Stirling engine on:

[Wikipedia]

[Google]

[Amazon]

A Stirling engine is a

A Stirling engine is a

Subsequent to the replacement of the Dundee foundry engine there is no record of the Stirling brothers having any further involvement with air engine development, and the Stirling engine never again competed with steam as an industrial scale power source. (Steam boilers were becoming safer and steam engines more efficient, thus presenting less of a target for rival prime movers). However, beginning about 1860, smaller engines of the Stirling/hot air type were produced in substantial numbers for applications in which reliable sources of low to medium power were required, such as pumping air for church organs or raising water.

These smaller engines generally operated at lower temperatures so as not to tax available materials, and so were relatively inefficient. Their selling point was that unlike steam engines, they could be operated safely by anybody capable of managing a fire. The 1906 Rider-Ericsson Engine Co. catalog claimed that "any gardener or ordinary domestic can operate these engines and no licensed or experienced engineer is required". Several types remained in production beyond the end of the century, but apart from a few minor mechanical improvements the design of the Stirling engine in general stagnated during this period.

Subsequent to the replacement of the Dundee foundry engine there is no record of the Stirling brothers having any further involvement with air engine development, and the Stirling engine never again competed with steam as an industrial scale power source. (Steam boilers were becoming safer and steam engines more efficient, thus presenting less of a target for rival prime movers). However, beginning about 1860, smaller engines of the Stirling/hot air type were produced in substantial numbers for applications in which reliable sources of low to medium power were required, such as pumping air for church organs or raising water.

These smaller engines generally operated at lower temperatures so as not to tax available materials, and so were relatively inefficient. Their selling point was that unlike steam engines, they could be operated safely by anybody capable of managing a fire. The 1906 Rider-Ericsson Engine Co. catalog claimed that "any gardener or ordinary domestic can operate these engines and no licensed or experienced engineer is required". Several types remained in production beyond the end of the century, but apart from a few minor mechanical improvements the design of the Stirling engine in general stagnated during this period.

During the early part of the 20th century, the role of the Stirling engine as a "domestic motor" was gradually taken over by

During the early part of the 20th century, the role of the Stirling engine as a "domestic motor" was gradually taken over by

Robert Stirling patented the first practical example of a closed-cycle hot air engine in 1816, and it was suggested by Fleeming Jenkin as early as 1884 that all such engines should therefore generically be called Stirling engines. This naming proposal found little favour, and the various types on the market continued to be known by the name of their individual designers or manufacturers, e.g., Rider's, Robinson's, or Heinrici's (hot) air engine. In the 1940s, the

Robert Stirling patented the first practical example of a closed-cycle hot air engine in 1816, and it was suggested by Fleeming Jenkin as early as 1884 that all such engines should therefore generically be called Stirling engines. This naming proposal found little favour, and the various types on the market continued to be known by the name of their individual designers or manufacturers, e.g., Rider's, Robinson's, or Heinrici's (hot) air engine. In the 1940s, the

The idealised Stirling cycle consists of four

The idealised Stirling cycle consists of four

As a consequence of closed-cycle operation, the heat driving a Stirling engine must be transmitted from a heat source to the working fluid by

As a consequence of closed-cycle operation, the heat driving a Stirling engine must be transmitted from a heat source to the working fluid by

The heat source may be provided by the

The heat source may be provided by the

Other Stirling configurations continue to interest engineers and inventors.

* The rotary Stirling engine seeks to convert power from the Stirling cycle directly into torque, similar to the rotary combustion engine. No practical engine has yet been built but a number of concepts, models and patents have been produced, such as the Quasiturbine engine.

* A hybrid between piston and rotary configuration is a double-acting engine. This design rotates the displacers on either side of the power piston. In addition to giving great design variability in the heat transfer area, this layout eliminates all but one external seal on the output shaft and one internal seal on the piston. Also, both sides can be highly pressurized as they balance against each other.

* Another alternative is the Fluidyne engine (or Fluidyne heat pump), which uses hydraulic pistons to implement the

Other Stirling configurations continue to interest engineers and inventors.

* The rotary Stirling engine seeks to convert power from the Stirling cycle directly into torque, similar to the rotary combustion engine. No practical engine has yet been built but a number of concepts, models and patents have been produced, such as the Quasiturbine engine.

* A hybrid between piston and rotary configuration is a double-acting engine. This design rotates the displacers on either side of the power piston. In addition to giving great design variability in the heat transfer area, this layout eliminates all but one external seal on the output shaft and one internal seal on the piston. Also, both sides can be highly pressurized as they balance against each other.

* Another alternative is the Fluidyne engine (or Fluidyne heat pump), which uses hydraulic pistons to implement the

Free-piston Stirling engines include those with liquid pistons and those with diaphragms as pistons. In a free-piston device, energy may be added or removed by an electrical linear alternator,

Free-piston Stirling engines include those with liquid pistons and those with diaphragms as pistons. In a free-piston device, energy may be added or removed by an electrical linear alternator,

Design of the flat double-acting Stirling engine solves the drive of a displacer with the help of the fact that areas of the hot and cold pistons of the displacer are different.

The drive does so without any mechanical transmission. Using diaphragms eliminates friction and need for lubricants.

When the displacer is in motion, the generator holds the working piston in the limit position, which brings the engine working cycle close to an ideal Stirling cycle. The ratio of the area of the heat exchangers to the volume of the machine increases by the implementation of a flat design.

Flat design of the working cylinder approximates thermal process of the expansion and compression closer to the isothermal one.

The disadvantage is a large area of the thermal insulation between the hot and cold space.

Design of the flat double-acting Stirling engine solves the drive of a displacer with the help of the fact that areas of the hot and cold pistons of the displacer are different.

The drive does so without any mechanical transmission. Using diaphragms eliminates friction and need for lubricants.

When the displacer is in motion, the generator holds the working piston in the limit position, which brings the engine working cycle close to an ideal Stirling cycle. The ratio of the area of the heat exchangers to the volume of the machine increases by the implementation of a flat design.

Flat design of the working cylinder approximates thermal process of the expansion and compression closer to the isothermal one.

The disadvantage is a large area of the thermal insulation between the hot and cold space.

At high temperatures and pressures, the oxygen in air-pressurized crankcases, or in the working gas of hot air engines, can combine with the engine's lubricating oil and explode. At least one person has died in such an explosion. Lubricants can also clog heat exchangers, especially the regenerator. For these reasons, designers prefer non-lubricated, low- coefficient of friction materials (such as rulon or

At high temperatures and pressures, the oxygen in air-pressurized crankcases, or in the working gas of hot air engines, can combine with the engine's lubricating oil and explode. At least one person has died in such an explosion. Lubricants can also clog heat exchangers, especially the regenerator. For these reasons, designers prefer non-lubricated, low- coefficient of friction materials (such as rulon or

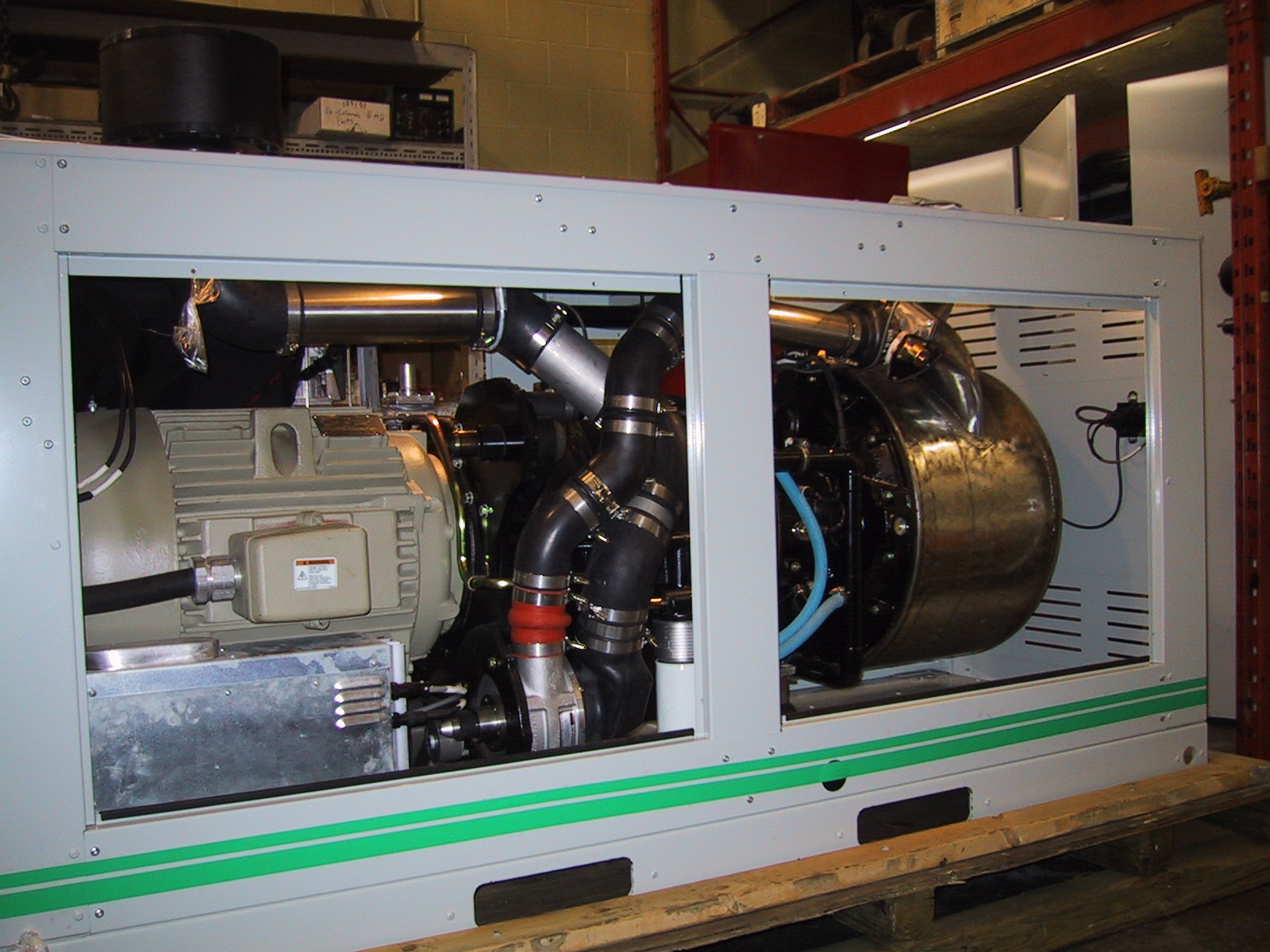

Applications of the Stirling engine range from heating and cooling to underwater power systems. A Stirling engine can function in reverse as a heat pump for heating or cooling. Other uses include combined heat and power, solar power generation, Stirling cryocoolers, heat pump, marine engines, low power model aircraft engines, and low temperature difference engines.

Applications of the Stirling engine range from heating and cooling to underwater power systems. A Stirling engine can function in reverse as a heat pump for heating or cooling. Other uses include combined heat and power, solar power generation, Stirling cryocoolers, heat pump, marine engines, low power model aircraft engines, and low temperature difference engines.

US patent 3548589

''. Granted to Atomic Energy Authority UK, 22 December 1970. * E.H. Cooke-Yarborough (1967). "A Proposal for a Heat-Powered Nonrotating Electrical Alternator", ''Harwell Memorandum AERE-M881''. * * * *

US patent 3552120

''. Granted to Research Corp, 5 January 1971. * * R.C. Belaire (1977). "Device for decreasing the start-up time for stirling engines",

US patent 4057962

'. Granted to Ford Motor Company, 15 November 1977. * * * * * C.D. West (1970). "Hydraulic Heat Engines", ''Harwell Momorandum AERE-R6522''. * * * * * * * * * * * * *

How Stirling Engines Work

(

How Beta-type Stirling Engines Work

(

Stirling Cycle Machine Analysis by Israel Urieli

* How to build your Stirling engine (2017)

Inquiry into the Hot Air Engines of the 19th Century

{{Authority control Articles containing video clips Cooling technology External combustion engines Heat pumps Hot air engines Piston engines Scottish inventions

A Stirling engine is a

A Stirling engine is a heat engine

A heat engine is a system that transfers thermal energy to do mechanical or electrical work. While originally conceived in the context of mechanical energy, the concept of the heat engine has been applied to various other kinds of energy, pa ...

that is operated by the cyclic expansion and contraction of air or other gas (the '' working fluid'') by exposing it to different temperatures, resulting in a net conversion of heat

In thermodynamics, heat is energy in transfer between a thermodynamic system and its surroundings by such mechanisms as thermal conduction, electromagnetic radiation, and friction, which are microscopic in nature, involving sub-atomic, ato ...

energy to mechanical work.

More specifically, the Stirling engine is a closed-cycle regenerative heat engine, with a permanent gaseous working fluid. ''Closed-cycle'', in this context, means a thermodynamic system

A thermodynamic system is a body of matter and/or radiation separate from its surroundings that can be studied using the laws of thermodynamics.

Thermodynamic systems can be passive and active according to internal processes. According to inter ...

in which the working fluid is permanently contained within the system. ''Regenerative'' describes the use of a specific type of internal heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contac ...

and thermal store, known as the ''regenerator''. Strictly speaking, the inclusion of the regenerator is what differentiates a Stirling engine from other closed-cycle hot air engines.

In the Stirling engine, a working fluid (e.g. air) is heated by energy supplied from outside the engine's interior space (cylinder). As the fluid expands, mechanical work is extracted by a piston, which is coupled to a displacer. The displacer moves the working fluid to a different location within the engine, where it is cooled, which creates a partial vacuum at the working cylinder, and more mechanical work is extracted. The displacer moves the cooled fluid back to the hot part of the engine, and the cycle continues.

A unique feature is the regenerator, which acts as a temporary heat store by retaining heat within the machine rather than dumping it into the heat sink, thereby increasing its efficiency.

The heat is supplied from the outside, so the hot area of the engine can be warmed with any external heat source. Similarly, the cooler part of the engine can be maintained by an external heat sink, such as running water or air flow. The gas is permanently retained in the engine, allowing a gas with the most-suitable properties to be used, such as helium or hydrogen. There are no intake and no exhaust gas flows so the machine is practically silent.

The machine is reversible so that if the shaft is turned by an external power source a temperature difference will develop across the machine; in this way it acts as a heat pump

A heat pump is a device that uses electricity to transfer heat from a colder place to a warmer place. Specifically, the heat pump transfers thermal energy using a heat pump and refrigeration cycle, cooling the cool space and warming the warm s ...

.

The Stirling engine was invented by Scotsman Robert Stirling in 1816 as an industrial prime mover to rival the steam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

, and its practical use was largely confined to low-power domestic applications for over a century.

Contemporary investment in renewable energy, especially solar energy

Solar energy is the radiant energy from the Sun's sunlight, light and heat, which can be harnessed using a range of technologies such as solar electricity, solar thermal energy (including solar water heating) and solar architecture. It is a ...

, has given rise to its application within concentrated solar power and as a heat pump.

History

Early hot air engines

Robert Stirling is considered one of the fathers of hot air engines, along with earlier innovators such as Guillaume Amontons, who built the first working hot air engine in 1699. Amontons was later followed by SirGeorge Cayley

Sir George Cayley, 6th Baronet (27 December 1773 – 15 December 1857) was an English engineer, inventor, and aviator. He is one of the most important people in the history of aeronautics. Many consider him to be the first true scientific ...

. This engine type was of those in which the fire is enclosed, and fed by air pumped in beneath the grate in sufficient quantity to maintain combustion, while by far the largest portion of the air enters above the fire, to be heated and expanded; the whole, together with the products of combustion, then acts on the piston, and passes through the working cylinder; and the operation being one of simple mixture only, no heating surface of metal is required, the air to be heated being brought into immediate contact with the fire.

Stirling came up with a first air engine in 1816. The principle of the Stirling Air Engine differs from that of Sir George Cayley

Sir George Cayley, 6th Baronet (27 December 1773 – 15 December 1857) was an English engineer, inventor, and aviator. He is one of the most important people in the history of aeronautics. Many consider him to be the first true scientific ...

(1807), in which the air is forced through the furnace and exhausted, whereas in Stirling's engine the air works in a closed circuit. The inventor devoted most of his attention to that.

A engine, built in 1818 for pumping water at an Ayrshire quarry, continued to work for some time until a careless attendant allowed the heater to overheat. This experiment proved to the inventor that, owing to the low working pressure obtainable, the engine could only be adapted to low power for which there was, at that time, no demand.

The Stirling 1816 patent was also about an " economiser," which is the predecessor of the regenerator. In this patent (# 4081) he describes the "economiser" technology and several applications where such technology can be used. Out of them came a new arrangement for a hot air engine.

With his brother James, Stirling patented a second hot air engine in 1827. They inverted the design so that the hot ends of the displacers were underneath the machinery, and they added a compressed air pump so the air within could be pressurised to around .

The Stirling brothers were followed shortly after (1828) by Parkinson & Crossley and Arnott in 1829.

These precursors, including Ericsson, have brought to the world the hot air engine technology and its enormous advantages over the steam engine. Each came with his own specific technology, and although the Stirling engine and the Parkinson & Crossley engines were quite similar, Robert Stirling distinguished himself by inventing the regenerator.

Parkinson and Crossley introduced the principle of using air of greater density than that of the atmosphere and so obtained an engine of greater power in the same compass. James Stirling followed this same idea when he built the famous Dundee engine.

The Stirling patent of 1827 was the base of the Stirling third patent of 1840. The changes from the 1827 patent were minor but essential, and this third patent led to the Dundee engine.

James Stirling presented his engine to the Institution of Civil Engineers in 1845, the first engine of this kind which, after various modifications, was efficiently constructed and heated, had a cylinder of in diameter, with a length of stroke of , and made 40 strokes or revolutions in a minute (40 rpm). This engine moved all the machinery at the Dundee Foundry Company's works for eight or ten months, and was previously found capable of raising 320,000 kg (700,000 lbs) 60 cm (2 ft) in a minute, a power of approximately .

Finding this power insufficient for their works, the Dundee Foundry Company erected the second engine with a cylinder of in diameter, a stroke of , and making 28 strokes in a minute. When this engine had been in continuous operation for over two years it had not only performed the work of the foundry in the most satisfactory manner but had been tested (by a friction brake on a third mover) to the extent of lifting nearly , approximately .

Invention and early development

The Stirling engine (or Stirling's air engine as it was known at the time) was invented and patented in 1816. It followed earlier attempts at making an air engine but was probably the first put to practical use when, in 1818, an engine built by Stirling was employed pumping water in aquarry

A quarry is a type of open-pit mining, open-pit mine in which dimension stone, rock (geology), rock, construction aggregate, riprap, sand, gravel, or slate is excavated from the ground. The operation of quarries is regulated in some juri ...

. The main subject of Stirling's original patent was a heat exchanger, which he called an " economiser" for its enhancement of fuel economy in a variety of applications. The patent also described in detail the employment of one form of the economiser in his unique closed-cycle air engine design in which application it is now generally known as a " regenerator". Subsequent development by Robert Stirling and his brother James, an engineer, resulted in patents for various improved configurations of the original engine including pressurization, which by 1843, had sufficiently increased power output to drive all the machinery at a Dundee

Dundee (; ; or , ) is the List of towns and cities in Scotland by population, fourth-largest city in Scotland. The mid-year population estimate for the locality was . It lies within the eastern central Lowlands on the north bank of the Firt ...

iron foundry.

A paper presented by James Stirling in June 1845 to the Institution of Civil Engineers

The Institution of Civil Engineers (ICE) is an independent professional association for civil engineers and a Charitable organization, charitable body in the United Kingdom. Based in London, ICE has over 92,000 members, of whom three-quarters ar ...

stated that his aims were not only to save fuel but also to create a safer alternative to the steam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

s of the time, whose boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centra ...

s frequently exploded, causing many injuries and fatalities. This has, however, been disputed.

The need for Stirling engines to run at very high temperatures to maximize power and efficiency exposed limitations in the materials of the day, and the few engines that were built in those early years suffered unacceptably frequent failures (albeit with far less disastrous consequences than boiler explosions). For example, the Dundee foundry engine was replaced by a steam engine after three hot cylinder failures in four years.

Later 19th century

Subsequent to the replacement of the Dundee foundry engine there is no record of the Stirling brothers having any further involvement with air engine development, and the Stirling engine never again competed with steam as an industrial scale power source. (Steam boilers were becoming safer and steam engines more efficient, thus presenting less of a target for rival prime movers). However, beginning about 1860, smaller engines of the Stirling/hot air type were produced in substantial numbers for applications in which reliable sources of low to medium power were required, such as pumping air for church organs or raising water.

These smaller engines generally operated at lower temperatures so as not to tax available materials, and so were relatively inefficient. Their selling point was that unlike steam engines, they could be operated safely by anybody capable of managing a fire. The 1906 Rider-Ericsson Engine Co. catalog claimed that "any gardener or ordinary domestic can operate these engines and no licensed or experienced engineer is required". Several types remained in production beyond the end of the century, but apart from a few minor mechanical improvements the design of the Stirling engine in general stagnated during this period.

Subsequent to the replacement of the Dundee foundry engine there is no record of the Stirling brothers having any further involvement with air engine development, and the Stirling engine never again competed with steam as an industrial scale power source. (Steam boilers were becoming safer and steam engines more efficient, thus presenting less of a target for rival prime movers). However, beginning about 1860, smaller engines of the Stirling/hot air type were produced in substantial numbers for applications in which reliable sources of low to medium power were required, such as pumping air for church organs or raising water.

These smaller engines generally operated at lower temperatures so as not to tax available materials, and so were relatively inefficient. Their selling point was that unlike steam engines, they could be operated safely by anybody capable of managing a fire. The 1906 Rider-Ericsson Engine Co. catalog claimed that "any gardener or ordinary domestic can operate these engines and no licensed or experienced engineer is required". Several types remained in production beyond the end of the century, but apart from a few minor mechanical improvements the design of the Stirling engine in general stagnated during this period.

20th-century revival

electric motor

An electric motor is a machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a electromagnetic coil, wire winding to gene ...

s and small internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

s. By the late 1930s, it was largely forgotten, only produced for toys and a few small ventilating fans.

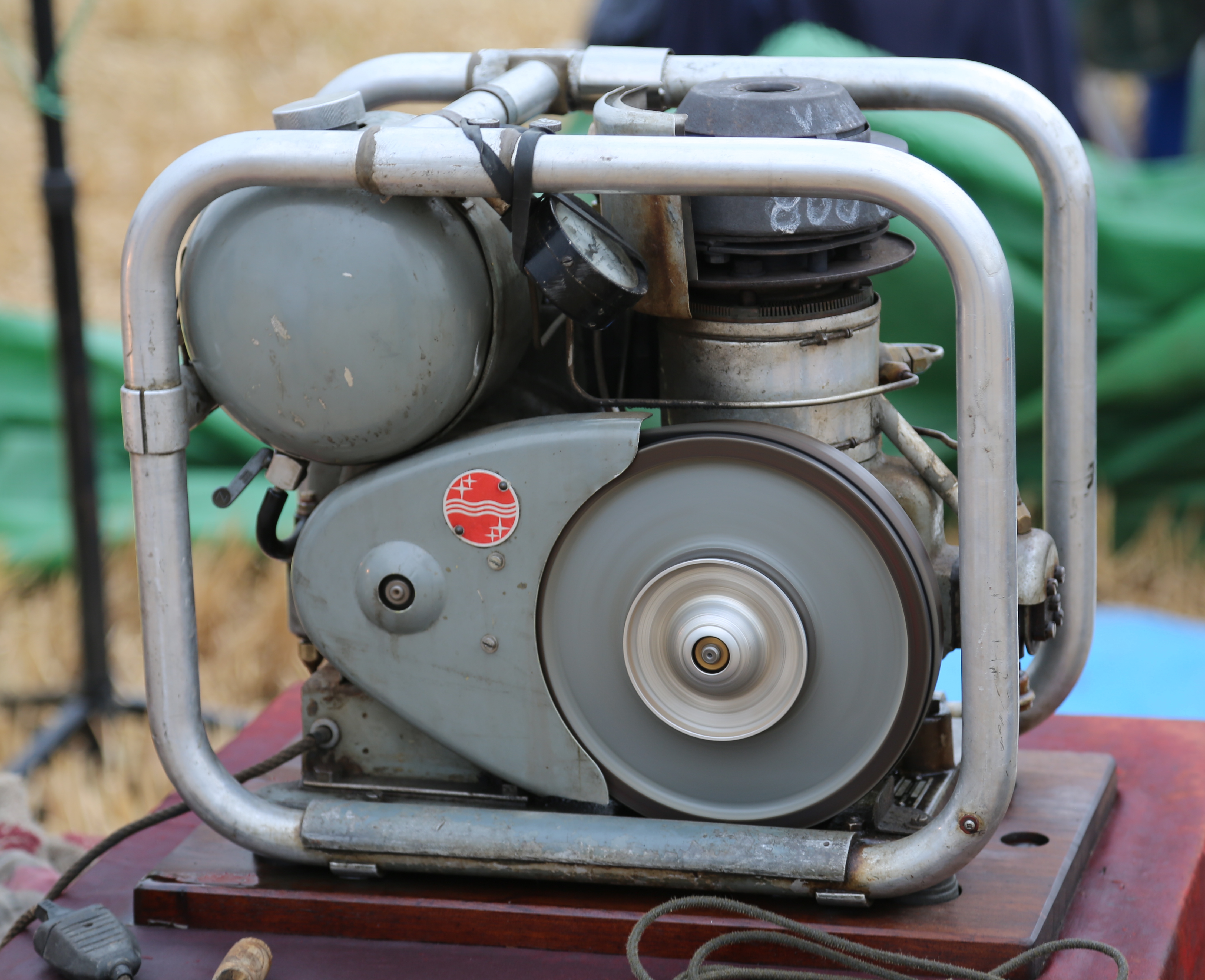

Philips MP1002CA

Around that time,Philips

Koninklijke Philips N.V. (), simply branded Philips, is a Dutch multinational health technology company that was founded in Eindhoven in 1891. Since 1997, its world headquarters have been situated in Amsterdam, though the Benelux headquarter ...

was seeking to expand sales of its radios into parts of the world where grid electricity and batteries were not consistently available. Philips' management decided that offering a low-power portable generator would facilitate such sales and asked a group of engineers at the company's research lab in Eindhoven

Eindhoven ( ; ) is a city and List of municipalities of the Netherlands, municipality of the Netherlands, located in the southern Provinces of the Netherlands, province of North Brabant, of which it is the largest municipality, and is also locat ...

to evaluate alternative ways of achieving this aim. After a systematic comparison of various prime movers, the team decided to go forward with the Stirling engine, citing its quiet operation (both audibly and in terms of radio interference) and ability to run on a variety of heat sources (common lamp oil – "cheap and available everywhere" – was favored). They were also aware that, unlike steam and internal combustion engines, virtually no serious development work had been carried out on the Stirling engine for many years and asserted that modern materials and know-how should enable great improvements.

By 1951, the 180/200 W generator set designated MP1002CA (known as the "Bungalow set") was ready for production and an initial batch of 250 was planned, but soon it became clear that they could not be made at a competitive price. Additionally, the advent of transistor radios and their much lower power requirements meant that the original reason for the set was disappearing. Approximately 150 of these sets were eventually produced. Some found their way into university and college engineering departments around the world, giving generations of students a valuable introduction to the Stirling engine; a letter dated March 1961 from Research and Control Instruments Ltd. London WC1 to North Devon Technical College, offering "remaining stocks... to institutions such as yourselves... at a special price of £75 net".

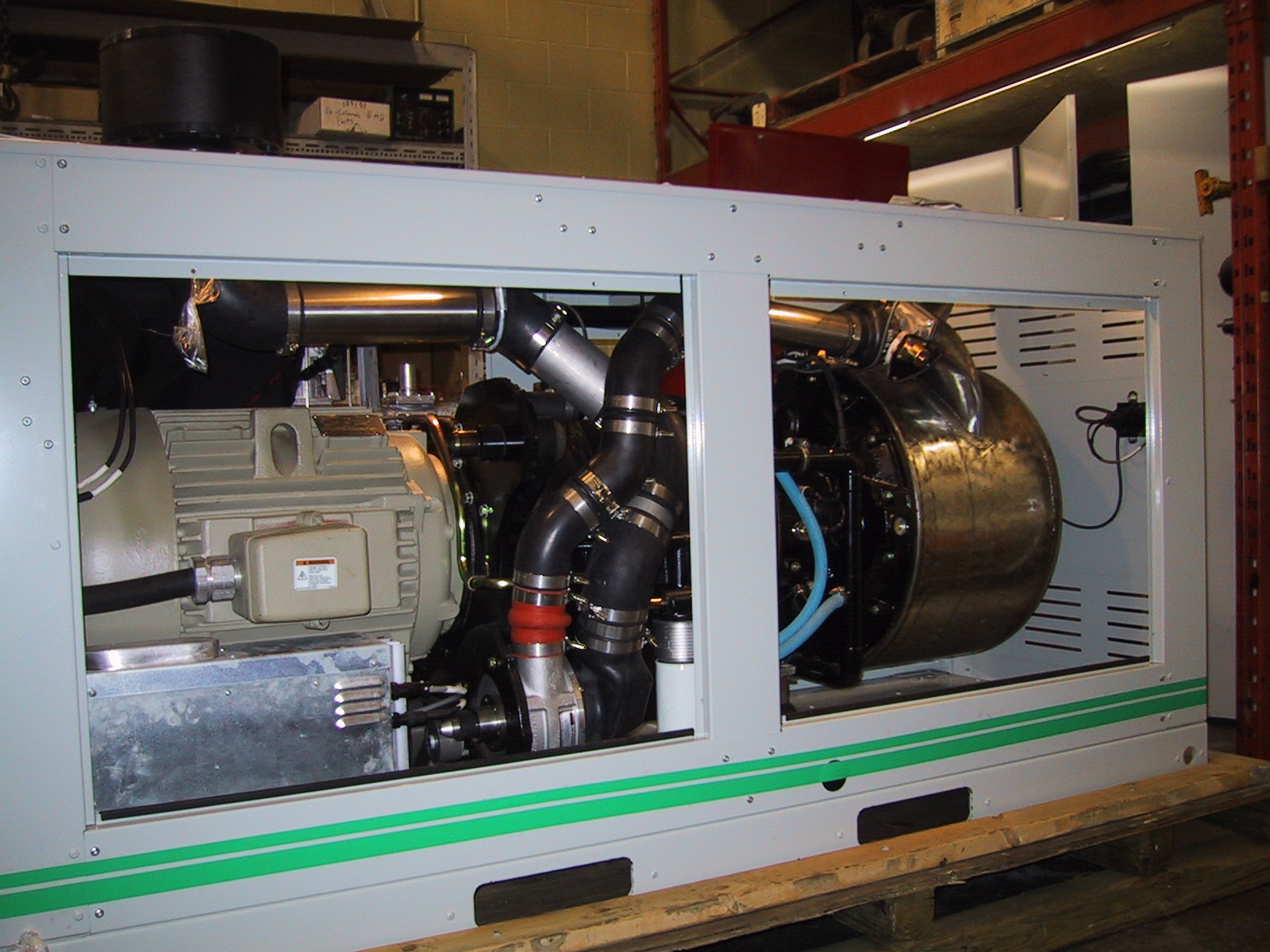

In parallel with the Bungalow set, Philips developed experimental Stirling engines for a wide variety of applications and continued to work in the field until the late 1970s, but only achieved commercial success with the "reversed Stirling engine" cryocooler

A cryocooler is a refrigerator designed to reach cryogenic temperatures (below 120 K, -153 °C, -243.4 °F). The term is most often used for smaller systems, typically table-top size, with input powers less than about 20 kW. Some can have inpu ...

. They filed a large number of patents and amassed a wealth of information which they licensed to other companies and which formed the basis of much of the development work in the modern era.

Submarine use

In 1996, the Swedish navy commissioned three Gotland-class submarines. On the surface, these boats are propelled by marine diesel engines; however, when submerged they use a Stirling-driven generator developed by Swedish shipbuilder Kockums to recharge batteries and provide electrical power for propulsion. A supply of liquid oxygen is carried to support burning of diesel fuel to power the engine. Stirling engines are also fitted to Swedish Södermanland-class submarines, the Archer-class submarines in service in Singapore, and the Japanese Sōryū-class submarines, with the engines license-built by Kawasaki Heavy Industries. In a submarine application, the Stirling engine offers the advantage of being exceptionally quiet when running.21st-century developments

By the turn of the 21st century, Stirling engines were used in the dish version of Concentrated Solar Power systems. A mirrored dish similar to a very large satellite dish directs and concentrates sunlight onto a thermal receiver, which absorbs and collects the heat and using a fluid transfers it into the Stirling engine. The resulting mechanical power is then used to run a generator or alternator to produce electricity. The core component of micro combined heat and power (CHP) units can be formed by a Stirling cycle engine, as they are more efficient and safer than a comparable steam engine. By 2003, CHP units were being commercially installed in domestic applications, such as home electrical generators. In 2013, an article was published about scaling laws of free-piston Stirling engines based on six characteristic dimensionless groups.Name and classification

Philips

Koninklijke Philips N.V. (), simply branded Philips, is a Dutch multinational health technology company that was founded in Eindhoven in 1891. Since 1997, its world headquarters have been situated in Amsterdam, though the Benelux headquarter ...

company was seeking a suitable name for its own version of the 'air engine', which by that time had been tested with working fluids other than air, and decided upon 'Stirling engine' in April 1945. However, nearly thirty years later, Graham Walker still had cause to bemoan the fact such terms as ''hot air engine'' remained interchangeable with ''Stirling engine'', which itself was applied widely and indiscriminately, a situation that continues.

Like the steam engine, the Stirling engine is traditionally classified as an external combustion engine

An external combustion engine (EC engine) is a Reciprocating engine, reciprocating heat engine where a working fluid, contained internally, is heated by combustion in an external source, through the engine wall or a heat exchanger. The fluid t ...

, as all heat transfers to and from the working fluid take place through a solid boundary (heat exchanger) thus isolating the combustion process and any contaminants it may produce from the working parts of the engine. This contrasts with an internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

, where heat input is by combustion of a fuel within the body of the working fluid. Most of the many possible implementations of the Stirling engine fall into the category of reciprocating piston engine.

Theory

thermodynamic processes

Classical thermodynamics considers three main kinds of thermodynamic processes: (1) changes in a system, (2) cycles in a system, and (3) flow processes.

(1) A Thermodynamic process is a process in which the thermodynamic state of a system is c ...

acting on the working fluid:

# Isothermal expansion. The expansion-space and associated heat exchanger are maintained at a constant high temperature, and the gas undergoes near-isothermal expansion absorbing heat from the hot source.

# Constant-volume (known as isovolumetric or isochoric) heat-removal. The gas is passed through the regenerator, where it cools, transferring heat to the regenerator for use in the next cycle.

# Isothermal compression. The compression space and associated heat exchanger are maintained at a constant low temperature so the gas undergoes near-isothermal compression rejecting heat to the cold sink

# Constant-volume (known as isovolumetric or isochoric) heat-addition. The gas passes back through the regenerator where it recovers much of the heat transferred in process 2, heating up on its way to the expansion space.

With the ideal, maximally efficient, Stirling engine, for the thermal reservoirs the ratio of the heat in to the heat out is the efficiency of the ideal Carnot cycle. This is the Carnot efficiency, which is the ratio of the Kelvin temperatures of the cold to the hot reservoir. With the ideal, maximally efficient, Carnot cycle, the isochores (constant volume) are replaced by adiabats (no net heat transfer because no heat transfer). For the ideal Stirling cycle, whatever heat enters during the isochoric leg where the temperature increases is totally released during the isochoric leg where the temperature decreases (no net heat transfer).

The engine is designed so the working gas is generally compressed in the colder portion of the engine and expanded in the hotter portion resulting in a net conversion of heat into work. An internal regenerative heat exchanger increases the Stirling engine's thermal efficiency compared to simpler hot air engines lacking this feature.

The Stirling engine uses the temperature difference between its hot end and cold end to establish a cycle of a fixed mass of gas, heated and expanded, and cooled and compressed, thus converting thermal energy

Energy () is the physical quantity, quantitative physical property, property that is transferred to a physical body, body or to a physical system, recognizable in the performance of Work (thermodynamics), work and in the form of heat and l ...

into mechanical energy. The greater the temperature difference between the hot and cold sources, the greater the thermal efficiency. The maximum theoretical efficiency is equivalent to that of the Carnot cycle, but the efficiency of real engines is less than this value because of friction and other losses.

Since the Stirling engine is a closed cycle, it contains a fixed mass of gas called the "working fluid", most commonly air, hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

or helium

Helium (from ) is a chemical element; it has chemical symbol, symbol He and atomic number 2. It is a colorless, odorless, non-toxic, inert gas, inert, monatomic gas and the first in the noble gas group in the periodic table. Its boiling point is ...

. In normal operation, the engine is sealed and no gas enters or leaves; no valves are required, unlike other types of piston engines. The Stirling engine, like most heat engines, cycles through four main processes: cooling, compression, heating, and expansion. This is accomplished by moving the gas back and forth between hot and cold heat exchangers, often with a regenerator between the heater and cooler. The hot heat exchanger is in thermal contact with an external heat source, such as a fuel burner, and the cold heat exchanger is in thermal contact with an external heat sink, such as air fins. A change in gas temperature causes a corresponding change in gas pressure, while the motion of the piston makes the gas alternately expand and compress.

The gas follows the behaviour described by the gas laws that describe how a gas's pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and eve ...

, temperature

Temperature is a physical quantity that quantitatively expresses the attribute of hotness or coldness. Temperature is measurement, measured with a thermometer. It reflects the average kinetic energy of the vibrating and colliding atoms making ...

, and volume

Volume is a measure of regions in three-dimensional space. It is often quantified numerically using SI derived units (such as the cubic metre and litre) or by various imperial or US customary units (such as the gallon, quart, cubic inch) ...

are related. When the gas is heated, the pressure rises (because it is in a sealed chamber) and this pressure then acts on the power piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder (engine), cylinder a ...

to produce a power stroke. When the gas is cooled the pressure drops and this drop means that the piston needs to do less work to compress the gas on the return stroke. The difference in work between the strokes yields a net positive power output.

When one side of the piston is open to the atmosphere, the operation is slightly different. As the sealed volume of working gas comes in contact with the hot side, it expands, doing work on both the piston and on the atmosphere. When the working gas contacts the cold side, its pressure drops below atmospheric pressure and the atmosphere pushes on the piston and does work on the gas.

Components

heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contac ...

s and finally to a heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is thermal management (electronics), ...

. A Stirling engine system has at least one heat source, one heat sink and up to five heat exchangers. Some types may combine or dispense with some of these.

Heat source

The heat source may be provided by the

The heat source may be provided by the combustion

Combustion, or burning, is a high-temperature exothermic redox chemical reaction between a fuel (the reductant) and an oxidant, usually atmospheric oxygen, that produces oxidized, often gaseous products, in a mixture termed as smoke. Combustion ...

of a fuel and, since the combustion products do not mix with the working fluid and hence do not come into contact with the internal parts of the engine, a Stirling engine can run on fuels that would damage other engine types' internals, such as landfill gas, which may contain siloxane that could deposit abrasive silicon dioxide

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundan ...

in conventional engines.

Other suitable heat sources include concentrated solar energy, geothermal energy

Geothermal energy is thermal energy extracted from the crust (geology), crust. It combines energy from the formation of the planet and from radioactive decay. Geothermal energy has been exploited as a source of heat and/or electric power for m ...

, nuclear energy

Nuclear energy may refer to:

*Nuclear power, the use of sustained nuclear fission or nuclear fusion to generate heat and electricity

*Nuclear binding energy, the energy needed to fuse or split a nucleus of an atom

*Nuclear potential energy, the pot ...

, waste heat and bioenergy

Bioenergy is a type of renewable energy that is derived from plants and animal waste. The Biomass (energy), biomass that is used as input materials consists of recently living (but now dead) organisms, mainly plants. Thus, Fossil fuel, fossil fu ...

. If solar power is used as a heat source, regular solar mirrors and solar dishes may be utilised. The use of Fresnel lens

A Fresnel lens ( ; ; or ) is a type of composite compact lens (optics), lens which reduces the amount of material required compared to a conventional lens by dividing the lens into a set of concentric annular sections.

The simpler Dioptrics, d ...

es and mirrors has also been advocated, for example in planetary surface exploration. Solar powered Stirling engines are increasingly popular as they offer an environmentally sound option for producing power while some designs are economically attractive in development projects.

Heat exchangers

Designing Stirling engine heat exchangers is a balance between high heat transfer with low viscous pumping losses, and low dead space (unswept internal volume). Engines that operate at high powers and pressures require that heat exchangers on the hot side be made of alloys that retain considerable strength at high temperatures and that don't corrode or creep. In small, low power engines the heat exchangers may simply consist of the walls of the respective hot and cold chambers, but where larger powers are required a greater surface area is needed to transfer sufficient heat. Typical implementations are internal and external fins or multiple small bore tubes for the hot side, and a cooler using a liquid (like water) for the cool side.Regenerator

In a Stirling engine, the regenerator is an internal heat exchanger and temporary heat store placed between the hot and cold spaces such that the working fluid passes through it first in one direction then the other, taking heat from the fluid in one direction, and returning it in the other. It can be as simple as metal mesh or foam, and benefits from high surface area, high heat capacity, low conductivity and low flow friction. Its function is to retain within thesystem

A system is a group of interacting or interrelated elements that act according to a set of rules to form a unified whole. A system, surrounded and influenced by its open system (systems theory), environment, is described by its boundaries, str ...

that heat which would otherwise be exchanged with the environment at temperatures intermediate to the maximum and minimum cycle temperatures, thus enabling the thermal efficiency of the cycle (though not of any practical engine) to approach the limiting Carnot efficiency.

The primary effect of regeneration in a Stirling engine is to increase the thermal efficiency by 'recycling' internal heat which would otherwise pass through the engine irreversibly. As a secondary effect, increased thermal efficiency yields a higher power output from a given set of hot and cold end heat exchangers. These usually limit the engine's heat throughput. In practice this additional power may not be fully realized as the additional "dead space" (unswept volume) and pumping loss inherent in practical regenerators reduces the potential efficiency gains from regeneration.

The design challenge for a Stirling engine regenerator is to provide sufficient heat transfer capacity without introducing too much additional internal volume ('dead space') or flow resistance. These inherent design conflicts are one of many factors that limit the efficiency of practical Stirling engines. A typical design is a stack of fine metal wire

file:Sample cross-section of high tension power (pylon) line.jpg, Overhead power cabling. The conductor consists of seven strands of steel (centre, high tensile strength), surrounded by four outer layers of aluminium (high conductivity). Sample d ...

meshes, with low porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

to reduce dead space, and with the wire axes perpendicular

In geometry, two geometric objects are perpendicular if they intersect at right angles, i.e. at an angle of 90 degrees or π/2 radians. The condition of perpendicularity may be represented graphically using the '' perpendicular symbol'', � ...

to the gas flow to reduce conduction in that direction and to maximize convective heat transfer.

The regenerator is the key component invented by Robert Stirling, and its presence distinguishes a true Stirling engine from any other closed-cycle hot air engine. Many small 'toy' Stirling engines, particularly low-temperature difference (LTD) types, do not have a distinct regenerator component and might be considered hot air engines; however, a small amount of regeneration is provided by the surface of the displacer itself and the nearby cylinder wall, or similarly the passage connecting the hot and cold cylinders of an alpha configuration engine.

Heat sink

The larger the temperature difference between the hot and cold sections of a Stirling engine, the greater the engine's efficiency. The heat sink is typically the environment the engine operates in, at ambient temperature. In the case of medium- to high-power engines, aradiator

A radiator is a heat exchanger used to transfer thermal energy from one medium to another for the purpose of cooling and heating. The majority of radiators are constructed to function in cars, buildings, and electronics.

A radiator is always a ...

is required to transfer the heat from the engine to the ambient air. Marine engines have the advantage of using cool ambient sea, lake, or river water, which is typically cooler than ambient air. In the case of combined heat and power systems, the engine's cooling water is used directly or indirectly for heating purposes, raising efficiency.

Alternatively, heat may be supplied at ambient temperature and the heat sink maintained at a lower temperature by such means as cryogenic fluid (see Liquid nitrogen economy

A liquid nitrogen engine is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized ...

) or iced water.

Displacer

The displacer is a special-purposepiston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder (engine), cylinder a ...

, used in Beta and Gamma type Stirling engines, to move the working gas back and forth between the hot and cold heat exchangers. Depending on the type of engine design, the displacer may or may not be sealed to the cylinder; i.e., it may be a loose fit within the cylinder, allowing the working gas to pass around it as it moves to occupy the part of the cylinder beyond. The Alpha type engine has a high stress on the hot side, that's why so few inventors started to use a hybrid piston for that side. The hybrid piston has a sealed part as a normal Alpha type engine, but it has a connected displacer part with smaller diameter as the cylinder around that. The compression ratio is a bit smaller than in the original Alpha type engines, but the stress factor is pretty low on the sealed parts.

Configurations

The three major types of Stirling engines are distinguished by the way they move the air between the hot and cold areas: # The ''alpha'' configuration has two power pistons, one in a hot cylinder, one in a cold cylinder, and the gas is driven between the two by the pistons; it is typically in a V-formation with the pistons joined at the same point on a crankshaft. # The ''beta'' configuration has a single cylinder with a hot end and a cold end, containing a power piston and a 'displacer' that drives the gas between the hot and cold ends. It is typically used with a rhombic drive to achieve the phase difference between the displacer and power pistons, but they can be joined 90 degrees out of phase on a crankshaft. # The ''gamma'' configuration has two cylinders: one containing a displacer, with a hot and a cold end, and one for the power piston; they are joined to form a single space, so the cylinders have equal pressure; the pistons are typically in parallel and joined 90 degrees out of phase on a crankshaft.Alpha

file:Alpha Stirling highres.gif, Alpha-type Stirling engine. There are two cylinders. The expansion cylinder (red) is maintained at a high temperature while the compression cylinder (blue) is cooled. The passage between the two cylinders contains the regenerator An alpha Stirling contains two power pistons in separate cylinders, one hot and one cold. The hot cylinder is situated inside the high-temperatureheat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contac ...

and the cold cylinder is situated inside the low-temperature heat exchanger. This type of engine has a high power-to-volume ratio but has technical problems because of the usually high temperature of the hot piston and the durability of its seals. In practice, this piston usually carries a large insulating head to move the seals away from the hot zone at the expense of some additional dead space. The crank angle has a major effect on efficiency and the best angle frequently must be found experimentally. An angle of 90° frequently locks.

A four-step description of the process is as follows:

# Most of the working gas is in the hot cylinder and has more contact with the hot cylinder's walls. This results in overall heating of the gas. Its pressure increases and the gas expands. Because the hot cylinder is at its maximum volume and the cold cylinder is at mid stroke (partial volume), the volume of the system is increased by expansion into the cold cylinder.

# The system is at its maximum volume and more gas has contact with the cold cylinder. This cools the gas, lowering its pressure. Because of flywheel momentum or other piston pairs on the same shaft, the hot cylinder begins an upstroke reducing the volume of the system.

# Almost all the gas is now in the cold cylinder and cooling continues. This continues to reduce the pressure of the gas and cause contraction. Because the hot cylinder is at minimum volume and the cold cylinder is at its maximum volume, the volume of the system is further reduced by compression of the cold cylinder inwards.

# The system is at its minimum volume and the gas has greater contact with the hot cylinder. The volume of the system increases by expansion of the hot cylinder.

Beta

file:Stirling Animation.gif, upBeta-type Stirling engine, with only one cylinder, hot at one end and cold at the other. A loose-fitting displacer shunts the air between the hot and cold ends of the cylinder. A power piston at the open end of the cylinder drives the flywheel A beta Stirling has a single power piston arranged within the same cylinder on the same shaft as a #Displacer, displacer piston. The displacer piston is a loose fit and does not extract any power from the expanding gas but only serves to shuttle the working gas between the hot and cold heat exchangers. When the working gas is pushed to the hot end of the cylinder it expands and pushes the power piston. When it is pushed to the cold end of the cylinder it contracts and the momentum of the machine, usually enhanced by a flywheel, pushes the power piston the other way to compress the gas. Unlike the alpha type, the beta type avoids the technical problems of hot moving seals, as the power piston is not in contact with the hot gas. # Power piston (dark grey) has compressed the gas, the displacer piston (light grey) has moved so that most of the gas is adjacent to the hot heat exchanger. # The heated gas increases in pressure and pushes the power piston to the farthest limit of the power stroke. # The displacer piston now moves, shunting the gas to the cold end of the cylinder. # The cooled gas is now compressed by the flywheel momentum. This takes less energy, since its pressure drops when it is cooled.Other types

Stirling cycle

The Stirling cycle is a thermodynamic cycle that describes the general class of Stirling devices. This includes the original Stirling engine that was invented, developed and patented in 1816 by Robert Stirling with help from his brother, an en ...

. The work produced by a Fluidyne engine goes into pumping the liquid. In its simplest form, the engine contains a working gas, a liquid, and two non-return valves.

* The Ringbom engine concept published in 1907 has no rotary mechanism or linkage for the displacer. This is instead driven by a small auxiliary piston, usually a thick displacer rod, with the movement limited by stops.

* The engineer Andy Ross invented a two-cylinder Stirling engine (positioned at 0°, not 90°) connected using a special yoke.

* The Franchot engine is a double-acting engine invented by Charles-Louis-Félix Franchot in the nineteenth century. In a double-acting engine, the pressure of the working fluid acts on both sides of the piston. One of the simplest forms of a double-acting machine, the Franchot engine consists of two pistons and two cylinders, and acts like two separate alpha machines. In the Franchot engine, each piston acts in two gas phases, which makes more efficient use of the mechanical components than a single-acting alpha machine. However, a disadvantage of this machine is that one connecting rod must have a sliding seal at the hot side of the engine, which is difficult when dealing with high pressures and temperatures.

Free-piston engines

Free-piston Stirling engines include those with liquid pistons and those with diaphragms as pistons. In a free-piston device, energy may be added or removed by an electrical linear alternator,

Free-piston Stirling engines include those with liquid pistons and those with diaphragms as pistons. In a free-piston device, energy may be added or removed by an electrical linear alternator, pump

A pump is a device that moves fluids (liquids or gases), or sometimes Slurry, slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

Mechanical pumps serve in a wide range of application ...

or other coaxial device. This avoids the need for a linkage, and reduces the number of moving parts. In some designs, friction and wear are nearly eliminated by the use of non-contact gas bearings or very precise suspension through planar springs.

Four basic steps in the cycle of a free-piston Stirling engine are:

# The power piston is pushed outwards by the expanding gas thus doing work. Gravity plays no role in the cycle.

# The gas volume in the engine increases and therefore the pressure reduces, which causes a pressure difference across the displacer rod to force the displacer towards the hot end. When the displacer moves, the piston is almost stationary and therefore the gas volume is almost constant. This step results in the constant volume cooling process, which reduces the pressure of the gas.

# The reduced pressure now arrests the outward motion of the piston and it begins to accelerate towards the hot end again and by its own inertia, compresses the now cold gas, which is mainly in the cold space.

# As the pressure increases, a point is reached where the pressure differential across the displacer rod becomes large enough to begin to push the displacer rod (and therefore also the displacer) towards the piston and thereby collapsing the cold space and transferring the cold, compressed gas towards the hot side in an almost constant volume process. As the gas arrives in the hot side the pressure increases and begins to move the piston outwards to initiate the expansion step as explained in (1).

In the early 1960s, William T. Beale of Ohio University

Ohio University (Ohio or OU) is a Public university, public research university with its main campus in Athens, Ohio, United States. The university was first conceived in the 1787 contract between the United States Department of the Treasury#Re ...

located in Athens, Ohio, invented a free piston version of the Stirling engine to overcome the difficulty of lubricating the crank mechanism. While the invention of the basic free piston Stirling engine is generally attributed to Beale, independent inventions of similar types of engines were made by E.H. Cooke-Yarborough and C. West at the Harwell Laboratories of the UK AERE. G.M. Benson also made important early contributions and patented many novel free-piston configurations.

The first known mention of a Stirling cycle machine using freely moving components is a British patent disclosure in 1876. This machine was envisaged as a refrigerator (i.e., the ''reversed'' Stirling cycle). The first consumer product to utilize a free piston Stirling device was a portable refrigerator manufactured by Twinbird Corporation of Japan and offered in the US by Coleman in 2004.

Flat engines

Design of the flat double-acting Stirling engine solves the drive of a displacer with the help of the fact that areas of the hot and cold pistons of the displacer are different.

The drive does so without any mechanical transmission. Using diaphragms eliminates friction and need for lubricants.

When the displacer is in motion, the generator holds the working piston in the limit position, which brings the engine working cycle close to an ideal Stirling cycle. The ratio of the area of the heat exchangers to the volume of the machine increases by the implementation of a flat design.

Flat design of the working cylinder approximates thermal process of the expansion and compression closer to the isothermal one.

The disadvantage is a large area of the thermal insulation between the hot and cold space.

Design of the flat double-acting Stirling engine solves the drive of a displacer with the help of the fact that areas of the hot and cold pistons of the displacer are different.

The drive does so without any mechanical transmission. Using diaphragms eliminates friction and need for lubricants.

When the displacer is in motion, the generator holds the working piston in the limit position, which brings the engine working cycle close to an ideal Stirling cycle. The ratio of the area of the heat exchangers to the volume of the machine increases by the implementation of a flat design.

Flat design of the working cylinder approximates thermal process of the expansion and compression closer to the isothermal one.

The disadvantage is a large area of the thermal insulation between the hot and cold space.

Thermoacoustic cycle

Thermoacoustic devices are very different from Stirling devices, although the individual path travelled by each working gas molecule does follow a realStirling cycle

The Stirling cycle is a thermodynamic cycle that describes the general class of Stirling devices. This includes the original Stirling engine that was invented, developed and patented in 1816 by Robert Stirling with help from his brother, an en ...

. These devices include the thermoacoustic engine and thermoacoustic refrigerator. High-amplitude acoustic standing wave

In physics, a standing wave, also known as a stationary wave, is a wave that oscillates in time but whose peak amplitude profile does not move in space. The peak amplitude of the wave oscillations at any point in space is constant with respect t ...

s cause compression and expansion analogous to a Stirling power piston, while out-of-phase acoustic travelling waves cause displacement along a temperature gradient

In vector calculus, the gradient of a scalar-valued differentiable function f of several variables is the vector field (or vector-valued function) \nabla f whose value at a point p gives the direction and the rate of fastest increase. The g ...

, analogous to a Stirling displacer piston. Thus a thermoacoustic device typically does not have a displacer, as found in a beta or gamma Stirling.

Other developments

NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the federal government of the United States, US federal government responsible for the United States ...

has considered nuclear-decay heated Stirling Engines for extended missions to the outer solar system. In 2018, NASA and the United States Department of Energy announced that they had successfully tested a new type of nuclear reactor called KRUSTY, which stands for "Kilopower Reactor Using Stirling TechnologY", and which is designed to be able to power deep space vehicles and probes as well as exoplanetary encampments.

At the 2012 Cable-Tec Expo put on by the Society of Cable Telecommunications Engineers, Dean Kamen took the stage with Time Warner Cable Chief Technology Officer Mike LaJoie to announce a new initiative between his company Deka Research and the SCTE. Kamen refers to it as a Stirling engine.

The smallest Stirling engine was built by two German scientists at the University of Stuttgart. It operates on the micron-length scale.

Operational considerations

Size and temperature

Very low-power engines have been built that run on a temperature difference of as little as 0.5 K. A ''displacer-type Stirling engine'' has one piston and one displacer. A temperature difference is required between the top and bottom of the large cylinder to run the engine. In the case of the ''low-temperature-difference'' (LTD) Stirling engine, the temperature difference between one's hand and the surrounding air can be enough to run the engine. The power piston in the displacer-type Stirling engine is tightly sealed and is controlled to move up and down as the gas inside expands. The displacer, on the other hand, is very loosely fitted so that air can move freely between the hot and cold sections of the engine as the piston moves up and down. The displacer moves up and down to cause most of the gas in the displacer cylinder to be either heated, or cooled. Stirling engines, especially those that run on small temperature differentials, are quite large for the amount of power that they produce (i.e., they have low specific power). This is primarily due to the heat transfer coefficient of gaseous convection, which limits theheat flux

In physics and engineering, heat flux or thermal flux, sometimes also referred to as heat flux density, heat-flow density or heat-flow rate intensity, is a flow of energy per unit area per unit time (physics), time. Its SI units are watts per sq ...

that can be attained in a typical cold heat exchanger to about 500 W/(m2·K), and in a hot heat exchanger to about 500–5000 W/(m2·K). Compared with internal combustion engines, this makes it more challenging for the engine designer to transfer heat into and out of the working gas. Because of the thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For ...

the required heat transfer grows with lower temperature difference, and the heat exchanger surface (and cost) for 1 kW output grows with (1/ΔT)2. Therefore, the specific cost of very low temperature difference engines is very high. Increasing the temperature differential and/or pressure allows Stirling engines to produce more power, assuming the heat exchangers are designed for the increased heat load, and can deliver the convected heat flux necessary.

A Stirling engine cannot start instantly; it literally needs to "warm up". This is true of all external combustion engines, but the warm up time may be longer for Stirlings than for others of this type such as steam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

s. Stirling engines are best used as constant speed engines.

Power output of a Stirling tends to be constant and to adjust it can sometimes require careful design and additional mechanisms. Typically, changes in output are achieved by varying the displacement of the engine (often through use of a swashplate crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, ...

arrangement), or by changing the quantity of working fluid, or by altering the piston/displacer phase angle, or in some cases simply by altering the engine load. This property is less of a drawback in hybrid electric propulsion or "base load" utility generation where constant power output is actually desirable.

Gas choice

The gas used should have a lowheat capacity

Heat capacity or thermal capacity is a physical property of matter, defined as the amount of heat to be supplied to an object to produce a unit change in its temperature. The SI unit of heat capacity is joule per kelvin (J/K).

Heat capacity is a ...

, so that a given amount of transferred heat leads to a large increase in pressure. Considering this issue, helium would be the best gas because of its very low heat capacity. Air is a viable working fluid, but the oxygen in a highly pressurized air engine can cause fatal accidents caused by lubricating oil explosions. Following one such accident Philips pioneered the use of other gases to avoid such risk of explosions.

* Hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

's low viscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

and high thermal conductivity

The thermal conductivity of a material is a measure of its ability to heat conduction, conduct heat. It is commonly denoted by k, \lambda, or \kappa and is measured in W·m−1·K−1.

Heat transfer occurs at a lower rate in materials of low ...

make it the most powerful working gas, primarily because the engine can run faster than with other gases. However, because of hydrogen absorption, and given the high diffusion rate associated with this low molecular weight

A molecule is a group of two or more atoms that are held together by Force, attractive forces known as chemical bonds; depending on context, the term may or may not include ions that satisfy this criterion. In quantum physics, organic chemi ...

gas, particularly at high temperatures, H2 leaks through the solid metal of the heater. Diffusion through carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, cobalt ...

is too high to be practical, but may be acceptably low for metals such as aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

, or even stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

. Certain ceramics also greatly reduce diffusion. Hermetic pressure vessel seals are necessary to maintain pressure inside the engine without replacement of lost gas. For high-temperature-differential (HTD) engines, auxiliary systems may be required to maintain high-pressure working fluid. These systems can be a gas storage bottle or a gas generator. Hydrogen can be generated by electrolysis

In chemistry and manufacturing, electrolysis is a technique that uses Direct current, direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of c ...

of water, the action of steam on red hot carbon-based fuel, by gasification of hydrocarbon fuel, or by the reaction of acid

An acid is a molecule or ion capable of either donating a proton (i.e. Hydron, hydrogen cation, H+), known as a Brønsted–Lowry acid–base theory, Brønsted–Lowry acid, or forming a covalent bond with an electron pair, known as a Lewis ...

on metal. Hydrogen can also cause the embrittlement of metals. Hydrogen is a flammable gas, which is a safety concern if released from the engine.

* Most technically advanced Stirling engines, like those developed for United States government labs, use helium

Helium (from ) is a chemical element; it has chemical symbol, symbol He and atomic number 2. It is a colorless, odorless, non-toxic, inert gas, inert, monatomic gas and the first in the noble gas group in the periodic table. Its boiling point is ...

as the working gas, because it functions close to the efficiency and power density of hydrogen with fewer of the material containment issues. Helium is inert, and hence not flammable. Helium is relatively expensive, and must be supplied as bottled gas. One test showed hydrogen to be 5% (absolute) more efficient than helium (24% relatively) in the GPU-3 Stirling engine. The researcher Allan Organ demonstrated that a well-designed air engine is theoretically just as ''efficient'' as a helium or hydrogen engine, but helium and hydrogen engines are several times more ''powerful per unit volume''.

* Some engines use air or nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

as the working fluid. These gases have much lower power density (which increases engine costs), but they are more convenient to use and they minimize the problems of gas containment and supply (which decreases costs). The use of compressed air

Compressed air is air kept under a pressure that is greater than atmospheric pressure. Compressed air in vehicle tires and shock absorbers are commonly used for improved traction and reduced vibration. Compressed air is an important medium for t ...

in contact with flammable materials or substances such as lubricating oil introduces an explosion hazard, because compressed air contains a high partial pressure

In a mixture of gases, each constituent gas has a partial pressure which is the notional pressure of that constituent gas as if it alone occupied the entire volume of the original mixture at the same temperature. The total pressure of an ideal g ...

of oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

. However, oxygen can be removed from air through an oxidation reaction or bottled nitrogen can be used, which is nearly inert and very safe.

* Other possible lighter-than-air gases include methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes ...

and ammonia

Ammonia is an inorganic chemical compound of nitrogen and hydrogen with the chemical formula, formula . A Binary compounds of hydrogen, stable binary hydride and the simplest pnictogen hydride, ammonia is a colourless gas with a distinctive pu ...

.

Pressurization

In most high-power Stirling engines, both the minimum pressure and mean pressure of the working fluid are above atmospheric pressure. This initial engine pressurization can be realized by a pump, or by filling the engine from a compressed gas tank, or even just by sealing the engine when the mean temperature is lower than the meanoperating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

. All of these methods increase the mass of working fluid in the thermodynamic cycle. All of the heat exchangers must be sized appropriately to supply the necessary heat transfer rates. If the heat exchangers are well designed and can supply the heat flux needed for convective heat transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, ...

, then the engine, in a first approximation, produces power in proportion to the mean pressure, as predicted by the West number and Beale number. In practice, the maximum pressure is also limited to the safe pressure of the pressure vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size o ...

. Like most aspects of Stirling engine design, optimization is multivariate, and often has conflicting requirements. A difficulty of pressurization is that while it improves the power, the heat required increases proportionately to the increased power. This heat transfer is made increasingly difficult with pressurization since increased pressure also demands increased thicknesses of the walls of the engine, which, in turn, increase the resistance to heat transfer.

Lubricants and friction

At high temperatures and pressures, the oxygen in air-pressurized crankcases, or in the working gas of hot air engines, can combine with the engine's lubricating oil and explode. At least one person has died in such an explosion. Lubricants can also clog heat exchangers, especially the regenerator. For these reasons, designers prefer non-lubricated, low- coefficient of friction materials (such as rulon or

At high temperatures and pressures, the oxygen in air-pressurized crankcases, or in the working gas of hot air engines, can combine with the engine's lubricating oil and explode. At least one person has died in such an explosion. Lubricants can also clog heat exchangers, especially the regenerator. For these reasons, designers prefer non-lubricated, low- coefficient of friction materials (such as rulon or graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

), with low normal force

In mechanics, the normal force F_n is the component of a contact force that is perpendicular to the surface that an object contacts. In this instance '' normal'' is used in the geometric sense and means perpendicular, as opposed to the meanin ...

s on the moving parts, especially for sliding seals. Some designs avoid sliding surfaces altogether by using diaphragms for sealed pistons. These are some of the factors that allow Stirling engines to have lower maintenance requirements and longer life than internal-combustion engines.

Efficiency

Theoreticalthermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For ...

equals that of the ideal Carnot cycle, i.e. the highest efficiency attainable by any heat engine. However, though it is useful for illustrating general principles, practical Stirling engines deviate substantially from the ideal. It has been argued that its indiscriminate use in many standard books on engineering thermodynamics has done a disservice to the study of Stirling engines in general.

Stirling engines cannot achieve total efficiencies typical of an internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

, the main constraint being thermal efficiency. During internal combustion, temperatures achieve around for a short period of time, resulting in greater mean heat supply temperature of the thermodynamic cycle than any Stirling engine could achieve. It is not possible to supply heat at temperatures that high by conduction, as it is done in Stirling engines because no material could conduct heat from combustion in that high temperature without huge heat losses and problems related to heat deformation of materials.