|

PBGA

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be put on a dual in-line or flat package. The whole bottom surface of the device can be used, instead of just the perimeter. The traces connecting the package's leads to the wires or balls which connect the die to package are also on average shorter than with a perimeter-only type, leading to better performance at high speeds. Soldering of BGA devices requires precise control and is usually done by automated processes such as in computer-controlled automatic reflow ovens. Description The BGA is descended from the pin grid array (PGA), which is a package with one face covered (or partly covered) with pins in a grid pattern which, in operation, conduct electrical signals between the integrated circuit and the printed circuit board (PCB) on wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder Ball Grid

Solder (; North American English, NA: ) is a fusible alloy, fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics. Soft solder typically has a melting point range of , and is commonly used in electronics, plumbing, and sheet metal work. Alloys that melt between are the most commonly used. Soldering performed using alloys with a melting point above is called "hard soldering", "silver soldering", or brazing. In specific proportions, some alloys are eutectic — that is, the alloy's melting point is the lowest possible for a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multi-chip Module

A multi-chip module (MCM) is generically an electronic assembly (such as a package with a number of conductor terminals or Lead (electronics), "pins") where multiple integrated circuits (ICs or "chips"), semiconductor Die (integrated circuit), dies and/or other discrete components are integrated, usually onto a unifying substrate, so that in use it can be treated as if it were a larger IC. Other terms for MCM packaging include "heterogeneous integration" or "hybrid integrated circuit". The advantage of using MCM packaging is it allows a manufacturer to use multiple components for modularity and/or to improve yields over a conventional monolithic IC approach. A Flip Chip Multi-Chip Module (FCMCM) is a multi-chip module that uses flip chip technology. A FCMCM may have one large die and several smaller dies all on the same module. Overview Multi-chip modules come in a variety of forms depending on the complexity and development philosophies of their designers. These can range from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interposer

An interposer is an electrical interface routing between one socket or connection and another. The purpose of an interposer is to spread a connection to a wider pitch or to reroute a connection to a different connection. An interposer can be made of either silicon or organic (printed circuit board-like) material. Interposer comes from the Latin word , meaning "to put between".interposes - definition of interposes by the Free Online Dictionary, Thesaurus and Encyclopedia They are often used in [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Whisker (metallurgy)

Metal whiskering is a phenomenon that occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment that used pure, or almost pure, tin solder in their production. It was noticed that small metal hairs or tendrils grew between metal solder pads, causing short circuits. Metal whiskers form in the presence of compressive stress. Germanium, zinc, cadmium, and even lead whiskers have been documented. Many techniques are used to mitigate the problem, including changes to the annealing (metallurgy), annealing process (heating and cooling), the addition of elements like copper and nickel, and the inclusion of conformal coatings. Traditionally, lead has been added to slow down whisker growth in tin-based solders. Following the RoHS, Restriction of Hazardous Substances Directive (RoHS), the European Union banned the use of lead in most consumer elec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pad Cratering

Pad cratering is a mechanically induced fracture in the resin between copper foil and outermost layer of fiberglass of a printed circuit board (PCB). It may be within the resin or at the resin to fiberglass interface. The pad remains connected to the component (usually a Ball Grid Array, BGA) and leaves a "crater" on the surface of the printed circuit board. Overview Pad cratering most often occurs during dynamic mechanical events such as mechanical shock or board flexure due to In-circuit test (ICT), board depaneling, or connector insertion. However, pad cratering has also been known to occur during thermal shock or even thermal cycling. Susceptibility to pad cratering can be impacted by several factors such as: PCB thickness, PCB laminate material properties, component size and stiffness, component location, and solder alloy selection among other factors. Testing IPC-9708 provides three test methods to characterize the pad cratering of a component and PCBA: pin pull, ball pull, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Head In Pillow (metallurgy)

In the assembly of integrated circuit packages to printed circuit boards, a head-in-pillow defect (HIP or HNP), also called ball-and-socket,https://aimsolder.com/sites/default/files/head-in-pillow_bga_defects.pdf is a failure of the soldering process. For example, in the case of a ball grid array (BGA) package, the pre-deposited solder ball on the package and the solder paste applied to the circuit board may both melt, but the melted solder does not join. A cross-section through the failed joint shows a distinct boundary between the solder ball on the part and the solder paste on the circuit board, rather like a section through a head resting on a pillow. The defect can be caused by surface oxidation or poor wetting of the solder, or by distortion of the integrated circuit package or circuit board by the heat of the soldering process. This is particularly a concern when using lead-free solder, which requires a higher processing temperature. The defect can be attributed to a cha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RoHS Compliant

The Restriction of Hazardous Substances Directive 2002/95/EC (RoHS 1), short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment, was adopted in February 2003 by the European Union. The initiative was to limit the amount of hazardous chemicals in electronics. The RoHS 1 directive took effect on 1 July 2006, and is required to be enforced and became a law in each member state. This directive restricts (with exceptions) the use of ten hazardous materials in the manufacture of various types of electronic and electrical equipment. In addition to the exceptions, there are exclusions for products such as solar panels. It is closely linked with the Waste Electrical and Electronic Equipment Directive (WEEE) 2002/96/EC (now superseded) which sets collection, recycling and recovery targets for electrical goods and is part of a legislative initiative to solve the problem of huge amounts of toxic electronic waste. In sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Expansion

Thermal expansion is the tendency of matter to increase in length, area, or volume, changing its size and density, in response to an increase in temperature (usually excluding phase transitions). Substances usually contract with decreasing temperature (thermal contraction), with rare exceptions within limited temperature ranges ('' negative thermal expansion''). Temperature is a monotonic function of the average molecular kinetic energy of a substance. As energy in particles increases, they start moving faster and faster, weakening the intermolecular forces between them and therefore expanding the substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. Prediction If an equation of state is available, it can be used t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stiffness

Stiffness is the extent to which an object resists deformation in response to an applied force. The complementary concept is flexibility or pliability: the more flexible an object is, the less stiff it is. Calculations The stiffness, k, of a body is a measure of the resistance offered by an elastic body to deformation. For an elastic body with a single degree of freedom (DOF) (for example, stretching or compression of a rod), the stiffness is defined as k = \frac where, * F is the force on the body * \delta is the displacement produced by the force along the same degree of freedom (for instance, the change in length of a stretched spring) Stiffness is usually defined under quasi-static conditions, but sometimes under dynamic loading. In the International System of Units, stiffness is typically measured in newtons per meter (N/m). In Imperial units, stiffness is typically measured in pounds (lbs) per inch. Generally speaking, deflections (or motions) of an infinitesima ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BGA Joint Xray

BGA may refer to: Organizations * Battle Ground Academy, a private school in Franklin, Tennessee, US * Behavior Genetics Association * Boldklubberne Glostrup Albertslund, a Danish football club * British Gear Association * British Gliding Association * British Go Association * British Geophysical Association * British-German Association * Bumitama Gunajaya Agro, an Indonesian palm oil company * Bundesverband Großhandel, Außenhandel, Dienstleistungen (The Federation of German Wholesale, Foreign Trade and Services) Transport * Brundall Gardens railway station, Norfolk, England, by National Rail station code * Palonegro International Airport, Colombia, by IATA code Other uses * Ball grid array, a type of surface-mount packaging used for integrated circuits * Cyanobacteria (blue-green algae) * Break glass alarm, a type of manually activated fire alarm; see Fire alarm pull station * ''Bach-Gesellschaft Ausgabe'', the first complete edition of Johann Sebastian Bach's composition ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inductance

Inductance is the tendency of an electrical conductor to oppose a change in the electric current flowing through it. The electric current produces a magnetic field around the conductor. The magnetic field strength depends on the magnitude of the electric current, and therefore follows any changes in the magnitude of the current. From Faraday's law of induction, any change in magnetic field through a circuit induces an electromotive force (EMF) (voltage) in the conductors, a process known as electromagnetic induction. This induced voltage created by the changing current has the effect of opposing the change in current. This is stated by Lenz's law, and the voltage is called ''back EMF''. Inductance is defined as the ratio of the induced voltage to the rate of change of current causing it. It is a proportionality constant that depends on the geometry of circuit conductors (e.g., cross-section area and length) and the magnetic permeability of the conductor and nearby materials. An ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

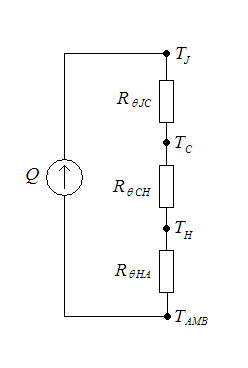

Thermal Resistance

In heat transfer, thermal engineering, and thermodynamics, thermal conductance and thermal resistance are fundamental concepts that describe the ability of materials or systems to conduct heat and the opposition they offer to the heat current. The ability to manipulate these properties allows engineers to control temperature gradient, prevent thermal shock, and maximize the efficiency of thermal systems. Furthermore, these principles find applications in a multitude of fields, including materials science, mechanical engineering, electronics, and energy management. Knowledge of these principles is crucial in various scientific, engineering, and everyday applications, from designing efficient temperature control, thermal insulation, and thermal management in industrial processes to optimizing the performance of electronic devices. Thermal conductance (''G'') measures the ability of a material or system to conduct heat. It provides insights into the ease with which heat can pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |