|

Palmgren-Miner Linear Damage Hypothesis

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocations

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number and a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

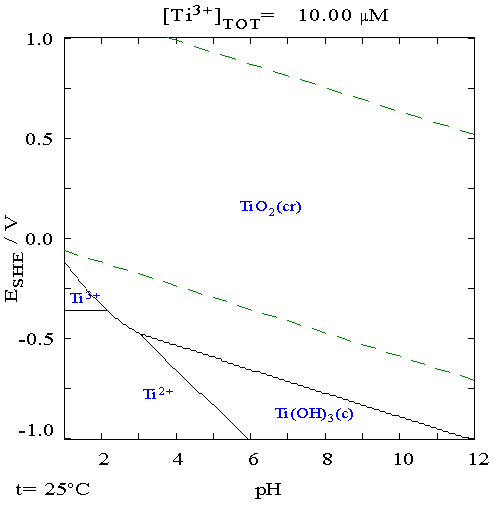

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide, is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and catalysts; and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fretting

Fretting refers to wear and sometimes corrosion damage of loaded surfaces in contact while they encounter small oscillatory movements tangential to the surface. Fretting is caused by adhesion of contact surface asperities, which are subsequently broken again by the small movement. This breaking causes wear debris to be formed. If the debris and/or surface subsequently undergo chemical reaction, i.e., mainly oxidation, the mechanism is termed fretting corrosion. Fretting degrades the surface, leading to increased surface roughness and micropits, which reduces the fatigue strength of the components. The amplitude of the relative sliding motion is often in the order of micrometers to millimeters, but can be as low as 3 nanometers. Typically fretting is encountered in shrink fits, bearing seats, bolted parts, splines, and dovetail connections. Materials Steel Fretting damage in steel can be identified by the presence of a pitted surface and fine 'red' iron oxide dust resembl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residual Stress

In materials science and solid mechanics, residual stresses are Stress (physics), stresses that remain in a solid material after the original cause of the stresses has been removed. Residual stress may be desirable or undesirable. For example, laser peening imparts deep beneficial compressive residual stresses into metal components such as turbine engine fan blades, and it is used in toughened glass to allow for large, thin, crack- and scratch-resistant glass displays on smartphones. However, unintended residual stress in a designed structure may cause it to Catastrophic failure, fail prematurely. Residual stresses can result from a variety of mechanisms including inelastic (Plasticity (physics), plastic) Deformation (engineering), deformations, temperature gradients (during thermal cycle) or structural changes (phase transformation). Heat from welding may cause localized expansion, which is taken up during welding by either the molten metal or the placement of parts being welde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemically Inert

In chemistry, the term chemically inert is used to describe a substance that is not chemically reactive. From a thermodynamic perspective, a substance is inert, or nonlabile, if it is thermodynamically unstable (positive standard Gibbs free energy of formation) yet decomposes at a slow, or negligible rate. Most of the noble gases, which appear in the last column of the periodic table, are classified as inert (or unreactive). These elements are stable in their naturally occurring form (gaseous form) and they are called inert gases. Noble gas The noble gases (helium, neon, argon, krypton, xenon and radon) were previously known as 'inert gases' because of their perceived lack of participation in any chemical reactions. The reason for this is that their outermost electron shells (valence shells) are completely filled, so that they have little tendency to gain or lose electrons. They are said to acquire a noble gas configuration, or a full electron configuration. It is now ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxidizing

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a decrease in the oxidation state. There are two classes of redox reactions: * ''Electron-transfer'' – Only one (usually) electron flows from the reducing agent to the oxidant. This type of redox reaction is often discussed in terms of redox couples and electrode potentials. * ''Atom transfer'' – An atom transfers from one substrate to another. For example, in the rusting of iron, the oxidation state of iron atoms increases as the iron converts to an oxide, and simultaneously the oxidation state of oxygen decreases as it accepts electrons released by the iron. Although oxidation reactions are commonly associated with the formation of oxides, other chemical species can serve the same function. In hydrogenation, C=C (and other) bonds ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

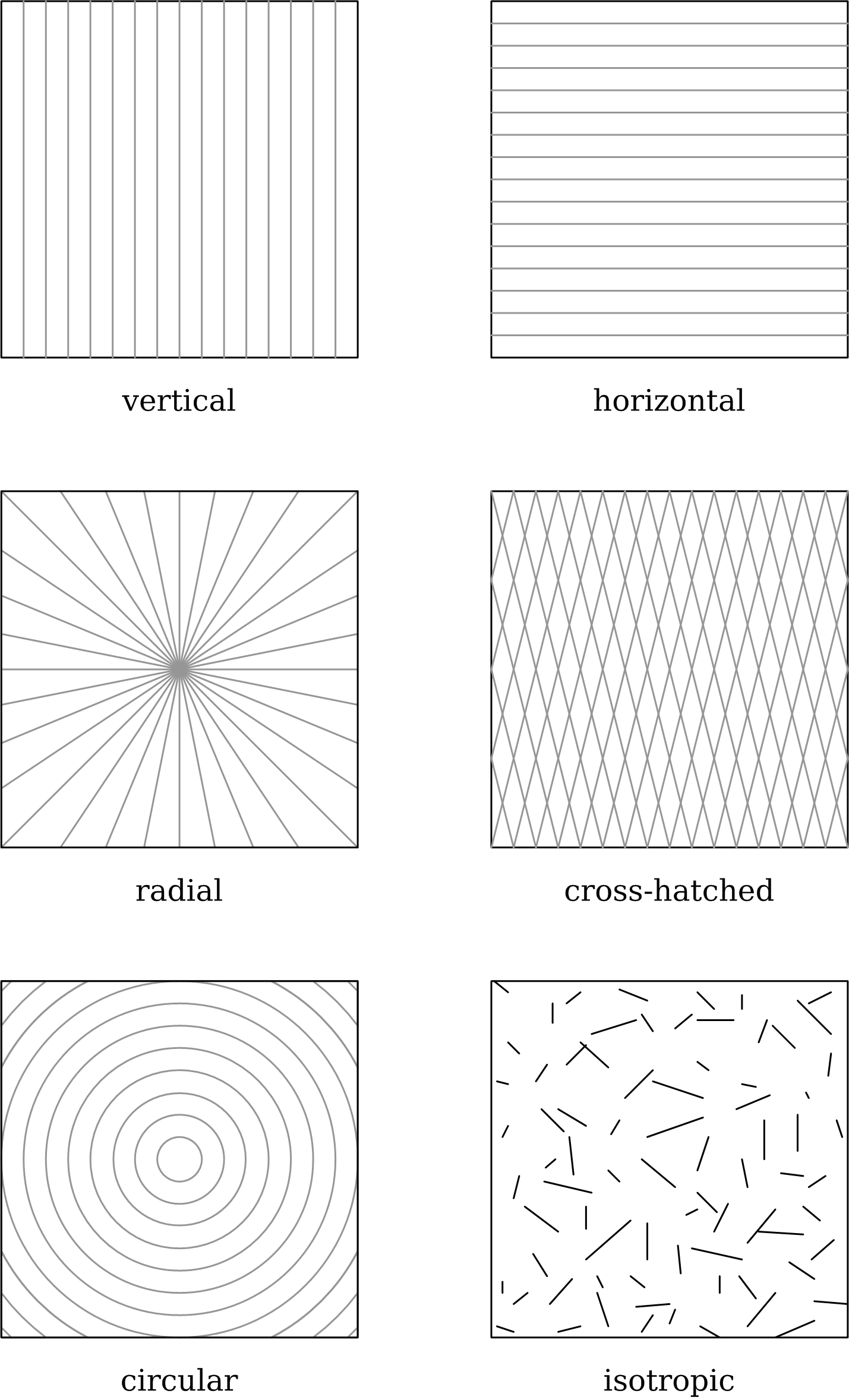

Surface Finish

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), polishing, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Temperature

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measured with a thermometer. Thermometers are calibrated in various temperature scales that historically have relied on various reference points and thermometric substances for definition. The most common scales are the Celsius scale with the unit symbol °C (formerly called ''centigrade''), the Fahrenheit scale (°F), and the Kelvin scale (K), the latter being used predominantly for scientific purposes. The kelvin is one of the seven base units in the International System of Units (SI). Absolute zero, i.e., zero kelvin or −273.15 °C, is the lowest point in the thermodynamic temperature scale. Experimentally, it can be approached very closely but not actually reached, as recognized in the third law of thermodynamics. It would be impossible to extract energy as heat from a body at that temperature. Temperature is important in all fields of natur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stochastic

Stochastic (, ) refers to the property of being well described by a random probability distribution. Although stochasticity and randomness are distinct in that the former refers to a modeling approach and the latter refers to phenomena themselves, these two terms are often used synonymously. Furthermore, in probability theory, the formal concept of a ''stochastic process'' is also referred to as a ''random process''. Stochasticity is used in many different fields, including the natural sciences such as biology, chemistry, ecology, neuroscience, and physics, as well as technology and engineering fields such as image processing, signal processing, information theory, computer science, cryptography, and telecommunications. It is also used in finance, due to seemingly random changes in financial markets as well as in medicine, linguistics, music, media, colour theory, botany, manufacturing, and geomorphology. Etymology The word ''stochastic'' in English was originally used as a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

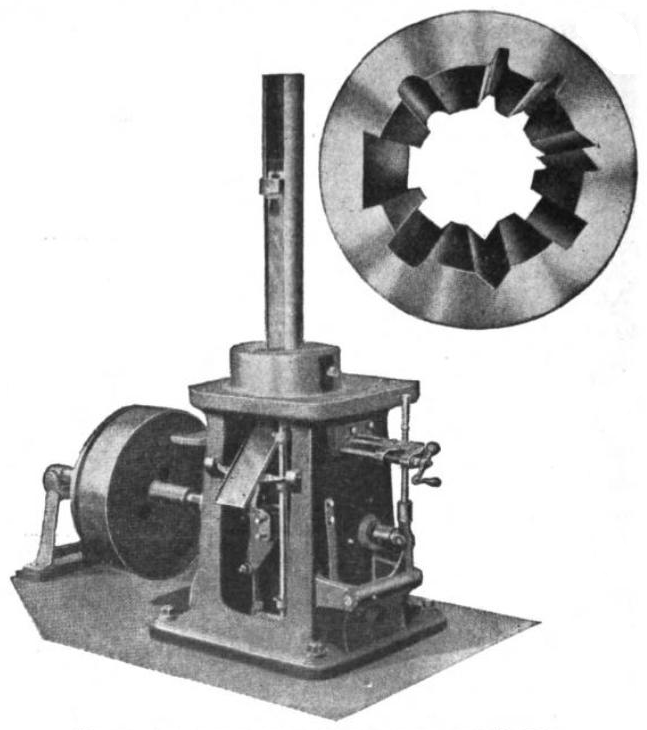

Key (engineering)

In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint. A keyed joint may allow relative axial movement between the parts. Commonly keyed components include gears, pulleys, couplings, and washers. Types There are five main types of keys: ''sunk'', ''saddle'', ''tangent'', ''round'', and ''spline''. Sunk key Types of sunk keys: ''rectangular'', ''square'', ''parallel sunk'', ''gib-head'', ''feather'', and ''Woodruff''. Parallel keys ''Parallel keys'' are the most widely used. They have a square or rectangular cross-section. Square keys are used for smaller shafts and rectangular faced keys are used for shaft diameters over or when the wall thickness o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |