|

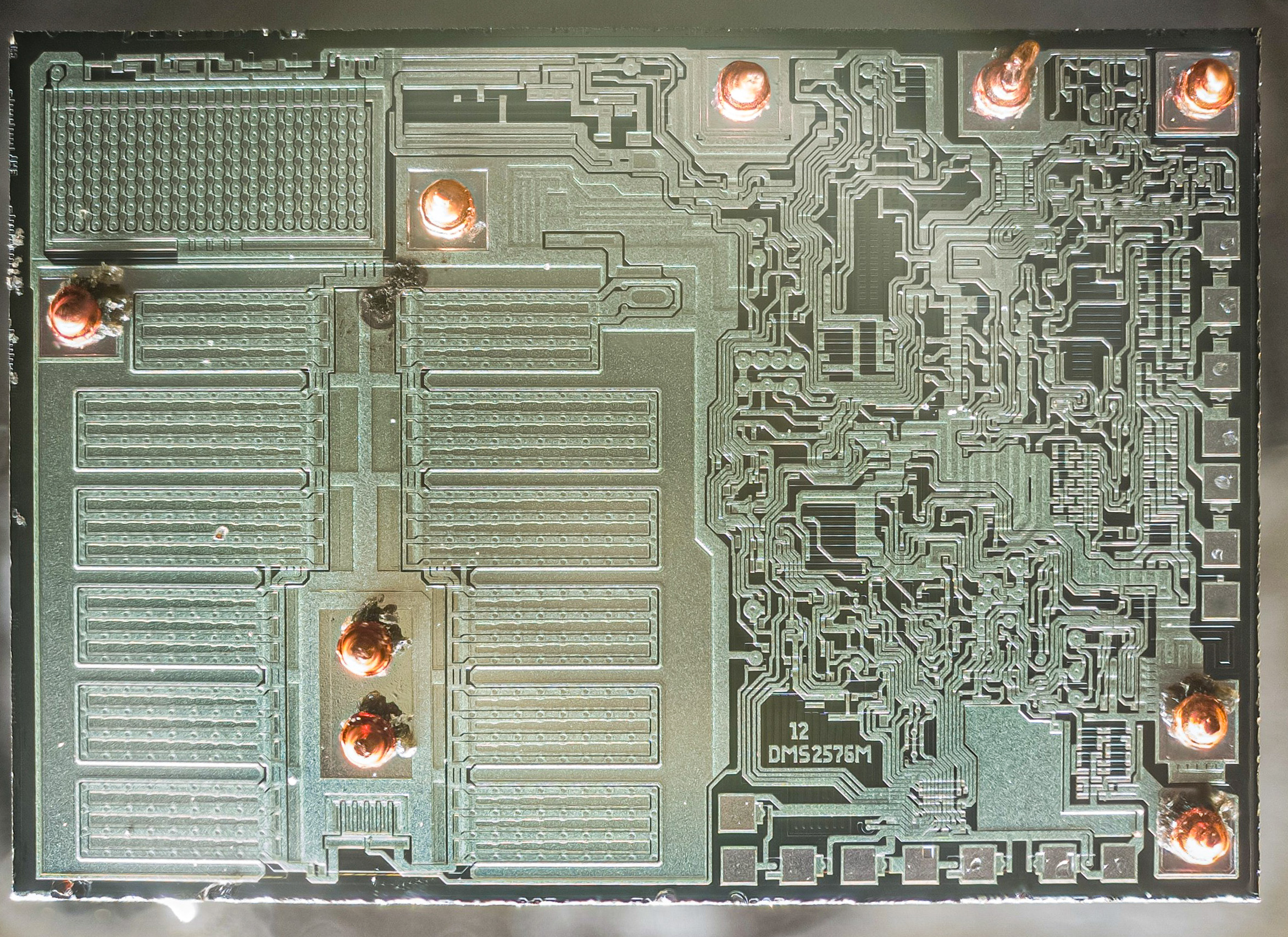

Chip Scale Package

A chip scale package or chip-scale package (CSP) is a type of integrated circuit package. Originally, CSP was the acronym for ''chip-size packaging.'' Since only a few packages are chip size, the meaning of the acronym was adapted to ''chip-scale packaging''. According to IPC's standard J-STD-012, ''Implementation of Flip Chip and Chip Scale Technology'', in order to qualify as chip scale, the package must have an area no greater than 1.2 times that of the die and it must be a single-die, direct surface mountable package. Another criterion that is often applied to qualify these packages as CSPs is their ball pitch should be no more than 1 mm. The concept was first proposed by Junichi Kasai of Fujitsu and Gen Murakami of Hitachi Cable in 1993. The first concept demonstration however came from Mitsubishi Electric. The die may be mounted on an interposer upon which pads or balls are formed, like with flip chip ball grid array (BGA) packaging, or the pads may be etched or pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Circuit

An integrated circuit (IC), also known as a microchip or simply chip, is a set of electronic circuits, consisting of various electronic components (such as transistors, resistors, and capacitors) and their interconnections. These components are etched onto a small, flat piece ("chip") of semiconductor material, usually silicon. Integrated circuits are used in a wide range of electronic devices, including computers, smartphones, and televisions, to perform various functions such as processing and storing information. They have greatly impacted the field of electronics by enabling device miniaturization and enhanced functionality. Integrated circuits are orders of magnitude smaller, faster, and less expensive than those constructed of discrete components, allowing a large transistor count. The IC's mass production capability, reliability, and building-block approach to integrated circuit design have ensured the rapid adoption of standardized ICs in place of designs using discre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IPC (electronics)

IPC is a global trade association whose aim is to standardize the assembly and production requirements of Electronics, electronic equipment and assemblies. IPC is headquartered in Bannockburn, Illinois, United States with additional offices in Washington, D.C. Atlanta, Ga., and Miami, Fla. in the United States, and overseas offices in China, Japan, Thailand, India, Germany, and Belgium. IPC is accredited by the American National Standards Institute (ANSI) as a Standards organization#Standards Developing Organizations .28SDOs.29, standards developing organization and is known globally for its standards. It publishes the most widely used acceptability standards in the electronics industry. History It was founded in 1957 as the Institute of Printed Circuits. Its name was later changed to the Institute for Interconnecting and Packaging Electronic Circuits to highlight the expansion from bare boards to packaging and electronic assemblies. In 1999, the organization formally changed i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (integrated Circuit)

A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is Semiconductor fabrication, fabricated. Typically, integrated circuits are produced in large batches on a single wafer (electronics), wafer of electronic-grade Monocrystalline silicon, silicon (EGS) or other semiconductor (such as Gallium arsenide, GaAs) through processes such as photolithography. The wafer is cut (wafer dicing, diced) into many pieces, each containing one copy of the circuit. Each of these pieces is called a die. There are three commonly used plural forms: ''dice'', ''dies,'' and ''die''. To simplify handling and integration onto a printed circuit board, most dies are integrated circuit packaging, packaged in List of electronic component packaging types, various forms. Manufacturing process Most dies are composed of silicon and used for integrated circuits. The process begins with the production of Single crystal, monocrystalline sili ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hitachi Cable

is a Japanese electric wire and cable manufacturing company. It was formed from Hitachi Densen Works, the Hitachi Works spin-off previously known as Densen Works. History The company was established in 1956 as a manufacturer of electric wire and cable for power distribution. In the half-century following the creation of the company Hitachi Cables have expanded its business operations to include the manufacture of rubbercopper cable and optical products. Although the company still actively engages in the development of raw materials for wires and cables, it has incorporated the development of telecommunications equipment into its product line. To that end, the product line now includes antennas and coaxial cables, compound semiconductors and various electronic components, including a terminal antenna for wireless communication. The company has also developed the WirelessIP5000, a wireless IP phone that supports the Session Initiation Protocol (SIP). As a related push into the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mitsubishi Electric

is a Japanese Multinational corporation, multinational electronics and electrical equipment manufacturing company headquartered in Tokyo, Japan. The company was established in 1921 as a spin-off from the electrical machinery manufacturing division of Mitsubishi Shipbuilding (Mitsubishi Heavy Industries) at the Kobe Shipyard. A member of the Mitsubishi, Mitsubishi Group, Mitsubishi Electric produces elevators and escalators, high-end home appliances, air conditioning, Factory automation, factory automation systems, train systems, electric motors, pumps, semiconductors, digital signage, and satellites. History Mitsubishi Electric was established as a spin-off from the Mitsubishi Group's other core company Mitsubishi Heavy Industries, then Mitsubishi Shipbuilding, as the latter divested a marine electric motor factory in Kobe, Nagasaki Prefecture, Nagasaki. It has since diversified to become the major electronics company. Mitsubishi Electric held the record for the fastest e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Springer Science+Business Media

Springer Science+Business Media, commonly known as Springer, is a German multinational publishing company of books, e-books and peer-reviewed journals in science, humanities, technical and medical (STM) publishing. Originally founded in 1842 in Berlin, it expanded internationally in the 1960s, and through mergers in the 1990s and a sale to venture capitalists it fused with Wolters Kluwer and eventually became part of Springer Nature in 2015. Springer has major offices in Berlin, Heidelberg, Dordrecht, and New York City. History Julius Springer founded Springer-Verlag in Berlin in 1842 and his son Ferdinand Springer grew it from a small firm of 4 employees into Germany's then second-largest academic publisher with 65 staff in 1872.Chronology ". Springer Science+Business Media. In 1964, Springer expanded its business internationally, op ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interposer

An interposer is an electrical interface routing between one socket or connection and another. The purpose of an interposer is to spread a connection to a wider pitch or to reroute a connection to a different connection. An interposer can be made of either silicon or organic (printed circuit board-like) material. Interposer comes from the Latin word , meaning "to put between".interposes - definition of interposes by the Free Online Dictionary, Thesaurus and Encyclopedia They are often used in [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flip Chip

Flip chip, also known as controlled collapse chip connection or its abbreviation, C4, is a method for interconnecting dies such as semiconductor devices, IC chips, integrated passive devices and microelectromechanical systems (MEMS), to external circuitry with solder bumps that have been deposited onto the chip pads. The technique was developed by General Electric's Light Military Electronics Department, Utica, New York. The solder bumps are deposited on the chip pads on the top side of the wafer during the final wafer processing step. In order to mount the chip to external circuitry (e.g., a circuit board or another chip or wafer), it is flipped over so that its top side faces down, and aligned so that its pads align with matching pads on the external circuit, and then the solder is reflowed to complete the interconnect. This is in contrast to wire bonding, in which the chip is mounted upright and fine wires are welded onto the chip pads and lead frame contacts to interconne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Grid Array

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be put on a dual in-line or flat package. The whole bottom surface of the device can be used, instead of just the perimeter. The traces connecting the package's leads to the wires or balls which connect the die to package are also on average shorter than with a perimeter-only type, leading to better performance at high speeds. Soldering of BGA devices requires precise control and is usually done by automated processes such as in computer-controlled automatic reflow ovens. Description The BGA is descended from the pin grid array (PGA), which is a package with one face covered (or partly covered) with pins in a grid pattern which, in operation, conduct electrical signals between the integrated circuit and the printed circuit board (PCB) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Wafer

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon (c-Si, silicium), used for the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells. The wafer serves as the substrate for microelectronic devices built in and upon the wafer. It undergoes many microfabrication processes, such as doping, ion implantation, etching, thin-film deposition of various materials, and photolithographic patterning. Finally, the individual microcircuits are separated by wafer dicing and packaged as an integrated circuit. History In the semiconductor industry, the term wafer appeared in the 1950s to describe a thin round slice of semiconductor material, typically germanium or silicon. The round shape characteristic of these wafers comes from single-crystal ingots usually produced using the Czochralski method. Though, silicon wafers were first introduced in the 1940s. By 1960, silicon wafers were ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |