|

Differential Hardening

Differential heat treatment (also called selective heat treatment or local heat treatment) is a technique used during heat treating to harden or soften certain areas of a steel object, creating a difference in hardness between these areas. There are many techniques for creating a difference in properties, but most can be defined as either ''differential hardening'' or ''differential tempering''. These were common heat treating techniques used historically in Europe and Asia, with possibly the most widely known example being from Japanese swordsmithing. Some modern varieties were developed in the twentieth century as metallurgical knowledge and technology rapidly increased. Differential hardening consists of either two methods. It can involve heating the metal evenly to a red-hot temperature and then cooling it at different rates, turning part of the object into very hard martensite while the rest cools slower and becomes softer pearlite. It may also consist of heating only a part of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Metallic materials consist of a microstructure of small crystals called "gra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jian

The ''jian'' (pronunciation (劍), English approximation: ) is a double-edged straight sword used during the last 2,500 years in China. The first Chinese sources that mention the ''jian'' date to the 7th century BCE, during the Spring and Autumn period; one of the earliest specimens being the Sword of Goujian. Historical one-handed versions have blades varying from in length. The weight of an average sword of blade-length would be in a range of approximately 700 to 900 grams (1.5 to 2 pounds). There are also larger two-handed versions used for training by many styles of Chinese martial arts. Professional ''jian'' practitioners are referred to as ''jianke'' ( or "swordsmen"; a term dating from the Han dynasty). In Chinese folklore, it is known as "The Gentleman of Weapons" and is considered one of the four major weapons, along with the ''gun'' (staff), '' qiang'' (spear), and the ''dao'' (sabre). These swords are also sometimes referred to as ''taijijian'' or "tai ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rockwell Hardness

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different loads or indenters. The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale. When testing metals, indentation hardness correlates linearly with tensile strength. History The differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book ''Die Kegelprobe'' (crudely, "the cone test"). The differential-depth method subtracted out the errors associated with the mechanical imperfections of the system, such as backlash and surface imperfections. The Brinell hardness test, invented in Sweden, was developed earlier – in 1900 – but it was slow, not us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure’s influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can tak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

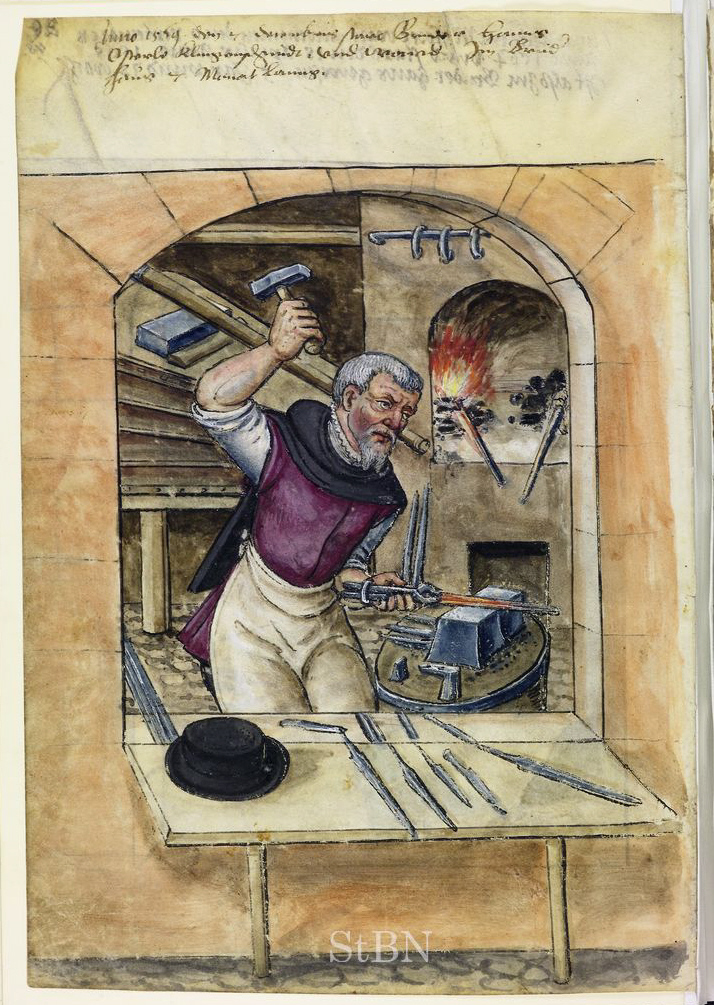

Bladesmithing

Bladesmithing is the art of making knives, swords, daggers and other blades using a forge, hammer, anvil, and other smithing tools. Bladesmiths employ a variety of metalworking techniques similar to those used by blacksmiths, as well as woodworking for knife and sword handles, and often leatherworking for sheaths. Bladesmithing is an art that is thousands of years old and found in cultures as diverse as China, Japan, India, Germany, Korea, the Middle East, Spain and the British Isles. As with any art shrouded in history, there are myths and misconceptions about the process. While traditionally bladesmithing referred to the manufacture of any blade by any means, the majority of contemporary craftsmen referred to as bladesmiths are those who primarily manufacture blades by means of using a forge to shape the blade as opposed to knifemakers who form blades by use of the stock removal method, although there is some overlap between both crafts. Related trades Many blade smiths were kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Katana Cross Section Diagram Showing Different Zones Of Hardness

A is a Japanese sword characterized by a curved, single-edged blade with a circular or squared guard and long grip to accommodate two hands. Developed later than the ''tachi'', it was used by samurai in feudal Japan and worn with the edge facing upward. Since the Muromachi period, many old ''tachi'' were cut from the root and shortened, and the blade at the root was crushed and converted into ''katana''. The specific term for ''katana'' in Japan is ''uchigatana'' (打刀) and the term ''katana'' (刀) often refers to single-edged swords from around the world. Etymology and loanwords The word ''katana'' first appears in Japanese in the '' Nihon Shoki'' of 720. The term is a compound of ''kata'' ("one side, one-sided") + ''na'' ("blade"), in contrast to the double-sided '' tsurugi''. See more at the Wiktionary entry. The ''katana'' belongs to the ''nihontō'' family of swords, and is distinguished by a blade length (''nagasa'') of more than 2 ''shaku'', approximately . ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Induction Hardening

Induction hardening is a type of surface hardening in which a metal part is induction-heated and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole. Process Induction heating is a non contact heating process which uses the principle of electromagnetic induction to produce heat inside the surface layer of a work-piece. By placing a conductive material into a strong alternating magnetic field, electric current can be made to flow in the material thereby creating heat due to the I2R losses in the material. In magnetic materials, further heat is generated below the curie point due to hysteresis losses. The current generated flows predominantly in the surface layer, the depth of this layer being dictated by the frequency of the alternating field, the surface power density, the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Induction Heating

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an induction coil that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide. An induction heater consists of an electromagnet and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor called eddy currents. The eddy currents flow through the resistance of the material, and heat it by Joule heating. In ferromagnetic and ferrimagnetic materials, such as iron, heat also is generated by magnetic hysteresis losses. The frequency of the electric current used for induction heating depends on the object size, material type, coupling (between the work coil and t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxy-acetylene Torch

Principle of burn cutting Oxy-fuel welding (commonly called oxyacetylene welding, oxy welding, or gas welding in the United States) and oxy-fuel cutting are processes that use fuel gases (or liquid fuels such as gasoline or petrol, diesel, bio diesel, kerosene, etc) and oxygen to weld or cut metals. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903. Pure oxygen, instead of air, is used to increase the flame temperature to allow localized melting of the workpiece material (e.g. steel) in a room environment. A common propane/air flame burns at about , a propane/oxygen flame burns at about , an oxyhydrogen flame burns at and an acetylene/oxygen flame burns at about . During the early 20th century, before the development and availability of coated arc welding electrodes in the late 1920s that were capable of making sound welds in steel, oxy-acetylene welding was the only process capable of making welds of excepti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Han Dynasty

The Han dynasty (, ; ) was an imperial dynasty of China (202 BC – 9 AD, 25–220 AD), established by Liu Bang (Emperor Gao) and ruled by the House of Liu. The dynasty was preceded by the short-lived Qin dynasty (221–207 BC) and a warring interregnum known as the ChuHan contention (206–202 BC), and it was succeeded by the Three Kingdoms period (220–280 AD). The dynasty was briefly interrupted by the Xin dynasty (9–23 AD) established by usurping regent Wang Mang, and is thus separated into two periods—the Western Han (202 BC – 9 AD) and the Eastern Han (25–220 AD). Spanning over four centuries, the Han dynasty is considered a golden age in Chinese history, and it has influenced the identity of the Chinese civilization ever since. Modern China's majority ethnic group refers to themselves as the "Han people", the Sinitic language is known as "Han language", and the written Chinese is referred to as "Han characters". The emperor was at the pinnacle of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Warring States

The Warring States period () was an era in ancient Chinese history characterized by warfare, as well as bureaucratic and military reforms and consolidation. It followed the Spring and Autumn period and concluded with the Qin wars of conquest that saw the annexation of all other contender states, which ultimately led to the Qin state's victory in 221 BC as the first unified Chinese empire, known as the Qin dynasty. Although different scholars point toward different dates ranging from 481 BC to 403 BC as the true beginning of the Warring States, Sima Qian's choice of 475 BC is the most often cited. The Warring States era also overlaps with the second half of the Eastern Zhou dynasty, though the Chinese sovereign, known as the king of Zhou, ruled merely as a figurehead and served as a backdrop against the machinations of the warring states. The "Warring States Period" derives its name from the ''Record of the Warring States'', a work compiled early in the Han dynasty. Geograph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nepal

Nepal (; ne, नेपाल ), formerly the Federal Democratic Republic of Nepal ( ne, सङ्घीय लोकतान्त्रिक गणतन्त्र नेपाल ), is a landlocked country in South Asia. It is mainly situated in the Himalayas, but also includes parts of the Indo-Gangetic Plain, bordering the Tibet Autonomous Region of China to the north, and India in the south, east, and west, while it is narrowly separated from Bangladesh by the Siliguri Corridor, and from Bhutan by the Indian state of Sikkim. Nepal has a diverse geography, including fertile plains, subalpine forested hills, and eight of the world's ten tallest mountains, including Mount Everest, the highest point on Earth. Nepal is a multi-ethnic, multi-lingual, multi-religious and multi-cultural state, with Nepali as the official language. Kathmandu is the nation's capital and the largest city. The name "Nepal" is first recorded in texts from the Vedic period of the India ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |