|

Single Crystal

In materials science, a single crystal (or single-crystal solid or monocrystalline solid) is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries.RIWD. "Reade Advanced Materials – Single Crystals". ''www.reade.com''. Retrieved 2021-02-28. The absence of the defects associated with grain boundaries can give monocrystals unique properties, particularly mechanical, optical and electrical, which can also be anisotropic, depending on the type of crystallographic structure. These properties, in addition to making some gems precious, are industrially used in technological applications, especially in optics and electronics. Because entropic effects favor the presence of some imperfections in the microstructure of solids, such as impurities, inhomogeneous strain and crystallographic defects such as dislocations, perfect single crystals of meaningful size are exceedingly rare in nature. The nece ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paracrystalline

In materials science, paracrystalline materials are defined as having short- and medium-range ordering in their lattice (similar to the liquid crystal phases) but lacking crystal-like long-range ordering at least in one direction. Origin and definition The words "paracrystallinity" and "paracrystal" were coined by the late Friedrich Rinne in the year 1933. Their German equivalents, e.g. "Parakristall", appeared in print one year earlier. A general theory of paracrystals has been formulated in a basic textbook, and then further developed/refined by various authors. Rolf Hosemann's definition of an ideal paracrystal is: "The electron density distribution of any material is equivalent to that of a paracrystal when there is for every building block one ideal point so that the distance statistics to other ideal points are identical for all of these points. The electron configuration of each building block around its ideal point is statistically independent of its counterpart in n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tantalum Single Crystal And 1cm3 Cube

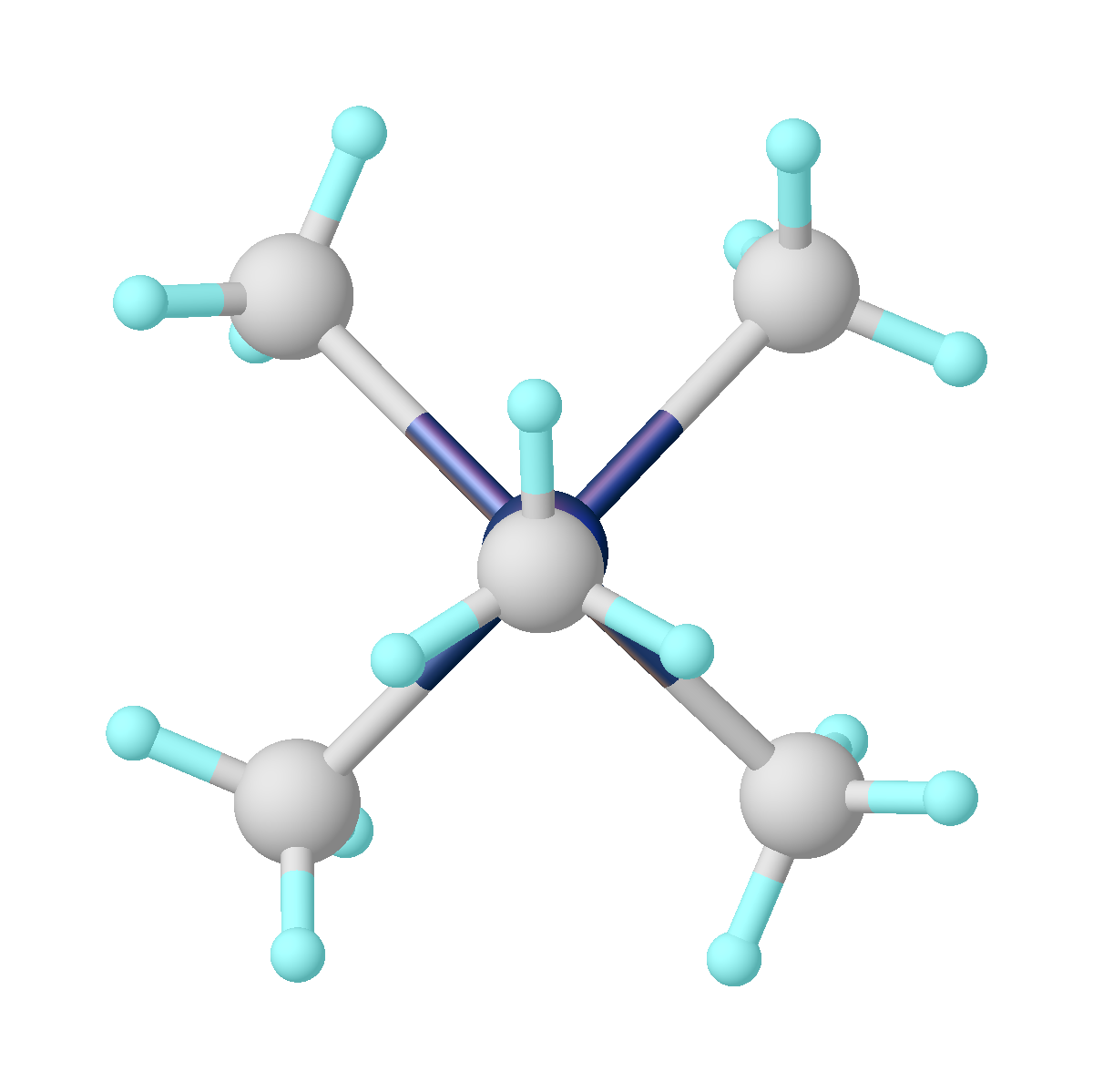

Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as ''tantalium'', it is named after Tantalus, a villain in Greek mythology. Tantalum is a very hard, ductile, lustrous, blue-gray transition metal that is highly corrosion-resistant. It is part of the refractory metals group, which are widely used as components of strong high-melting-point alloys. It is a group 5 element, along with vanadium and niobium, and it always occurs in geologic sources together with the chemically similar niobium, mainly in the mineral groups tantalite, columbite and coltan. The chemical inertness and very high melting point of tantalum make it valuable for laboratory and industrial equipment such as reaction vessels and vacuum furnaces. It is used in tantalum capacitors for electronic equipment such as computers. Tantalum is considered a technology-critical element by the European Commission. History Tantalum was discovered in Sweden in 1802 by Anders Ekeberg, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquid Phase Epitaxy

Epitaxy refers to a type of crystal growth or material deposition in which new crystalline layers are formed with one or more well-defined orientations with respect to the crystalline seed layer. The deposited crystalline film is called an epitaxial film or epitaxial layer. The relative orientation(s) of the epitaxial layer to the seed layer is defined in terms of the orientation of the crystal lattice of each material. For most epitaxial growths, the new layer is usually crystalline and each crystallographic domain of the overlayer must have a well-defined orientation relative to the substrate crystal structure. Epitaxy can involve single-crystal structures, although grain-to-grain epitaxy has been observed in granular films. For most technological applications, single domain epitaxy, which is the growth of an overlayer crystal with one well-defined orientation with respect to the substrate crystal, is preferred. Epitaxy can also play an important role while growing superlatti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quartz Synthese

Quartz is a hard, crystalline mineral composed of silica (silicon dioxide). The atoms are linked in a continuous framework of SiO4 silicon-oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical formula of SiO2. Quartz is the second most abundant mineral in Earth's continental crust, behind feldspar. Quartz exists in two forms, the normal α-quartz and the high-temperature β-quartz, both of which are chiral. The transformation from α-quartz to β-quartz takes place abruptly at . Since the transformation is accompanied by a significant change in volume, it can easily induce microfracturing of ceramics or rocks passing through this temperature threshold. There are many different varieties of quartz, several of which are classified as gemstones. Since antiquity, varieties of quartz have been the most commonly used minerals in the making of jewelry and hardstone carvings, especially in Eurasia. Quartz is the mineral defining the val ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Verneuil Method

The Verneuil method (or Verneuil process or Verneuil technique), also called flame fusion, was the first commercially successful method of manufacturing synthetic gemstones, developed in the late 1883 by the French chemist Auguste Verneuil. It is primarily used to produce the ruby, sapphire and padparadscha varieties of corundum, as well as the diamond simulants rutile, strontium titanate and spinel. The principle of the process involves melting a finely powdered substance using an oxyhydrogen flame, and crystallising the melted droplets into a boule. The process is considered to be the founding step of modern industrial crystal growth technology, and remains in wide use to this day. History Since the study of alchemy began, there have been attempts to synthetically produce precious stones, and ruby, being one of the prized cardinal gems, has long been a prime candidate. In the 19th century, significant advances were achieved, with the first ruby formed by melting two small ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kyropoulos Method

The Kyropoulos method, KY method, or Kyropoulos technique, is a method of bulk crystal growth used to obtain single crystals. The largest application of the Kyropoulos method is to grow large boules ''Boules'' () is a collective name for a wide range of games similar to bowls and bocce (In French: jeu or jeux, in Croatian: boćanje and in Italian: gioco or giochi) in which the objective is to throw or roll heavy balls (called in France, ... of single crystal sapphire used to produce substrate (electronics), substrates for the manufacture gallium nitride-based Light-emitting diode#Blue and ultraviolet, LEDs, and as a durable optical material.Dobrovinskaya, Elena R., Leonid A. Lytvynov, and Valerian Pishchik. Sapphire: material, manufacturing, applications. Springer Science & Business Media, 2009. History The method is named for , who proposed the technique in 1926 as a method to grow brittle alkali metal halide, alkali halide and alkali earth metal crystals for precis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recrystallization (chemistry)

In chemistry, recrystallization is a technique used to purify chemicals. By dissolving a mixture of a compound and impurities in an appropriate solvent, either the desired compound or impurities can be removed from the solution, leaving the other behind. It is named for the crystals often formed when the compound precipitates out. Alternatively, ''recrystallization'' can refer to the natural growth of larger ice crystals at the expense of smaller ones. Chemistry In chemistry, recrystallization is a procedure for purifying compounds. The most typical situation is that a desired "compound A" is contaminated by a small amount of "impurity B". There are various methods of purification that may be attempted (see Separation process), recrystallization being one of them. There are also different recrystallization techniques that can be used such as: Single-solvent recrystallization Typically, the mixture of "compound A" and "impurity B" is dissolved in the smallest amount of hot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sublimation (chemistry)

Sublimation is the transition of a substance directly from the solid to the gas state, without passing through the liquid state. Sublimation is an endothermic process that occurs at temperatures and pressures below a substance's triple point in its phase diagram, which corresponds to the lowest pressure at which the substance can exist as a liquid. The reverse process of sublimation is deposition or desublimation, in which a substance passes directly from a gas to a solid phase. Sublimation has also been used as a generic term to describe a solid-to-gas transition (sublimation) followed by a gas-to-solid transition ( deposition). While vaporization from liquid to gas occurs as evaporation from the surface if it occurs below the boiling point of the liquid, and as boiling with formation of bubbles in the interior of the liquid if it occurs at the boiling point, there is no such distinction for the solid-to-gas transition which always occurs as sublimation from the surface. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrothermal Synthesis

Hydrothermal synthesis includes the various techniques of crystallizing substances from high-temperature aqueous solutions at high vapor pressures; also termed "hydrothermal method". The term " hydrothermal" is of geologic origin. Geochemists and mineralogists have studied hydrothermal phase equilibria since the beginning of the twentieth century. George W. Morey at the Carnegie Institution and later, Percy W. Bridgman at Harvard University did much of the work to lay the foundations necessary to containment of reactive media in the temperature and pressure range where most of the hydrothermal work is conducted. Hydrothermal synthesis can be defined as a method of synthesis of single crystals that depends on the solubility of minerals in hot water under high pressure. The crystal growth is performed in an apparatus consisting of a steel pressure vessel called an autoclave, in which a nutrient is supplied along with water. A temperature gradient is maintained between the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |