|

Micro-pulling-down

The micro-pulling-down (μ-PD) method is a crystal growth technique based on continuous transport of the melted substance through micro-channel(s) made in a crucible bottom. Continuous solidification of the melt is progressed on a liquid/solid interface positioned under the crucible. In a steady state, both the melt and the crystal are pulled-down with a constant (but generally different) velocity. Many different types of crystal are grown by this technique, including Y3Al5O12, Si, Si-Ge, LiNbO3, α-Al2O3, Y2O3, Sc2O3, LiF, CaF2, BaF2, etc. Crystal growth routine Standard routine procedure used in the growth of most of μ-PD crystals is well developed. The general stages of the growths include: * Charging of the crucible with starting materials (mixture of powders) * Heating of the crucible until starting materials in the crucible are completely melted * Upward displacement of the seed until its contact with the meniscus or crucible * Formation of the meniscus and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yttrium Aluminium Garnet

Yttrium aluminium garnet (YAG, Y3 Al5 O12) is a synthetic crystalline material of the garnet group. It is a cubic yttrium aluminium oxide phase, with other examples being YAlO3 (YAP) in a hexagonal or an orthorhombic, perovskite-like form, and the monoclinic Y4Al2O9 (YAM). Due to its broad optical transparency, low internal stress, high hardness, chemical and heat resistance, YAG is used for a variety of optics. Its lack of birefringence (unlike sapphire) makes it an interesting material for high-energy/high-power laser systems. Laser damage levels of YAG ranged from 1.1 to 2.2 kJ/cm² (1064 nm, 10 ns). YAG, like garnet and sapphire, has no uses as a laser medium when pure. However, after being doped with an appropriate ion, YAG is commonly used as a host material in various solid-state lasers. Rare earth elements such as neodymium and erbium can be doped into YAG as active laser ions, yielding Nd:YAG and Er:YAG lasers, respectively. Cerium-doped YAG (Ce:YAG ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lithium Niobate

Lithium niobate () is a non-naturally-occurring salt consisting of niobium, lithium, and oxygen. Its single crystals are an important material for optical waveguides, mobile phones, piezoelectric sensors, optical modulators and various other linear and non-linear optical applications. Lithium niobate is sometimes referred to by the brand name linobate. Properties Lithium niobate is a colorless solid, and it is insoluble in water. It has a trigonal crystal system, which lacks inversion symmetry and displays ferroelectricity, the Pockels effect, the piezoelectric effect, photoelasticity and nonlinear optical polarizability. Lithium niobate has negative uniaxial birefringence which depends slightly on the stoichiometry of the crystal and on temperature. It is transparent for wavelengths between 350 and 5200 nanometers. Lithium niobate can be doped by magnesium oxide, which increases its resistance to optical damage (also known as photorefractive damage) when doped above the op ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

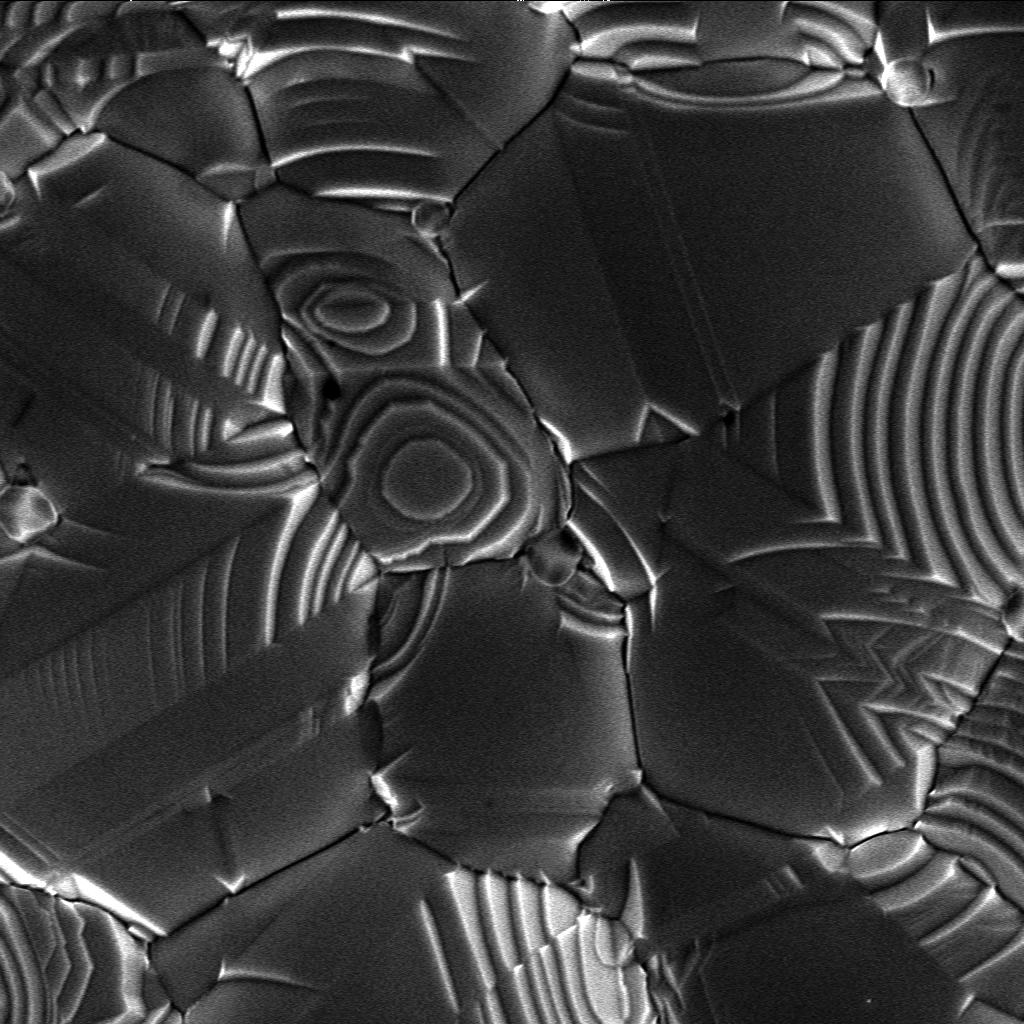

Crystal Growth

A crystal is a solid material whose constituent atoms, molecules, or ions are arranged in an orderly repeating pattern extending in all three spatial dimensions. Crystal growth is a major stage of a crystallization process, and consists of the addition of new atoms, ions, or polymer strings into the characteristic arrangement of the crystalline lattice. The growth typically follows an initial stage of either homogeneous or heterogeneous (surface catalyzed) nucleation, unless a "seed" crystal, purposely added to start the growth, was already present. The action of crystal growth yields a crystalline solid whose atoms or molecules are close packed, with fixed positions in space relative to each other. The crystalline state of matter is characterized by a distinct structural rigidity and very high resistance to deformation (i.e. changes of shape and/or volume). Most crystalline solids have high values both of Young's modulus and of the shear modulus of elasticity. This contras ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Growth

A crystal is a solid material whose constituent atoms, molecules, or ions are arranged in an orderly repeating pattern extending in all three spatial dimensions. Crystal growth is a major stage of a crystallization process, and consists of the addition of new atoms, ions, or polymer strings into the characteristic arrangement of the crystalline lattice. The growth typically follows an initial stage of either homogeneous or heterogeneous (surface catalyzed) nucleation, unless a "seed" crystal, purposely added to start the growth, was already present. The action of crystal growth yields a crystalline solid whose atoms or molecules are close packed, with fixed positions in space relative to each other. The crystalline state of matter is characterized by a distinct structural rigidity and very high resistance to deformation (i.e. changes of shape and/or volume). Most crystalline solids have high values both of Young's modulus and of the shear modulus of elasticity. This contras ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Growth

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuit (IC) chips such as modern computer processors, microcontrollers, and memory chips such as NAND flash and DRAM that are present in everyday electrical and electronic devices. It is a multiple-step sequence of photolithographic and chemical processing steps (such as surface passivation, thermal oxidation, planar diffusion and junction isolation) during which electronic circuits are gradually created on a wafer made of pure semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. The entire manufacturing process takes time, from start to packaged chips ready for shipment, at least six to eight weeks (tape-out only, not including the circuit design) and is performed in highly specialized semiconductor fabrication plants, also called foundries or fabs. All fabrication takes place inside a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Processes

Industrial processes are procedures involving chemical, physical, electrical or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry. Chemical processes by main basic material Certain chemical process yield important basic materials for society, e.g., (cement, steel, aluminum, and fertilizer). However, these chemical reactions contribute to climate change by emitting carbon dioxide, a greenhouse gas, through chemical reactions, as well as through the combustion of fossil fuels to generate the high temperatures needed to reach the activation energies of the chemical reactions. Cement (the paste within concrete) * Calcination – Limestone, which is largely composed of fossilized calcium carbonate (CaCO3), breaks down at high temperatures into useable calcium oxide (CaO) and carbon dioxide gas (), which gets released as a by-product. This chemical reaction, call ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Processes

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., without breaking chemical bonds. Chemical substances can be simple substances (substances consisting of a single chemical element), chemical compounds, or alloys. Chemical substances are often called 'pure' to set them apart from mixtures. A common example of a chemical substance is pure water; it has the same properties and the same ratio of hydrogen to oxygen whether it is isolated from a river or made in a laboratory. Other chemical substances commonly encountered in pure form are diamond (carbon), gold, table salt ( sodium chloride) and refined sugar ( sucrose). However, in practice, no substance is entirely pure, and chemical purity is specified according to the intended use of the chemical. Chemical substances exist as solids ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

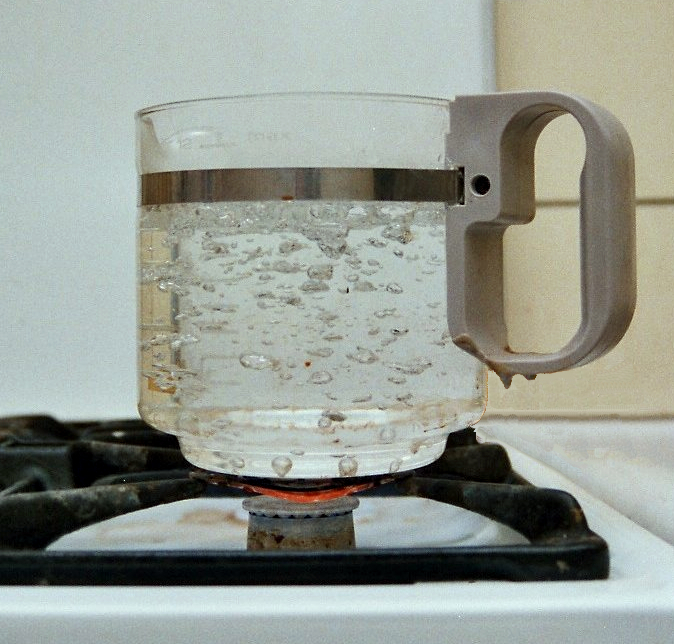

Verneuil Process

The Verneuil method (or Verneuil process or Verneuil technique), also called flame fusion, was the first commercially successful method of manufacturing synthetic gemstones, developed in the late 1883 by the French chemist Auguste Verneuil. It is primarily used to produce the ruby, sapphire and padparadscha varieties of corundum, as well as the diamond simulants rutile, strontium titanate and spinel. The principle of the process involves melting a finely powdered substance using an oxyhydrogen flame, and crystallising the melted droplets into a boule. The process is considered to be the founding step of modern industrial crystal growth technology, and remains in wide use to this day. History Since the study of alchemy began, there have been attempts to synthetically produce precious stones, and ruby, being one of the prized cardinal gems, has long been a prime candidate. In the 19th century, significant advances were achieved, with the first ruby formed by melting two smaller ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shaping Processes In Crystal Growth

Shaping processes in crystal growth are a collection of techniques for growing bulk crystals of a defined shape from a melt, usually by constraining the shape of the liquid meniscus by means of a mechanical shaper. Crystals are commonly grown as fibers, solid cylinders, hollow cylinders (or tubes), and sheets (or plates). More complex shapes such as tubes with a complex cross section, and domes have also been produced.Dobrovinskaya, Elena R., Leonid A. Lytvynov, and Valerian Pishchik. Sapphire: material, manufacturing, applications. Springer Science & Business Media, 2009. Using a shaping process can produce a near net shape crystal and reduce the manufacturing cost for crystals which are composed of very expensive or difficult to machine materials. List of shaping processes * Horizontal Ribbon Growth (HRG, 1959) *Edge-defined Film-fed Growth (EFG, 1960) *Low Angle Silicon Sheet (LASS, 1981) * Micro-pulling-down (µ-PD) * Stepanov technique * String ribbon Edge-defined film-f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser-heated Pedestal Growth

Laser-heated pedestal growth (LHPG) or laser floating zone (LFZ) is a crystal growth technique. A narrow region of a crystal is melted with a powerful CO2 or YAG laser. The laser and hence the floating zone, is moved along the crystal. The molten region melts impure solid at its forward edge and leaves a wake of purer material solidified behind it. This technique for growing crystals from the melt (liquid/solid phase transition) is used in materials research. Advantages The main advantages of this technique are the high pulling rates (60 times greater than the conventional Czochralski technique) and the possibility of growing materials with very high melting points. In addition, LHPG is a crucible-free technique, which allows single crystals to be grown with high purity and low stress. The geometric shape of the crystals (the technique can produce small diameters), and the low production cost, make the single-crystal fibers (SCF) produced by LHPG suitable substitutes for bulk c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flux Method

The flux method of crystal growth is a method where the components of the desired substance are dissolved in a solvent (flux). The method is particularly suitable for crystals needing to be free from thermal strain. It takes place in a crucible made of highly stable, non-reactive material. For production of oxide crystals, metals such as platinum, tantalum, and niobium are common. Production of metallic crystals generally uses crucibles made from ceramics such as alumina, zirconia, and boron nitride. The crucibles and their contents are often isolated from the air for reaction, either by sealing them in a quartz ampoule or by using a furnace with atmosphere control. A saturated solution is prepared by keeping the constituents of the desired crystal and the flux at a temperature slightly above the saturation temperature long enough to form a complete solution. Then the crucible is cooled in order to allow the desired material to precipitate. Crystal formation can begin by spontaneou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Float-zone Silicon

Float-zone silicon is very pure silicon obtained by vertical zone melting. The process was developed at Bell Labs by Henry Theuerer in 1955 as a modification of a method developed by William Gardner Pfann for germanium. In the vertical configuration molten silicon has sufficient surface tension to keep the charge from separating. The major advantages is crucibleless growth that prevents contamination of the silicon from the vessel itself and therefore an inherently high-purity alternative to boule crystals grown by the Czochralski method. The concentrations of light impurities, such as carbon (C) and oxygen (O2) elements, are extremely low. Another light impurity, nitrogen (N2), helps to control microdefects and also brings about an improvement in mechanical strength of the wafers, and is now being intentionally added during the growth stages. The diameters of float-zone wafers are generally not greater than 200 mm due to the surface tension limitations during growth. A polycry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |