|

SunEdison

SunEdison, Inc. (formerly MEMC Electronic Materials) is a renewable energy company headquartered in the U.S. In addition to developing, building, owning, and operating solar power plants and wind energy plants, it also manufactures high purity polysilicon, monocrystalline silicon ingots, silicon wafers, solar modules, solar energy systems, and solar module racking systems. Originally a silicon-wafer manufacturer established in 1959 as the Monsanto Electronic Materials Company, the company was sold by Monsanto in 1989. It is one of the leading solar-power companies worldwide, and with its acquisition of wind-energy company First Wind in 2014, SunEdison is the leading renewable energy development company in the world. In 2015, SunEdison sold off its subsidiary SunEdison Semiconductor, marking the completion of SunEdison, Inc.'s transition from a semiconductor-wafer company to a dedicated renewable-energy corporation. Following years of major expansion and the announcement of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

First Wind

First Wind is an independent renewable energy company. It develops and operates utility-scale power projects in the United States. It employs more than 220 workers. Headquartered in Boston, the company developed and operated renewable energy projects in Maine, Vermont, Massachusetts, New York, Utah, Idaho, Washington and Hawaii with a combined capacity of nearly 1,300 megawatts. In addition to renewable energy projects, the company developed and operates two generator leads. History The company was founded in 2002. First Wind began as a utility-scale wind power Wind power or wind energy is mostly the use of wind turbines to generate electricity. Wind power is a popular, sustainable, renewable energy source that has a much smaller impact on the environment than burning fossil fuels. Historically ... developer and operator, but in 2014 the company brought its first solar energy projects online. In November 2014 First Wind was purchased by SunEdison and its yield ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photovoltaic Plant

A photovoltaic power station, also known as a solar park, solar farm, or solar power plant, is a large-scale grid-connected photovoltaic power system (PV system) designed for the supply of merchant power. They are different from most building-mounted and other decentralised solar power because they supply power at the utility level, rather than to a local user or users. The generic expression utility-scale solar is sometimes used to describe this type of project. The solar power source is solar panels that convert light directly to electricity. However, this differs from and should not be confused with concentrated solar power, the other major large-scale solar generation technology, which uses heat to drive a variety of conventional generator systems. Both approaches have their own advantages and disadvantages, but to date, for a variety of reasons, photovoltaic technology has seen much wider use. , about 97% of utility-scale solar power capacity was PV. In some countries, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solar Power Plant

A photovoltaic power station, also known as a solar park, solar farm, or solar power plant, is a large-scale grid-connected photovoltaic power system (PV system) designed for the supply of merchant power. They are different from most building-mounted and other decentralised solar power because they supply power at the utility level, rather than to a local user or users. The generic expression utility-scale solar is sometimes used to describe this type of project. The solar power source is solar panels that convert light directly to electricity. However, this differs from and should not be confused with concentrated solar power, the other major large-scale solar generation technology, which uses heat to drive a variety of conventional generator systems. Both approaches have their own advantages and disadvantages, but to date, for a variety of reasons, photovoltaic technology has seen much wider use. , about 97% of utility-scale solar power capacity was PV. In some countries, th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vivint Solar

Vivint Solar was an American provider of photovoltaic solar energy generation systems, primarily for residential customers. The company was established in 2011 as an offshoot of home automation and security company Vivint and was headquartered in Lehi, Utah. The company primarily used a power purchase agreement (PPA) business model where Vivint Solar installed and maintained a solar system on a customer's home, then sells power to the customer at an agreed upon rate for a set term. In 2020, the company was purchased by Sunrun, another solar company primarily focused on the PPA business model for $3.2 billion. At the time of the merger, Vivint Solar had installed a total of 1.29 gigawatts of power for over 188,000 customers in 23 U.S. states (Arizona, California, Colorado, Connecticut, Florida, Hawaii, Illinois, Maryland, Massachusetts, Nevada, New Hampshire, New Jersey, New Mexico, New York, Pennsylvania, Rhode Island, South Carolina, Texas, Utah, Vermont, and Virginia). History ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polysilicon

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar photovoltaic and electronics industry. Polysilicon is produced from metallurgical grade silicon by a chemical purification process, called the Siemens process. This process involves distillation of volatile silicon compounds, and their decomposition into silicon at high temperatures. An emerging, alternative process of refinement uses a fluidized bed reactor. The photovoltaic industry also produces upgraded metallurgical-grade silicon (UMG-Si), using metallurgical instead of chemical purification processes. When produced for the electronics industry, polysilicon contains impurity levels of less than one part per billion (ppb), while polycrystalline solar grade silicon (SoG-Si) is generally less pure. A few companies from China, Germany, Japan, Korea and the United States, such as GCL-Poly, Wacker Ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polysilicon

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar photovoltaic and electronics industry. Polysilicon is produced from metallurgical grade silicon by a chemical purification process, called the Siemens process. This process involves distillation of volatile silicon compounds, and their decomposition into silicon at high temperatures. An emerging, alternative process of refinement uses a fluidized bed reactor. The photovoltaic industry also produces upgraded metallurgical-grade silicon (UMG-Si), using metallurgical instead of chemical purification processes. When produced for the electronics industry, polysilicon contains impurity levels of less than one part per billion (ppb), while polycrystalline solar grade silicon (SoG-Si) is generally less pure. A few companies from China, Germany, Japan, Korea and the United States, such as GCL-Poly, Wacker Ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Wafer

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon (c-Si), used for the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells. The wafer serves as the substrate for microelectronic devices built in and upon the wafer. It undergoes many microfabrication processes, such as doping, ion implantation, etching, thin-film deposition of various materials, and photolithographic patterning. Finally, the individual microcircuits are separated by wafer dicing and packaged as an integrated circuit. History In the semiconductor or silicon wafer industry, the term wafer appeared in the 1950s to describe a thin round slice of semiconductor material, typically germanium or silicon. Round shape comes from single-crystal ingots usually produced using the Czochralski method. Silicon wafers were first introduced in the 1940s. By 1960, silicon wafers were being manufactured in the U.S. by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solar Wafer

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon (c-Si), used for the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells. The wafer serves as the substrate for microelectronic devices built in and upon the wafer. It undergoes many microfabrication processes, such as doping, ion implantation, etching, thin-film deposition of various materials, and photolithographic patterning. Finally, the individual microcircuits are separated by wafer dicing and packaged as an integrated circuit. History In the semiconductor or silicon wafer industry, the term wafer appeared in the 1950s to describe a thin round slice of semiconductor material, typically germanium or silicon. Round shape comes from single-crystal ingots usually produced using the Czochralski method. Silicon wafers were first introduced in the 1940s. By 1960, silicon wafers were being manufactured in the U.S. by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Crystal

Monocrystalline silicon, more often called single-crystal silicon, in short mono c-Si or mono-Si, is the base material for silicon-based discrete components and integrated circuits used in virtually all modern electronic equipment. Mono-Si also serves as a photovoltaic, light-absorbing material in the manufacture of solar cells. It consists of silicon in which the crystal lattice of the entire solid is continuous, unbroken to its edges, and free of any grain boundaries (i.e. a single crystal). Mono-Si can be prepared as an intrinsic semiconductor that consists only of exceedingly pure silicon, or it can be doped by the addition of other elements such as boron or phosphorus to make p-type or n-type silicon. Due to its semiconducting properties, single-crystal silicon is perhaps the most important technological material of the last few decades—the "silicon era", because its availability at an affordable cost has been essential for the development of the electronic devices on w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Mechanical Polishing

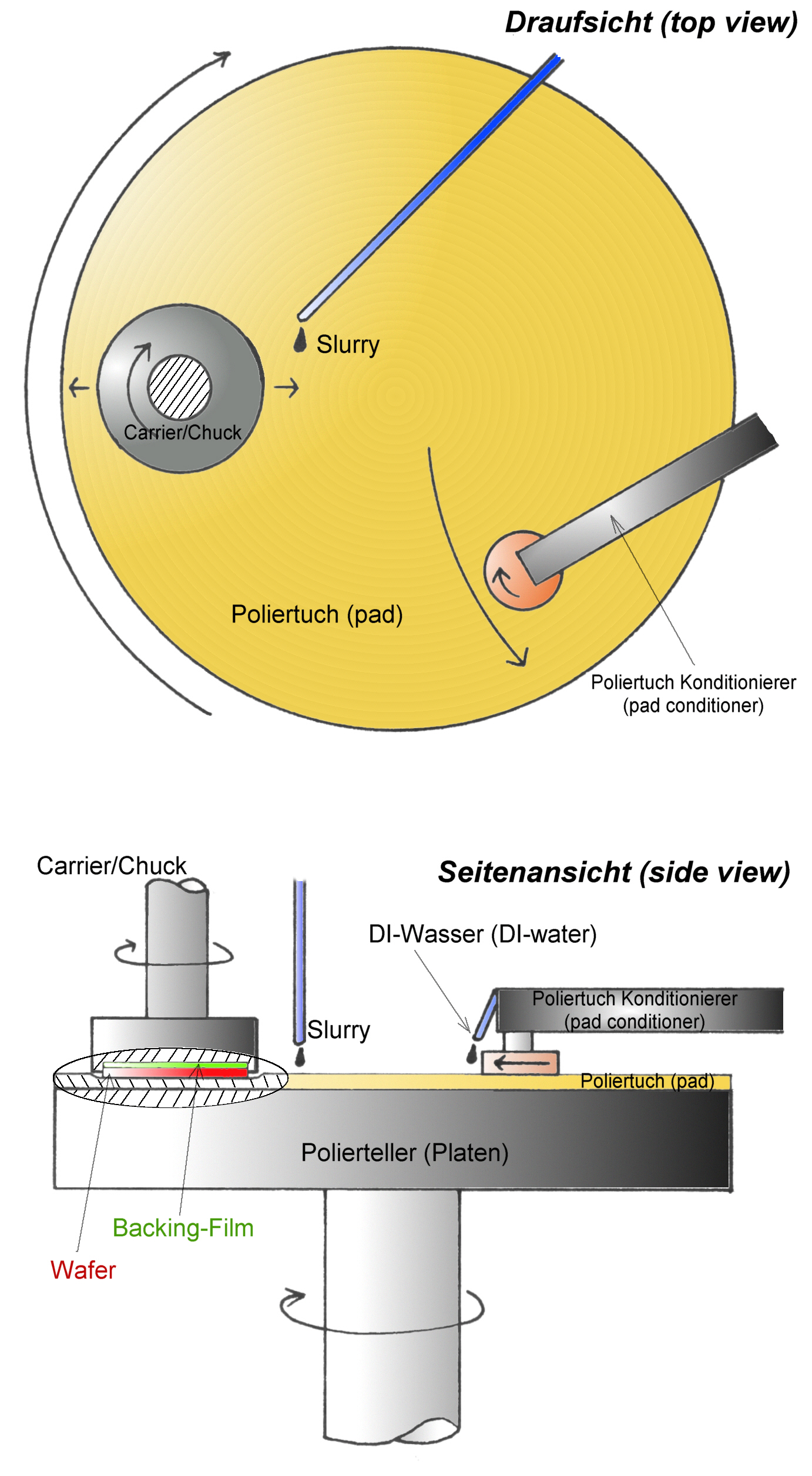

Chemical mechanical polishing (CMP) or planarization is a process of smoothing surfaces with the combination of chemical and mechanical forces. It can be thought of as a hybrid of chemical etching and free abrasive polishing. Description The process uses an abrasive and corrosive chemical slurry (commonly a colloid) in conjunction with a polishing pad and retaining ring, typically of a greater diameter than the wafer. The pad and wafer are pressed together by a dynamic polishing head and held in place by a plastic retaining ring. The dynamic polishing head is rotated with different axes of rotation (i.e., not concentric). This removes material and tends to even out any irregular topography, making the wafer flat or planar. This may be necessary to set up the wafer for the formation of additional circuit elements. For example, CMP can bring the entire surface within the depth of field of a photolithography system, or selectively remove material based on its position. Typical depth-o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epitaxial Wafer

An epitaxial wafer (also called epi wafer, epi-wafer, or epiwafer) is a wafer of semiconducting material made by epitaxial growth (epitaxy) for use in photonics, microelectronics, spintronics, or photovoltaics. The epi layer may be the same material as the substrate, typically monocrystaline silicon, or it may be a more exotic material with specific desirable qualities. Silicon epi wafers were first developed around 1966, and achieved commercial acceptance by the early 1980s. Methods for growing the epitaxial layer on monocrystalline silicon or other wafers include: various types of chemical vapor deposition (CVD) classified as Atmospheric pressure CVD (APCVD) or metal organic chemical vapor deposition (MOCVD), as well as molecular beam epitaxy (MBE). Two "kerfless" methods (without abrasive sawing) for separating the epitaxial layer from the substrate are called "implant-cleave" and "stress liftoff". A method applicable when the epi-layer and substrate are the same material empl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Private Company

A privately held company (or simply a private company) is a company whose shares and related rights or obligations are not offered for public subscription or publicly negotiated in the respective listed markets, but rather the company's stock is offered, owned, traded, exchanged privately, or Over-the-counter (finance), over-the-counter. In the case of a closed corporation, there are a relatively small number of shareholders or company members. Related terms are closely-held corporation, unquoted company, and unlisted company. Though less visible than their public company, publicly traded counterparts, private companies have major importance in the world's economy. In 2008, the 441 list of largest private non-governmental companies by revenue, largest private companies in the United States accounted for ($1.8 trillion) in revenues and employed 6.2 million people, according to ''Forbes''. In 2005, using a substantially smaller pool size (22.7%) for comparison, the 339 companies on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)