Solder Ball Grid on:

[Wikipedia]

[Google]

[Amazon]

Solder (; NA: ) is a fusible metal

Solder (; NA: ) is a fusible metal

The

The

Hard solders are used for brazing, and melt at higher temperatures. Alloys of copper with either zinc or silver are the most common.

In

Hard solders are used for brazing, and melt at higher temperatures. Alloys of copper with either zinc or silver are the most common.

In

Phase diagrams of different types of solder alloys

Fusible alloys Soldering Lead alloys

Solder (; NA: ) is a fusible metal

Solder (; NA: ) is a fusible metal alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics.

Soft solder typically has a melting point range of , and is commonly used in electronics

Electronics is a scientific and engineering discipline that studies and applies the principles of physics to design, create, and operate devices that manipulate electrons and other Electric charge, electrically charged particles. It is a subfield ...

, plumbing

Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses piping, pipes, valves, piping and plumbing fitting, plumbing fixtures, Storage tank, tanks, and other apparatuses to convey fluids. HVAC, Heating and co ...

, and sheet metal work. Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

s that melt between are the most commonly used. Soldering performed using alloys with a melting point above is called "hard soldering", "silver soldering", or brazing

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

Brazing differs from welding in ...

.

In specific proportions, some alloys are eutectic — that is, the alloy's melting

Melting, or fusion, is a physical process that results in the phase transition of a substance from a solid to a liquid. This occurs when the internal energy of the solid increases, typically by the application of heat or pressure, which inc ...

point is the lowest possible for a mixture of those components, and coincides with the freezing point. Non-eutectic alloys can have markedly different ''solidus

Solidus (Latin for "solid") may refer to:

* Solidus (coin)

The ''solidus'' (Latin 'solid'; : ''solidi'') or ''nomisma'' () was a highly pure gold coin issued in the Later Roman Empire and Byzantine Empire. It was introduced in the early ...

'' and '' liquidus'' temperatures, as they have distinct liquid and solid transitions. Non-eutectic mixtures often exist as a paste of solid particles in a melted matrix of the lower-melting phase as they approach high enough temperatures. In electrical work, if the joint is disturbed while in this "pasty" state before it fully solidifies, a poor electrical connection may result; use of eutectic solder reduces this problem. The pasty state of a non-eutectic solder can be exploited in plumbing, as it allows molding of the solder during cooling, e.g. for ensuring watertight joint of pipes, resulting in a so-called "wiped joint".

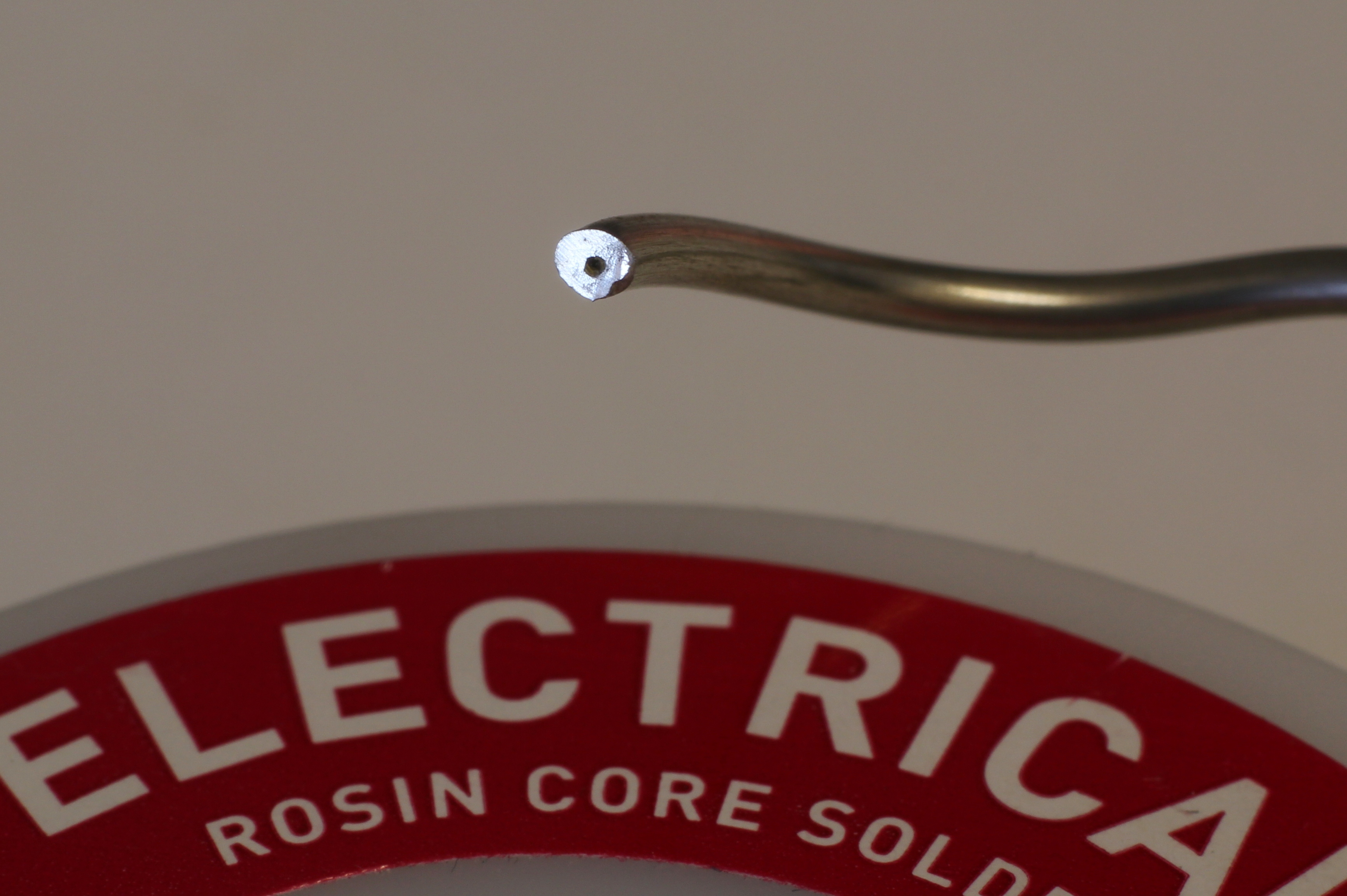

For electrical and electronics work, solder wire is available in a range of thicknesses for hand-soldering (manual soldering is performed using a soldering iron

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces.

A soldering iron is composed of a heated metal tip (the ''bit'') and an insulated handle. Heating is o ...

or soldering gun

A soldering gun is an approximately pistol-shaped, electrically powered tool for soldering metals using tin-based solder to achieve a strong mechanical bond with good electrical contact. The tool has a trigger-style switch so it can be easily ope ...

), and with cores containing flux

Flux describes any effect that appears to pass or travel (whether it actually moves or not) through a surface or substance. Flux is a concept in applied mathematics and vector calculus which has many applications in physics. For transport phe ...

. It is also available as a room temperature paste, as a preformed foil shaped to match the workpiece which may be more suited for mechanized mass-production, or in small "tabs" that can be wrapped around the joint and melted with a flame where an iron isn't usable or available, as for instance in field repairs. Alloys of lead and tin were commonly used in the past and are still available; they are particularly convenient for hand-soldering. Lead-free solders have been increasing in use due to regulatory requirements plus the health and environmental benefits of avoiding lead-based electronic components. They are almost exclusively used today in consumer electronics.

Plumbers often use bars of solder, much thicker than the wire used for electrical applications, and apply flux separately; many plumbing-suitable soldering fluxes are too corrosive (or conductive) to be used in electrical or electronic work. Jeweler

A bench jeweler is an artisan who uses a combination of skills to make and repair jewelry. Some of the more common skills that a bench jeweler might employ include antique restoration, silversmithing, goldsmithing, stone setting, engraving, ...

s often use solder in thin sheets, which they cut into snippets.

Etymology

The word solder comes from theMiddle English

Middle English (abbreviated to ME) is a form of the English language that was spoken after the Norman Conquest of 1066, until the late 15th century. The English language underwent distinct variations and developments following the Old English pe ...

word , via Old French

Old French (, , ; ) was the language spoken in most of the northern half of France approximately between the late 8th -4; we might wonder whether there's a point at which it's appropriate to talk of the beginnings of French, that is, when it wa ...

and , from the Latin , meaning "to make solid".

Composition

Lead-based

Tin

Tin is a chemical element; it has symbol Sn () and atomic number 50. A silvery-colored metal, tin is soft enough to be cut with little force, and a bar of tin can be bent by hand with little effort. When bent, a bar of tin makes a sound, the ...

-lead (Sn-Pb) solders, also called ''soft solders'', are commercially available with tin concentrations between 5% and 70% by weight. The greater the tin concentration, the greater the solder's tensile

Tension is the pulling or stretching force transmitted axially along an object such as a string, rope, chain, rod, truss member, or other object, so as to stretch or pull apart the object. In terms of force, it is the opposite of ''compression ...

and shear strength

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a mater ...

s. Lead mitigates the formation of tin whiskers

Metal whiskering is a phenomenon that occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment tha ...

, though the precise mechanism for this is unknown. Today, many techniques are used to mitigate the problem, including changes to the annealing process (heating and cooling), addition of elements like copper and nickel, and the application of conformal coating

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied with 25–250 μm thickness on electronic circuitry to protect against moisture and ...

s. Alloys commonly used for electrical soldering are 60/40 Sn-Pb, which melts at , and 63/37 Sn-Pb used principally in electrical/electronic work. The latter mixture is a eutectic alloy of these metals, which:

# has the lowest melting point () of all the tin-lead alloys; and

# the melting point is truly a ''point'' — not a range.

In the United States, since 1974, lead is prohibited in solder and flux in plumbing applications for drinking water use, per the Safe Drinking Water Act

The Safe Drinking Water Act (SDWA) is the primary federal law in the United States intended to ensure safe drinking water for the public. Pursuant to the act, the Environmental Protection Agency (EPA) is required to set standards for drinking wa ...

. Historically, a higher proportion of lead was used, commonly 50/50. This had the advantage of making the alloy solidify more slowly. With the pipes being physically fitted together before soldering, the solder could be wiped over the joint to ensure water tightness. Although lead water pipes were displaced by copper when the significance of lead poisoning

Lead poisoning, also known as plumbism and saturnism, is a type of metal poisoning caused by lead in the body. Symptoms may include abdominal pain, constipation, headaches, irritability, memory problems, infertility, numbness and paresthesia, t ...

began to be fully appreciated, lead solder was still used until the 1980s because it was thought that the amount of lead that could leach into water from the solder was negligible from a properly soldered joint. The electrochemical

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference and identifiable chemical change. These reactions involve electrons moving via an electronically conducting phase (typi ...

couple of copper and lead promotes corrosion of the lead and tin. Tin, however, is protected by insoluble oxide. Since even small amounts of lead have been found detrimental to health as a potent neurotoxin

Neurotoxins are toxins that are destructive to nervous tissue, nerve tissue (causing neurotoxicity). Neurotoxins are an extensive class of exogenous chemical neurological insult (medical), insultsSpencer 2000 that can adversely affect function ...

, lead in plumbing solder was replaced by silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

(food-grade applications) or antimony

Antimony is a chemical element; it has chemical symbol, symbol Sb () and atomic number 51. A lustrous grey metal or metalloid, it is found in nature mainly as the sulfide mineral stibnite (). Antimony compounds have been known since ancient t ...

, with copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

often added, and the proportion of tin was increased (see lead-free solder).

The addition of tin—more expensive than lead—improves wetting

Wetting is the ability of a liquid to displace gas to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. These interactions occur in the presence of either a gaseous phase or ...

properties of the alloy; lead itself has poor wetting characteristics. High-tin tin-lead alloys have limited use as the workability range can be provided by a cheaper high-lead alloy.

Lead-tin solders readily dissolve gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

plating and form brittle intermetallics.

60/40 Sn-Pb solder oxidizes on the surface, forming a complex 4-layer structure: tin(IV) oxide

Tin(IV) oxide, also known as stannic oxide, is the inorganic compound with the formula SnO2. The mineral form of SnO2 is called cassiterite, and this is the main ore of tin. With many other names, this oxide of tin is an important material in ti ...

on the surface, below it a layer of tin(II) oxide

Tin(II) oxide (stannous oxide) is a compound with the formula SnO. It is composed of tin and oxygen where tin has the oxidation state of +2. There are two forms, a stable blue-black form and a metastable red form.

Preparation and reactions

Blu ...

with finely dispersed lead, followed by a layer of tin(II) oxide with finely dispersed tin and lead, and the solder alloy itself underneath.

Lead, and to some degree tin, as used in solder contains small but significant amounts of radioisotope

A radionuclide (radioactive nuclide, radioisotope or radioactive isotope) is a nuclide that has excess numbers of either neutrons or protons, giving it excess nuclear energy, and making it unstable. This excess energy can be used in one of three ...

impurities. Radioisotopes undergoing alpha decay

Alpha decay or α-decay is a type of radioactive decay in which an atomic nucleus emits an alpha particle (helium nucleus). The parent nucleus transforms or "decays" into a daughter product, with a mass number that is reduced by four and an a ...

are a concern due to their tendency to cause soft error

In electronics and computing, a soft error is a type of error where a signal or datum is wrong. Errors may be caused by a defect, usually understood either to be a mistake in design or construction, or a broken component. A soft error is also a ...

s. Polonium-210

Polonium-210 (210Po, Po-210, historically radium F) is an isotope of polonium. It undergoes alpha decay to stable 206Pb with a half-life of 138.376 days (about months), the longest half-life of all naturally occurring polonium isotopes (210– ...

is especially troublesome; lead-210

Lead (82Pb) has four observationally stable isotopes: 204Pb, 206Pb, 207Pb, 208Pb. Lead-204 is entirely a primordial nuclide and is not a radiogenic nuclide. The three isotopes lead-206, lead-207, and lead-208 represent the ends of three decay ch ...

beta decay

In nuclear physics, beta decay (β-decay) is a type of radioactive decay in which an atomic nucleus emits a beta particle (fast energetic electron or positron), transforming into an isobar of that nuclide. For example, beta decay of a neutron ...

s to bismuth-210

Bismuth (83Bi) has 41 known isotopes, ranging from 184Bi to 224Bi. Bismuth has no stable isotopes, but does have one very long-lived isotope; thus, the standard atomic weight can be given as . Although bismuth-209 is now known to be radioactive, i ...

which then beta decays to polonium-210, an intense emitter of alpha particle

Alpha particles, also called alpha rays or alpha radiation, consist of two protons and two neutrons bound together into a particle identical to a helium-4 nucleus. They are generally produced in the process of alpha decay but may also be produce ...

s. Uranium-238

Uranium-238 ( or U-238) is the most common isotope of uranium found in nature, with a relative abundance of 99%. Unlike uranium-235, it is non-fissile, which means it cannot sustain a chain reaction in a thermal-neutron reactor. However, it i ...

and thorium-232

Thorium-232 () is the main naturally occurring isotope of thorium, with a relative abundance of 99.98%. It has a half life of 14.05 billion years, which makes it the longest-lived isotope of thorium. It decays by alpha decay to radium-228; its de ...

are other significant contaminants of alloys of lead.

Lead-free

The

The European Union

The European Union (EU) is a supranational union, supranational political union, political and economic union of Member state of the European Union, member states that are Geography of the European Union, located primarily in Europe. The u ...

Waste Electrical and Electronic Equipment Directive

The Waste Electrical and Electronic Equipment Directive (WEEE Directive) is a European Community Directive, numbered 2012/19/EU, concerned with waste electrical and electronic equipment (WEEE). Together with the RoHS Directive 2011/65/EU, i ...

and Restriction of Hazardous Substances Directive

The Restriction of Hazardous Substances Directive 2002/95/EC (RoHS 1), short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment, was adopted in February 2003 by the European Uni ...

were adopted in early 2003 and came into effect on July 1, 2006, restricting the inclusion of lead in most consumer electronics sold in the EU, and having a broad effect on consumer electronics sold worldwide. In the US, manufacturers may receive tax benefits by reducing the use of lead-based solder. Lead-free solders in commercial use may contain tin, copper, silver, bismuth

Bismuth is a chemical element; it has symbol Bi and atomic number 83. It is a post-transition metal and one of the pnictogens, with chemical properties resembling its lighter group 15 siblings arsenic and antimony. Elemental bismuth occurs nat ...

, indium

Indium is a chemical element; it has Symbol (chemistry), symbol In and atomic number 49. It is a silvery-white post-transition metal and one of the softest elements. Chemically, indium is similar to gallium and thallium, and its properties are la ...

, zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

, antimony

Antimony is a chemical element; it has chemical symbol, symbol Sb () and atomic number 51. A lustrous grey metal or metalloid, it is found in nature mainly as the sulfide mineral stibnite (). Antimony compounds have been known since ancient t ...

, and traces of other metals. Most lead-free replacements for conventional 60/40 and 63/37 Sn-Pb solder have melting points from 50 to 200 °C higher, though there are also solders with much lower melting points. Lead-free solder typically requires around 2% flux by mass for adequate wetting ability.

When lead-free solder is used in wave soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit bo ...

, a slightly modified solder pot may be desirable (e.g. titanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

liners or impellers) to reduce maintenance cost due to increased tin-scavenging of high-tin solder.

Lead-free solder is prohibited in critical applications, such as aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial, and military applications. Aerospace engineering consists of aeronautics and astron ...

, military and medical projects, because joints are likely to suffer from metal fatigue failure under stress (such as that from thermal expansion and contraction). Although this is a property that conventional leaded solder possesses as well (like any metal), the point at which stress fatigue will usually occur in leaded solder is substantially above the level of stresses normally encountered.

Tin-silver-copper (Sn-Ag-Cu, or ''SAC'') solders are used by two-thirds of Japanese manufacturers for reflow and wave soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit bo ...

, and by about 75% of companies for hand soldering. The widespread use of this popular lead-free solder alloy family is based on the reduced melting point of the Sn-Ag-Cu ternary eutectic behavior (), which is below the 22/78 Sn-Ag (wt.%) eutectic of and the 99.3/0.7 Sn-Cu eutectic of . The ternary eutectic behavior of Sn-Ag-Cu and its application for electronics assembly was discovered (and patented) by a team of researchers from Ames Laboratory

Ames National Laboratory, formerly Ames Laboratory, is a United States Department of Energy national laboratory located in Ames, Iowa, and affiliated with Iowa State University. It is a top-level national laboratory for research on national sec ...

, Iowa State University

Iowa State University of Science and Technology (Iowa State University, Iowa State, or ISU) is a Public university, public land-grant university, land-grant research university in Ames, Iowa, United States. Founded in 1858 as the Iowa Agricult ...

, and from Sandia National Laboratories

Sandia National Laboratories (SNL), also known as Sandia, is one of three research and development laboratories of the United States Department of Energy's National Nuclear Security Administration (NNSA). Headquartered in Kirtland Air Force B ...

-Albuquerque.

Much recent research has focused on the addition of a fourth element to Sn-Ag-Cu solder, in order to provide compatibility for the reduced cooling rate of solder sphere reflow for assembly of ball grid array

A ball grid array (BGA) is a type of surface-mount packaging (a chip carrier) used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be pu ...

s. Examples of these four-element compositions are 18/64/14/4 tin-silver-copper-zinc (Sn-Ag-Cu-Zn) (melting range 217–220 °C) and 18/64/16/2 tin-silver-copper-manganese

Manganese is a chemical element; it has Symbol (chemistry), symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese was first isolated in the 1770s. It is a transition m ...

(Sn-Ag-Cu-Mn; melting range of 211–215 °C).

Tin-based solders readily dissolve gold, forming brittle intermetallic joins; for Sn-Pb alloys the critical concentration of gold to embrittle the joint is about 4%. Indium-rich solders (usually indium-lead) are more suitable for soldering thicker gold layers as the dissolution rate of gold in indium is much slower. Tin-rich solders also readily dissolve silver; for soldering silver metallization or surfaces, alloys with addition of silver are suitable; tin-free alloys are also a choice, though their wetting ability is poorer. If the soldering time is long enough to form the intermetallics, the tin surface of a joint soldered to gold is very dull.

Hard solder

Hard solders are used for brazing, and melt at higher temperatures. Alloys of copper with either zinc or silver are the most common.

In

Hard solders are used for brazing, and melt at higher temperatures. Alloys of copper with either zinc or silver are the most common.

In silversmithing

A silversmith is a metalworker who crafts objects from silver. The terms ''silversmith'' and ''goldsmith'' are not exact synonyms, as the techniques, training, history, and guilds are (or were, at least) largely the same but differed in that t ...

or jewelry

Jewellery (or jewelry in American English) consists of decorative items worn for personal adornment such as brooches, ring (jewellery), rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the ...

making, special hard solders are used that will pass assay

An assay is an investigative (analytic) procedure in laboratory medicine, mining, pharmacology, environmental biology and molecular biology for qualitatively assessing or quantitatively measuring the presence, amount, or functional activity ...

. They contain a high proportion of the metal being soldered and lead is not used in these alloys. These solders vary in hardness, designated as "enameling", "hard", "medium", "easy" and "repair". Enameling solder has a high melting point, close to that of the material itself, to prevent the joint desoldering

In electronics, desoldering is the removal of solder and components from a Printed circuit board, circuit board for troubleshooting, repair, replacement, and salvage.

Tools

Desoldering tools and materials include the following:

*Solder wick

*H ...

during firing in the enameling process. The remaining solder types are used in decreasing order of hardness during the process of making an item, to prevent a previously soldered seam or joint desoldering while additional sites are soldered. Easy solder or repair solder are also often used for repair work for the same reason. Flux is also used to prevent joints from desoldering.

Silver solder is also used in manufacturing to join metal parts that cannot be welded. The alloys used for these purposes contain a high proportion of silver (up to 40%), and may also contain cadmium

Cadmium is a chemical element; it has chemical symbol, symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12 element, group 12, zinc and mercury (element), mercury. Like z ...

.

Alloys

Different elements serve different roles in the solder alloy: *Antimony

Antimony is a chemical element; it has chemical symbol, symbol Sb () and atomic number 51. A lustrous grey metal or metalloid, it is found in nature mainly as the sulfide mineral stibnite (). Antimony compounds have been known since ancient t ...

is added to increase strength without affecting wettability. Prevents tin pest. Should be avoided on zinc, cadmium, or galvanized metals as the resulting joint is brittle.

* Bismuth

Bismuth is a chemical element; it has symbol Bi and atomic number 83. It is a post-transition metal and one of the pnictogens, with chemical properties resembling its lighter group 15 siblings arsenic and antimony. Elemental bismuth occurs nat ...

significantly lowers the melting point and improves wettability. In presence of sufficient lead and tin, bismuth forms crystals of with melting point of only 95 °C, which diffuses along the grain boundaries and may cause a joint failure at relatively low temperatures. A high-power part pre-tinned with an alloy of lead can therefore desolder under load when soldered with a bismuth-containing solder. Such joints are also prone to cracking. Alloys with more than 47% Bi expand upon cooling, which may be used to offset thermal expansion mismatch stresses. Retards growth of tin whiskers

Metal whiskering is a phenomenon that occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment tha ...

. Relatively expensive, limited availability.

* Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

improves resistance to thermal cycle fatigue, and improves wetting

Wetting is the ability of a liquid to displace gas to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. These interactions occur in the presence of either a gaseous phase or ...

properties of the molten solder. It also slows down the rate of dissolution of copper from the board and part leads in the liquid solder. Copper in solders forms intermetallic compounds. Supersaturated (by about 1%) solution of copper in tin may be employed to inhibit dissolution of thin-film under-bump metallization of BGA chips, e.g. as .

* Nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

can be added to the solder alloy to form a supersaturated solution to inhibit dissolution of thin-film under-bump metallization. In tin-copper alloys, small addition of Ni (<0.5 wt%) inhibits the formation of voids and interdiffusion of Cu and Sn elements. Inhibits copper dissolution, even more in synergy with bismuth. Nickel presence stabilizes the copper-tin intermetallics, inhibits growth of pro-eutectic β-tin dendrites (and therefore increases fluidity near the melting point of copper-tin eutectic), promotes shiny bright surface after solidification, inhibits surface cracking at cooling; such alloys are called "nickel-modified" or "nickel-stabilized". Small amounts increase melt fluidity, most at 0.06%. Suboptimal amounts may be used to avoid patent issues. Fluidity reduction increase hole filling and mitigates bridging and icicles.

* Cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. ...

is used instead of nickel to avoid patent issues in improving fluidity. Does not stabilize intermetallic growths in solid alloy.

* Indium

Indium is a chemical element; it has Symbol (chemistry), symbol In and atomic number 49. It is a silvery-white post-transition metal and one of the softest elements. Chemically, indium is similar to gallium and thallium, and its properties are la ...

lowers the melting point and improves ductility. In presence of lead it forms a ternary compound that undergoes phase change at 114 °C. Very high cost (several times of silver), low availability. Easily oxidizes, which causes problems for repairs and reworks, especially when oxide-removing flux cannot be used, e.g. during GaAs die attachment. Indium alloys are used for cryogenic applications, and for soldering gold as gold dissolves in indium much less than in tin. Indium can also solder many nonmetals (e.g. glass, mica, alumina, magnesia, titania, zirconia

Zirconium dioxide (), sometimes known as zirconia (not to be confused with zirconium silicate or zircon), is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral ba ...

, porcelain, brick, concrete, and marble). Prone to diffusion into semiconductors and cause undesired doping. At elevated temperatures easily diffuses through metals. Low vapor pressure, suitable for use in vacuum systems. Forms brittle intermetallics with gold; indium-rich solders on thick gold are unreliable. Indium-based solders are prone to corrosion, especially in presence of chloride

The term chloride refers to a compound or molecule that contains either a chlorine anion (), which is a negatively charged chlorine atom, or a non-charged chlorine atom covalently bonded to the rest of the molecule by a single bond (). The pr ...

ions.

* Lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

is inexpensive and has suitable properties. Worse wetting than tin. Toxic, being phased out. Retards growth of tin whiskers, inhibits tin pest. Lowers solubility of copper and other metals in tin.

* Silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

provides mechanical strength, but has worse ductility than lead. In absence of lead, it improves resistance to fatigue from thermal cycles. Using SnAg solders with HASL-SnPb-coated leads forms phase with melting point at 179 °C, which moves to the board-solder interface, solidifies last, and separates from the board. Addition of silver to tin significantly lowers solubility of silver coatings in the tin phase. In eutectic tin-silver (3.5% Ag) alloy and similar alloys (e.g. SAC305) it tends to form platelets of , which, if formed near a high-stress spot, may serve as initiating sites for cracks and cause poor shock and drop performance; silver content needs to be kept below 3% to inhibit such problems.King-Ning Tu (2007) ''Solder Joint Technology – Materials, Properties, and Reliability''. Springer. High ion mobility, tends to migrate and form short circuits at high humidity under DC bias. Promotes corrosion of solder pots, increases dross formation.

* Tin

Tin is a chemical element; it has symbol Sn () and atomic number 50. A silvery-colored metal, tin is soft enough to be cut with little force, and a bar of tin can be bent by hand with little effort. When bent, a bar of tin makes a sound, the ...

is the usual main structural metal of the alloy. It has good strength and wetting. On its own it is prone to tin pest

Tin pest is an autocatalytic, allotropic transformation of the element tin, which causes deterioration of tin objects at low temperatures. Tin pest has also been called ''tin disease'', ''tin blight'', ''tin plague'', or ''tin leprosy''. It is ...

and growth of tin whiskers

Metal whiskering is a phenomenon that occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment tha ...

. Readily dissolves silver, gold and to less but still significant extent many other metals, e.g. copper; this is a particular concern for tin-rich alloys with higher melting points and reflow temperatures.

* Zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

lowers the melting point and is low-cost. However, it is highly susceptible to corrosion and oxidation in air, therefore zinc-containing alloys are unsuitable for some purposes, e.g. wave soldering, and zinc-containing solder pastes have shorter shelf life than zinc-free. Can form brittle Cu-Zn intermetallic layers in contact with copper. Readily oxidizes which impairs wetting, requires a suitable flux.

* Germanium

Germanium is a chemical element; it has Symbol (chemistry), symbol Ge and atomic number 32. It is lustrous, hard-brittle, grayish-white and similar in appearance to silicon. It is a metalloid or a nonmetal in the carbon group that is chemically ...

in tin-based lead-free solders influences formation of oxides; at below 0.002% it increases formation of oxides. Optimal concentration for suppressing oxidation is at 0.005%. Used in e.g. Sn100C alloy. Patented.

* Rare-earth element

The rare-earth elements (REE), also called the rare-earth metals or rare earths, and sometimes the lanthanides or lanthanoids (although scandium and yttrium, which do not belong to this series, are usually included as rare earths), are a set o ...

s, when added in small amounts, refine the matrix structure in tin-copper alloys by segregating impurities at the grain boundaries. However, excessive addition results in the formation of tin whiskers; it also results in spurious rare earth phases, which easily oxidize and deteriorate the solder properties.

* Phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

is used as antioxidant to inhibit dross formation. Decreases fluidity of tin-copper alloys.

Impurities

Impurities usually enter the solder reservoir by dissolving the metals present in the assemblies being soldered. Dissolving of process equipment is not common as the materials are usually chosen to be insoluble in solder. *Aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

– little solubility, causes sluggishness of solder and dull gritty appearance due to formation of oxides. Addition of antimony to solders forms Al-Sb intermetallics that are segregated into dross

Dross is a mass of solid impurities floating on a molten metal or dispersed in the metal, such as in wrought iron. It forms on the surface of low- melting-point metals such as tin, lead, zinc or aluminium or alloys by oxidation of the metal. Fo ...

. Promotes embrittlement.

* Antimony

Antimony is a chemical element; it has chemical symbol, symbol Sb () and atomic number 51. A lustrous grey metal or metalloid, it is found in nature mainly as the sulfide mineral stibnite (). Antimony compounds have been known since ancient t ...

– added intentionally, up to 0.3% improves wetting, larger amounts slowly degrade wetting. Increases melting point.

* Arsenic

Arsenic is a chemical element; it has Symbol (chemistry), symbol As and atomic number 33. It is a metalloid and one of the pnictogens, and therefore shares many properties with its group 15 neighbors phosphorus and antimony. Arsenic is not ...

– forms thin intermetallics with adverse effects on mechanical properties, causes dewetting of brass surfaces

* Cadmium

Cadmium is a chemical element; it has chemical symbol, symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12 element, group 12, zinc and mercury (element), mercury. Like z ...

– causes sluggishness of solder, forms oxides and tarnishes

* Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

– most common contaminant, forms needle-shaped intermetallics, causes sluggishness of solders, grittiness of alloys, decreased wetting

* Gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

– easily dissolves, forms brittle intermetallics, contamination above 0.5% causes sluggishness and decreases wetting. Lowers melting point of tin-based solders. Higher-tin alloys can absorb more gold without embrittlement.

* Iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

– forms intermetallics, causes grittiness, but rate of dissolution is very low; readily dissolves in lead-tin above 427 °C.

* Lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

– causes Restriction of Hazardous Substances Directive compliance problems at above 0.1%.

* Nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

– causes grittiness, very little solubility in Sn-Pb

* Phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

– forms tin and lead phosphide

In chemistry, a phosphide is a compound containing the ion or its equivalent. Many different phosphides are known, with widely differing structures. Most commonly encountered on the binary phosphides, i.e. those materials consisting only of pho ...

s, causes grittiness and dewetting, present in electroless nickel plating

* Silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

– often added intentionally, in high amounts forms intermetallics that cause grittiness and formation of pimples on the solder surface, potential for embrittlement

* Sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

– forms lead and tin sulfide

Sulfide (also sulphide in British English) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to large families o ...

s, causes dewetting

* Zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

– in melt forms excessive dross, in solidified joints rapidly oxidizes on the surface; zinc oxide is insoluble in fluxes, impairing repairability; copper and nickel barrier layers may be needed when soldering brass to prevent zinc migration to the surface; potential for embrittlement

Board finishes vs wave soldering bath impurities buildup:

* HASL, lead-free (Hot Air Level): usually virtually pure tin. Does not contaminate high-tin baths.

* HASL, leaded: some lead dissolves into the bath

* ENIG (Electroless Nickel Immersion Gold): typically 100-200 microinches of nickel with 3-5 microinches of gold on top. Some gold dissolves into the bath, but limits exceeding buildup is rare.

* Immersion silver: typically 10–15 microinches of silver. Some dissolves into the bath, limits exceeding buildup is rare.

* Immersion tin: does not contaminate high-tin baths.

* OSP (Organic solderability preservative): usually imidazole-class compounds forming a thin layer on the copper surface. Copper readily dissolves in high-tin baths.

Flux

Flux

Flux describes any effect that appears to pass or travel (whether it actually moves or not) through a surface or substance. Flux is a concept in applied mathematics and vector calculus which has many applications in physics. For transport phe ...

is a reducing agent

In chemistry, a reducing agent (also known as a reductant, reducer, or electron donor) is a chemical species that "donates" an electron to an (called the , , , or ).

Examples of substances that are common reducing agents include hydrogen, carbon ...

designed to help reduce (return oxidized metals to their metallic state) metal oxides at the points of contact to improve the electrical connection and mechanical strength. The two principal types of flux are acid flux (sometimes called "active flux"), containing strong acids, used for metal mending and plumbing, and rosin

Rosin (), also known as colophony or Greek pitch (), is a resinous material obtained from pine trees and other plants, mostly conifers. The primary components of rosin are diterpenoids, i.e., C20 carboxylic acids. Rosin consists mainly of r ...

flux (sometimes called "passive flux"), used in electronics. Rosin flux comes in a variety of "activities", corresponding roughly to the speed and effectiveness of the organic acid components of the rosin in dissolving metallic surface oxides, and consequently the corrosiveness of the flux residue.

Due to concerns over atmospheric pollution

Air pollution is the presence of substances in the air that are harmful to humans, other living beings or the environment. Pollutants can be gases like ozone or nitrogen oxides or small particles like soot and dust. It affects both outdoor air ...

and hazardous waste

Hazardous waste is waste that must be handled properly to avoid damaging human health or the environment. Waste can be hazardous because it is Toxicity, toxic, Chemical reaction, reacts violently with other chemicals, or is Corrosion, corrosive, ...

disposal, the electronics industry

The electronics industry is the industry (economics), industry that produces electronic devices. It emerged in the 20th century and is today one of the largest global industries. Contemporary society uses a vast array of electronic devices that ar ...

has been gradually shifting from rosin flux to water-soluble flux, which can be removed with deionized water

Purified water is water that has been mechanically filtered or processed to remove impurities and make it suitable for use. Distilled water was, formerly, the most common form of purified water, but, in recent years, water is more frequently pu ...

and detergent

A detergent is a surfactant or a mixture of surfactants with Cleanliness, cleansing properties when in Concentration, dilute Solution (chemistry), solutions. There are a large variety of detergents. A common family is the alkylbenzene sulfonate ...

, instead of hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and Hydrophobe, hydrophobic; their odor is usually fain ...

solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

s. Water-soluble fluxes are generally more conductive than traditionally used electrical / electronic fluxes and so have more potential for electrically interacting with a circuit; in general it is important to remove their traces after soldering. Some rosin type flux traces likewise should be removed, and for the same reason.

In contrast to using traditional bars or coiled wires of all-metal solder and manually applying flux to the parts being joined, much hand soldering since the mid-20th century has used flux-core solder. This is manufactured as a coiled wire of solder, with one or more continuous bodies of inorganic acid or rosin flux embedded lengthwise inside it. As the solder melts onto the joint, it frees the flux and releases that on it as well.

Operation

The solidifying behavior depends on the alloy composition. Pure metals solidify at a certain temperature, forming crystals of one phase. Eutectic alloys also solidify at a single temperature, all components precipitating simultaneously in so-called coupled growth. Non-eutectic compositions on cooling start to first precipitate the non-eutectic phase; dendrites when it is a metal, large crystals when it is an intermetallic compound. Such a mixture of solid particles in a molten eutectic is referred to as a mushy state. Even a relatively small proportion of solids in the liquid can dramatically lower its fluidity. The temperature of total solidification is the solidus of the alloy, the temperature at which all components are molten is the liquidus. The mushy state is desired where a degree of plasticity is beneficial for creating the joint, allowing filling larger gaps or being wiped over the joint (e.g. when soldering pipes). In hand soldering of electronics it may be detrimental as the joint may appear solidified while it is not yet. Premature handling of such joint then disrupts its internal structure and leads to compromised mechanical integrity.Intermetallics

Many different intermetallic compounds are formed during solidifying of solders and during their reactions with the soldered surfaces. The intermetallics form distinct phases, usually as inclusions in a ductile solid solution matrix, but also can form the matrix itself with metal inclusions or form crystalline matter with different intermetallics. Intermetallics are often hard and brittle. Finely distributed intermetallics in a ductile matrix yield a hard alloy while coarse structure gives a softer alloy. A range of intermetallics often forms between the metal and the solder, with increasing proportion of the metal; e.g. forming a structure of . Layers of intermetallics can form between the solder and the soldered material. These layers may cause mechanical reliability weakening and brittleness, increased electrical resistance, or electromigration and formation of voids. The gold-tin intermetallics layer is responsible for poor mechanical reliability of tin-soldered gold-plated surfaces where the gold plating did not completely dissolve in the solder. Two processes play a role in a solder joint formation: interaction between the substrate and molten solder, and solid-state growth of intermetallic compounds. The base metal dissolves in the molten solder in an amount depending on its solubility in the solder. The active constituent of the solder reacts with the base metal with a rate dependent on the solubility of the active constituents in the base metal. The solid-state reactions are more complex – the formation of intermetallics can be inhibited by changing the composition of the base metal or the solder alloy, or by using a suitable barrier layer to inhibit diffusion of the metals. Some example interactions include: * Gold and palladium readily dissolve in solders. Copper and nickel tend to form intermetallic layers during normal soldering profiles. Indium forms intermetallics as well. * Indium-gold intermetallics are brittle and occupy about 4 times more volume than the original gold. Bonding wires are especially susceptible to indium attack. Such intermetallic growth, together with thermal cycling, can lead to failure of the bonding wires. * Copper plated with nickel and gold is often used. The thin gold layer facilitates good solderability of nickel as it protects the nickel from oxidation; the layer has to be thin enough to rapidly and completely dissolve so bare nickel is exposed to the solder. * Lead-tin solder layers on copper leads can form copper-tin intermetallic layers; the solder alloy is then locally depleted of tin and form a lead-rich layer. The Sn-Cu intermetallics then can get exposed to oxidation, resulting in impaired solderability. * – common on solder-copper interface, forms preferentially when excess of tin is available; in presence of nickel, compound can be formed * – common on solder-copper interface, forms preferentially when excess of copper is available, more thermally stable than , often present when higher-temperature soldering occurred * – common on solder-nickel interface * – very slow formation * Sn - at higher concentration of silver (over 3%) in tin forms platelets that can serve as crack initiation sites. * – β-phase – brittle, forms at excess of tin. Detrimental to properties of tin-based solders to gold-plated layers. * – forms on the boundary between gold and indium-lead solder, acts as a barrier against further dissolution of goldPreform

A preform is a pre-made shape of solder specially designed for the application where it is to be used. Many methods are used to manufacture the solder preform, stamping being the most common. The solder preform may include the solder flux needed for the soldering process. This can be an internal flux, inside the solder preform, or external, with the solder preform coated.Similar substances

Glass solder is used to joinglass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

es to other glasses, ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

s, metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

s, semiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping level ...

s, mica

Micas ( ) are a group of silicate minerals whose outstanding physical characteristic is that individual mica crystals can easily be split into fragile elastic plates. This characteristic is described as ''perfect basal cleavage''. Mica is co ...

, and other materials, in a process called glass frit bonding. The glass solder has to flow and wet the soldered surfaces well below the temperature where deformation or degradation of either of the joined materials or nearby structures (e.g., metallization layers on chips or ceramic substrates) occurs. The usual temperature of achieving flowing and wetting is between .

See also

* Body solder * Graping *Restriction of Hazardous Substances Directive

The Restriction of Hazardous Substances Directive 2002/95/EC (RoHS 1), short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment, was adopted in February 2003 by the European Uni ...

* Solderability

* Solder alloys

* Solder mask

* Solder fatigue

* Wood's metal

Wood's metal, also known as Lipowitz's alloy or by the commercial names Cerrobend, Bendalloy, Pewtalloy and MCP 158, is a fusible metal alloy (having a low melting point) that is useful for soldering and making custom metal parts. The alloy is n ...

* Solder paste

Solder paste is a preparation of powdered solder in sticky Flux (metallurgy), flux paste primarily used to solder surface mount components onto printed circuit boards. It is also possible to solder through-hole pin in paste components by printi ...

References

External links

* {{cite EB1911, wstitle=Solder, volume=25 , page=374 , short=xPhase diagrams of different types of solder alloys

Fusible alloys Soldering Lead alloys