|

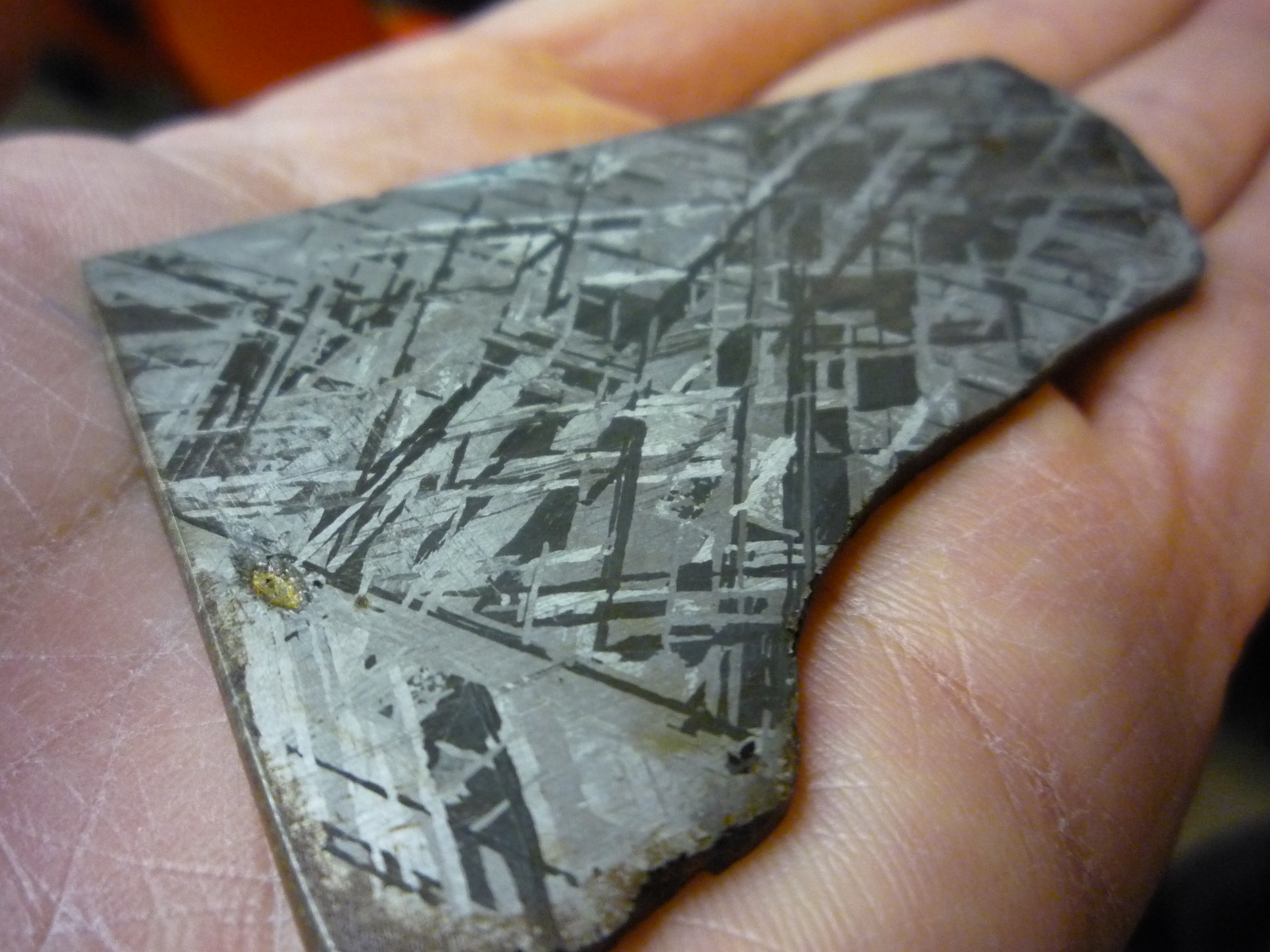

Grain Boundary

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional defects in the crystal structure, and tend to decrease the electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation of new phases from the solid. They are also important to many of the mechanisms of creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. High and low angle boundaries It is convenient to categorize grain boundaries according to the extent of misorientation between the two grains. ''Low-angle grain boundaries'' (''LAGB'') or ''subgrain boundaries'' are those with a misorientation less than about 15 degrees. Generally speaking they are composed of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron Microscopy

An electron microscope is a microscope that uses a beam of electrons as a source of illumination. It uses electron optics that are analogous to the glass lenses of an optical light microscope to control the electron beam, for instance focusing it to produce magnified images or electron diffraction patterns. As the wavelength of an electron can be up to 100,000 times smaller than that of visible light, electron microscopes have a much higher resolution of about 0.1 nm, which compares to about 200 nm for light microscopes. ''Electron microscope'' may refer to: * Transmission electron microscope (TEM) where swift electrons go through a thin sample * Scanning transmission electron microscope (STEM) which is similar to TEM with a scanned electron probe * Scanning electron microscope (SEM) which is similar to STEM, but with thick samples * Electron microprobe similar to a SEM, but more for chemical analysis * Low-energy electron microscope (LEEM), used to image surfaces * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recovery (metallurgy)

In metallurgy, recovery is a process by which a metal or alloy's deformed grains can reduce their stored energy by the removal or rearrangement of defects in their crystal structure. These defects, primarily dislocations, are introduced by plastic deformation of the material and act to increase the yield strength of a material. Since recovery reduces the dislocation density, the process is normally accompanied by a reduction in a material's strength and a simultaneous increase in the ductility. As a result, recovery may be considered beneficial or detrimental depending on the circumstances. Recovery is related to the similar processes of recrystallization and grain growth, each of them being stages of annealing. Recovery competes with recrystallization, as both are driven by the stored energy, but is also thought to be a necessary prerequisite for the nucleation of recrystallized grains. It is so called because there is a recovery of the electrical conductivity due to a reduc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recrystallization (metallurgy)

In materials science, recrystallization is a process by which deformed grains are replaced by a new set of defect-free grains that nucleate and grow until the original grains have been entirely consumed. Recrystallization is usually accompanied by a reduction in the strength and hardness of a material and a simultaneous increase in the ductility. Thus, the process may be introduced as a deliberate step in metals processing or may be an undesirable byproduct of another processing step. The most important industrial uses are softening of metals previously hardened or rendered brittle by cold work, and control of the grain structure in the final product. Recrystallization temperature is typically 0.3–0.4 times the melting point for pure metals and 0.5 times for alloys. Definition Recrystallization is defined as the process in which grains of a crystal structure come in a new structure or new crystal shape. A precise definition of recrystallization is difficult to state as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere. Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores. Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Growth

In materials science, grain growth is the increase in size of grains (crystallites) in a material at high temperature. This occurs when recovery and recrystallisation are complete and further reduction in the internal energy can only be achieved by reducing the total area of grain boundary. The term is commonly used in metallurgy but is also used in reference to ceramics and minerals. The behaviors of grain growth is analogous to the coarsening behaviors of grains, which implied that both of grain growth and coarsening may be dominated by the same physical mechanism. Importance of grain growth The practical performances of polycrystalline materials are strongly affected by the formed microstructure inside, which is mostly dominated by grain growth behaviors. For example, most materials exhibit the Hall–Petch effect at room-temperature and so display a higher yield stress when the grain size is reduced (assuming abnormal grain growth has not taken place). At high temperatur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poisson's Ratio

In materials science and solid mechanics, Poisson's ratio (symbol: ( nu)) is a measure of the Poisson effect, the deformation (expansion or contraction) of a material in directions perpendicular to the specific direction of loading. The value of Poisson's ratio is the negative of the ratio of transverse strain to axial strain. For small values of these changes, is the amount of transversal elongation divided by the amount of axial compression. Most materials have Poisson's ratio values ranging between 0.0 and 0.5. For soft materials, such as rubber, where the bulk modulus is much higher than the shear modulus, Poisson's ratio is near 0.5. For open-cell polymer foams, Poisson's ratio is near zero, since the cells tend to collapse in compression. Many typical solids have Poisson's ratios in the range of 0.2 to 0.3. The ratio is named after the French mathematician and physicist Siméon Poisson. Origin Poisson's ratio is a measure of the Poisson effect, the phenomenon in whi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the Elasticity (physics), elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain: :G \ \stackrel\ \frac = \frac = \frac where :\tau_ = F/A \, = shear stress :F is the force which acts :A is the area on which the force acts :\gamma_ = shear strain. In engineering :=\Delta x/l = \tan \theta , elsewhere := \theta :\Delta x is the transverse displacement :l is the initial length of the area. The derived SI unit of shear modulus is the Pascal (unit), pascal (Pa), although it is usually expressed in Pascal (unit), gigapascals (GPa) or in thousand pounds per square inch (ksi). Its dimensional analysis, dimensional form is M1L−1T−2, replacing ''force'' by ''mass'' times ''acceleration''. Explanation The shear modulus is one of several quantities for measuring the stiffness of materials. All of them arise in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystallography

Crystallography is the branch of science devoted to the study of molecular and crystalline structure and properties. The word ''crystallography'' is derived from the Ancient Greek word (; "clear ice, rock-crystal"), and (; "to write"). In July 2012, the United Nations recognised the importance of the science of crystallography by proclaiming 2014 the International Year of Crystallography.UN announcement "International Year of Crystallography" iycr2014.org. 12 July 2012 Crystallography is a broad topic, and many of its subareas, such as X-ray crystallography, are themselves important scientific topics. Crystallography ranges from the fundamentals of crystal structure to the mathematics of Crystal system, crystal geometry, including those that are Aperiodic crystal, not periodic or quasi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotation Matrix

In linear algebra, a rotation matrix is a transformation matrix that is used to perform a rotation (mathematics), rotation in Euclidean space. For example, using the convention below, the matrix :R = \begin \cos \theta & -\sin \theta \\ \sin \theta & \cos \theta \end rotates points in the plane counterclockwise through an angle about the origin of a two-dimensional Cartesian coordinate system. To perform the rotation on a plane point with standard coordinates , it should be written as a column vector, and matrix multiplication, multiplied by the matrix : : R\mathbf = \begin \cos \theta & -\sin \theta \\ \sin \theta & \cos \theta \end \begin x \\ y \end = \begin x\cos\theta-y\sin\theta \\ x\sin\theta+y\cos\theta \end. If and are the coordinates of the endpoint of a vector with the length ''r'' and the angle \phi with respect to the -axis, so that x = r \cos \phi and y = r \sin \phi, then the above equations become the List of trigonometric identities#Angle sum and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |