bladesmithing on:

[Wikipedia]

[Google]

[Amazon]

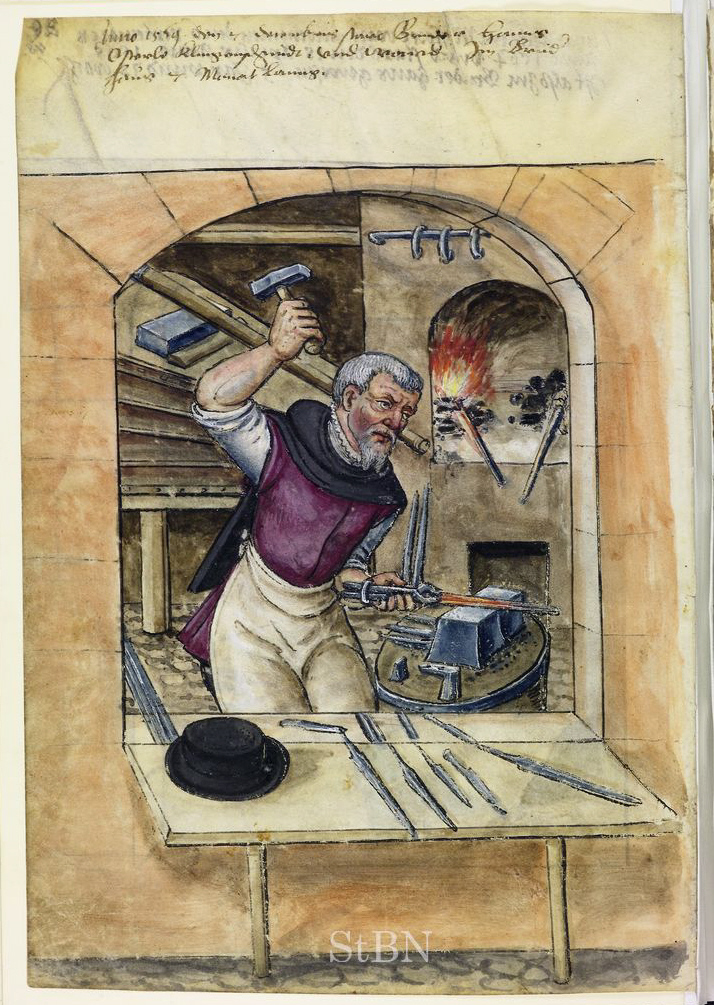

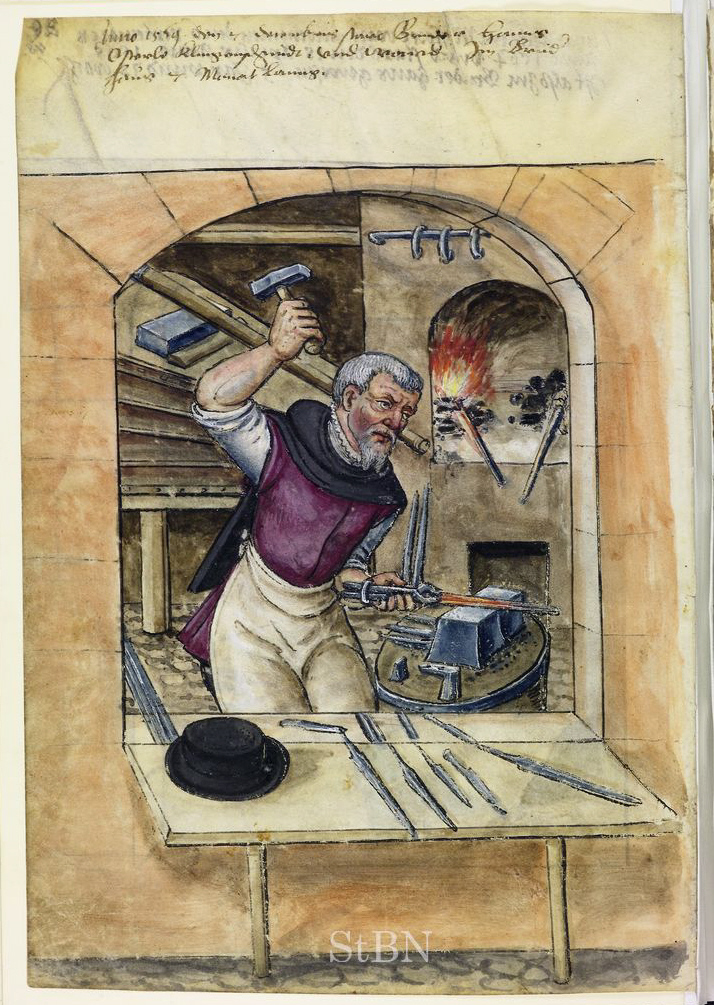

Bladesmithing is the art of making

Bladesmithing is the art of making

The Germanic

The Germanic

Legendary Swords' Sharpness, Strength From Nanotubes, Study Says

The American Bladesmith Society

{{Authority control Blade weapons Metalworking occupations

Bladesmithing is the art of making

Bladesmithing is the art of making knives

A knife ( : knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced ...

, sword

A sword is an edged, bladed weapon intended for manual cutting or thrusting. Its blade, longer than a knife or dagger, is attached to a hilt and can be straight or curved. A thrusting sword tends to have a straighter blade with a pointed ti ...

s, daggers

A dagger is a fighting knife with a very sharp point and usually two sharp edges, typically designed or capable of being used as a thrusting or stabbing weapon.State v. Martin, 633 S.W.2d 80 (Mo. 1982): This is the dictionary or popular-use def ...

and other blade

A blade is the portion of a tool, weapon, or machine with an edge that is designed to puncture, chop, slice or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are to be used on. Historic ...

s using a forge

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to th ...

, hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as w ...

, anvil

An anvil is a metalworking tool consisting of a large block of metal (usually forged or cast steel), with a flattened top surface, upon which another object is struck (or "worked").

Anvils are as massive as practical, because the higher th ...

, and other smithing tools. Bladesmiths employ a variety of metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale ...

techniques similar to those used by blacksmith

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from #Other metals, other metals, by forging the metal, using tools to hammer, bend, and cut (cf. tinsmith). Blacksmiths produce objects such ...

s, as well as woodworking

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, woodworking joints, joinery, carpentry, and woodturning.

History

Along with Rock (geology), stone, clay and animal parts, ...

for knife and sword handles, and often leatherworking

Leather crafting or simply leathercraft is the practice of making leather into craft objects or works of art, using shaping techniques, coloring techniques or both.

Techniques

Dyeing

The application of pigments carried by solvents or water in ...

for sheaths. Bladesmithing is an art that is thousands of years old and found in cultures as diverse as China, Japan, India, Germany, Korea, the Middle East, Spain and the British Isles. As with any art shrouded in history, there are myths and misconceptions about the process. While traditionally bladesmithing referred to the manufacture of any blade by any means, the majority of contemporary craftsmen referred to as bladesmiths are those who primarily manufacture blades by means of using a forge to shape the blade as opposed to knifemakers who form blades by use of the stock removal Stock removal is the process of removing material (stock) from a workpiece. Stock removal processes include:Degarmo, p. viii.

*Machining

* Milling

*Turning

*Drilling

*Grinding

* Filing

*Broaching

* Shaping

* Planing

*Sawing

Stock removal processes ...

method, although there is some overlap between both crafts.

Related trades

Many blade smiths were known by other titles according to the kind of blade that they produced: * A swordsmith's specialty is making swords. * Aknifemaker

Knife making is the process of manufacturing a knife by any one or a combination of processes: stock removal, forging to shape, welded lamination or investment cast. Typical metals used come from the carbon steel, tool, or stainless steel fami ...

makes knives

A knife ( : knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced ...

and other cutlery.

* A scythesmith is a smith who makes scythe

A scythe ( ) is an agricultural hand tool for mowing grass or harvesting crops. It is historically used to cut down or reap edible grains, before the process of threshing. The scythe has been largely replaced by horse-drawn and then tractor m ...

s.

Historic bladesmithing

Historically speaking, bladesmithing is an art that has survived and thrived over thousands of years. Many different parts of the world have different styles of bladesmithing, some more well-known than others.Egyptian

Ancient Egyptians referred to iron as "copper from the heavens" because their lack ofsmelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a ch ...

technology limited their accessible iron supplies to what little native

Native may refer to:

People

* Jus soli, citizenship by right of birth

* Indigenous peoples, peoples with a set of specific rights based on their historical ties to a particular territory

** Native Americans (disambiguation)

In arts and entert ...

iron they could recover from meteorite

A meteorite is a solid piece of debris from an object, such as a comet, asteroid, or meteoroid, that originates in outer space and survives its passage through the atmosphere to reach the surface of a planet or Natural satellite, moon. When the ...

s. Despite iron's rarity, they gained enough familiarity with ironworking techniques to have used wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a ...

in the manufacture of swords and blades as early as 3000 BC. They exported this technique to Assyria, Babylon and Greece through trade and as they conquered other lands and were conquered themselves.

Celtic

TheProto-Celtic

Proto-Celtic, or Common Celtic, is the ancestral proto-language of all known Celtic languages, and a descendant of Proto-Indo-European. It is not attested in writing but has been partly Linguistic reconstruction, reconstructed through the compar ...

Hallstatt culture

The Hallstatt culture was the predominant Western Europe, Western and Central European Archaeological culture, culture of Late Bronze Age Europe, Bronze Age (Hallstatt A, Hallstatt B) from the 12th to 8th centuries BC and Early Iron Age Europe ...

(8th century BC) were among the earliest users of iron swords. During the Hallstatt period, they made swords both in bronze as well as iron with rounded tips. Toward the end of the Hallstatt period, around 600-500BC, these swords were replaced with short daggers. The La Tene culture reintroduced the sword, which were very different from the traditional shape and construction of the Bronze Age and early Iron Age, characterized by a more pointed tip.

Chinese

Traditional Chinese blades (''jian

The ''jian'' (pronunciation (劍), English approximation: ) is a double-edged straight sword used during the last 2,500 years in China. The first Chinese sources that mention the ''jian'' date to the 7th century BCE, during the Spring and ...

s'') are usually of ''sanmei'' (three plate) construction, which involved sandwiching a core of hard steel between two plates of softer steel. The central plate protrudes slightly from its surrounding pieces, allowing for a sharp edge, while the softer spine protects the brittle core. Some blades had ''wumei'' or five plate construction, with two more soft plates being used at the central ridge. Bronze ''jian'' were often made in a somewhat similar manner: in this case an alloy with a high copper content would be used to make a resilient core and spine, while the edge would be made from a high-tin-content alloy for sharpness and welded onto the rest of the blade.

The swordsmiths of China are often credited with the forging technology that was carried to Korea and Japan, allowing swordsmiths in those places to create such weapons as the ''katana''. This technology included folding, inserting alloys, and differential hardening of the edge, which historically has been the most common technique around the world. While the Japanese would be more influenced by the Chinese ''dāo'' (single-edged swords of various forms), the early Japanese swords known as ''ken'' are often based on the ''jian''. One-sided ''jians'' from the Tang dynasty provided the basis for various Japanese forging styles and techniques. The Korean version of the ''jian'' is known as the ''geom'' or ''gum'', and these swords often preserve features found in Ming-era ''jian'', such as openwork pommels and sharply angled tips.

Korean

Korea has a history of swordsmithing dating back 3,000 years. Although Korea was in close proximity to both Japan and China, no native systems of swordsmanship and swordmaking developed in Korea.Korean sword

Korean swords have served a central place in the defense of the nation for thousands of years. Although typical Korean land battles have taken place in wide valleys and narrow mountain passes, which favor use of the spear and bow, the sword found ...

s include long swords such as the yeoh do, geom, and hyup do and curved swords such as Samindo. Metal swords of double bladed leaf structure have been found throughout Korea dating back to the Bronze Age. These bronze swords were around 32 cm in overall length, with a short handle.

Japanese

The technology that led to the development of the Japanese sword originated in China and was brought to Japan by way of Korea. The oldest steel swords found in Japan date to the fourth or fifth century A.D. Although appearing to be ceremonial in nature, samples of these straight blades preserved in theShōsōin

The is the treasure house of Tōdai-ji Temple in Nara, Japan. The building is in the ''azekura'' ( log-cabin) style with a raised floor. It lies to the northwest of the Great Buddha Hall. The Shōsō-in houses artifacts connected to Emperor Shō ...

were hand-forged with hardened cutting edges. By the time of the Heian period

The is the last division of classical Japanese history, running from 794 to 1185. It followed the Nara period, beginning when the 50th emperor, Emperor Kanmu, moved the capital of Japan to Heian-kyō (modern Kyoto). means "peace" in Japanese. ...

(794—1185 AD) the Japanese sword took on its distinctive curved shape as a mounted horseman would have more use for a slashing type of blade as opposed to a thrusting type. These swords were known as ''tachi

A is a type of traditionally made Japanese sword (''nihonto'') worn by the samurai class of feudal Japan. ''Tachi'' and ''katana'' generally differ in length, degree of curvature, and how they were worn when sheathed, the latter depending on t ...

''.

Due to the quality of metal found in Japan, Japanese bladesmithing became an extremely rigid, precise process, involving folding and forge-welding the steel many times over to create a laminated

Lamination is the technique/process of manufacturing a Raw material, material in multiple layers, so that the composite material achieves improved strength of materials, strength, stability, sound insulation, visual appearance, appearance, or ...

blade. By the time of the Kamakura period

The is a period of Japanese history that marks the governance by the Kamakura shogunate, officially established in 1192 in Kamakura by the first ''shōgun'' Minamoto no Yoritomo after the conclusion of the Genpei War, which saw the struggle bet ...

(1185–1333 AD), Japan was under the rule of a military class and repelling Mongol

The Mongols ( mn, Монголчууд, , , ; ; russian: Монголы) are an East Asian ethnic group native to Mongolia, Inner Mongolia in China and the Buryatia Republic of the Russian Federation. The Mongols are the principal member of ...

invasions. This became known as the "Golden era" of Japanese bladesmithing under Emperor Toba II, who became a bladesmith himself. After abdicating, Toba II summoned Japan's finest bladesmiths around him in an effort to develop the perfect sword. It was determined that a sword had to be hard in order to maintain a sharp cutting edge, yet hard steel is brittle and can shatter under the stress of a heavy blow. Swordsmiths in Japan found the solution by wrapping a softer low-carbon steel core such as wrought iron, in a jacket of high-carbon steel and then hardening the edge. However, under heavy usage, the edge would be more prone to chipping than its European counterparts, which were typically designed to deal with heavier armor than Japanese blades. This was answered by allowing projections of softer steel known as ''ashi'' to form in the hardened cutting edge during differential hardening of the blade.

The Mongol invasions

The Mongol invasions and conquests took place during the 13th and 14th centuries, creating history's largest contiguous empire: the Mongol Empire ( 1206- 1368), which by 1300 covered large parts of Eurasia. Historians regard the Mongol devastati ...

brought with them a need for swords also suited for hand-to-hand combat and the smiths began manufacture of shorter blades to meet this need. It was during the Muromachi period

The is a division of Japanese history running from approximately 1336 to 1573. The period marks the governance of the Muromachi or Ashikaga shogunate (''Muromachi bakufu'' or ''Ashikaga bakufu''), which was officially established in 1338 by t ...

that the ''katana

A is a Japanese sword characterized by a curved, single-edged blade with a circular or squared guard and long grip to accommodate two hands. Developed later than the ''tachi'', it was used by samurai in feudal Japan and worn with the edge fa ...

'' and ''tantō

A is one of the traditionally made Japanese swords ( ''nihonto'') that were worn by the samurai class of feudal Japan. The tantō dates to the Heian period, when it was mainly used as a weapon but evolved in design over the years to become more ...

'' came into being. By the sixteenth century, Japanese bladesmithing had become so renowned throughout Asia that the Japanese turned to large scale manufacturing of swords as an export to China. Smiths at Sakai

is a city located in Osaka Prefecture, Japan. It has been one of the largest and most important seaports of Japan since the medieval era. Sakai is known for its keyhole-shaped burial mounds, or kofun, which date from the fifth century and incl ...

also crafted knives for cutting tobacco

Tobacco is the common name of several plants in the genus '' Nicotiana'' of the family Solanaceae, and the general term for any product prepared from the cured leaves of these plants. More than 70 species of tobacco are known, but the ...

, which had been introduced by the Portuguese. The Sakai bladesmithing industry received a major boost from the Tokugawa shogunate

The Tokugawa shogunate (, Japanese 徳川幕府 ''Tokugawa bakufu''), also known as the , was the military government of Japan during the Edo period from 1603 to 1868. Nussbaum, Louis-Frédéric. (2005)"''Tokugawa-jidai''"in ''Japan Encyclopedia ...

(1603–1868), which granted Sakai a special seal of approval and enhanced its reputation for quality.

The Haitorei Edict in 1876 banned carrying of swords in public, which, combined with the decimation of the samurai class caused a heavy decline in the number of swords produced throughout the country. Sword-making was completely banned following World War II and did not resume until 1953, under heavy restrictions to preserve it solely as an art. In modern-day Japan a swordsmith is still only allowed to manufacture two swords a month by law, for example. As a result, many smiths travel to Taiwan or China to make extra swords for the export market as foreign-made swords are also illegal in Japan. Bladesmithing is still practiced in the cities of Sakai (Osaka Prefecture) and Seki (Gifu Prefecture).

Germanic

The Germanic

The Germanic Migration period

The Migration Period was a period in European history marked by large-scale migrations that saw the fall of the Western Roman Empire and subsequent settlement of its former territories by various tribes, and the establishment of the post-Roman ...

peoples also had advanced bladesmithing techniques for their level of technology. Migration Era smiths would often forge-weld blades of multiple materials, and their blades were typically double-edged and straight. Migration Era blades were often forged with a hard steel edge wrapped around a pattern welded core. Pattern welding was adopted from the neighbouring Romans, who had employed such technique since the second century AD.

Indian

Bladesmithing was common practice in India during the Middle Ages. A special type of steel known asWootz

Wootz steel, also known as Seric steel, is a crucible steel characterized by a pattern of bands and high carbon content. These bands are formed by sheets of microscopic carbides within a tempered martensite or pearlite matrix in higher carbon st ...

or Damascus steel

Damascus steel was the forged steel of the blades of swords smithed in the Near East from ingots of Wootz steel either imported from Southern India or made in production centres in Sri Lanka, or Khorasan, Iran. These swords are characterize ...

was often used in South Asia. The term Damascus steel can refer to two different types of artefacts. One is the true Damascus steel, or Wootz steel, which is a high carbon alloy with tremendous edge retention possibly due to its composition of carbon nanotubes and carbide nanowires, with a wavy surface texture originating from the crystalline structure of alloy metals such as tungsten and vanadium - elements that occur naturally in iron ore from southern India - to the surface during the manufacturing process. This is still in debate as metallurgist John Verhoeven at Iowa State University believes the nanowires to occur in most steels. The other is a composite structure made by welding together iron and steel to give a visible pattern on the surface, called pattern welded steel. Although both were referred to as Damascus steels, true Damascus steels were not replicated in Europe until 1821.

Spain

Between the 15th and 17th centuries the Toledo sword-making industry enjoyed a great boom, to the point where itsproducts

Product may refer to:

Business

* Product (business), an item that serves as a solution to a specific consumer problem.

* Product (project management), a deliverable or set of deliverables that contribute to a business solution

Mathematics

* Produ ...

came to be regarded as the best in Europe.

Middle East

Damascus Steel

Damascus steel was the forged steel of the blades of swords smithed in the Near East from ingots of Wootz steel either imported from Southern India or made in production centres in Sri Lanka, or Khorasan, Iran. These swords are characterize ...

was commonly used in the Middle East.

Modern bladesmithing

Bladesmithing began declining after theIndustrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

. With improvements in steel production, bladesmiths no longer had to forge steel and knives could be machined from flat bars of steel. As cutlery companies moved to mass production of blades and machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

s became more available, the art of forging steel began to disappear as knifemakers could grind blades out of existing stock. By the mid 20th century, bladesmithing had been relegated to a cottage industry carried out by a handful of bladesmiths.

One of these bladesmiths was William F. Moran, who forged his knives using a coal forge in the manner of a blacksmith using a hammer and anvil to shape the steel. Moran began trying to revive the ancient process of forging Damascus steel

Damascus steel was the forged steel of the blades of swords smithed in the Near East from ingots of Wootz steel either imported from Southern India or made in production centres in Sri Lanka, or Khorasan, Iran. These swords are characterize ...

in the late 1960s. However, no living bladesmith knew the exact techniques and without a recipe for the process, it was in danger of being lost; through trial and error he taught himself pattern welding

Pattern welding is the practice in sword and knife making of forming a blade of several metal pieces of differing composition that are forge welding, forge-welded together and twisted and manipulated to form a pattern. Often mistakenly called Dam ...

and referred to his end product as "Damascus steel".

In 1972, Moran was elected president of the Knifemakers' Guild The Knifemakers' Guild is an American organization, based in Richfield, Utah, made up of knifemakers to promote custom knives, encourage ethical business practices, assist with technical aspects of knife making, and to sponsor knife shows. The Guild ...

. The following year he unveiled his "Damascus knives" at the Guild Show and created a revival of interest in the forged blade, and along with the knives he gave away free booklets detailing how he made them, to encourage other knifemakers to take up the hammer and anvil. In 1976 he founded the American Bladesmith Society The American Bladesmith Society, or ABS, is a non-profit organization composed of knifemakers whose primary function is to promote the techniques of forging steel blades. The ABS was founded by knifemaker William F. Moran, who came up with the con ...

(ABS). Despite its name, this was an international group of knife makers dedicated to preserving the forged blade and educating the public about traditional bladesmithing techniques. The handful of traditional bladesmiths in the 1960s rose to several hundred by 2005.

Tools

The basic art and principles of forging a blade has remained similar for thousands of years and the modern bladesmith uses a variety of tools and techniques in order to produce a blade. Forges formerly fed by wood, coke, or coal are still in use, but gas forges are becoming the standard. Likewise the smith's hammer is being eclipsed by the use of hydraulic forging presses andpower hammer

Power hammers are mechanical forging hammers that use an electrical power source or steam to raise the hammer preparatory to striking, and accelerate it onto the work being hammered. They are also called open die power forging hammers. They ha ...

s.

Steel

Modern bladesmiths use a variety ofsteels

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

to produce their blades, most commonly high carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, coba ...

, such as SAE 1075

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally Alloy steel#Low-alloy steels, low-alloy manganese, medium-carbo ...

or SAE 1095

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon stee ...

(the '10' representing the 10-series carbon steels, while '75' '85' and '95' reflect the carbon content of the steel), tool steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive har ...

such as O-1, A-2, D2 other tool or high carbon steels, or a variety of steels welded in layers, commonly referred to as "Damascus".

When forging, the blade material is heated to a high temperature or forging temperature in a forge and shaped with a hammer on an anvil to achieve the desired shape, often to near final dimension, where very little stock removal, if any, is required to finish. Steel can be folded either to form decorative pattern welded steel or to refine raw steel, or as the Japanese call it, tamahagane. Grain size is kept at a minimum as grain growth can happen quite easily if the blade material is overheated.

Sword

A sword is an edged, bladed weapon intended for manual cutting or thrusting. Its blade, longer than a knife or dagger, is attached to a hilt and can be straight or curved. A thrusting sword tends to have a straighter blade with a pointed ti ...

s and longer blades, in modern times, are often crafted of 5160 carbon spring steel

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon steel ...

, which is not as hard or brittle as a high carbon steel (such as 1095), but is more durable and less prone to breakage, and therefore more suitable for longer weapons. 5160 carbon spring steel is sometimes used for leaf springs

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. Originally called a ''laminated'' or ''carriage spring'', and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, ...

in American trucks, making it readily available in the US. In Europe, EN-45 is more commonly used.

Damascus steel

Many bladesmiths are able to forge a special type of steel using a technique calledpattern welding

Pattern welding is the practice in sword and knife making of forming a blade of several metal pieces of differing composition that are forge welding, forge-welded together and twisted and manipulated to form a pattern. Often mistakenly called Dam ...

, producing a metal erroneously referred to as Damascus steel. Modern pattern-welded steel can be highly decorative as well as durable (if welded in certain ways with proper steels), and is often used in custom knife- and sword-crafting. Bill Moran is said to be the "Father of Modern Damascus Steel".

See also

* Sword replica *Metalsmith

A metalsmith or simply smith is a craftsperson fashioning useful items (for example, tools, kitchenware, tableware, jewelry, armor and weapons) out of various metals. Smithing is one of the oldest list of metalworking occupations, metalworking o ...

* Kris

The kris, or ''keris'' in the Indonesian language, is an asymmetrical dagger with distinctive blade-patterning achieved through alternating laminations of iron and nickelous iron (''pamor''). Of Javanese origin, the kris is famous for its disti ...

References

Further reading

* Erik; Jones, F.D. Oberg. ''Machinery's Handbook 13th Ed'', 1946.Legendary Swords' Sharpness, Strength From Nanotubes, Study Says

External links

The American Bladesmith Society

{{Authority control Blade weapons Metalworking occupations