intensity of the scattered light to obtain the average molecular weight ''Mw'' of a macromolecule like a polymer or a protein in solution. Measurement of the scattering ...

, can used to determine the number-average molecular weight, weight-average molecular weight, and dispersity

In chemistry, the dispersity is a measure of the heterogeneity of sizes of molecules or particles in a mixture. A collection of objects is called uniform if the objects have the same size, shape, or mass. A sample of objects that have an inconsi ...

.

*Scattering techniques, such as static light scattering

Static light scattering is a technique in physical chemistry that measures the intensity of the scattered light to obtain the average molecular weight ''Mw'' of a macromolecule like a polymer or a protein in solution. Measurement of the scattering ...

and small-angle neutron scattering

Small-angle neutron scattering (SANS) is an experimental technique that uses elastic neutron scattering at small scattering angles to investigate the structure of various substances at a mesoscopic scale of about 1–100 nm.

Small angle n ...

, are used to determine the dimensions (radius of gyration ''Radius of gyration'' or gyradius of a body about the axis of rotation is defined as the radial distance to a point which would have a moment of inertia the same as the body's actual distribution of mass, if the total mass of the body were concentr ...

) of macromolecules in solution or in the melt. These techniques are also used to characterize the three-dimensional structure of microphase-separated block polymers, polymeric micelles, and other materials.

*Wide-angle X-ray scattering

In X-ray crystallography, wide-angle X-ray scattering (WAXS) or wide-angle X-ray diffraction (WAXD) is the analysis of Bragg peaks scattered to wide angles, which (by Bragg's law) are caused by sub-nanometer-sized structures. It is an X-ray-diffr ...

(also called wide-angle X-ray diffraction) is used to determine the crystalline structure of polymers (or lack thereof).

*Spectroscopy techniques, including Fourier-transform infrared spectroscopy

Fourier-transform infrared spectroscopy (FTIR) is a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid, or gas. An FTIR spectrometer simultaneously collects high-resolution spectral data over a wide spectra ...

, Raman spectroscopy, and nuclear magnetic resonance spectroscopy

Nuclear magnetic resonance spectroscopy, most commonly known as NMR spectroscopy or magnetic resonance spectroscopy (MRS), is a spectroscopic technique to observe local magnetic fields around atomic nuclei. The sample is placed in a magnetic fie ...

, can be used to determine the chemical composition.

* Differential scanning calorimetry is used to characterize the thermal properties of polymers, such as the glass-transition temperature, crystallization temperature, and melting temperature. The glass-transition temperature can also be determined by dynamic mechanical analysis

Dynamic mechanical analysis (abbreviated DMA) is a technique used to study and characterize materials. It is most useful for studying the viscoelastic behavior of polymers. A sinusoidal stress is applied and the strain in the material is measured, ...

.

*Thermogravimetry

Thermogravimetric analysis or thermal gravimetric analysis (TGA) is a method of thermal analysis in which the mass of a sample is measured over time as the temperature changes. This measurement provides information about physical phenomena, such ...

is a useful technique to evaluate the thermal stability of the polymer.

*Rheology

Rheology (; ) is the study of the flow of matter, primarily in a fluid (liquid or gas) state, but also as "soft solids" or solids under conditions in which they respond with Plasticity (physics), plastic flow rather than deforming Elasticity (phy ...

is used to characterize the flow and deformation behavior. It can be used to determine the viscosity, modulus, and other rheological properties. Rheology is also often used to determine the molecular architecture (molecular weight, molecular weight distribution, branching) and to understand how the polymer can be processed.

Degradation

Polymer degradation is a change in the properties—tensile strength,color

Color (American English) or colour (British English) is the visual perceptual property deriving from the spectrum of light interacting with the photoreceptor cells of the eyes. Color categories and physical specifications of color are associ ...

, shape, or molecular weight—of a polymer or polymer-based product under the influence of one or more environmental factors, such as heat

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is ...

, light

Light or visible light is electromagnetic radiation that can be perceived by the human eye. Visible light is usually defined as having wavelengths in the range of 400–700 nanometres (nm), corresponding to frequencies of 750–420 te ...

, and the presence of certain chemical

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., w ...

s, oxygen, and enzymes. This change in properties is often the result of bond breaking in the polymer backbone (chain scission

Chain scission is a term used in polymer chemistry describing the Fracture in polymers, degradation of a polymer main chain. It is often caused by Thermal degradation of polymers, thermal stress (heat) or ionizing radiation (e.g. light, UV radiatio ...

) which may occur at the chain ends or at random positions in the chain.

Although such changes are frequently undesirable, in some cases, such as biodegradation

Biodegradation is the breakdown of organic matter by microorganisms, such as bacteria and fungi. It is generally assumed to be a natural process, which differentiates it from composting. Composting is a human-driven process in which biodegrada ...

and recycling

Recycling is the process of converting waste materials into new materials and objects. The recovery of energy from waste materials is often included in this concept. The recyclability of a material depends on its ability to reacquire the p ...

, they may be intended to prevent environmental pollution

Pollution is the introduction of contaminants into the natural environment that cause adverse change. Pollution can take the form of any substance (solid, liquid, or gas) or energy (such as radioactivity, heat, sound, or light). Pollutants, the ...

. Degradation can also be useful in biomedical settings. For example, a copolymer of polylactic acid and polyglycolic acid

Polyglycolide or poly(glycolic acid) (PGA), also spelled as polyglycolic acid, is a biodegradable, thermoplastic polymer and the simplest linear, aliphatic polyester. It can be prepared starting from glycolic acid by means of polycondensation or r ...

is employed in hydrolysable stitches that slowly degrade after they are applied to a wound.

The susceptibility of a polymer to degradation depends on its structure. Epoxies and chains containing aromatic functionalities are especially susceptible to UV degradation

In polymer chemistry photo-oxidation (sometimes: oxidative photodegradation) is the degradation of a polymer surface due to the combined action of light and oxygen. It is the most significant factor in the weathering of plastics. Photo-oxidatio ...

while polyesters are susceptible to degradation by hydrolysis

Hydrolysis (; ) is any chemical reaction in which a molecule of water breaks one or more chemical bonds. The term is used broadly for substitution, elimination, and solvation reactions in which water is the nucleophile.

Biological hydrolys ...

. Polymers containing an unsaturated backbone degrade via ozone cracking

Cracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking. The problem was formerly very common, especially in tires, but is now rarely seen in those ...

. Carbon based polymers are more susceptible to thermal degradation than inorganic polymer

An inorganic polymer is a polymer with a skeletal structure that does not include carbon atoms in the backbone. Polymers containing inorganic and organic components are sometimes called hybrid polymers, and most so-called inorganic polymers are ...

s such as polydimethylsiloxane

Polydimethylsiloxane (PDMS), also known as dimethylpolysiloxane or dimethicone, belongs to a group of polymeric organosilicon compounds that are commonly referred to as silicones. PDMS is the most widely used silicon-based organic polymer, as its ...

and are therefore not ideal for most high-temperature applications.

The degradation of polyethylene occurs by random scission—a random breakage of the bonds that hold the atom

Every atom is composed of a nucleus and one or more electrons bound to the nucleus. The nucleus is made of one or more protons and a number of neutrons. Only the most common variety of hydrogen has no neutrons.

Every solid, liquid, gas, ...

s of the polymer together. When heated above 450 °C, polyethylene degrades to form a mixture of hydrocarbons. In the case of chain-end scission, monomers are released and this process is referred to as unzipping or depolymerization Depolymerization (or depolymerisation) is the process of converting a polymer into a monomer or a mixture of monomers. This process is driven by an increase in entropy.

Ceiling temperature

The tendency of polymers to depolymerize is indicated by ...

. Which mechanism dominates will depend on the type of polymer and temperature; in general, polymers with no or a single small substituent in the repeat unit will decompose via random-chain scission.

The sorting of polymer waste for recycling purposes may be facilitated by the use of the resin identification code

The ASTM International Resin Identification Coding System, often abbreviated RIC, is a set of symbols appearing on plastic products that identify the plastic resin out of which the product is made. It was developed in 1988 by the Society of t ...

s developed by the Society of the Plastics Industry

Founded in 1937, the Society of the Plastics Industry, Inc. was a professional society representing individuals in the plastics industry. In 2010, the organization began doing business as SPI: The Plastics Industry Trade Association, before changi ...

to identify the type of plastic.

Product failure

Failure ofsafety-critical

A safety-critical system (SCS) or life-critical system is a system whose failure or malfunction may result in one (or more) of the following outcomes:

* death or serious injury to people

* loss or severe damage to equipment/property

* environme ...

polymer components can cause serious accidents, such as fire in the case of cracked and degraded polymer fuel line

A fuel line is a hose or pipe used to transfer fuel from one point in a vehicle to another. The United States Environmental Protection Agency defines a fuel line as "all hoses or tubing designed to contain liquid fuel or fuel vapor. This includes ...

s. Chlorine-induced cracking of acetal resin

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. As with many other synthetic pol ...

plumbing joints and polybutylene

Polybutylene (polybutene-1, poly(1-butene), PB-1) is a polyolefin or saturated polymer with the chemical formula (CH2CH(Et))n. Not be confused with polybutene, PB-1 is mainly used in piping.

Production

Polybutylene is produced by polymerisatio ...

pipes has caused many serious floods in domestic properties, especially in the US in the 1990s. Traces of chlorine

Chlorine is a chemical element with the Symbol (chemistry), symbol Cl and atomic number 17. The second-lightest of the halogens, it appears between fluorine and bromine in the periodic table and its properties are mostly intermediate betwee ...

in the water supply attacked polymers present in the plumbing, a problem which occurs faster if any of the parts have been poorly extruded

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex c ...

or injection molded

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

. Attack of the acetal joint occurred because of faulty molding, leading to cracking along the threads of the fitting where there is stress concentration.

Polymer oxidation has caused accidents involving medical device

A medical device is any device intended to be used for medical purposes. Significant potential for hazards are inherent when using a device for medical purposes and thus medical devices must be proved safe and effective with reasonable assura ...

s. One of the oldest known failure modes is ozone cracking caused by chain scission when ozone

Ozone (), or trioxygen, is an inorganic molecule with the chemical formula . It is a pale blue gas with a distinctively pungent smell. It is an allotrope of oxygen that is much less stable than the diatomic allotrope , breaking down in the lo ...

gas attacks susceptible elastomers, such as natural rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Thailand, Malaysia, and ...

and nitrile rubber

Nitrile rubber, also known as nitrile butadiene rubber, NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene. Trade names include Perbunan, Nipol, Krynac and Europrene. This rubber i ...

. They possess double bonds in their repeat units which are cleaved during ozonolysis

In organic chemistry, ozonolysis is an organic reaction where the unsaturated bonds of alkenes (), alkynes (), or azo compounds () are cleaved with ozone (). Alkenes and alkynes form organic compounds in which the multiple carbon–carbon b ...

. Cracks in fuel lines can penetrate the bore of the tube and cause fuel leakage. If cracking occurs in the engine compartment, electric sparks can ignite the gasoline

Gasoline (; ) or petrol (; ) (see ) is a transparent, petroleum-derived flammable liquid that is used primarily as a fuel in most spark-ignited internal combustion engines (also known as petrol engines). It consists mostly of organic co ...

and can cause a serious fire. In medical use degradation of polymers can lead to changes of physical and chemical characteristics of implantable devices.

Nylon 66

Nylon 66 (loosely written nylon 6-6, nylon 6/6, nylon 6,6, or nylon 6:6) is a type of polyamide or nylon. It, and nylon 6, are the two most common for textile and plastic industries. Nylon 66 is made of two monomers each containing 6 carbon atoms, ...

is susceptible to acid hydrolysis

In organic chemistry, acid hydrolysis is a hydrolysis process in which a protic acid is used to catalyze the cleavage of a chemical bond via a nucleophilic substitution reaction, with the addition of the elements of water (H2O). For example, in th ...

, and in one accident, a fractured fuel line led to a spillage of diesel into the road. If diesel fuel

Diesel fuel , also called diesel oil, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a result of compression of the inlet air and ...

leaks onto the road, accidents to following cars can be caused by the slippery nature of the deposit, which is like black ice

Black ice, sometimes called clear ice, is a thin coating of glaze ice on a surface, especially on streets. The ice itself is not black, but visually transparent, allowing the often black road below to be seen through it. The typically low level ...

. Furthermore, the asphalt concrete

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and tarmac, bitumen macadam, or rolled asphalt in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface roads, parkin ...

road surface will suffer damage as a result of the diesel fuel dissolving the asphaltene

Asphaltenes are molecular substances that are found in crude oil, along with resins, aromatic hydrocarbons, and saturates (i.e. saturated hydrocarbons such as alkanes). The word "asphaltene" was coined by Boussingault in 1837 when he noticed tha ...

s from the composite material, this resulting in the degradation of the asphalt surface and structural integrity of the road.

See also

* Biopolymer *Ideal chain

Ideal may refer to:

Philosophy

* Ideal (ethics), values that one actively pursues as goals

* Platonic ideal, a philosophical idea of trueness of form, associated with Plato

Mathematics

* Ideal (ring theory), special subsets of a ring considered ...

* Catenation

*Inorganic polymer

An inorganic polymer is a polymer with a skeletal structure that does not include carbon atoms in the backbone. Polymers containing inorganic and organic components are sometimes called hybrid polymers, and most so-called inorganic polymers are ...

* Important publications in polymer chemistry

*Oligomer

In chemistry and biochemistry, an oligomer () is a molecule that consists of a few repeating units which could be derived, actually or conceptually, from smaller molecules, monomers.Quote: ''Oligomer molecule: A molecule of intermediate relativ ...

*Polymer adsorption Adsorption is the adhesion of ions or molecules onto the surface of another phase. Adsorption may occur via physisorption and chemisorption. Ions and molecules can adsorb to many types of surfaces including polymer surfaces. A polymer is a large mo ...

* Polymer classes

*Polymer engineering Polymer engineering is generally an engineering field that designs, analyses, and modifies polymer materials. Polymer engineering covers aspects of the petrochemical industry, polymerization, structure and characterization of polymers, properties of ...

*Polymerization

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many fo ...

* Polymery (botany)

*Reactive compatibilization

Reactive compatibilization is the process of modifying a mixed immiscible blend of polymers to arrest phase separation and allow for the formation of a stable, long-term continuous phase. It is done via the addition of a reactive polymer, miscible ...

*Sequence-controlled polymer

A sequence-controlled polymer is a macromolecule, in which the sequence of monomers is controlled to some degree. This control can be absolute but not necessarily. In other words, a sequence-controlled polymer can be uniform (its dispersity Ð is ...

*Shape-memory polymer

Shape-memory polymers (SMPs) are polymeric smart materials that have the ability to return from a deformed state (temporary shape) to their original (permanent) shape when induced by an external stimulus (trigger), such as temperature change.

P ...

*Sol–gel process

In materials science, the sol–gel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides, especially the oxides of silicon (Si) and titanium (Ti). The process involves con ...

* Supramolecular polymer

*Thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate ...

*Thermosetting polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

References

Bibliography

* * * *External links

How to Analyze Polymers Using X-ray Diffraction

{{Portal bar, Science, Chemistry, Numismatics, Electronics, Algae, Money Polymer chemistry Soft matter Materials science