|

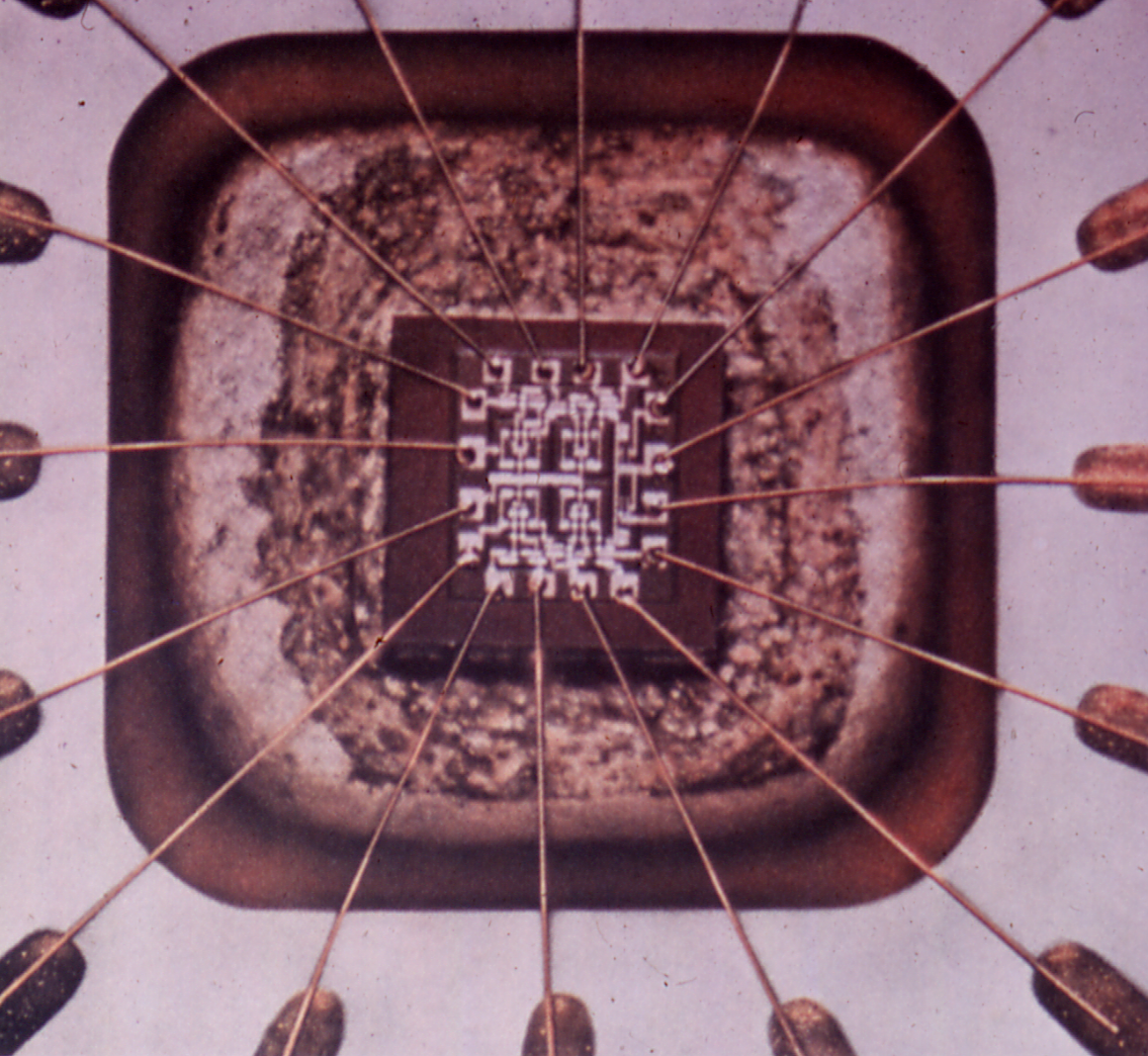

Flip Chip

Flip chip, also known as controlled collapse chip connection or its abbreviation, C4, is a method for interconnecting dies such as semiconductor devices, IC chips, integrated passive devices and microelectromechanical systems (MEMS), to external circuitry with solder bumps that have been deposited onto the chip pads. The technique was developed by General Electric's Light Military Electronics Department, Utica, New York. The solder bumps are deposited on the chip pads on the top side of the wafer during the final wafer processing step. In order to mount the chip to external circuitry (e.g., a circuit board or another chip or wafer), it is flipped over so that its top side faces down, and aligned so that its pads align with matching pads on the external circuit, and then the solder is reflowed to complete the interconnect. This is in contrast to wire bonding, in which the chip is mounted upright and fine wires are welded onto the chip pads and lead frame contacts to interconne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Celeron Mobile

Celeron is a series of IA-32 and x86-64 computer microprocessors targeted at low-cost personal computers, manufactured by Intel from 1998 until 2023. The first Celeron-branded CPU was introduced on April 15, 1998, and was based on the Pentium II. Celeron-branded processors released from 2009 to 2023 are compatible with IA-32 software. They typically offer less performance per clock speed compared to flagship Intel CPU lines, such as the Pentium or Core brands. They often have less cache or intentionally disabled advanced features, with variable impact on performance. While some Celeron designs have achieved strong performance for their segment, the majority of the Celeron line has exhibited noticeably degraded performance. This has been the primary justification for the higher cost of other Intel CPU brands versus the Celeron range. In September 2022, Intel announced that the Celeron brand, along with Pentium, were to be replaced with the new "Intel Processor" branding for low ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Air Reflow

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil. Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for through-hole components by filling the holes with solder paste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tape-automated Bonding

Tape-automated bonding (TAB) is a process that places bare semiconductor chips (dies) like integrated circuits onto a flexible circuit board (FPC) by attaching them to fine conductors in a polyamide or polyimide (like trade names Kapton or UPILEX) film carrier. This FPC with the die(s) (TAB inner lead bonding, ILB) can be mounted on the system or module board or assembled inside a package (TAB outer lead bonding, OLB). Typically the FPC includes from one to three conductive layers and all inputs and outputs of the semiconductor die are connected simultaneously during the TAB bonding. Tape automated bonding is one of the methods needed for achieving chip-on-flex (COF) assembly and it is one of the first roll-to-roll processing (also called R2R, reel-to-reel) type methods in the electronics manufacturing. Process The TAB mounting is done such that the bonding sites of the die, usually in the form of bumps or balls made of gold, solder or anisotropic conductive material, are conne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroless Copper Plating

Electroless copper plating is a chemical process that deposits an even layer of copper on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containing copper salts and a reducing agent such as formaldehyde. Unlike electroplating, electroless plating processes in general do not require passing an electric current through the bath and the substrate; the reduction of the metal cations in solution to metallic is achieved by purely chemical means, through an autocatalytic reaction. Thus electroless plating creates an even layer of metal regardless of the geometry of the surface – in contrast to electroplating which suffers from uneven current density due to the effect of substrate shape on the electric field at its surface. Moreover, electroless plating can be applied to non-conductive surfaces. Process In a typical formulation of the process, the surfaces to be coated are primed with a palladium catalyst and th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Grid Array

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be put on a dual in-line or flat package. The whole bottom surface of the device can be used, instead of just the perimeter. The traces connecting the package's leads to the wires or balls which connect the die to package are also on average shorter than with a perimeter-only type, leading to better performance at high speeds. Soldering of BGA devices requires precise control and is usually done by automated processes such as in computer-controlled automatic reflow ovens. Description The BGA is descended from the pin grid array (PGA), which is a package with one face covered (or partly covered) with pins in a grid pattern which, in operation, conduct electrical signals between the integrated circuit and the printed circuit board (PCB) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or Electrical wiring, "wire" Electronic component, components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds Via (electronics), vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Siemens AG

Siemens AG ( ) is a German multinational technology conglomerate. It is focused on industrial automation, building automation, rail transport and health technology. Siemens is the largest engineering company in Europe, and holds the position of global market leader in industrial automation and industrial software. The origins of the conglomerate can be traced back to 1847 to the ''Telegraphen Bau-Anstalt von Siemens & Halske'' established in Berlin by Werner von Siemens and Johann Georg Halske. In 1966, the present-day corporation emerged from the merger of three companies: Siemens & Halske, Siemens-Schuckert, and Siemens-Reiniger-Werke. Today headquartered in Munich and Berlin, Siemens and its subsidiaries employ approximately 320,000 people worldwide and reported a global revenue of around €78 billion in 2023. The company is a component of the DAX and Euro Stoxx 50 stock market indices. As of December 2023, Siemens is the second largest German company by market ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Bridge

A thermal column (or thermal) is a rising mass of buoyant air, a convective current in the atmosphere, that transfers heat energy vertically. Thermals are created by the uneven heating of Earth's surface from solar radiation, and are an example of convection, specifically atmospheric convection. Thermals on Earth The Sun warms the ground, which in turn warms the air directly above. The warm air near the surface expands, becoming less dense than the surrounding air. The lighter air rises and cools due to its expansion in the lower pressure at higher altitudes. It stops rising when it has cooled to the same temperature, thus density, as the surrounding air. Associated with a thermal is a downward flow surrounding the thermal column. The downward-moving exterior is caused by colder air being displaced at the top of the thermal. The size and strength of thermals are influenced by the properties of the lower atmosphere (the ''troposphere''). When the air is cold, bubbles of warm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reflow Solder

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil. Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for through-hole components by filling the holes with solder paste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flip Chip Side-view

Flip, FLIP, or flips may refer to: People * Flip (nickname), a list of people * Lil' Flip (born 1981), American rapper * Flip Simmons, Australian actor and musician * Flip Wilson, American comedian Arts and entertainment Fictional characters * Flip (''Little Nemo''), a cartoon character * Flip, the title character of '' Flip's Twisted World'', a video game * Flip the Frog, a cartoon character * Flip the grasshopper, a character in the children's book '' The Adventures of Maya the Bee'' Music * Flip Records (1950s), a rhythm and blues and doo-wop label based in Los Angeles * Flip Records (1994), a record label in California * Flips, a short name of The Flaming Lips, an American rock band formed in 1983 * ''Flip'' (album), a 1985 solo album by Nils Lofgren * ''The Flip'' (album), a 1969 album by jazz saxophonist Hank Mobley * "Flip", by Barenaked Ladies from '' Detour de Force'' Business * Flip or Flipping, an American term for buying and reselling something quickly, particu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosonic Bonding

Thermosonic bonding is widely used to wire bond silicon integrated circuits into computers. Alexander Coucoulas was named "Father of Thermosonic Bonding" by George Harman, the world's foremost authority on wire bonding, where he referenced Coucoulas's leading edge publications in his book, ''Wire Bonding In Microelectronics''.Coucoulas, A., Trans. Metallurgical Society Of AIME, "Ultrasonic Welding of Aluminum Leads to Tantalum Thin Films", 1966, pp. 587–589. abstract https://sites.google.com/site/coucoulasthermosonicbondaltaCoucoulas, A., "Hot Work Ultrasonic Bonding – A Method Of Facilitating Metal Flow By Restoration Processes", Proc. 20th IEEE Electronic Components Conf. Washington, D.C., May 1970, pp. 549–556.https://sites.google.com/site/hotworkultrasonicbonding Owing to the well proven reliability of thermosonic bonds, it is extensively used to connect the central processing units (CPUs), which are encapsulated silicon integrated circuits that serve as the "brains" of to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Fabrication

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as microprocessors, microcontrollers, and memories (such as RAM and flash memory). It is a multiple-step photolithographic and physico-chemical process (with steps such as thermal oxidation, thin-film deposition, ion-implantation, etching) during which electronic circuits are gradually created on a wafer, typically made of pure single-crystal semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. This article focuses on the manufacture of integrated circuits, however steps such as etching and photolithography can be used to manufacture other devices such as LCD and OLED displays. The fabrication process is performed in highly specialized semiconductor fabrication plants, also called foundries or "fabs", with the central part being the " clean room". In more advanced semi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |