polysilicon on:

[Wikipedia]

[Google]

[Amazon]

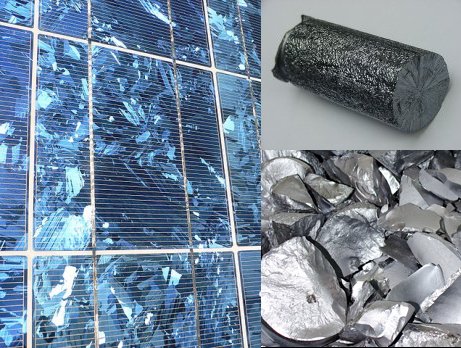

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity,

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity,

In single-crystal silicon, also known as

In single-crystal silicon, also known as

The Siemens process is the most commonly used method of polysilicon production, especially for electronics, with close to 75% of the world's production using this process as of 2005.

The process converts MG Si to SiHCl3 and then to silicon in a reactor, thus removing

The Siemens process is the most commonly used method of polysilicon production, especially for electronics, with close to 75% of the world's production using this process as of 2005.

The process converts MG Si to SiHCl3 and then to silicon in a reactor, thus removing

Currently, polysilicon is commonly used for the conducting gate materials in semiconductor devices such as

Currently, polysilicon is commonly used for the conducting gate materials in semiconductor devices such as

Prices of polysilicon are often divided into two categories, contract and spot prices, and higher purity commands higher prices. While in booming installation times, price rally occurs in polysilicon. Not only spot prices surpass contract prices in the market; but it is also hard to acquire enough polysilicon. Buyers will accept down payment and long-term agreements to acquire a large enough volume of polysilicon. On the contrary, spot prices will be below contract prices once the solar PV installation is in a down trend. In late 2010, booming installation brought up the spot prices of polysilicon. In the first half of 2011, prices of polysilicon kept strong owing to the FIT policies of Italy. The solar PV price survey and market research firm, PVinsights, reported that the prices of polysilicon might be dragged down by lack of installation in the second half of 2011. As recently as 2008 prices were over $400/kg spiking from levels around $200/kg, while seen falling to $15/kg in 2013.

Prices of polysilicon are often divided into two categories, contract and spot prices, and higher purity commands higher prices. While in booming installation times, price rally occurs in polysilicon. Not only spot prices surpass contract prices in the market; but it is also hard to acquire enough polysilicon. Buyers will accept down payment and long-term agreements to acquire a large enough volume of polysilicon. On the contrary, spot prices will be below contract prices once the solar PV installation is in a down trend. In late 2010, booming installation brought up the spot prices of polysilicon. In the first half of 2011, prices of polysilicon kept strong owing to the FIT policies of Italy. The solar PV price survey and market research firm, PVinsights, reported that the prices of polysilicon might be dragged down by lack of installation in the second half of 2011. As recently as 2008 prices were over $400/kg spiking from levels around $200/kg, while seen falling to $15/kg in 2013.

Polycrystalline Silicon Procurement Solutions

{{Photovoltaics Silicon, Polycrystalline Crystals Silicon solar cells Silicon forms

polycrystalline

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains.

Bacillite is a type of crystallite. It is rodlike with parallel longulites.

Stru ...

form of silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic tab ...

, used as a raw material by the solar photovoltaic

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials that exhibit the photovoltaic effect, a phenomenon studied in physics, photochemistry, and electrochemistry. The photovoltaic effect is commercially us ...

and electronics industry

The electronics industry is the economic sector that produces electronic devices. It emerged in the 20th century and is today one of the largest global industries. Contemporary society uses a vast array of electronic devices built-in automated or ...

.

Polysilicon is produced from metallurgical grade silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic table ...

by a chemical purification process, called the Siemens process

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (substra ...

. This process involves distillation

Distillation, or classical distillation, is the process of separation process, separating the components or substances from a liquid mixture by using selective boiling and condensation, usually inside an apparatus known as a still. Dry distilla ...

of volatile silicon compounds, and their decomposition

Decomposition or rot is the process by which dead organic substances are broken down into simpler organic or inorganic matter such as carbon dioxide, water, simple sugars and mineral salts. The process is a part of the nutrient cycle and is e ...

into silicon at high temperatures. An emerging, alternative process of refinement uses a fluidized bed reactor

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst ...

. The photovoltaic industry also produces upgraded metallurgical-grade silicon (UMG-Si), using metallurgical instead of chemical purification processes. When produced for the electronics industry, polysilicon contains impurity levels of less than one part per billion

In science and engineering, the parts-per notation is a set of pseudo-units to describe small values of miscellaneous dimensionless quantities, e.g. mole fraction or mass fraction. Since these fractions are quantity-per-quantity measures, they ...

(ppb), while polycrystalline solar grade silicon (SoG-Si) is generally less pure. A few companies from China, Germany, Japan, Korea and the United States, such as GCL-Poly

GCL-Poly (), founded in 1996, is a subsidiary of Golden Concord Group Limited (GCL), a green energy supplier in China, providing power and heat via cogeneration, incineration and wind power. As of 2009 it was the largest supplier of polysilicon ...

, Wacker Chemie

Wacker Chemie AG is a German multinational chemical company which was founded in 1914 by Alexander Wacker. The company is controlled by the Wacker family holding more than 50 percent of the shares. The corporation is operating more than 25 prod ...

, OCI, and Hemlock Semiconductor, as well as the Norwegian headquartered REC

REC or Rec is a shortening of Recording, the process of capturing data onto a storage medium.

REC may also refer to:

Educational institutes

* Regional Engineering College, colleges of engineering and technology education in India

* Rajalakshmi E ...

, accounted for most of the worldwide production of about 230,000 tonnes in 2013.

The polysilicon feedstock – large rods, usually broken into chunks of specific sizes and packaged in clean rooms before shipment – is directly cast into multicrystalline ingots

An ingot is a piece of relatively pure material, usually metal, that is cast into a shape suitable for further processing. In steelmaking, it is the first step among semi-finished casting products. Ingots usually require a second procedure of sha ...

or submitted to a recrystallization process to grow single crystal boules

''Boules'' () is a collective name for a wide range of games similar to bowls and bocce (In French: jeu or jeux, in Croatian: boćanje and in Italian: gioco or giochi) in which the objective is to throw or roll heavy balls (called in France, ...

. The boules are then sliced into thin silicon wafers

A wafer is a crisp, often sweet, very thin, flat, light and dry biscuit, often used to decorate ice cream, and also used as a garnish on some sweet dishes. Wafers can also be made into cookies with cream flavoring sandwiched between them. They ...

and used for the production of solar cells

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physics, physical and Chemical substance, chemical phenomenon.integrated circuits

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

and other semiconductor devices

A semiconductor device is an electronic component that relies on the electronic properties of a semiconductor material (primarily silicon, germanium, and gallium arsenide, as well as organic semiconductors) for its function. Its conductivity li ...

.

Polysilicon consists of small crystal

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macros ...

s, also known as crystallites

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains.

Bacillite is a type of crystallite. It is rodlike with parallel longulites.

Stru ...

, giving the material its typical metal flake effect. While polysilicon and multisilicon are often used as synonyms, multicrystalline usually refers to crystals larger than one millimetre. Multicrystalline solar cells are the most common type of solar cells in the fast-growing PV market and consume most of the worldwide produced polysilicon. About 5 tons of polysilicon is required to manufacture one 1 megawatt

The watt (symbol: W) is the unit of Power (physics), power or radiant flux in the International System of Units, International System of Units (SI), equal to 1 joule per second or 1 kg⋅m2⋅s−3. It is used to quantification (science), ...

(MW) conventional solar modules. Polysilicon is distinct from monocrystalline silicon

Monocrystalline silicon, more often called single-crystal silicon, in short mono c-Si or mono-Si, is the base material for silicon-based discrete components and integrated circuits used in virtually all modern electronic equipment. Mono-Si also ...

and amorphous silicon

Amorphous silicon (a-Si) is the non-crystalline form of silicon used for solar cells and thin-film transistors in LCDs.

Used as semiconductor material for a-Si solar cells, or thin-film silicon solar cells, it is deposited in thin films onto ...

.

Polycrystalline vs monocrystalline silicon

In single-crystal silicon, also known as

In single-crystal silicon, also known as monocrystalline silicon

Monocrystalline silicon, more often called single-crystal silicon, in short mono c-Si or mono-Si, is the base material for silicon-based discrete components and integrated circuits used in virtually all modern electronic equipment. Mono-Si also ...

, the crystalline framework is homogeneous, which can be recognized by an even external colouring. The entire sample is one single, continuous and unbroken crystal as its structure contains no grain boundaries

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional crystallographic defect, defects in the crystal structure, and tend to decrease the ...

. Large single crystal

In materials science, a single crystal (or single-crystal solid or monocrystalline solid) is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries.RIWD. "Re ...

s are rare in nature and can also be difficult to produce in the laboratory (see also recrystallisation). In contrast, in an amorphous structure the order in atomic positions is limited to short range.

Polycrystalline and paracrystalline

In materials science, paracrystalline materials are defined as having short- and medium-range ordering in their lattice (similar to the liquid crystal phases) but lacking crystal-like long-range ordering at least in one direction.

Origin and d ...

phases are composed of a number of smaller crystals or ''crystallite

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains.

Bacillite is a type of crystallite. It is rodlike with parallel longulites.

Stru ...

s.'' Polycrystalline silicon (or semi-crystalline silicon, polysilicon, poly-Si, or simply "poly") is a material consisting of multiple small silicon crystals. Polycrystalline cells can be recognized by a visible grain, a "metal flake effect". Semiconductor grade (also solar grade) polycrystalline silicon is converted to single-crystal silicon – meaning that the randomly associated crystallites of silicon in polycrystalline silicon are converted to a large single crystal

In materials science, a single crystal (or single-crystal solid or monocrystalline solid) is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries.RIWD. "Re ...

. Single-crystal silicon is used to manufacture most Si-based microelectronic

Microelectronics is a subfield of electronics. As the name suggests, microelectronics relates to the study and manufacture (or microfabrication) of very small electronic designs and components. Usually, but not always, this means micrometre-sc ...

devices. Polycrystalline silicon can be as much as 99.9999% pure. Ultra-pure poly is used in the semiconductor

A semiconductor is a material which has an electrical resistivity and conductivity, electrical conductivity value falling between that of a electrical conductor, conductor, such as copper, and an insulator (electricity), insulator, such as glas ...

industry, starting from poly rods that are two to three meters in length. In microelectronic

Microelectronics is a subfield of electronics. As the name suggests, microelectronics relates to the study and manufacture (or microfabrication) of very small electronic designs and components. Usually, but not always, this means micrometre-sc ...

industry (semiconductor industry), poly is used both at the macroscale and microscale (component) level. Single crystals are grown using the Czochralski method

The Czochralski method, also Czochralski technique or Czochralski process, is a method of crystal growth used to obtain single crystals of semiconductors (e.g. silicon, germanium and gallium arsenide), metals (e.g. palladium, platinum, silver, ...

, zone melting

Zone melting (or zone refining, or floating-zone method, or floating-zone technique) is a group of similar methods of purifying crystals, in which a narrow region of a crystal is melted, and this molten zone is moved along the crystal. The molte ...

and Bridgman technique Bridgman is a surname, and may refer to:

* David Bridgman, Australian architect

* Elijah Coleman Bridgman (1801–1861), American missionary in China

* Frederick Arthur Bridgman (1847-1928), American artist

* George Bridgman (1865-1943), anatomist ...

s.

Polycrystalline silicon components

At the component level, polysilicon has long been used as the conducting gate material inMOSFET

The metal–oxide–semiconductor field-effect transistor (MOSFET, MOS-FET, or MOS FET) is a type of field-effect transistor (FET), most commonly fabricated by the controlled oxidation of silicon. It has an insulated gate, the voltage of which d ...

and CMOS

Complementary metal–oxide–semiconductor (CMOS, pronounced "sea-moss", ) is a type of metal–oxide–semiconductor field-effect transistor (MOSFET) fabrication process that uses complementary and symmetrical pairs of p-type and n-type MOSFE ...

processing technologies. For these technologies it is deposited using low-pressure chemical-vapour deposition (LPCVD

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (substra ...

) reactors at high temperatures and is usually heavily doped n-type or p-type.

More recently, intrinsic and doped polysilicon is being used in large-area electronics

In the field of electronic devices, roll-to-roll processing, also known as web processing, reel-to-reel processing or R2R, is the process of creating electronic devices on a roll of flexible plastic, metal foil, or flexible glass. In other fields p ...

as the active and/or doped layers in thin-film transistor

A thin-film transistor (TFT) is a special type of field-effect transistor (FET) where the transistor is thin relative to the plane of the device. TFTs are grown on a supporting (but non-conducting) substrate. A common substrate is glass, becaus ...

s. Although it can be deposited by LPCVD

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (substra ...

, plasma-enhanced chemical vapour deposition (PECVD

Plasma-enhanced chemical vapor deposition (PECVD) is a chemical vapor deposition process used to deposit thin films from a gas state (vapor) to a solid state on a substrate. Chemical reactions are involved in the process, which occur after creati ...

), or solid-phase crystallization of amorphous silicon

Amorphous silicon (a-Si) is the non-crystalline form of silicon used for solar cells and thin-film transistors in LCDs.

Used as semiconductor material for a-Si solar cells, or thin-film silicon solar cells, it is deposited in thin films onto ...

in certain processing regimes, these processes still require relatively high temperatures of at least 300 °C. These temperatures make deposition of polysilicon possible for glass substrates but not for plastic substrates.

The deposition of polycrystalline silicon on plastic substrates is motivated by the desire to be able to manufacture digital displays on flexible screens. Therefore, a relatively new technique called laser crystallization has been devised to crystallize a precursor amorphous silicon (a-Si) material on a plastic substrate without melting or damaging the plastic. Short, high-intensity ultraviolet

Ultraviolet (UV) is a form of electromagnetic radiation with wavelength from 10 nanometer, nm (with a corresponding frequency around 30 Hertz, PHz) to 400 nm (750 Hertz, THz), shorter than that of visible light, but longer than ...

laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word "laser" is an acronym for "light amplification by stimulated emission of radiation". The fir ...

pulses are used to heat the deposited a-Si material to above the melting point of silicon, without melting the entire substrate.

The molten silicon will then crystallize as it cools. By precisely controlling the temperature gradients, researchers have been able to grow very large grains, of up to hundreds of micrometers in size in the extreme case, although grain sizes of 10 nanometer

330px, Different lengths as in respect to the molecular scale.

The nanometre (international spelling as used by the International Bureau of Weights and Measures; SI symbol: nm) or nanometer (American and British English spelling differences#-re ...

s to 1 micrometer Micrometer can mean:

* Micrometer (device), used for accurate measurements by means of a calibrated screw

* American spelling of micrometre

The micrometre ( international spelling as used by the International Bureau of Weights and Measures; ...

are also common. In order to create devices on polysilicon over large-areas however, a crystal grain size smaller than the device feature size is needed for homogeneity of the devices. Another method to produce poly-Si at low temperatures is metal-induced crystallization where an amorphous-Si thin film can be crystallized at temperatures as low as 150 °C if annealed while in contact of another metal film such as aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

, gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile met ...

, or silver

Silver is a chemical element with the Symbol (chemistry), symbol Ag (from the Latin ', derived from the Proto-Indo-European wikt:Reconstruction:Proto-Indo-European/h₂erǵ-, ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, whi ...

.

Polysilicon has many applications in VLSI

Very large-scale integration (VLSI) is the process of creating an integrated circuit (IC) by combining millions or billions of MOS transistors onto a single chip. VLSI began in the 1970s when MOS integrated circuit (Metal Oxide Semiconductor) c ...

manufacturing. One of its primary uses is as gate electrode material for MOS devices. A polysilicon gate's electrical conductivity may be increased by depositing a metal (such as tungsten) or a metal silicide (such as tungsten silicide) over the gate. Polysilicon may also be employed as a resistor, a conductor, or as an ohmic contact for shallow junctions, with the desired electrical conductivity attained by doping the polysilicon material.

One major difference between polysilicon and a-Si is that the mobility of the charge carrier

In physics, a charge carrier is a particle or quasiparticle that is free to move, carrying an electric charge, especially the particles that carry electric charges in electrical conductors. Examples are electrons, ions and holes. The term is used ...

s of the polysilicon can be orders of magnitude larger and the material also shows greater stability under electric field

An electric field (sometimes E-field) is the physical field that surrounds electrically charged particles and exerts force on all other charged particles in the field, either attracting or repelling them. It also refers to the physical field fo ...

and light-induced stress. This allows more complex, high-speed circuitry to be created on the glass substrate along with the a-Si devices, which are still needed for their low- leakage characteristics. When polysilicon and a-Si devices are used in the same process this is called hybrid processing. A complete polysilicon active layer process is also used in some cases where a small pixel size is required, such as in projection displays.

Feedstock for PV industry

Polycrystalline silicon is the key feedstock in the crystalline silicon based photovoltaic industry and used for the production of conventionalsolar cell

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon.

s. For the first time, in 2006, over half of the world's supply of polysilicon was being used by PV manufacturers. The solar industry was severely hindered by a shortage

In economics, a shortage or excess demand is a situation in which the demand for a product or service exceeds its supply in a market. It is the opposite of an excess supply ( surplus).

Definitions

In a perfect market (one that matches a sim ...

in supply of polysilicon feedstock and was forced to idle about a quarter of its cell and module manufacturing capacity in 2007. Only twelve factories were known to produce solar-grade polysilicon in 2008; however, by 2013 the number increased to over 100 manufacturers. Monocrystalline silicon is higher priced and a more efficient semiconductor than polycrystalline as it has undergone additional recrystallization via the Czochralski method.

Deposition methods

Polysilicon deposition, or the process of depositing a layer of polycrystalline silicon on a semiconductor wafer, is achieved by thechemical decomposition

Chemical decomposition, or chemical breakdown, is the process or effect of simplifying a single chemical entity (normal molecule, reaction intermediate, etc.) into two or more fragments. Chemical decomposition is usually regarded and defined as t ...

of silane

Silane is an inorganic compound with chemical formula, . It is a colourless, pyrophoric, toxic gas with a sharp, repulsive smell, somewhat similar to that of acetic acid. Silane is of practical interest as a precursor to elemental silicon. Sila ...

(SiH4) at high temperatures of 580 to 650 °C. This pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''py ...

process releases hydrogen.

:(g) → Si(s) + 2 (g) CVD at 500-800°C

Polysilicon layers can be deposited using 100% silane at a pressure of or with 20–30% silane (diluted in nitrogen) at the same total pressure. Both of these processes can deposit polysilicon on 10–200 wafers per run, at a rate of 10–20 nm/min and with thickness uniformities of ±5%. Critical process variables for polysilicon deposition include temperature, pressure, silane concentration, and dopant concentration. Wafer spacing and load size have been shown to have only minor effects on the deposition process. The rate of polysilicon deposition increases rapidly with temperature, since it follows Arrhenius behavior, that is deposition rate = A·exp(–qEa/kT) where q is electron charge and k is the Boltzmann constant

The Boltzmann constant ( or ) is the proportionality factor that relates the average relative kinetic energy of particles in a gas with the thermodynamic temperature of the gas. It occurs in the definitions of the kelvin and the gas constant, ...

. The activation energy (Ea) for polysilicon deposition is about 1.7 eV. Based on this equation, the rate of polysilicon deposition increases as the deposition temperature increases. There will be a minimum temperature, however, wherein the rate of deposition becomes faster than the rate at which unreacted silane arrives at the surface. Beyond this temperature, the deposition rate can no longer increase with temperature, since it is now being hampered by lack of silane from which the polysilicon will be generated. Such a reaction is then said to be 'mass-transport-limited.' When a polysilicon deposition process becomes mass-transport-limited, the reaction rate becomes dependent primarily on reactant concentration, reactor geometry, and gas flow.

When the rate at which polysilicon deposition occurs is slower than the rate at which unreacted silane arrives, then it is said to be surface-reaction-limited. A deposition process that is surface-reaction-limited is primarily dependent on reactant concentration and reaction temperature. Deposition processes must be surface-reaction-limited because they result in excellent thickness uniformity and step coverage. A plot of the logarithm of the deposition rate against the reciprocal of the absolute temperature in the surface-reaction-limited region results in a straight line whose slope is equal to –qEa/k.

At reduced pressure levels for VLSI manufacturing, polysilicon deposition rate below 575 °C is too slow to be practical. Above 650 °C, poor deposition uniformity and excessive roughness will be encountered due to unwanted gas-phase reactions and silane depletion. Pressure can be varied inside a low-pressure reactor either by changing the pumping speed or changing the inlet gas flow into the reactor. If the inlet gas is composed of both silane and nitrogen, the inlet gas flow, and hence the reactor pressure, may be varied either by changing the nitrogen flow at constant silane flow, or changing both the nitrogen and silane flow to change the total gas flow while keeping the gas ratio constant. Recent investigations have shown that e-beam evaporation, followed by SPC (if needed) can be a cost-effective and faster alternative for producing solar-grade poly-Si thin films. Modules produced by such method are shown to have a photovoltaic efficiency of ~6%.

Polysilicon doping, if needed, is also done during the deposition process, usually by adding phosphine, arsine, or diborane. Adding phosphine or arsine results in slower deposition, while adding diborane increases the deposition rate. The deposition thickness uniformity usually degrades when dopants are added during deposition.

Siemens process

transition metal

In chemistry, a transition metal (or transition element) is a chemical element in the d-block of the periodic table (groups 3 to 12), though the elements of group 12 (and less often group 3) are sometimes excluded. They are the elements that can ...

and dopant

A dopant, also called a doping agent, is a trace of impurity element that is introduced into a chemical material to alter its original electrical or optical properties. The amount of dopant necessary to cause changes is typically very low. When ...

impurities. The process is relatively expensive and slow.

Upgraded metallurgical-grade silicon

Upgraded metallurgical-grade (UMG) silicon (also known as UMG-Si)solar cell

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon.

is being produced as a low cost alternative to polysilicon created by the Siemens process

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (substra ...

. UMG-Si greatly reduces impurities in a variety of ways that require less equipment and energy than the Siemens process. It is about 99% pure which is three or more orders of magnitude less pure and about 10 times less expensive than polysilicon ($1.70 to $3.20 per kg from 2005 to 2008 compared to $40 to $400 per kg for polysilicon). It has the potential to provide nearly-as-good solar cell efficiency at 1/5 the capital expenditure, half the energy requirements, and less than $15/kg.

In 2008 several companies were touting the potential of UMG-Si in 2010, but the credit crisis greatly lowered the cost of polysilicon and several UMG-Si producers put plans on hold. The Siemens process will remain the dominant form of production for years to come due to more efficiently implementing the Siemens process. GT Solar claims a new Siemens process can produce at $27/kg and may reach $20/kg in 5 years. GCL-Poly expects production costs to be $20/kg by end of 2011. Elkem Solar estimates their UMG costs to be $25/kg, with a capacity of 6,000 tonnes by the end of 2010. Calisolar expects UMG technology to produce at $12/kg in 5 years with boron at 0.3 ppm and phosphorus at 0.6 ppm. At $50/kg and 7.5 g/W, module manufacturers spend $0.37/W for the polysilicon. For comparison, if a CdTe manufacturer pays spot price for tellurium ($420/kg in April 2010) and has a 3 μm thickness, their cost would be 10 times less, $0.037/Watt. At 0.1 g/W and $31/ozt for silver, polysilicon solar producers spend $0.10/W on silver.

Q-Cells, Canadian Solar, and Calisolar have used Timminco UMG. Timminco is able to produce UMG-Si with 0.5 ppm boron for $21/kg but were sued by shareholders because they had expected $10/kg. RSI and Dow Corning have also been in litigation over UMG-Si technology.

Potential for use of polycrystalline silicon

Currently, polysilicon is commonly used for the conducting gate materials in semiconductor devices such as

Currently, polysilicon is commonly used for the conducting gate materials in semiconductor devices such as MOSFET

The metal–oxide–semiconductor field-effect transistor (MOSFET, MOS-FET, or MOS FET) is a type of field-effect transistor (FET), most commonly fabricated by the controlled oxidation of silicon. It has an insulated gate, the voltage of which d ...

s; however, it has potential for large-scale photovoltaic devices. The abundance, stability, and low toxicity of silicon, combined with the low cost of polysilicon relative to single crystals makes this variety of material attractive for photovoltaic production. Grain size has been shown to have an effect on the efficiency of polycrystalline solar cells. Solar cell efficiency increases with grain size. This effect is due to reduced recombination in the solar cell. Recombination, which is a limiting factor for current in a solar cell, occurs more prevalently at grain boundaries, see figure 1.

The resistivity, mobility, and free-carrier concentration in monocrystalline silicon vary with doping concentration of the single crystal silicon. Whereas the doping of polycrystalline silicon does have an effect on the resistivity, mobility, and free-carrier concentration, these properties strongly depend on the polycrystalline grain size, which is a physical parameter that the material scientist can manipulate. Through the methods of crystallization to form polycrystalline silicon, an engineer can control the size of the polycrystalline grains which will vary the physical properties of the material.

Novel ideas for polycrystalline silicon

The use of polycrystalline silicon in the production of solar cells requires less material and therefore provides higher profits and increased manufacturing throughput. Polycrystalline silicon does not need to be deposited on a silicon wafer to form a solar cell, rather it can be deposited on other-cheaper materials, thus reducing the cost. Not requiring a silicon wafer alleviates the silicon shortages occasionally faced by the microelectronics industry. An example of not using a silicon wafer is crystalline silicon on glass (CSG) materials A primary concern in the photovoltaics industry is cell efficiency. However, sufficient cost savings from cell manufacturing can be suitable to offset reduced efficiency in the field, such as the use of larger solar cell arrays compared with more compact/higher efficiency designs. Designs such as CSG are attractive because of a low cost of production even with reduced efficiency. Higher efficiency devices yield modules that occupy less space and are more compact; however, the 5–10% efficiency of typical CSG devices still makes them attractive for installation in large central-service stations, such as a power station. The issue of efficiency versus cost is a value decision of whether one requires an "energy dense" solar cell or sufficient area is available for the installation of less expensive alternatives. For instance, a solar cell used for power generation in a remote location might require a more highly efficient solar cell than one used for low-power applications, such as solaraccent lighting Accent lighting focuses light on a particular area or object. It is often used to highlight art or other artifacts. Common types of accent lights include wall sconces, floodlights, recessed lights, torchère lamps, or track lighting. The brighter l ...

or pocket calculators, or near established power grids.

Manufacturers

Capacity

The polysilicon manufacturing market is growing rapidly. According toDigitimes

DigiTimes () is a daily newspaper for semiconductor, electronics, computer and communications industries in Taiwan and the Greater China region. It was established in 1998. The company is based in Taipei, Taiwan and currently has a daily newsp ...

, in July 2011, the total polysilicon production in 2010 was 209,000 tons. First-tier suppliers account for 64% of the market while China-based polysilicon firms have 30% of market share. The total production is likely to increase 37.4% to 281,000 tons by end of 2011. For 2012, EETimes

''EE Times'' (''Electronic Engineering Times'') is an electronics industry magazine published in the United States since 1972. EE Times is currently owned by AspenCore, a division of Arrow Electronics since August 2016.

Since its acquisition ...

Asia predicts 328,000 tons production with only 196,000 tons of demand, with spot prices expected to fall 56%. While good for renewable energy prospects, the subsequent drop in price could be brutal for manufacturers. As of late 2012, SolarIndustryMag reports a capacity of 385,000 tons will be reached by yearend 2012.

But as established producers (mentioned below) expand their capacities, additional newcomers – many from Asia – are moving into the market. Even long-time players in the field have recently had difficulties expanding plant production. It is yet unclear which companies will be able to produce at costs low enough to be profitable after the steep drop in spot-prices of the last months.

Leading producer capacities.

Wacker's projected its total hyperpure-polysilicon production capacity to increase to 67,000 metric tons by 2014, due to its new polysilicon-production facility in Cleveland, Tennessee (USA) with an annual capacity of 15,000 metric tons.

; Other manufacturers

*''LDK Solar

LDK Solar Co. Ltd., located in Xinyu City, Jiangxi province in the People's Republic of China, manufactures multicrystalline solar wafers used in solar cells, and provides wafering services for both monocrystalline

In materials science, a ...

'' (2010: 15 kt) China.

*''Tokuyama Corporation

is a Japanese, Tokyo-based chemical company and the world's fourth largest silicon manufacturer.

The company was founded as Nihon Soda Kogyo Co., Ltd., a producer of soda ash in 1918 by Katsujiro Iwai. It changed name in 1936 to Tokuyama Soda C ...

'' (2009: 8 kt, Jan 2013: 11 kt, 2015: 31 kt) Japan

Japan ( ja, 日本, or , and formally , ''Nihonkoku'') is an island country in East Asia. It is situated in the northwest Pacific Ocean, and is bordered on the west by the Sea of Japan, while extending from the Sea of Okhotsk in the north ...

.

*'' MEMC/SunEdison

SunEdison, Inc. (formerly MEMC Electronic Materials) is a renewable energy company headquartered in the U.S. In addition to developing, building, owning, and operating solar power plants and wind energy plants, it also manufactures high purity po ...

'' (2010: 8 kt, Jan 2013: 18 kt) USA.

*''Hankook Silicon'' (2011: 3.2 kt, 2013: 14.5 kt)

*''Nitol Solar

Nitol Solar Group Ltd. was a vertically integrated company group based in Usolye-Sibirskoye, Russia. The company had two plants and was intended to produce solar-grade polycrystalline silicon from trichlorsilane by Siemens-process for solar ene ...

'', (2011: 5 kt, Jan 2011), Russia

*'' Mitsubishi Polysilicon'' (2008: 4.3 kt)

*''Osaka Titanium Technologies

is a Japanese non-ferrous metal manufacturing company based in Amagasaki, Hyōgo Prefecture, Japan. It is the world's second largest producer of titanium sponge after VSMPO-Avisma.

It produces titanium products using the Kroll process, and also ...

'' (2008: 4.2 kt)

*''Daqo'', (2011: 4.3 kt, under construction 3 kt), China

*''Beijing Lier High-temperature Materials Co.'' (2012: 5 kt)

*''Qatar Solar Technologies'', at Ras Laffan

Ras Laffan Industrial City ( ar, راس لفان, Ra’s Lafān) is an industrial hub located north of Doha, Qatar. It is administrated by QatarEnergy.

Ras Laffan Industrial City is Qatar's main site for production of liquefied natural gas and ...

, announced an 8,000 mt facility for start in 2013.

Price

Dumping

The Chinese government accused United States andSouth Korea

South Korea, officially the Republic of Korea (ROK), is a country in East Asia, constituting the southern part of the Korea, Korean Peninsula and sharing a Korean Demilitarized Zone, land border with North Korea. Its western border is formed ...

n manufacturers of predatory pricing

Predatory pricing is a Pricing strategies, pricing strategy, using the method of undercutting on a larger scale, where a Article 102 of the Treaty on the Functioning of the European Union#Dominance, dominant firm in an industry will deliberately ...

or "dumping". As a consequence, in 2013 it imposed import tariffs

A tariff is a tax imposed by the government of a country or by a supranational union on imports or exports of goods. Besides being a source of revenue for the government, import duties can also be a form of regulation of foreign trade and poli ...

of as much as 57 percent on polysilicon shipped from these two countries in order to stop the product from being sold below cost.

Waste

Due to the rapid growth in manufacturing in China and the lack of regulatory controls, there have been reports of the dumping of wastesilicon tetrachloride

Silicon tetrachloride or tetrachlorosilane is the inorganic compound with the formula SiCl4. It is a colourless volatile liquid that fumes in air. It is used to produce high purity silicon and silica for commercial applications.

Preparation

Silic ...

. Normally the waste silicon tetrachloride is recycled but this adds to the cost of manufacture as it needs to be heated to .

See also

*Metallurgical grade silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic table ...

*Wafer (electronics)

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon

Crystalline silicon or (c-Si) Is the crystalline forms of silicon, either polycrystalline silicon (poly-Si, consisting o ...

*Polycrystal

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains.

Bacillite is a type of crystallite. It is rodlike with parallel longulites.

Stru ...

*Nanocrystalline silicon

Nanocrystalline silicon (nc-Si), sometimes also known as microcrystalline silicon (μc-Si), is a form of porous silicon. It is an allotropic form of silicon with paracrystalline structure—is similar to amorphous silicon (a-Si), in that it has ...

*Amorphous silicon

Amorphous silicon (a-Si) is the non-crystalline form of silicon used for solar cells and thin-film transistors in LCDs.

Used as semiconductor material for a-Si solar cells, or thin-film silicon solar cells, it is deposited in thin films onto ...

*Cadmium telluride

Cadmium telluride (CdTe) is a stable crystalline compound formed from cadmium and tellurium. It is mainly used as the semiconducting material in cadmium telluride photovoltaics and an infrared optical window. It is usually sandwiched with cadmi ...

*Thin-film solar cell

A thin-film solar cell is a second generation solar cell that is made by depositing one or more thin layers, or thin film (TF) of photovoltaic material on a substrate, such as glass, plastic or metal. Thin-film solar cells are commercially use ...

*Solar cell

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon.

*Photovoltaic module

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials that exhibit the photovoltaic effect, a phenomenon studied in physics, photochemistry, and electrochemistry. The photovoltaic effect is commercially us ...

*Photovoltaics

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials that exhibit the photovoltaic effect, a phenomenon studied in physics, photochemistry, and electrochemistry. The photovoltaic effect is commercially us ...

References

External links

*Polycrystalline Silicon Procurement Solutions

{{Photovoltaics Silicon, Polycrystalline Crystals Silicon solar cells Silicon forms