Pcb Design on:

[Wikipedia]

[Google]

[Amazon]

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in

Before the development of printed circuit boards, electrical and electronic circuits were wired point-to-point on a chassis. Typically, the chassis was a sheet metal frame or pan, sometimes with a wooden bottom. Components were attached to the chassis, usually by insulators when the connecting point on the chassis was metal, and then their leads were connected directly or with jumper wires by

Before the development of printed circuit boards, electrical and electronic circuits were wired point-to-point on a chassis. Typically, the chassis was a sheet metal frame or pan, sometimes with a wooden bottom. Components were attached to the chassis, usually by insulators when the connecting point on the chassis was metal, and then their leads were connected directly or with jumper wires by

The Austrian engineer

The Austrian engineer

Manufacturing starts from the fabrication data generated by computer aided design, and component information. The fabrication data is read into the CAM (Computer Aided Manufacturing) software. CAM performs the following functions:

# Input of the fabrication data.

# Verification of the data

# Compensation for deviations in the manufacturing processes (e.g. scaling to compensate for distortions during lamination)

# Panelization

# Output of the digital tools (copper patterns, drill files, inspection, and others)

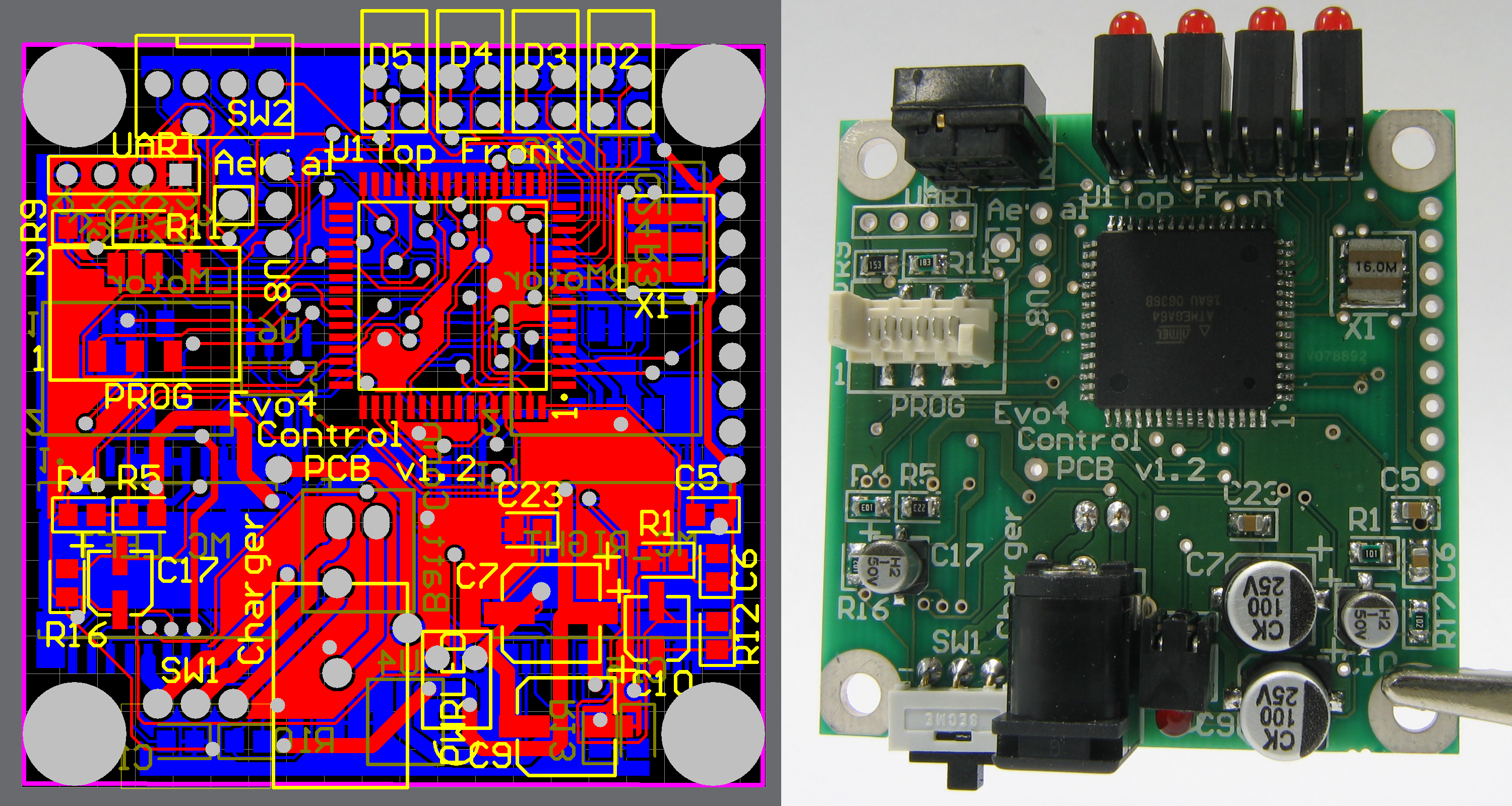

Initially PCBs were designed manually by creating a

Manufacturing starts from the fabrication data generated by computer aided design, and component information. The fabrication data is read into the CAM (Computer Aided Manufacturing) software. CAM performs the following functions:

# Input of the fabrication data.

# Verification of the data

# Compensation for deviations in the manufacturing processes (e.g. scaling to compensate for distortions during lamination)

# Panelization

# Output of the digital tools (copper patterns, drill files, inspection, and others)

Initially PCBs were designed manually by creating a

The process by which copper traces are applied to the surface is known as ''etching'' after the subtractive method of the process, though there are also additive and semi-additive methods.

Subtractive methods remove copper from an entirely copper-coated board to leave only the desired copper pattern. The simplest method, used for small-scale production and often by hobbyists, is immersion etching, in which the board is submerged in etching solution such as ferric chloride. Compared with methods used for mass production, the etching time is long. Heat and agitation can be applied to the bath to speed the etching rate. In bubble etching, air is passed through the etchant bath to agitate the solution and speed up etching. Splash etching uses a motor-driven paddle to splash boards with etchant; the process has become commercially obsolete since it is not as fast as spray etching. In spray etching, the etchant solution is distributed over the boards by nozzles, and recirculated by pumps. Adjustment of the nozzle pattern, flow rate, temperature, and etchant composition gives predictable control of etching rates and high production rates. As more copper is consumed from the boards, the etchant becomes saturated and less effective; different etchants have different capacities for copper, with some as high as 150 grams of copper per litre of solution. In commercial use, etchants can be regenerated to restore their activity, and the dissolved copper recovered and sold. Small-scale etching requires attention to disposal of used etchant, which is corrosive and toxic due to its metal content. The etchant removes copper on all surfaces not protected by the resist. "Undercut" occurs when etchant attacks the thin edge of copper under the resist; this can reduce conductor widths and cause open-circuits. Careful control of etch time is required to prevent undercut. Where metallic plating is used as a resist, it can "overhang" which can cause short-circuits between adjacent traces when closely spaced. Overhang can be removed by wire-brushing the board after etching.

In additive methods the pattern is

The process by which copper traces are applied to the surface is known as ''etching'' after the subtractive method of the process, though there are also additive and semi-additive methods.

Subtractive methods remove copper from an entirely copper-coated board to leave only the desired copper pattern. The simplest method, used for small-scale production and often by hobbyists, is immersion etching, in which the board is submerged in etching solution such as ferric chloride. Compared with methods used for mass production, the etching time is long. Heat and agitation can be applied to the bath to speed the etching rate. In bubble etching, air is passed through the etchant bath to agitate the solution and speed up etching. Splash etching uses a motor-driven paddle to splash boards with etchant; the process has become commercially obsolete since it is not as fast as spray etching. In spray etching, the etchant solution is distributed over the boards by nozzles, and recirculated by pumps. Adjustment of the nozzle pattern, flow rate, temperature, and etchant composition gives predictable control of etching rates and high production rates. As more copper is consumed from the boards, the etchant becomes saturated and less effective; different etchants have different capacities for copper, with some as high as 150 grams of copper per litre of solution. In commercial use, etchants can be regenerated to restore their activity, and the dissolved copper recovered and sold. Small-scale etching requires attention to disposal of used etchant, which is corrosive and toxic due to its metal content. The etchant removes copper on all surfaces not protected by the resist. "Undercut" occurs when etchant attacks the thin edge of copper under the resist; this can reduce conductor widths and cause open-circuits. Careful control of etch time is required to prevent undercut. Where metallic plating is used as a resist, it can "overhang" which can cause short-circuits between adjacent traces when closely spaced. Overhang can be removed by wire-brushing the board after etching.

In additive methods the pattern is

Multi-layer printed circuit boards have trace layers inside the board. This is achieved by laminating a stack of materials in a press by applying pressure and heat for a period of time. This results in an inseparable one piece product. For example, a four-layer PCB can be fabricated by starting from a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom pre-preg and copper foil. It is then drilled, plated, and etched again to get traces on top and bottom layers.

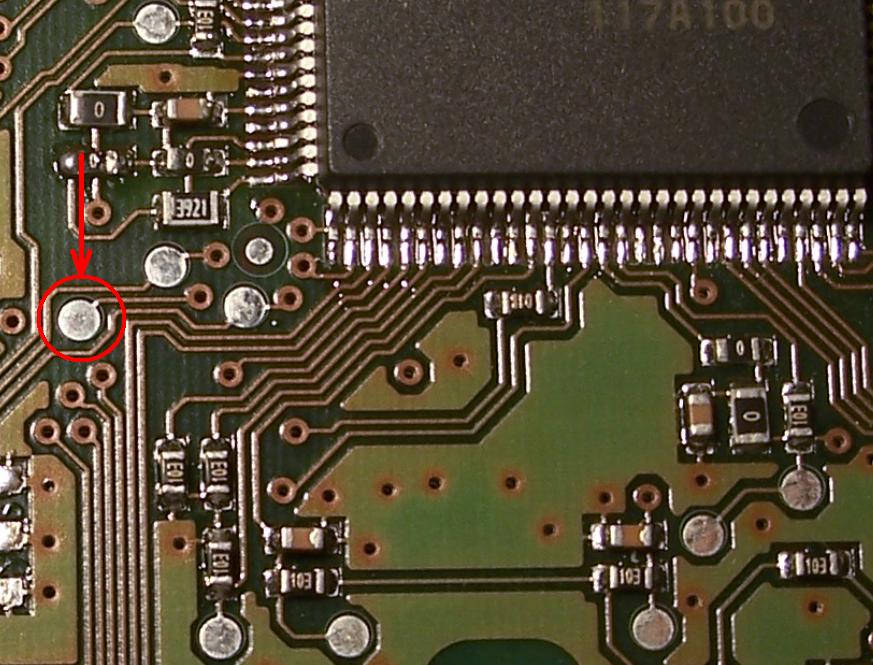

The inner layers are given a complete machine inspection before lamination because mistakes cannot be corrected afterwards. Automatic optical inspection (AOI) machines compare an image of the board with the digital image generated from the original design data. Automated Optical Shaping (AOS) machines can then add missing copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. PCB tracks can have a width of just 10 micrometers.

Multi-layer printed circuit boards have trace layers inside the board. This is achieved by laminating a stack of materials in a press by applying pressure and heat for a period of time. This results in an inseparable one piece product. For example, a four-layer PCB can be fabricated by starting from a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom pre-preg and copper foil. It is then drilled, plated, and etched again to get traces on top and bottom layers.

The inner layers are given a complete machine inspection before lamination because mistakes cannot be corrected afterwards. Automatic optical inspection (AOI) machines compare an image of the board with the digital image generated from the original design data. Automated Optical Shaping (AOS) machines can then add missing copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. PCB tracks can have a width of just 10 micrometers.

Holes through a PCB are typically drilled with

Holes through a PCB are typically drilled with

In assembly the bare board is populated (or "stuffed") with electronic components to form a functional ''printed circuit assembly'' (PCA), sometimes called a "printed circuit board assembly" (PCBA). In

In assembly the bare board is populated (or "stuffed") with electronic components to form a functional ''printed circuit assembly'' (PCA), sometimes called a "printed circuit board assembly" (PCBA). In

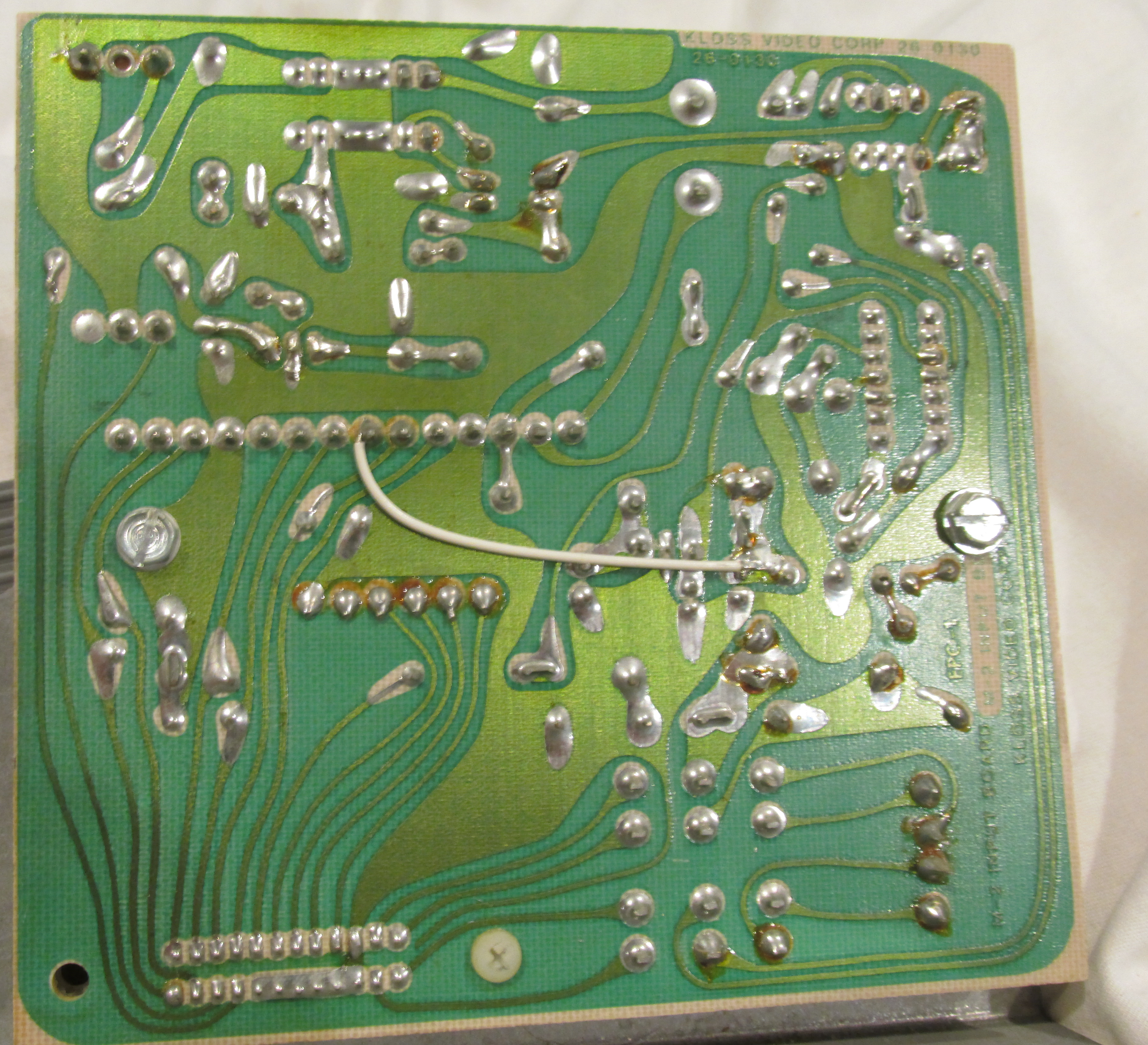

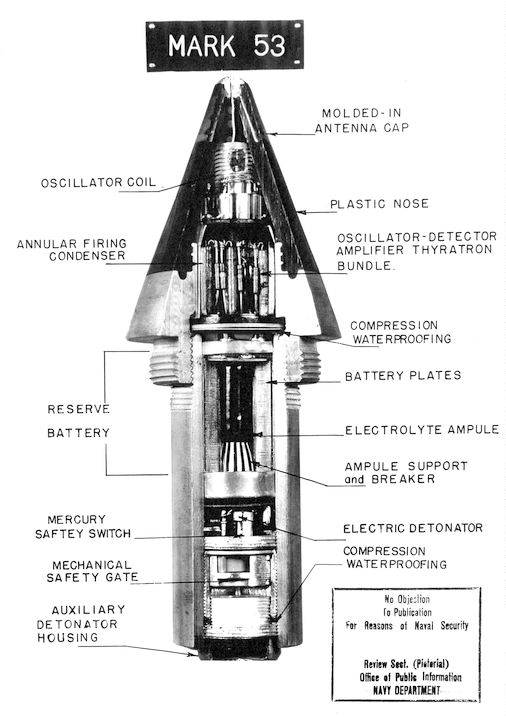

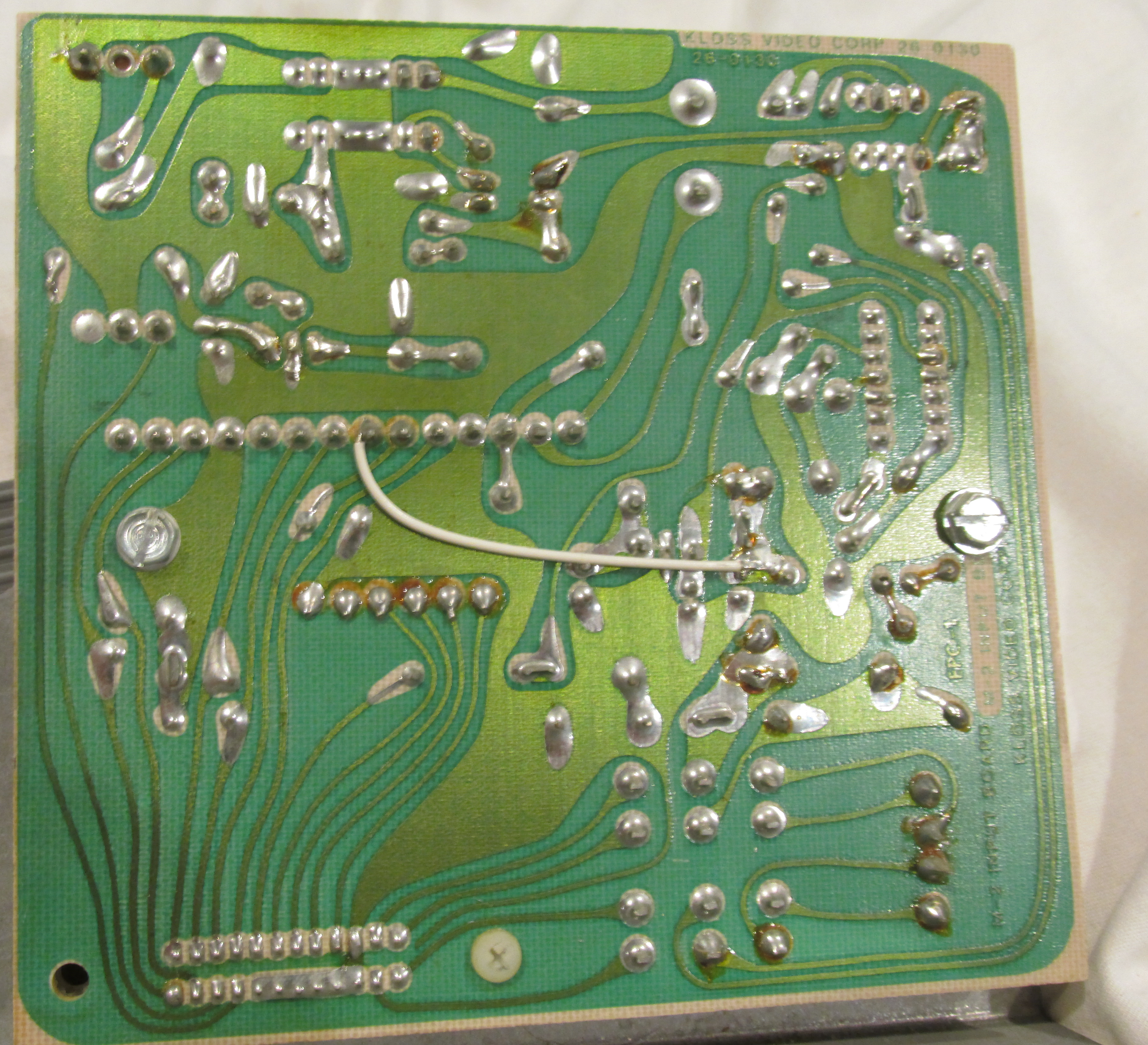

Cordwood construction can save significant space and was often used with Through-hole technology, wire-ended components in applications where space was at a premium (such as fuzes, missile guidance, and telemetry systems) and in high-speed computers, where short traces were important. In cordwood construction, axial-leaded components were mounted between two parallel planes. The components were either soldered together with jumper wire or they were connected to other components by thin nickel ribbon welded at right angles onto the component leads. To avoid shorting together different interconnection layers, thin insulating cards were placed between them. Perforations or holes in the cards allowed component leads to project through to the next interconnection layer. One disadvantage of this system was that special nickel-leaded components had to be used to allow reliable interconnecting welds to be made. Differential thermal expansion of the component could put pressure on the leads of the components and the PCB traces and cause mechanical damage (as was seen in several modules on the Apollo program). Additionally, components located in the interior are difficult to replace. Some versions of cordwood construction used soldered single-sided PCBs as the interconnection method (as pictured), allowing the use of normal-leaded components at the cost of being difficult to remove the boards or replace any component that is not at the edge.

Before the advent of integrated circuits, this method allowed the highest possible component packing density; because of this, it was used by a number of computer vendors including Control Data Corporation. The cordwood method of construction was used only rarely once PCBs became widespread, mainly in aerospace or other extremely high-density electronics.

Cordwood construction can save significant space and was often used with Through-hole technology, wire-ended components in applications where space was at a premium (such as fuzes, missile guidance, and telemetry systems) and in high-speed computers, where short traces were important. In cordwood construction, axial-leaded components were mounted between two parallel planes. The components were either soldered together with jumper wire or they were connected to other components by thin nickel ribbon welded at right angles onto the component leads. To avoid shorting together different interconnection layers, thin insulating cards were placed between them. Perforations or holes in the cards allowed component leads to project through to the next interconnection layer. One disadvantage of this system was that special nickel-leaded components had to be used to allow reliable interconnecting welds to be made. Differential thermal expansion of the component could put pressure on the leads of the components and the PCB traces and cause mechanical damage (as was seen in several modules on the Apollo program). Additionally, components located in the interior are difficult to replace. Some versions of cordwood construction used soldered single-sided PCBs as the interconnection method (as pictured), allowing the use of normal-leaded components at the cost of being difficult to remove the boards or replace any component that is not at the edge.

Before the advent of integrated circuits, this method allowed the highest possible component packing density; because of this, it was used by a number of computer vendors including Control Data Corporation. The cordwood method of construction was used only rarely once PCBs became widespread, mainly in aerospace or other extremely high-density electronics.

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering

Electrical engineering is an engineering discipline concerned with the study, design, and application of equipment, devices, and systems which use electricity, electronics, and electromagnetism. It emerged as an identifiable occupation in the l ...

to connect electronic components to one another in a controlled manner. It takes the form of a laminated

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materia ...

sandwich structure of conductive and insulating layers: each of the conductive layers is designed with an artwork pattern of traces, planes and other features (similar to wires on a flat surface) etched from one or more sheet layers of copper laminated

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materia ...

onto and/or between sheet layers of a non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers in the shape designed to accept the component's terminals, generally by means of soldering

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involv ...

, to both electrically connect and mechanically fasten them to it. Another manufacturing process adds vias

The Vias GmbH (stylized VIAS) is a rail service company based in Frankfurt (Germany). The name of the company was taken from the Latin word via for ''way'' and the letter ''S'' for service. It operates rail services in the states of Hesse, Rhine ...

: plated-through holes that allow interconnections between layers.

Printed circuit boards are used in nearly all electronic products. Alternatives to PCBs include wire wrap and point-to-point construction

Point-to-point construction is a non-automated method of construction of electronics Electronic circuit, circuits widely used before the use of printed circuit boards (PCBs) and automated assembly gradually became widespread following their intr ...

, both once popular but now rarely used. PCBs require additional design effort to lay out the circuit, but manufacturing and assembly can be automated. Electronic design automation software is available to do much of the work of layout. Mass-producing circuits with PCBs is cheaper and faster than with other wiring methods, as components are mounted and wired in one operation. Large numbers of PCBs can be fabricated at the same time, and the layout has to be done only once. PCBs can also be made manually in small quantities, with reduced benefits.

PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of surface mount technology. However, multilayer PCBs make repair, analysis, and field modification of circuits much more difficult and usually impractical.

The world market for bare PCBs exceeded $60.2 billion in 2014 and is estimated to reach $79 billion by 2024.

History

Predecessors

Before the development of printed circuit boards, electrical and electronic circuits were wired point-to-point on a chassis. Typically, the chassis was a sheet metal frame or pan, sometimes with a wooden bottom. Components were attached to the chassis, usually by insulators when the connecting point on the chassis was metal, and then their leads were connected directly or with jumper wires by

Before the development of printed circuit boards, electrical and electronic circuits were wired point-to-point on a chassis. Typically, the chassis was a sheet metal frame or pan, sometimes with a wooden bottom. Components were attached to the chassis, usually by insulators when the connecting point on the chassis was metal, and then their leads were connected directly or with jumper wires by soldering

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involv ...

, or sometimes using crimp connectors, wire connector lugs on screw terminals, or other methods. Circuits were large, bulky, heavy, and relatively fragile (even discounting the breakable glass envelopes of the vacuum tubes that were often included in the circuits), and production was labor-intensive, so the products were expensive.

Development of the methods used in modern printed circuit boards started early in the 20th century. In 1903, a German inventor, Albert Hanson, described flat foil conductors laminated to an insulating board, in multiple layers. Thomas Edison

Thomas Alva Edison (February 11, 1847October 18, 1931) was an American inventor and businessman. He developed many devices in fields such as electric power generation, mass communication, sound recording, and motion pictures. These inventi ...

experimented with chemical methods of plating conductors onto linen paper in 1904. Arthur Berry in 1913 patented a print-and- etch method in the UK, and in the United States Max Schoop obtained a patent to flame-spray metal onto a board through a patterned mask. Charles Ducas in 1925 patented a method of electroplating circuit patterns.

Predating the printed circuit invention, and similar in spirit, was John Sargrove's 1936–1947 Electronic Circuit Making Equipment (ECME) which sprayed metal onto a Bakelite plastic board. The ECME could produce three radio boards per minute.

Early PCBs

The Austrian engineer

The Austrian engineer Paul Eisler

Paul Eisler (1907 – 26 October 1992, London) was an Austrian inventor born in Vienna. Among his innovations were the printed circuit board. In 2012, ''Printed Circuit Design & Fab'' magazine named its Hall of Fame after Eisler.

Early life and e ...

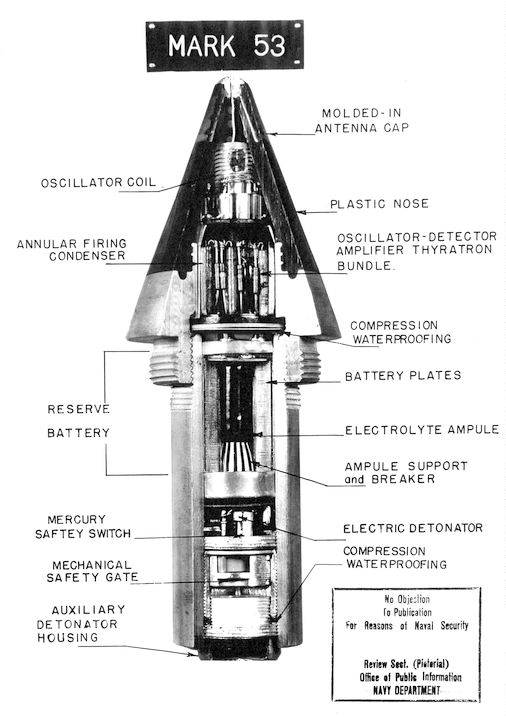

invented the printed circuit as part of a radio set while working in the UK around 1936. In 1941 a multi-layer printed circuit was used in German magnetic influence naval mines.

Around 1943 the USA began to use the technology on a large scale to make proximity fuzes for use in World War II. Such fuzes required an electronic circuit that could withstand being fired from a gun, and could be produced in quantity. The Centralab Division of Globe Union submitted a proposal which met the requirements: a ceramic plate would be screenprinted with metallic paint for conductors and carbon material for resistors, with ceramic disc capacitors and subminiature vacuum tubes soldered in place. The technique proved viable, and the resulting patent on the process, which was classified by the U.S. Army, was assigned to Globe Union. It was not until 1984 that the Institute of Electrical and Electronics Engineers (IEEE) awarded Harry W. Rubinstein the Cledo Brunetti Award for early key contributions to the development of printed components and conductors on a common insulating substrate. Rubinstein was honored in 1984 by his alma mater, the University of Wisconsin-Madison

A university () is an institution of higher (or tertiary) education and research which awards academic degrees in several academic disciplines. Universities typically offer both undergraduate and postgraduate programs. In the United States, th ...

, for his innovations in the technology of printed electronic circuits and the fabrication of capacitors. This invention also represents a step in the development of integrated circuit technology, as not only wiring but also passive components were fabricated on the ceramic substrate.

Post-war developments

In 1948, the USA released the invention for commercial use. Printed circuits did not become commonplace in consumer electronics until the mid-1950s, after the ''Auto-Sembly'' process was developed by the United States Army. At around the same time in the UK work along similar lines was carried out byGeoffrey Dummer

Geoffrey William Arnold Dummer, MBE (1945), C. Eng., IEE Premium Award, FIEEE, MIEE, USA Medal of Freedom with Bronze Palm (25 February 1909 – 9 September 2002) was an English electronics engineer and consultant, who is credited as be ...

, then at the RRDE.

Motorola was an early leader in bringing the process into consumer electronics, announcing in August 1952 the adoption of "plated circuits" in home radios after six years of research and a $1M investment. Motorola soon began using its trademarked term for the process, PLAcir, in its consumer radio advertisements. Hallicrafters released its first "foto-etch" printed circuit product, a clock-radio, on 1 November 1952.

Even as circuit boards became available, the point-to-point chassis construction method remained in common use in industry (such as TV and hi-fi sets) into at least the late 1960s. Printed circuit boards were introduced to reduce the size, weight, and cost of parts of the circuitry. In 1960, a small consumer radio receiver might be built with all its circuitry on one circuit board, but a TV set would probably contain one or more circuit boards.

Originally, every electronic component had wire lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

s, and a PCB had holes drilled for each wire of each component. The component leads were then inserted through the holes and solder

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable ...

ed to the copper PCB traces. This method of assembly is called ''through-hole'' construction. In 1949, Moe Abramson and Stanislaus F. Danko of the United States Army Signal Corps developed the ''Auto-Sembly'' process in which component leads were inserted into a copper foil interconnection pattern and dip soldered. The patent they obtained in 1956 was assigned to the U.S. Army. With the development of board lamination

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materia ...

and etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other types ...

techniques, this concept evolved into the standard printed circuit board fabrication process in use today. Soldering could be done automatically by passing the board over a ripple, or wave, of molten solder in a wave-soldering machine. However, the wires and holes are inefficient since drilling holes is expensive and consumes drill bits and the protruding wires are cut off and discarded.

From the 1980s onward, small surface mount parts have been used increasingly instead of through-hole components; this has led to smaller boards for a given functionality and lower production costs, but with some additional difficulty in servicing faulty boards.

In the 1990s the use of multilayer surface boards became more frequent. As a result, size was further minimized and both flexible and rigid PCBs were incorporated in different devices. In 1995 PCB manufacturers began using microvia

Microvias are used as the interconnects between layers in high density interconnect (HDI) substrates and printed circuit boards (PCBs) to accommodate the high input/output

In computing, input/output (I/O, or informally io or IO) is the commun ...

technology to produce High-Density Interconnect (HDI) PCBs.

Recent advances

Recent advances in3D printing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer co ...

have meant that there are several new techniques in PCB creation. 3D printed electronics (PEs) can be utilized to print items layer by layer and subsequently the item can be printed with a liquid ink that contains electronic functionalities.

HDI (High Density Interconnect) technology allows for a denser design on the PCB and thus potentially smaller PCBs with more traces and/or components in a given area. As a result, the paths between components can be shorter. HDIs use blind/buried vias, or a combination that includes microvias. With multi-layer HDI PCBs the interconnection of several vias stacked on top of each other (stacked vías, instead of one deep buried via) can be made stronger, thus enhancing reliability in all conditions. The most common applications for HDI technology are computer and mobile phone components as well as medical equipment and military communication equipment. A 4-layer HDI microvia PCB is equivalent in quality to an 8-layer through-hole PCB, so HDI technology can reduce costs.

Composition

A basic PCB consists of a flat sheet of insulating material and a layer ofcopper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

foil

Foil may refer to:

Materials

* Foil (metal), a quite thin sheet of metal, usually manufactured with a rolling mill machine

* Metal leaf, a very thin sheet of decorative metal

* Aluminium foil, a type of wrapping for food

* Tin foil, metal foil ...

, laminated to the substrate. Chemical etching divides the copper into separate conducting lines called tracks or ''circuit traces'', pads for connections, vias to pass connections between layers of copper, and features such as solid conductive areas for electromagnetic shielding

In electrical engineering, electromagnetic shielding is the practice of reducing or blocking the electromagnetic field (EMF) in a space with barriers made of conductive or magnetic materials. It is typically applied to enclosures, for isolatin ...

or other purposes. The tracks function as wires fixed in place, and are insulated from each other by air and the board substrate material. The surface of a PCB may have a coating that protects the copper from corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

and reduces the chances of solder short

Short may refer to:

Places

* Short (crater), a lunar impact crater on the near side of the Moon

* Short, Mississippi, an unincorporated community

* Short, Oklahoma, a census-designated place

People

* Short (surname)

* List of people known as ...

s between traces or undesired electrical contact with stray bare wires. For its function in helping to prevent solder shorts, the coating is called solder resist or solder mask.

The pattern to be etched into each copper layer of a PCB is called the "artwork". The etching is usually done using photoresist

A photoresist (also known simply as a resist) is a light-sensitive material used in several processes, such as photolithography and photoengraving, to form a patterned coating on a surface. This process is crucial in the electronic industry.

...

which is coated onto the PCB, then exposed to light projected in the pattern of the artwork. The resist material protects the copper from dissolution into the etching solution. The etched board is then cleaned. A PCB design can be mass-reproduced in a way similar to the way photographs can be mass-duplicated from film negative

In photography, a negative is an image, usually on a strip or sheet of transparent plastic film, in which the lightest areas of the photographed subject appear darkest and the darkest areas appear lightest. This reversed order occurs because th ...

s using a photographic printer.

FR-4 glass epoxy is the most common insulating substrate. Another substrate material is cotton paper impregnated with phenolic resin

Phenol formaldehyde resins (PF) or phenolic resins (also infrequently called phenoplasts) are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. Used as the basis for Bakelite, PFs were the first commerc ...

, often tan or brown.

When a PCB has no components installed, it is less ambiguously called a ''printed wiring board'' (''PWB'') or ''etched wiring board''. However, the term "printed wiring board" has fallen into disuse. A PCB populated with electronic components is called a ''printed circuit assembly'' (''PCA''), ''printed circuit board assembly'' or ''PCB assembly'' (''PCBA''). In informal usage, the term "printed circuit board" most commonly means "printed circuit assembly" (with components). The IPC preferred term for an assembled board is ''circuit card assembly'' (''CCA''), and for an assembled backplane

A backplane (or "backplane system") is a group of electrical connectors in parallel with each other, so that each pin of each connector is linked to the same relative pin of all the other connectors, forming a computer bus. It is used as a back ...

it is ''backplane assembly''. "Card" is another widely used informal term for a "printed circuit assembly".

For example, expansion card

In computing, an expansion card (also called an expansion board, adapter card, peripheral card or accessory card) is a printed circuit board that can be inserted into an electrical connector, or expansion slot (also referred to as a bus sl ...

.

A PCB may be printed with a legend identifying the components, test points, or identifying text. Originally, silkscreen printing

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh ...

was used for this purpose, but today other, finer quality printing methods are usually used. Normally the legend does not affect the function of a PCBA.

Layers

A printed circuit board can have multiple layers of copper which almost always are arranged in pairs. The number of layers and the interconnection designed between them (vias, PTHs) provide a general estimate of the board complexity. Using more layers allow for more routing options and better control of signal integrity, but are also time consuming and costly to manufacture. Likewise, selection of the vias for the board also allow fine tuning of the board size, escaping of signals off complex ICs, routing, and long term reliability, but are tightly coupled with production complexity and cost. One of the simplest boards to produce is the two-layer board. It has copper on both sides that are referred to as external layers; multi layer boards sandwich additional internal layers of copper and insulation. After two-layer PCBs, the next step up is the four-layer. The four layer board adds significantly more routing options in the internal layers as compared to the two layer board, and often some portion of the internal layers is used as ground plane or power plane, to achieve better signal integrity, higher signaling frequencies, lower EMI, and better power supply decoupling. In multi-layer boards, the layers of material are laminated together in an alternating sandwich: copper, substrate, copper, substrate, copper, etc.; each plane of copper is etched, and any internal vias (that will not extend to both outer surfaces of the finished multilayer board) are plated-through, before the layers are laminated together. Only the outer layers need be coated; the inner copper layers are protected by the adjacent substrate layers.Component mounting

Through-hole (leaded) resistors Through-hole devices mounted on the circuit board of a mid-1980s Commodore 64 home computer A box of drill bits used for making holes in printed circuit boards. While tungsten-carbide bits are very hard, they eventually wear out or break. Drilling is a considerable part of the cost of a through-hole printed circuit board file:Surface Mount Components.jpg, Surface mount components, including resistors,transistor

upright=1.4, gate (G), body (B), source (S) and drain (D) terminals. The gate is separated from the body by an insulating layer (pink).

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch ...

s and an integrated circuit

file:Mouse printed circuit board both sides IMG 0959a.JPG, A PCB in a computer mouse

A computer mouse (plural mice, sometimes mouses) is a hand-held pointing device that detects two-dimensional motion relative to a surface. This motion is typically translated into the motion of a pointer on a display, which allows a smooth ...

: the component side (left) and the printed side (right)

"Through hole" components are mounted by their wire leads passing through the board and soldered to traces on the other side. "Surface mount" components are attached by their leads to copper traces on the same side of the board. A board may use both methods for mounting components. PCBs with only through-hole mounted components are now uncommon. Surface mounting is used for transistor

upright=1.4, gate (G), body (B), source (S) and drain (D) terminals. The gate is separated from the body by an insulating layer (pink).

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch ...

s, diodes, IC chip

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny M ...

s, resistors, and capacitors. Through-hole mounting may be used for some large components such as electrolytic capacitors and connectors.

The first PCBs used through-hole technology

In electronics, through-hole technology (also spelled "thru-hole") is a manufacturing scheme in which leads on the components are inserted through holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side, either ...

, mounting electronic components by lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

s inserted through holes on one side of the board and soldered onto copper traces on the other side. Boards may be single-sided, with an unplated component side, or more compact double-sided boards, with components soldered on both sides. Horizontal installation of through-hole parts with two axial leads (such as resistors, capacitors, and diodes) is done by bending the leads 90 degrees in the same direction, inserting the part in the board (often bending leads located on the back of the board in opposite directions to improve the part's mechanical strength), soldering the leads, and trimming off the ends. Leads may be soldered

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable ...

either manually or by a wave soldering

Wave soldering is a bulk soldering process used for the manufacturing of printed circuit boards. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the ci ...

machine. Through-hole manufacture adds to board cost by requiring many holes to be drilled accurately, and it limits the available routing area for signal trace In electronics, a signal trace or circuit trace on a printed circuit board (PCB) or integrated circuit (IC) is the equivalent of a wire for conducting signals. Each trace consists of a flat, narrow part of the copper foil that remains after etching ...

s on layers immediately below the top layer on multi-layer boards, since the holes must pass through all layers to the opposite side. Once surface-mounting came into use, small-sized SMD components were used where possible, with through-hole mounting only of components unsuitably large for surface-mounting due to power requirements or mechanical limitations, or subject to mechanical stress which might damage the PCB (e.g. by lifting the copper off the board surface).

Surface-mount technology emerged in the 1960s, gained momentum in the early 1980s, and became widely used by the mid-1990s.

Components were mechanically redesigned to have small metal tabs or end caps that could be soldered directly onto the PCB surface, instead of wire leads to pass through holes. Components became much smaller and component placement on both sides of the board became more common than with through-hole mounting, allowing much smaller PCB assemblies with much higher circuit densities.

Surface mounting lends itself well to a high degree of automation, reducing labor costs and greatly increasing production rates compared with through-hole circuit boards. Components can be supplied mounted on carrier tapes. Surface mount components can be about one-quarter to one-tenth of the size and weight of through-hole components, and passive components much cheaper. However, prices of semiconductor surface mount devices (SMDs) are determined more by the chip itself than the package, with little price advantage over larger packages, and some wire-ended components, such as 1N4148 small-signal switch diodes, are actually significantly cheaper than SMD equivalents.

Electrical properties

Each trace consists of a flat, narrow part of thecopper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

foil that remains after etching. Its resistance, determined by its width, thickness, and length, must be sufficiently low for the current the conductor will carry. Power and ground traces may need to be wider than signal traces. In a multi-layer board one entire layer may be mostly solid copper to act as a ground plane for shielding and power return. For microwave

Microwave is a form of electromagnetic radiation with wavelengths ranging from about one meter to one millimeter corresponding to frequencies between 300 MHz and 300 GHz respectively. Different sources define different frequency ra ...

circuits, transmission line

In electrical engineering, a transmission line is a specialized cable or other structure designed to conduct electromagnetic waves in a contained manner. The term applies when the conductors are long enough that the wave nature of the transmi ...

s can be laid out in a planar form such as stripline or microstrip with carefully controlled dimensions to assure a consistent impedance. In radio-frequency and fast switching circuits the inductance and capacitance

Capacitance is the capability of a material object or device to store electric charge. It is measured by the change in charge in response to a difference in electric potential, expressed as the ratio of those quantities. Commonly recognized ar ...

of the printed circuit board conductors become significant circuit elements, usually undesired; conversely, they can be used as a deliberate part of the circuit design, as in distributed-element filter

A distributed-element filter is an electronic filter in which capacitance, inductance, and resistance (the elements of the circuit) are not localised in discrete capacitors, inductors, and resistors as they are in conventional filters. Its purpo ...

s, antennae, and fuse

Fuse or FUSE may refer to:

Devices

* Fuse (electrical), a device used in electrical systems to protect against excessive current

** Fuse (automotive), a class of fuses for vehicles

* Fuse (hydraulic), a device used in hydraulic systems to protect ...

s, obviating the need for additional discrete components. High density interconnects (HDI) PCBs have tracks and/or vias with a width or diameter of under 152 micrometers.

Materials

Laminates

Laminates are manufactured by curing under pressure and temperature layers of cloth or paper withthermoset

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer ( resin). Curing is induced by heat or suitable radiation ...

resin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on n ...

to form an integral final piece of uniform thickness. The size can be up to in width and length. Varying cloth weaves (threads per inch or cm), cloth thickness, and resin percentage are used to achieve the desired final thickness and dielectric

In electromagnetism, a dielectric (or dielectric medium) is an electrical insulator that can be polarised by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the mate ...

characteristics. Available standard laminate thickness are listed in

ANSI/IPC-D-275.

The cloth or fiber material used, resin material, and the cloth to resin ratio determine the laminate's type designation (FR-4, CEM

Cem Sultan (also spelled Djem or Jem) or Sultan Cem or Şehzade Cem (December 22, 1459 – February 25, 1495, ; ota, جم سلطان, Cem sulṭān; tr, Cem Sultan; french: Zizim), was a claimant to the Ottoman throne in the 15th century.

Ce ...

-1, G-10, etc.) and therefore the characteristics of the laminate produced. Important characteristics are the level to which the laminate is fire retardant

A fire retardant is a substance that is used to slow down or stop the spread of fire or reduce its intensity. This is commonly accomplished by chemical reactions that reduce the flammability of fuels or delay their combustion. Fire retardants m ...

, the dielectric constant (er), the loss tangent

Dielectric loss quantifies a dielectric material's inherent dissipation of electromagnetic energy (e.g. heat). It can be parameterized in terms of either the loss angle ''δ'' or the corresponding loss tangent tan ''δ''. Both refer to the ...

(tan δ), the tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials t ...

, the shear strength

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a materi ...

, the glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rub ...

(Tg), and the Z-axis expansion coefficient (how much the thickness changes with temperature).

There are quite a few different dielectrics that can be chosen to provide different insulating values depending on the requirements of the circuit. Some of these dielectrics are polytetrafluoroethylene (Teflon), FR-4, FR-1, CEM-1 or CEM-3. Well known pre-preg materials used in the PCB industry are FR-2 (phenolic cotton paper), FR-3 (cotton paper and epoxy), FR-4 (woven glass and epoxy), FR-5 (woven glass and epoxy), FR-6 (matte glass and polyester), G-10 (woven glass and epoxy), CEM-1 (cotton paper and epoxy), CEM-2 (cotton paper and epoxy), CEM-3 (non-woven glass and epoxy), CEM-4 (woven glass and epoxy), CEM-5 (woven glass and polyester). Thermal expansion is an important consideration especially with ball grid array

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be pu ...

(BGA) and naked die technologies, and glass fiber offers the best dimensional stability.

FR-4 is by far the most common material used today. The board stock with unetched copper on it is called "copper-clad laminate".

With decreasing size of board features and increasing frequencies, small nonhomogeneities like uneven distribution of fiberglass or other filler, thickness variations, and bubbles in the resin matrix, and the associated local variations in the dielectric constant, are gaining importance.

Key substrate parameters

The circuitboard substrates are usually dielectric composite materials. The composites contain a matrix (usually an epoxy resin) and a reinforcement (usually a woven, sometimes nonwoven, glass fibers, sometimes even paper), and in some cases a filler is added to the resin (e.g. ceramics; titanate ceramics can be used to increase the dielectric constant). The reinforcement type defines two major classes of materials: woven and non-woven. Woven reinforcements are cheaper, but the high dielectric constant of glass may not be favorable for many higher-frequency applications. The spatially nonhomogeneous structure also introduces local variations in electrical parameters, due to different resin/glass ratio at different areas of the weave pattern. Nonwoven reinforcements, or materials with low or no reinforcement, are more expensive but more suitable for some RF/analog applications. The substrates are characterized by several key parameters, chiefly thermomechanical (glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rub ...

, tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials t ...

, shear strength

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a materi ...

, thermal expansion

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions.

Temperature is a monotonic function of the average molecular kinetic ...

), electrical ( dielectric constant, loss tangent

Dielectric loss quantifies a dielectric material's inherent dissipation of electromagnetic energy (e.g. heat). It can be parameterized in terms of either the loss angle ''δ'' or the corresponding loss tangent tan ''δ''. Both refer to the ...

, dielectric breakdown voltage, leakage current

In electronics, leakage is the gradual transfer of electrical energy across a boundary normally viewed as insulating, such as the spontaneous discharge of a charged capacitor, magnetic coupling of a transformer with other components, or flow of cu ...

, tracking resistance...), and others (e.g. moisture absorption

Moisture is the presence of a liquid, especially water, often in trace amounts. Small amounts of water may be found, for example, in the air ( humidity), in foods, and in some commercial products. Moisture also refers to the amount of water va ...

).

At the glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rub ...

the resin in the composite softens and significantly increases thermal expansion; exceeding Tg then exerts mechanical overload on the board components - e.g. the joints and the vias. Below Tg the thermal expansion of the resin roughly matches copper and glass, above it gets significantly higher. As the reinforcement and copper confine the board along the plane, virtually all volume expansion projects to the thickness and stresses the plated-through holes. Repeated soldering or other exposition to higher temperatures can cause failure of the plating, especially with thicker boards; thick boards therefore require a matrix with a high Tg.

The materials used determine the substrate's dielectric constant. This constant is also dependent on frequency, usually decreasing with frequency. As this constant determines the signal propagation speed, frequency dependence introduces phase distortion in wideband applications; as flat a dielectric constant vs frequency characteristics as is achievable is important here. The impedance of transmission lines decreases with frequency, therefore faster edges of signals reflect more than slower ones.

Dielectric breakdown voltage determines the maximum voltage gradient the material can be subjected to before suffering a breakdown (conduction, or arcing, through the dielectric).

Tracking resistance determines how the material resists high voltage electrical discharges creeping over the board surface.

Loss tangent determines how much of the electromagnetic energy from the signals in the conductors is absorbed in the board material. This factor is important for high frequencies. Low-loss materials are more expensive. Choosing unnecessarily low-loss material is a common engineering error in high-frequency digital design; it increases the cost of the boards without a corresponding benefit. Signal degradation by loss tangent and dielectric constant can be easily assessed by an eye pattern

In telecommunication, an eye pattern, also known as an eye diagram, is an oscilloscope display in which a digital signal from a receiver is repetitively sampled and applied to the vertical input, while the data rate is used to trigger the horiz ...

.

Moisture absorption occurs when the material is exposed to high humidity or water. Both the resin and the reinforcement may absorb water; water also may be soaked by capillary forces through voids in the materials and along the reinforcement. Epoxies of the FR-4 materials are not too susceptible, with absorption of only 0.15%. Teflon has very low absorption of 0.01%. Polyimides and cyanate esters, on the other side, suffer from high water absorption. Absorbed water can lead to significant degradation of key parameters; it impairs tracking resistance, breakdown voltage, and dielectric parameters. Relative dielectric constant of water is about 73, compared to about 4 for common circuit board materials. Absorbed moisture can also vaporize on heating, as during soldering, and cause cracking and delamination, the same effect responsible for "popcorning" damage on wet packaging of electronic parts. Careful baking of the substrates may be required to dry them prior to soldering.

Common substrates

Often encountered materials: * FR-2,phenolic paper

Phenolic paper is a material often used to make printed circuit board substrates (the flat board to which the components and traces are attached). It is a very tough board made of wood fibre and phenolic polymers. It is most commonly brown in c ...

or phenolic cotton paper, paper impregnated with a phenol formaldehyde resin

Phenol formaldehyde resins (PF) or phenolic resins (also infrequently called phenoplasts) are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. Used as the basis for Bakelite, PFs were the first commerc ...

. Common in consumer electronics with single-sided boards. Electrical properties inferior to FR-4. Poor arc resistance. Generally rated to 105 °C.

* FR-4, a woven fiberglass

Fiberglass (American English) or fibreglass ( Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass clo ...

cloth impregnated with an epoxy resin. Low water absorption (up to about 0.15%), good insulation properties, good arc resistance. Very common. Several grades with somewhat different properties are available. Typically rated to 130 °C.

* Aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

, or ''metal core board'' or insulated metal substrate

The role of the substrate in power electronics is to provide the interconnections to form an electric circuit (like a printed circuit board), and to cool the components. Compared to materials and techniques used in lower power microelectronics, ...

(IMS), clad with thermally conductive thin dielectric - used for parts requiring significant cooling - power switches, LEDs. Consists of usually single, sometimes double layer thin circuit board based on e.g. FR-4, laminated on aluminum sheet metal, commonly 0.8, 1, 1.5, 2 or 3 mm thick. The thicker laminates sometimes also come with thicker copper metalization.

* Flexible substrates - can be a standalone copper-clad foil or can be laminated to a thin stiffener, e.g. 50-130 µm

** Kapton or UPILEX

Upilex is a heat-resistant polyimide film that is the product of the polycondensation reaction between biphenyl tetracarboxylic dianhydride ( BPDA) monomers and a diamine. Its properties include dimensional stability, low water absorption, high c ...

, a polyimide foil. Used for flexible printed circuits, in this form common in small form-factor consumer electronics or for flexible interconnects. Resistant to high temperatures.

** Pyralux, a polyimide-fluoropolymer composite foil. Copper layer can delaminate during soldering.

Less-often encountered materials:

* FR-1, like FR-2, typically specified to 105 °C, some grades rated to 130 °C. Room-temperature punchable. Similar to cardboard. Poor moisture resistance. Low arc resistance.

* FR-3, cotton paper impregnated with epoxy. Typically rated to 105 °C.

* FR-5, woven fiberglass and epoxy, high strength at higher temperatures, typically specified to 170 °C.

* FR-6, matte glass and polyester

* G-10, woven glass and epoxy - high insulation resistance, low moisture absorption, very high bond strength. Typically rated to 130 °C.

* G-11, woven glass and epoxy - high resistance to solvents, high flexural strength retention at high temperatures. Typically rated to 170 °C.

* CEM-1, cotton paper and epoxy

* CEM-2, cotton paper and epoxy

* CEM-3, non-woven glass and epoxy

* CEM-4, woven glass and epoxy

* CEM-5, woven glass and polyester

* PTFE, ("Teflon") - expensive, low dielectric loss, for high frequency applications, very low moisture absorption (0.01%), mechanically soft. Difficult to laminate, rarely used in multilayer applications.

* PTFE, ceramic filled - expensive, low dielectric loss, for high frequency applications. Varying ceramics/PTFE ratio allows adjusting dielectric constant and thermal expansion.

* RF-35, fiberglass-reinforced ceramics-filled PTFE. Relatively less expensive, good mechanical properties, good high-frequency properties.

* Alumina, a ceramic. Hard, brittle, very expensive, very high performance, good thermal conductivity.

* Polyimide, a high-temperature polymer. Expensive, high-performance. Higher water absorption (0.4%). Can be used from cryogenic temperatures to over 260 °C.

Copper thickness

Copper thickness of PCBs can be specified directly or as the weight of copper per area (in ounce per square foot) which is easier to measure. Oneounce

The ounce () is any of several different units of mass, weight or volume and is derived almost unchanged from the , an Ancient Roman unit of measurement.

The avoirdupois ounce (exactly ) is avoirdupois pound; this is the United States customa ...

per square foot

The square foot (plural square feet; abbreviated sq. ft, sf, or ft2; also denoted by '2) is an imperial unit and U.S. customary unit (non- SI, non-metric) of area, used mainly in the United States and partially in Canada, the United Kingdom, Bang ...

is 1.344 mils or 34 micrometers thickness. ''Heavy copper'' is a layer exceeding three ounces of copper per ft2, or approximately 0.0042 inches (4.2 mils, 105 μm) thick. Heavy copper layers are used for high current or to help dissipate heat.

On the common FR-4 substrates, 1 oz copper per ft2 (35 µm) is the most common thickness; 2 oz (70 µm) and 0.5 oz (17.5 µm) thickness is often an option. Less common are 12 and 105 µm, 9 µm is sometimes available on some substrates. Flexible substrates typically have thinner metalization. Metal-core boards for high power devices commonly use thicker copper; 35 µm is usual but also 140 and 400 µm can be encountered.

In the USA, copper foil thickness is specified in units of ounce

The ounce () is any of several different units of mass, weight or volume and is derived almost unchanged from the , an Ancient Roman unit of measurement.

The avoirdupois ounce (exactly ) is avoirdupois pound; this is the United States customa ...

s per square foot (oz/ft2), commonly referred to simply as ''ounce''. Common thicknesses are 1/2 oz/ft2 (150 g/m), 1 oz/ft2 (300 g/m), 2 oz/ft2 (600 g/m), and 3 oz/ft2 (900 g/m). These work out to thicknesses of 17.05 μm (0.67 thou

The word ''thou'' is a second-person singular pronoun in English. It is now largely archaic, having been replaced in most contexts by the word '' you'', although it remains in use in parts of Northern England and in Scots (). ''Thou'' is the ...

), 34.1 μm (1.34 thou

The word ''thou'' is a second-person singular pronoun in English. It is now largely archaic, having been replaced in most contexts by the word '' you'', although it remains in use in parts of Northern England and in Scots (). ''Thou'' is the ...

), 68.2 μm (2.68 thou), and 102.3 μm (4.02 thou), respectively. 1/2 oz/ft2 foil is not widely used as a finished copper weight, but is used for outer layers when plating for through holes will increase the finished copper weight Some PCB manufacturers refer to 1 oz/ft2 copper foil as having a thickness of 35 μm (may also be referred to as 35 μ, 35 micron

The micrometre ( international spelling as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American spelling), also commonly known as a micron, is a unit of length in the International System of Un ...

, or 35 mic).

* 1/0 – denotes 1 oz/ft2 copper one side, with no copper on the other side.

* 1/1 – denotes 1 oz/ft2 copper on both sides.

* H/0 or H/H – denotes 0.5 oz/ft2 copper on one or both sides, respectively.

* 2/0 or 2/2 – denotes 2 oz/ft2 copper on one or both sides, respectively.

Construction

Design

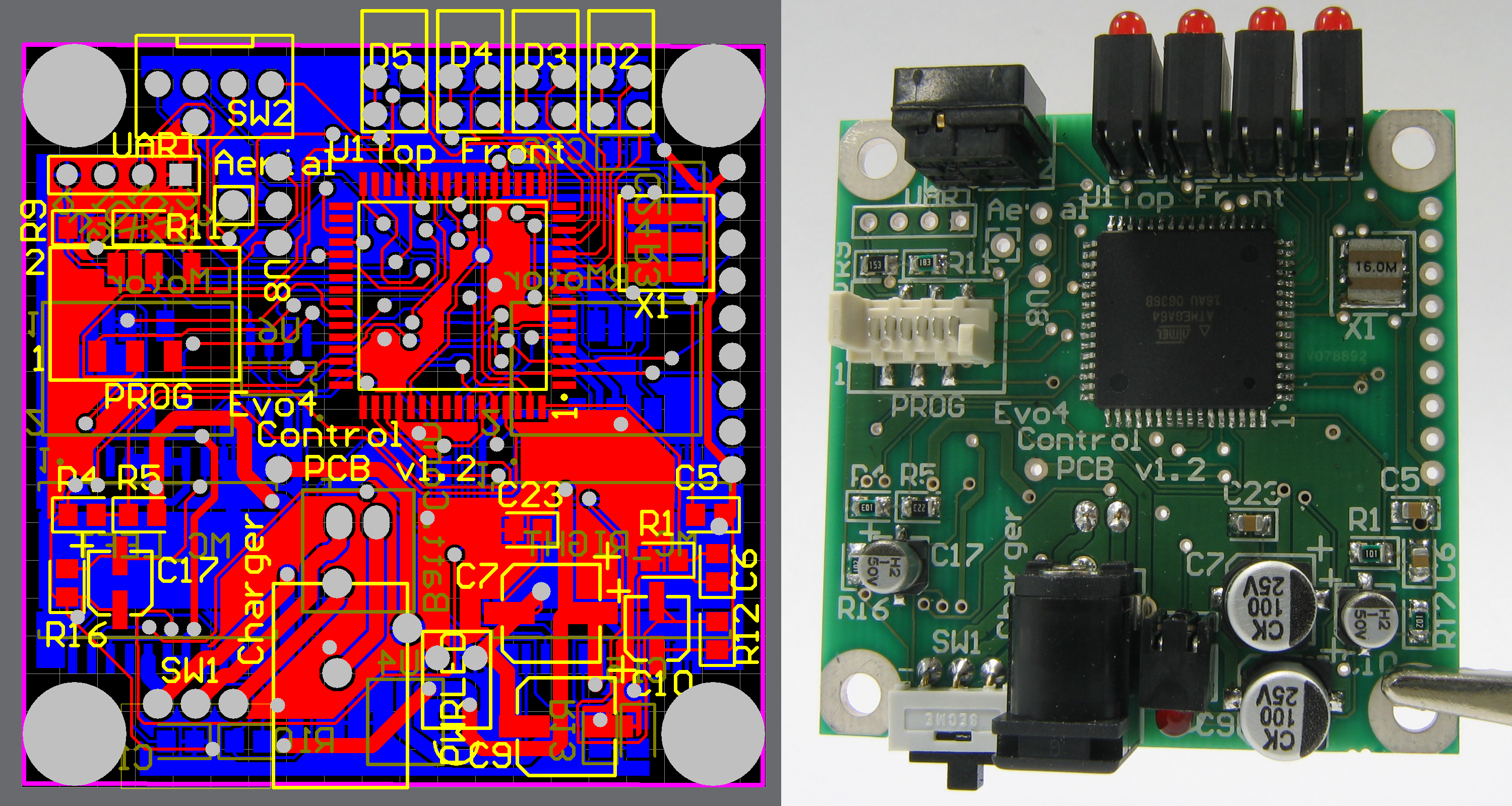

Manufacturing starts from the fabrication data generated by computer aided design, and component information. The fabrication data is read into the CAM (Computer Aided Manufacturing) software. CAM performs the following functions:

# Input of the fabrication data.

# Verification of the data

# Compensation for deviations in the manufacturing processes (e.g. scaling to compensate for distortions during lamination)

# Panelization

# Output of the digital tools (copper patterns, drill files, inspection, and others)

Initially PCBs were designed manually by creating a

Manufacturing starts from the fabrication data generated by computer aided design, and component information. The fabrication data is read into the CAM (Computer Aided Manufacturing) software. CAM performs the following functions:

# Input of the fabrication data.

# Verification of the data

# Compensation for deviations in the manufacturing processes (e.g. scaling to compensate for distortions during lamination)

# Panelization

# Output of the digital tools (copper patterns, drill files, inspection, and others)

Initially PCBs were designed manually by creating a photomask

A photomask is an opaque plate with holes or transparencies that allow light to shine through in a defined pattern. They are commonly used in photolithography and the production of integrated circuits (ICs or "chips") in particular. Masks are used ...

on a clear mylar

BoPET (biaxially-oriented polyethylene terephthalate) is a polyester film made from stretched polyethylene terephthalate (PET) and is used for its high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and a ...

sheet, usually at two or four times the true size. Starting from the schematic diagram the component pin pads were laid out on the mylar and then traces were routed to connect the pads. Rub-on dry transfer

Dry transfers (also called rub-ons or rubdowns) are decals that can be applied without the use of water or other solvent. The decal itself is on a backing material such as paper or plastic sheeting much like a transparency. The dry transfer is ...

s of common component footprints increased efficiency. Traces were made with self-adhesive tape. Pre-printed non-reproducing grids on the mylar assisted in layout. The finished photomask was photolithographically reproduced onto a photoresist coating on the blank copper-clad boards.

Modern PCBs are designed with dedicated layout software, generally in the following steps:

# Schematic capture

Schematic capture or schematic entry is a step in the design cycle of electronic design automation (EDA) at which the electronic diagram, or electronic schematic of the designed electronic circuit is created by a designer. This is done interact ...

through an electronic design automation (''EDA'') tool.

# Card dimensions and template are decided based on required circuitry and enclosure of the PCB.

# The positions of the components and heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, th ...

s are determined.

# Layer stack of the PCB is decided, with one to tens of layers depending on complexity. Ground and power plane

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich struc ...

s are decided. A power plane is the counterpart to a ground plane and behaves as an AC signal ground while providing DC power to the circuits mounted on the PCB. Signal interconnections are traced on signal planes. Signal planes can be on the outer as well as inner layers. For optimal EMI

EMI Group Limited (originally an initialism for Electric and Musical Industries, also referred to as EMI Records Ltd. or simply EMI) was a British Transnational corporation, transnational Conglomerate (company), conglomerate founded in March 1 ...

performance high frequency signals are routed in internal layers between power or ground planes.

# Line impedance is determined using dielectric layer thickness, routing copper thickness and trace-width. Trace separation is also taken into account in case of differential signals. Microstrip, stripline or dual stripline can be used to route signals.

# Components are placed. Thermal considerations and geometry are taken into account. Vias and lands are marked.

# Signal trace In electronics, a signal trace or circuit trace on a printed circuit board (PCB) or integrated circuit (IC) is the equivalent of a wire for conducting signals. Each trace consists of a flat, narrow part of the copper foil that remains after etching ...

s are routed. Electronic design automation tools usually create clearances and connections in power and ground planes automatically.

# Fabrication data consists of a set of Gerber file

The Gerber format is an open ASCII vector format for printed circuit board (PCB) designs. It is the de facto standard used by PCB industry software to describe the printed circuit board images: copper layers, solder mask, legend, drill data, et ...

s, a drill file, and a pick-and-place file.

Panelization

Several small printed circuit boards can be grouped together for processing as a panel. A panel consisting of a design duplicated ''n''-times is also called an ''n''-panel, whereas a ''multi-panel'' combines several different designs onto a single panel. The outer tooling strip often includes tooling holes, a set of panel fiducials, a test coupon, and may includehatched copper pour

Hatch or The Hatch may refer to:

Common meanings

Biology

*Hatch, to emerge from an egg

*Hatch(ing), the process of egg incubation

Portals

*Hatch, a sealed or secure door of a ship, submarine, aircraft, spacecraft, or automobile

*Hatch, a slui ...

or similar patterns for even copper distribution over the whole panel in order to avoid bending. The assemblers often mount components on panels rather than single PCBs because this is efficient. Panelization may also be necessary for boards with components placed near an edge of the board because otherwise the board could not be mounted during assembly. Most assembly shops require a free area of at least 10 mm around the board.

The panel is eventually broken into individual PCBs along perforations or grooves in the panel through milling or cutting. For milled panels a common distance between the individual boards is 2–3 mm. Today depaneling is often done by lasers which cut the board with no contact. Laser depaneling reduces stress on the fragile circuits, improving the yield of defect-free units.

Copper patterning

The first step is to replicate the pattern in the fabricator's CAM system on a protective mask on the copper foil PCB layers. Subsequent etching removes the unwanted copper unprotected by the mask. (Alternatively, a conductive ink can be ink-jetted on a blank (non-conductive) board. This technique is also used in the manufacture ofhybrid circuit

A hybrid integrated circuit (HIC), hybrid microcircuit, hybrid circuit or simply hybrid is a miniaturized electronic circuit constructed of individual devices, such as semiconductor devices (e.g. transistors, diodes or monolithic ICs) and ...

s.)

# ''Silk screen printing

Silk is a natural protein fiber, some forms of which can be woven into textiles. The protein fiber of silk is composed mainly of fibroin and is produced by certain insect larvae to form cocoons. The best-known silk is obtained from the coc ...

'' uses etch-resistant inks to create the protective mask.

# ''Photoengraving

Photoengraving is a process that uses a light-sensitive photoresist applied to the surface to be engraved to create a mask that protects some areas during a subsequent operation which etches, dissolves, or otherwise removes some or all of the mat ...

'' uses a photomask and developer to selectively remove a UV-sensitive photoresist coating and thus create a photoresist mask that will protect the copper below it. Direct imaging techniques are sometimes used for high-resolution requirements. Experiments have been made with thermal resist. A laser may be used instead of a photomask. This is known as maskless lithography

Maskless lithography (MPL) is a photomask-less photolithography-like technology used to project or focal-spot write the image pattern onto a chemical resist-coated substrate (e.g. wafer) by means of UV radiation or electron beam.

In microlithograp ...

or direct imaging.

# '' PCB milling'' uses a two or three-axis mechanical milling system to mill away the copper foil from the substrate. A PCB milling machine (referred to as a 'PCB Prototyper') operates in a similar way to a plotter, receiving commands from the host software that control the position of the milling head in the x, y, and (if relevant) z axis.

# ''Laser resist ablation'' Spray black paint onto copper clad laminate, place into CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a p ...

laser plotter. The laser raster-scans the PCB and ablates (vaporizes) the paint where no resist is wanted. (Note: laser copper ablation is rarely used and is considered experimental.)

# ''Laser etching'' The copper may be removed directly by a CNC laser. Like PCB milling above this is used mainly for prototyping.

# ''EDM

EDM or E-DM may refer to:

Music

* Electronic dance music

* Early Day Miners, American band

Science and technology

* Electric dipole moment

* Electrical discharge machining

* Electronic distance measurement

*Entry, Descent, and landing demonstrat ...

etching'' uses an electrical discharge

An electric discharge is the release and transmission of electricity in an applied electric field through a medium such as a gas (ie., an outgoing flow of electric current through a non-metal medium).American Geophysical Union, National Research ...

to remove a metal from a substrate submerged into a dielectric fluid

The method chosen depends on the number of boards to be produced and the required resolution.

; Large volume:

* Silk screen printing – Used for PCBs with bigger features

* Photoengraving – Used when finer features are required

; Small volume:

* Print onto transparent film and use as photo mask along with photo-sensitized boards, then etch. (Alternatively, use a film photoplotter)

* Laser resist ablation

* PCB milling

* Laser etching

; Hobbyist:

* Laser-printed resist: Laser-print onto toner transfer paper, heat-transfer with an iron or modified laminator onto bare laminate, soak in water bath, touch up with a marker, then etch.

* Vinyl film and resist, non-washable marker, some other methods. Labor-intensive, only suitable for single boards.

Etching

PCB copper electroplating line in the process of pattern plating copper PCBs in process of having copper pattern plated (note the blue dry film resist The process by which copper traces are applied to the surface is known as ''etching'' after the subtractive method of the process, though there are also additive and semi-additive methods.

Subtractive methods remove copper from an entirely copper-coated board to leave only the desired copper pattern. The simplest method, used for small-scale production and often by hobbyists, is immersion etching, in which the board is submerged in etching solution such as ferric chloride. Compared with methods used for mass production, the etching time is long. Heat and agitation can be applied to the bath to speed the etching rate. In bubble etching, air is passed through the etchant bath to agitate the solution and speed up etching. Splash etching uses a motor-driven paddle to splash boards with etchant; the process has become commercially obsolete since it is not as fast as spray etching. In spray etching, the etchant solution is distributed over the boards by nozzles, and recirculated by pumps. Adjustment of the nozzle pattern, flow rate, temperature, and etchant composition gives predictable control of etching rates and high production rates. As more copper is consumed from the boards, the etchant becomes saturated and less effective; different etchants have different capacities for copper, with some as high as 150 grams of copper per litre of solution. In commercial use, etchants can be regenerated to restore their activity, and the dissolved copper recovered and sold. Small-scale etching requires attention to disposal of used etchant, which is corrosive and toxic due to its metal content. The etchant removes copper on all surfaces not protected by the resist. "Undercut" occurs when etchant attacks the thin edge of copper under the resist; this can reduce conductor widths and cause open-circuits. Careful control of etch time is required to prevent undercut. Where metallic plating is used as a resist, it can "overhang" which can cause short-circuits between adjacent traces when closely spaced. Overhang can be removed by wire-brushing the board after etching.

In additive methods the pattern is

The process by which copper traces are applied to the surface is known as ''etching'' after the subtractive method of the process, though there are also additive and semi-additive methods.

Subtractive methods remove copper from an entirely copper-coated board to leave only the desired copper pattern. The simplest method, used for small-scale production and often by hobbyists, is immersion etching, in which the board is submerged in etching solution such as ferric chloride. Compared with methods used for mass production, the etching time is long. Heat and agitation can be applied to the bath to speed the etching rate. In bubble etching, air is passed through the etchant bath to agitate the solution and speed up etching. Splash etching uses a motor-driven paddle to splash boards with etchant; the process has become commercially obsolete since it is not as fast as spray etching. In spray etching, the etchant solution is distributed over the boards by nozzles, and recirculated by pumps. Adjustment of the nozzle pattern, flow rate, temperature, and etchant composition gives predictable control of etching rates and high production rates. As more copper is consumed from the boards, the etchant becomes saturated and less effective; different etchants have different capacities for copper, with some as high as 150 grams of copper per litre of solution. In commercial use, etchants can be regenerated to restore their activity, and the dissolved copper recovered and sold. Small-scale etching requires attention to disposal of used etchant, which is corrosive and toxic due to its metal content. The etchant removes copper on all surfaces not protected by the resist. "Undercut" occurs when etchant attacks the thin edge of copper under the resist; this can reduce conductor widths and cause open-circuits. Careful control of etch time is required to prevent undercut. Where metallic plating is used as a resist, it can "overhang" which can cause short-circuits between adjacent traces when closely spaced. Overhang can be removed by wire-brushing the board after etching.

In additive methods the pattern is electroplated

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be ...

onto a bare substrate using a complex process. The advantage of the additive method is that less material is needed and less waste is produced. In the full additive process the bare laminate is covered with a photosensitive film which is imaged (exposed to light through a mask and then developed which removes the unexposed film). The exposed areas are sensitized in a chemical bath, usually containing palladium and similar to that used for through hole plating which makes the exposed area capable of bonding metal ions. The laminate is then plated with copper in the sensitized areas. When the mask is stripped, the PCB is finished.