Rum on:

[Wikipedia]

[Google]

[Amazon]

Rum is a

Rum is a

The origin of the word "rum" is unclear. The most widely accepted hypothesis is that it is related to "rumbullion", a beverage made from boiling sugar cane stalks, or possibly "rumbustion," which was a slang word for "uproar" or "tumult"; a noisy uncontrollable exuberance, though the origin of those words and the nature of the relationship are unclear.Anatoly Liberman, "The Rum History of the Word 'Rum'", ''OUPblog'

The origin of the word "rum" is unclear. The most widely accepted hypothesis is that it is related to "rumbullion", a beverage made from boiling sugar cane stalks, or possibly "rumbustion," which was a slang word for "uproar" or "tumult"; a noisy uncontrollable exuberance, though the origin of those words and the nature of the relationship are unclear.Anatoly Liberman, "The Rum History of the Word 'Rum'", ''OUPblog'

October 6, 2010

''

''s.v.'' 'rum, ''adj.1'' '''s.v.'' 'rumbullion'

/ref> Both words surfaced in English about the same time as rum did (1651 for "rumbullion", and before 1654 "rum"). There have been various other theories: * It is often connected to the British slang adjective "rum", meaning "high quality", and indeed the collocation "rum booze" is attested.''

''s.v.'' 'rum, ''adj.1'' '

/ref> Given the harshness of early rum, this is unlikely.Curtis (2006), pp. 34-35 * That it is related to ramboozle and rumfustian, popular British drinks of the mid-17th century. However, neither was made with rum, but rather eggs, ale, wine, sugar, and various spices. * That it comes from the large drinking glasses used by Dutch seamen known as ''

After development of rum in the Caribbean, the drink's popularity spread to

After development of rum in the Caribbean, the drink's popularity spread to

Rum's association with piracy began with English

Rum's association with piracy began with English

Rum became an important trade good in the early period of the colony of

Rum became an important trade good in the early period of the colony of

Within the Caribbean, each island or production area has a unique style. For the most part, these styles can be grouped by the language traditionally spoken. Due to the overwhelming influence of Puerto Rican rum, most rum consumed in the United States is produced in the "Spanish-speaking" style.

* English-speaking areas are known for darker rums with a fuller taste that retains a greater amount of the underlying molasses flavor. Rums from the

Within the Caribbean, each island or production area has a unique style. For the most part, these styles can be grouped by the language traditionally spoken. Due to the overwhelming influence of Puerto Rican rum, most rum consumed in the United States is produced in the "Spanish-speaking" style.

* English-speaking areas are known for darker rums with a fuller taste that retains a greater amount of the underlying molasses flavor. Rums from the

by Nick Davis, BBC News, 6 September 2015 The term, denoting home made, strong rum, appears in New Zealand since at least the early 19th century. Jamaican rum was granted

Most rum is produced from molasses, which is made from sugarcane. A rum's quality is dependent on the quality and variety of the sugar cane that was used to create it. The sugar cane's quality depends on the soil type and climate that it was grown in. Within the Caribbean, much of this molasses is from Brazil.

A notable exception is the French-speaking islands, where sugarcane juice is the preferred base ingredient. In Brazil itself, the distilled alcoholic drink derived from cane juice is distinguished from rum and called ''

Most rum is produced from molasses, which is made from sugarcane. A rum's quality is dependent on the quality and variety of the sugar cane that was used to create it. The sugar cane's quality depends on the soil type and climate that it was grown in. Within the Caribbean, much of this molasses is from Brazil.

A notable exception is the French-speaking islands, where sugarcane juice is the preferred base ingredient. In Brazil itself, the distilled alcoholic drink derived from cane juice is distinguished from rum and called ''

extract

* * * *

Introduction

Rum is a

Rum is a liquor

Liquor (or a spirit) is an alcoholic drink produced by distillation of grains, fruits, vegetables, or sugar, that have already gone through alcoholic fermentation. Other terms for liquor include: spirit drink, distilled beverage or hard ...

made by fermenting

Fermentation is a metabolic process that produces chemical changes in organic substrates through the action of enzymes. In biochemistry, it is narrowly defined as the extraction of energy from carbohydrates in the absence of oxygen. In food ...

and then distilling

Distillation, or classical distillation, is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation, usually inside an apparatus known as a still. Dry distillation is the heating ...

sugarcane

Sugarcane or sugar cane is a species of (often hybrid) tall, Perennial plant, perennial grass (in the genus ''Saccharum'', tribe Andropogoneae) that is used for sugar Sugar industry, production. The plants are 2–6 m (6–20 ft) tall with ...

molasses

Molasses () is a viscous substance resulting from refining sugarcane or sugar beets into sugar. Molasses varies in the amount of sugar, method of extraction and age of the plant. Sugarcane molasses is primarily used to sweeten and flavour foods ...

or sugarcane juice

Sugarcane juice is the liquid extracted from pressed sugarcane. It is consumed as a beverage in many places, especially where sugarcane is commercially grown, such as Southeast Asia, the Indian subcontinent, North Africa, and Latin America.

Sug ...

. The distillate, a clear liquid, is usually aged in oak

An oak is a tree or shrub in the genus ''Quercus'' (; Latin "oak tree") of the beech family, Fagaceae. There are approximately 500 extant species of oaks. The common name "oak" also appears in the names of species in related genera, notably ''L ...

barrels. Rum is produced in nearly every sugar-producing region of the world, such as the Philippines

The Philippines (; fil, Pilipinas, links=no), officially the Republic of the Philippines ( fil, Republika ng Pilipinas, links=no),

* bik, Republika kan Filipinas

* ceb, Republika sa Pilipinas

* cbk, República de Filipinas

* hil, Republ ...

, where Tanduay

Tanduay Distillers, Inc. () is a Philippine alcoholic beverage company. It is a subsidiary of LT Group, a conglomerate owned by Filipino business magnate Lucio Tan. As of 2019, it is the world's largest rum brand.

History

Tanduay traces its or ...

is the largest producer of rum globally.

Rums are produced in various grades. Light rums are commonly used in cocktail

A cocktail is an alcoholic mixed drink. Most commonly, cocktails are either a combination of spirits, or one or more spirits mixed with other ingredients such as tonic water, fruit juice, flavored syrup, or cream. Cocktails vary widely across ...

s, whereas "golden" and "dark" rums were typically consumed straight or neat, iced ("on the rocks

Various unique terminology is used in bartending.

Definitions and usage

Straight, up, and straight up

In bartending, the terms "straight up" and "up" ordinarily refer to an alcoholic drink that is shaken or stirred with ice and then strained ...

"), or used for cooking, but are now commonly consumed with mixers. Premium rums are made to be consumed either straight or iced.

Rum plays a part in the culture of most islands of the West Indies

The West Indies is a subregion of North America, surrounded by the North Atlantic Ocean and the Caribbean Sea that includes 13 independent island countries and 18 dependencies and other territories in three major archipelagos: the Greater A ...

as well as the Maritime provinces and Newfoundland

Newfoundland and Labrador (; french: Terre-Neuve-et-Labrador; frequently abbreviated as NL) is the easternmost province of Canada, in the country's Atlantic region. The province comprises the island of Newfoundland and the continental region ...

, in Canada

Canada is a country in North America. Its ten provinces and three territories extend from the Atlantic Ocean to the Pacific Ocean and northward into the Arctic Ocean, covering over , making it the world's second-largest country by tot ...

. The beverage has associations with the Royal Navy

The Royal Navy (RN) is the United Kingdom's naval warfare force. Although warships were used by English and Scottish kings from the early medieval period, the first major maritime engagements were fought in the Hundred Years' War against F ...

(where it was mixed with water or beer to make grog

Grog is a term used for a variety of alcoholic beverages.

The word originally referred to rum diluted with water (and later on long sea voyages, also added the juice of limes or lemons), which British Vice-Admiral Edward Vernon introduced ...

) and piracy

Piracy is an act of robbery or criminal violence by ship or boat-borne attackers upon another ship or a coastal area, typically with the goal of stealing cargo and other valuable goods. Those who conduct acts of piracy are called pirates, v ...

(where it was consumed as bumbo). Rum has also served as a medium of economic exchange, used to help fund enterprises such as slavery

Slavery and enslavement are both the state and the condition of being a slave—someone forbidden to quit one's service for an enslaver, and who is treated by the enslaver as property. Slavery typically involves slaves being made to perf ...

(see Triangular trade

Triangular trade or triangle trade is trade between three ports or regions. Triangular trade usually evolves when a region has export commodities that are not required in the region from which its major imports come. It has been used to offset t ...

), organized crime, and military insurgencies (e.g., the American Revolution

The American Revolution was an ideological and political revolution that occurred in British America between 1765 and 1791. The Americans in the Thirteen Colonies formed independent states that defeated the British in the American Revolut ...

and Australia's Rum Rebellion

The Rum Rebellion of 1808 was a ''coup d'état'' in the then-British penal colony of New South Wales, staged by the New South Wales Corps in order to depose Governor William Bligh. Australia's first and only military coup, the name derives from ...

).

Etymology

The origin of the word "rum" is unclear. The most widely accepted hypothesis is that it is related to "rumbullion", a beverage made from boiling sugar cane stalks, or possibly "rumbustion," which was a slang word for "uproar" or "tumult"; a noisy uncontrollable exuberance, though the origin of those words and the nature of the relationship are unclear.Anatoly Liberman, "The Rum History of the Word 'Rum'", ''OUPblog'

The origin of the word "rum" is unclear. The most widely accepted hypothesis is that it is related to "rumbullion", a beverage made from boiling sugar cane stalks, or possibly "rumbustion," which was a slang word for "uproar" or "tumult"; a noisy uncontrollable exuberance, though the origin of those words and the nature of the relationship are unclear.Anatoly Liberman, "The Rum History of the Word 'Rum'", ''OUPblog'October 6, 2010

''

Oxford English Dictionary

The ''Oxford English Dictionary'' (''OED'') is the first and foundational historical dictionary of the English language, published by Oxford University Press (OUP). It traces the historical development of the English language, providing a com ...

'', Third Edition, 2011''s.v.'' 'rum, ''adj.1'' '

/ref> Both words surfaced in English about the same time as rum did (1651 for "rumbullion", and before 1654 "rum"). There have been various other theories: * It is often connected to the British slang adjective "rum", meaning "high quality", and indeed the collocation "rum booze" is attested.''

Oxford English Dictionary

The ''Oxford English Dictionary'' (''OED'') is the first and foundational historical dictionary of the English language, published by Oxford University Press (OUP). It traces the historical development of the English language, providing a com ...

'', Third Edition, 2011''s.v.'' 'rum, ''adj.1'' '

/ref> Given the harshness of early rum, this is unlikely.Curtis (2006), pp. 34-35 * That it is related to ramboozle and rumfustian, popular British drinks of the mid-17th century. However, neither was made with rum, but rather eggs, ale, wine, sugar, and various spices. * That it comes from the large drinking glasses used by Dutch seamen known as ''

rummer

A rummer (also known as a Römer or Roemer, among other variations) was a type of large drinking glass studded with prunts to ensure a safe grip, popular mainly in the Rhineland and the Netherlands from the 15th through the 17th century. Rummers l ...

s'', from the Dutch word ''roemer'', a drinking glass.

* Other theories consider it to be short for ''iterum'', Latin

Latin (, or , ) is a classical language belonging to the Italic branch of the Indo-European languages. Latin was originally a dialect spoken in the lower Tiber area (then known as Latium) around present-day Rome, but through the power of the ...

for "again; a second time", or ''arôme'', French for aroma.Blue p. 73

Regardless of the original source, the name was already in common use by 1654, when the General Court of Connecticut ordered the confiscations of "whatsoever Barbados liquors, commonly called rum, kill devil and the like". A short time later in May 1657, the General Court of Massachusetts

The Massachusetts General Court (formally styled the General Court of Massachusetts) is the state legislature of the Commonwealth of Massachusetts. The name "General Court" is a hold-over from the earliest days of the Massachusetts Bay Colony, ...

also decided to make illegal the sale of strong liquor "whether knowne by the name of rumme, strong water, wine, brandy, etc".

In current usage, the name used for a rum is often based on its place of origin.

For rums from places mostly in Latin America where Spanish is spoken, the word ''ron'' is used. A ''ron añejo'' ("aged rum") is a premium spirit.

''Rhum'' is the term that typically distinguishes rum made from fresh sugar cane juice from rum made from molasses in French-speaking locales like Martinique. A ''rhum vieux'' ("old rum") is an aged French rum that meets several other requirements.

Some of the many other names for rum are Nelson

Nelson may refer to:

Arts and entertainment

* ''Nelson'' (1918 film), a historical film directed by Maurice Elvey

* ''Nelson'' (1926 film), a historical film directed by Walter Summers

* ''Nelson'' (opera), an opera by Lennox Berkeley to a lib ...

's blood, kill-devil, demon water, pirate's drink, navy neaters, and Barbados water.

A version of rum from Newfoundland

Newfoundland and Labrador (; french: Terre-Neuve-et-Labrador; frequently abbreviated as NL) is the easternmost province of Canada, in the country's Atlantic region. The province comprises the island of Newfoundland and the continental region ...

is referred to by the name screech, while some low-grade West Indies

The West Indies is a subregion of North America, surrounded by the North Atlantic Ocean and the Caribbean Sea that includes 13 independent island countries and 18 dependencies and other territories in three major archipelagos: the Greater A ...

rums are called tafia

Tafia (possibly an alteration of ''ratafia'', via aphesis) is a kind of rum made from sugarcane juice. It is typically unaged whereas rum is typically aged in wooden barrels to reduce the level of fusel. Most of the fusel is absorbed in the first ...

.

History

Precursors and Origins

* An early rum-like drink is '' brum'', which has been produced by theMalay people

Malays ( ms, Orang Melayu, Jawi: أورڠ ملايو) are an Austronesian ethnic group native to eastern Sumatra, the Malay Peninsula and coastal Borneo, as well as the smaller islands that lie between these locations — areas that are ...

for thousands of years.

* ''Shidhu'', a drink produced by fermentation and distillation of sugarcane juice, is mentioned in Sanskrit texts.

* Marco Polo

Marco Polo (, , ; 8 January 1324) was a Venetian merchant, explorer and writer who travelled through Asia along the Silk Road between 1271 and 1295. His travels are recorded in ''The Travels of Marco Polo'' (also known as ''Book of the Marv ...

recorded a 14th-century account of a "very good wine of sugar(cane)" that was offered to him in the area that became modern-day Iran

Iran, officially the Islamic Republic of Iran, and also called Persia, is a country located in Western Asia. It is bordered by Iraq and Turkey to the west, by Azerbaijan and Armenia to the northwest, by the Caspian Sea and Turkmeni ...

.

* Maria Dembinska states that King Peter I of Cyprus

Peter I (9 October 1328 – 17 January 1369) was King of Cyprus and titular King of Jerusalem from his father's abdication on 24 November 1358 until his death in 1369. He was invested as titular Count of Tripoli in 1346. As King of Cyprus, ...

, also called Pierre I de Lusignan (9 October 1328 – 17 January 1369), brought rum with him as a gift for the other royal dignitaries at the Congress of Kraków

The Congress of Kraków (Polish: ''Zjazd krakowski'') was a meeting of monarchs initiated by King Casimir III the Great of Poland and held in Kraków (Cracow) around September 22–27, 1364. The pretext for calling the meeting was very likely a pr ...

, held in 1364. This is plausible given the position of Cyprus as a significant producer of sugar in the Middle Ages, although the alcoholic sugar drink named rum by Dembinska may not have resembled modern distilled rums very closely. Dembinska also suggests Cyprus rum was often drunk mixed with an almond milk

Almond milk is a plant-based milk with a watery texture and nutty flavor manufactured from almonds, although some types or brands are flavored in imitation of cow's milk. It does not contain cholesterol or lactose and is low in saturated fat. ...

drink, also produced in Cyprus, called ''soumada

Orgeat syrup is a sweet syrup made from almonds, sugar, and rose water or orange flower water. It was originally made with a barley-almond blend. It has a pronounced almond taste and is used to flavor many cocktails. Orgeat syrup is an importan ...

.''

* Rum production has been recorded for Brazil in the 1520s,

Cavalcante, Messias Soares. A verdadeira história da cachaça. São Paulo: Sá Editora, 2011. 608p.

* A liquid identified as rum has been found in a tin bottle found on the Swedish warship ''Vasa'', which sank in 1628.

Many historians now believe that rum-making found its way to the Caribbean islands along with sugarcane and its cultivation methods from Brazil.

The traditional history of modern style rum tells of its invention in the Caribbean, in the 17th century, by slave

Slavery and enslavement are both the state and the condition of being a slave—someone forbidden to quit one's service for an enslaver, and who is treated by the enslaver as property. Slavery typically involves slaves being made to perf ...

s on sugarcane plantations, who discovered that molasses

Molasses () is a viscous substance resulting from refining sugarcane or sugar beets into sugar. Molasses varies in the amount of sugar, method of extraction and age of the plant. Sugarcane molasses is primarily used to sweeten and flavour foods ...

, a by-product

A by-product or byproduct is a secondary product derived from a production process, manufacturing process or chemical reaction; it is not the primary product or service being produced.

A by-product can be useful and marketable or it can be consid ...

of the sugar refining process, could be fermented into alcohol, and then distilled.

The earliest record, in a 1651 document from Barbados, mentions the island of Nevis

Nevis is a small island in the Caribbean Sea that forms part of the inner arc of the Leeward Islands chain of the West Indies. Nevis and the neighbouring island of Saint Kitts constitute one country: the Federation of Saint Kitts and Ne ...

in particular:Blue p. 70

By the late 17th century rum had replaced French brandy

Brandy is a liquor produced by distilling wine. Brandy generally contains 35–60% alcohol by volume (70–120 US proof) and is typically consumed as an after-dinner digestif. Some brandies are aged in wooden casks. Others are coloured with ...

as the exchange-alcohol of choice in the triangle trade

Triangular trade or triangle trade is trade between three ports or regions. Triangular trade usually evolves when a region has export commodities that are not required in the region from which its major imports come. It has been used to offset t ...

. Canoemen and guards on the African side of the trade, who had previously been paid in brandy, were now paid in rum.

Colonial North America

After development of rum in the Caribbean, the drink's popularity spread to

After development of rum in the Caribbean, the drink's popularity spread to Colonial North America

The colonial history of the United States covers the history of European colonization of North America from the early 17th century until the incorporation of the Thirteen Colonies into the United States after the Revolutionary War. In the ...

. To support the demand for the drink, the first rum distillery in the Thirteen Colonies

The Thirteen Colonies, also known as the Thirteen British Colonies, the Thirteen American Colonies, or later as the United Colonies, were a group of Kingdom of Great Britain, British Colony, colonies on the Atlantic coast of North America. Fo ...

was set up in 1664 on Staten Island

Staten Island ( ) is a borough of New York City, coextensive with Richmond County, in the U.S. state of New York. Located in the city's southwest portion, the borough is separated from New Jersey by the Arthur Kill and the Kill Van Kull an ...

. Boston, Massachusetts had a distillery three years later.Blue p. 74 The manufacture of rum became early colonial New England's largest and most prosperous industry. New England became a distilling center due to the technical, metalworking and cooperage skills and abundant lumber; the rum produced there was lighter, more like whiskey. Much of the rum was exported, distillers in Newport, R.I.

Newport is an American seaside city on Aquidneck Island in Newport County, Rhode Island. It is located in Narragansett Bay, approximately southeast of Providence, south of Fall River, Massachusetts, south of Boston, and northeast of New Yo ...

even made an extra strong rum specifically to be used as a slave currency. Rhode Island

Rhode Island (, like ''road'') is a U.S. state, state in the New England region of the Northeastern United States. It is the List of U.S. states by area, smallest U.S. state by area and the List of states and territories of the United States ...

rum even joined gold as an accepted currency in Europe for a period of time.Blue p. 76 While New England triumphed on price and consistency Europeans still viewed the best rums as coming from the Caribbean. Estimates of rum consumption in the American colonies before the American Revolutionary War

The American Revolutionary War (April 19, 1775 – September 3, 1783), also known as the Revolutionary War or American War of Independence, was a major war of the American Revolution. Widely considered as the war that secured the independence of t ...

had every man, woman, or child drinking an average of of rum each year.Tannahill p. 295

In the 18th century ever increasing demands for sugar, molasses, rum, and slaves led to a feedback loop which intensified the triangular trade.Tannahill p. 296 When France banned the production of rum in their New World possessions to end the domestic competition with brandy, New England distillers were then able to undercut producers in the British West Indies

The British West Indies (BWI) were colonized British territories in the West Indies: Anguilla, the Cayman Islands, Turks and Caicos Islands, Montserrat, the British Virgin Islands, Antigua and Barbuda, The Bahamas, Barbados, Dominica, Grena ...

by buying cut rate molasses from French sugar plantations. Outcry from the British rum industry led to the Molasses Act

The Molasses Act of 1733 was an Act of the Parliament of Great Britain (citation 6 Geo II. c. 13) that imposed a tax of six pence per gallon on imports of molasses from non-British colonies. Parliament created the act largely at the insistence of ...

of 1733 which levied a prohibitive tax on molasses imported into the Thirteen Colonies from foreign countries or colonies. Rum at this time accounted for approximately 80% of New England’s exports and paying the duty would have put the distilleries out of business: as a result, both compliance with and enforcement of the act were minimal. Strict enforcement of the Molasses Act’s successor, the Sugar Act

The Sugar Act 1764, also known as the American Revenue Act 1764 or the American Duties Act, was a revenue-raising act passed by the Parliament of Great Britain on 5 April 1764. The preamble to the act stated: "it is expedient that new provisi ...

, in 1764 may have helped cause the American Revolution

The American Revolution was an ideological and political revolution that occurred in British America between 1765 and 1791. The Americans in the Thirteen Colonies formed independent states that defeated the British in the American Revolut ...

. In the slave trade, rum was also used as a medium of exchange

In economics, a medium of exchange is any item that is widely acceptable in exchange for goods and services. In modern economies, the most commonly used medium of exchange is currency.

The origin of "mediums of exchange" in human societies is ass ...

. For example, the slave Venture Smith

Venture Smith (Birth name: Broteer Furro) (c. 1729 – 1805) was an African-American farmer and craftsman. Smith was kidnapped when he was six and a half years old in West Africa and was taken to Anomabo on the Gold Coast (modern-day Ghana) t ...

(whose history was later published) had been purchased in Africa, for four gallons of rum plus a piece of calico

Calico (; in British usage since 1505) is a heavy plain-woven textile made from unbleached, and often not fully processed, cotton. It may also contain unseparated husk parts. The fabric is far coarser than muslin, but less coarse and thick than ...

.

In "The Doctor's Secret Journal", an account of the happenings at Fort Michilimackinac in northern Michigan from 1769 to 1772 by Daniel Morison, a surgeon's mate, noted that there was not much for the men to do and drinking rum was very popular. In fact, Ensign Robert Johnstone, one of the officers, "thought proper to turn trader by selling (the) common rum to the soldiers & all others by whom he might gain a penny in this clandestine Manner." To conceal this theft, "he was observed to have filled up several Barrels of common rum with boiling water to make up the Leakage." Ensign Johnstone had no trouble selling this diluted rum.

The popularity of rum continued after the American Revolution; George Washington

George Washington (February 22, 1732, 1799) was an American military officer, statesman, and Founding Father who served as the first president of the United States from 1789 to 1797. Appointed by the Continental Congress as commander of th ...

insisting on a barrel of Barbados

Barbados is an island country in the Lesser Antilles of the West Indies, in the Caribbean region of the Americas, and the most easterly of the Caribbean Islands. It occupies an area of and has a population of about 287,000 (2019 estimate). ...

rum at his 1789 inauguration.

Rum started to play an important role in the political system; candidates attempted to influence the outcome of an election through their generosity with rum. The people would attend the hustings to see which candidate appeared more generous. The candidate was expected to drink with the people to show he was independent and truly a republican.

Eventually the restrictions on sugar imports from the British West Indies

The British West Indies (BWI) were colonized British territories in the West Indies: Anguilla, the Cayman Islands, Turks and Caicos Islands, Montserrat, the British Virgin Islands, Antigua and Barbuda, The Bahamas, Barbados, Dominica, Grena ...

, combined with the development of American whiskey

Whisky or whiskey is a type of distilled alcoholic beverage made from fermented grain mash. Various grains (which may be malted) are used for different varieties, including barley, corn, rye, and wheat. Whisky is typically aged in wooden cask ...

s, led to a decline in the drink's popularity in North America.

Naval rum

Rum's association with piracy began with English

Rum's association with piracy began with English privateer

A privateer is a private person or ship that engages in maritime warfare under a commission of war. Since robbery under arms was a common aspect of seaborne trade, until the early 19th century all merchant ships carried arms. A sovereign or deleg ...

s' trading in the valuable commodity. Some of the privateers became pirates and buccaneers, with a continuing fondness for rum; the association between the two was only strengthened by literary works such as Robert Louis Stevenson

Robert Louis Stevenson (born Robert Lewis Balfour Stevenson; 13 November 1850 – 3 December 1894) was a Scottish novelist, essayist, poet and travel writer. He is best known for works such as ''Treasure Island'', ''Strange Case of Dr Jekyll a ...

's ''Treasure Island

''Treasure Island'' (originally titled ''The Sea Cook: A Story for Boys''Hammond, J. R. 1984. "Treasure Island." In ''A Robert Louis Stevenson Companion'', Palgrave Macmillan Literary Companions. London: Palgrave Macmillan. .) is an adventure no ...

''.

The association of rum with the Royal Navy

The Royal Navy (RN) is the United Kingdom's naval warfare force. Although warships were used by English and Scottish kings from the early medieval period, the first major maritime engagements were fought in the Hundred Years' War against F ...

began in 1655, when a Royal Navy

The Royal Navy (RN) is the United Kingdom's naval warfare force. Although warships were used by English and Scottish kings from the early medieval period, the first major maritime engagements were fought in the Hundred Years' War against F ...

fleet captured the island of Jamaica

Jamaica (; ) is an island country situated in the Caribbean Sea. Spanning in area, it is the third-largest island of the Greater Antilles and the Caribbean (after Cuba and Hispaniola). Jamaica lies about south of Cuba, and west of His ...

. With the availability of domestically produced rum, the British changed the daily ration of liquor given to seamen from French brandy

Brandy is a liquor produced by distilling wine. Brandy generally contains 35–60% alcohol by volume (70–120 US proof) and is typically consumed as an after-dinner digestif. Some brandies are aged in wooden casks. Others are coloured with ...

to rum.

Navy rum was originally a blend mixed from rums produced in the West Indies

The West Indies is a subregion of North America, surrounded by the North Atlantic Ocean and the Caribbean Sea that includes 13 independent island countries and 18 dependencies and other territories in three major archipelagos: the Greater A ...

. It was initially supplied at a strength of 100 degrees (UK) proof, 57% alcohol by volume (ABV), as that was the only strength that could be tested (by the gunpowder test) before the invention of the hydrometer

A hydrometer or lactometer is an instrument used for measuring density or relative density of liquids based on the concept of buoyancy. They are typically calibrated and graduated with one or more scales such as specific gravity.

A hydrometer ...

. The term "Navy strength" is used in modern Britain to specify spirits bottled at 57% ABV.

While the ration was originally given neat, or mixed with lime juice, the practice of watering down the rum began around 1740. To help minimize the effect of the alcohol on his sailors, Admiral Edward Vernon

Admiral Edward Vernon (12 November 1684 – 30 October 1757) was an English naval officer. He had a long and distinguished career, rising to the rank of admiral after 46 years service. As a vice admiral during the War of Jenkins' Ear, in 1 ...

had the rum ration watered, producing a mixture that became known as grog

Grog is a term used for a variety of alcoholic beverages.

The word originally referred to rum diluted with water (and later on long sea voyages, also added the juice of limes or lemons), which British Vice-Admiral Edward Vernon introduced ...

. Many believe the term was coined in honour of the grogram cloak Admiral Vernon wore in rough weather. The Royal Navy continued to give its sailors a daily rum ration, known as a "tot", until the practice was abolished on 31 July 1970.

Today, a tot (totty) of rum is still issued on special occasions, using an order to "splice the mainbrace

"Splice the mainbrace" is an order given aboard naval vessels to issue the crew with an alcoholic drink. Originally an order for one of the most difficult emergency repair jobs aboard a sailing ship, it became a euphemism for authorized celebrator ...

", which may only be given by a member of the royal family or, on certain occasions, the admiralty board in the UK, with similar restrictions in other Commonwealth navies. Recently, such occasions have included royal marriages or birthdays, or special anniversaries. In the days of daily rum rations, the order to "splice the mainbrace" meant double rations would be issued.

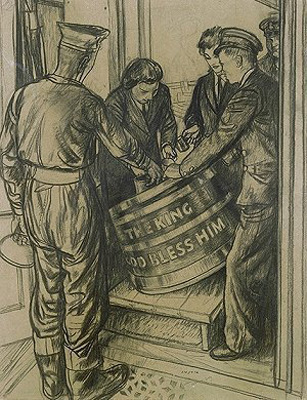

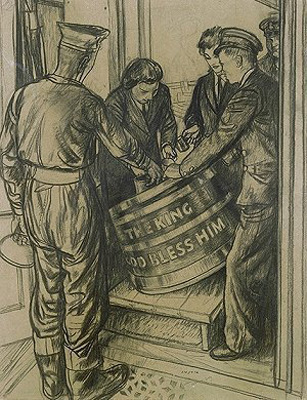

A legend involving naval rum and Horatio Nelson

Vice-Admiral Horatio Nelson, 1st Viscount Nelson, 1st Duke of Bronte (29 September 1758 – 21 October 1805) was a British flag officer in the Royal Navy. His inspirational leadership, grasp of strategy, and unconventional tactics brought abo ...

says that following his victory and death at the Battle of Trafalgar

The Battle of Trafalgar (21 October 1805) was a naval engagement between the British Royal Navy and the combined fleets of the French and Spanish Navies during the War of the Third Coalition (August–December 1805) of the Napoleonic Wars (180 ...

, Nelson's body was preserved in a cask of rum to allow transportation back to England. Upon arrival, however, the cask was opened and found to be empty of rum. The ickledbody was removed and, upon inspection, it was discovered that the sailors had drilled a hole in the bottom of the cask and drunk all the rum, hence the term "Nelson's blood" being used to describe rum. It also serves as the basis for the term tapping the admiral

In the Royal Navy, ''sucking the monkey'', ''bleeding the monkey'', or ''tapping the admiral'' was the practice of sucking liquor from a cask through a straw. This usually involved making a small hole with a gimlet in a keg or barrel and using a s ...

being used to describe surreptitiously sucking liquor from a cask through a straw. The details of the story are disputed, as many historians claim the cask contained French brandy

Brandy is a liquor produced by distilling wine. Brandy generally contains 35–60% alcohol by volume (70–120 US proof) and is typically consumed as an after-dinner digestif. Some brandies are aged in wooden casks. Others are coloured with ...

, whilst others claim instead the term originated from a toast

Toast most commonly refers to:

* Toast (food), bread browned with dry heat

* Toast (honor), a ritual in which a drink is taken

Toast may also refer to:

Places

* Toast, North Carolina, a census-designated place in the United States

Books

* '' ...

to Admiral Nelson. Variations of the story, involving different notable corpses, have been in circulation for many years. The official record states merely that the body was placed in "refined spirits" and does not go into further detail.

The Royal New Zealand Navy

The Royal New Zealand Navy (RNZN; mi, Te Taua Moana o Aotearoa, , Sea Warriors of New Zealand) is the maritime arm of the New Zealand Defence Force. The fleet currently consists of nine ships. The Navy had its origins in the Naval Defence Act ...

was the last naval force to give sailors a free daily tot of rum. The Royal Canadian Navy

The Royal Canadian Navy (RCN; french: Marine royale canadienne, ''MRC'') is the Navy, naval force of Canada. The RCN is one of three environmental commands within the Canadian Armed Forces. As of 2021, the RCN operates 12 frigates, four attack s ...

still gives a rum ration on special occasions; the rum is usually provided out of the commanding officer's fund, and is 150 proof (75%). The order to "splice the mainbrace" (i.e. take rum) can be given by the Queen as commander-in-chief, as occurred on 29 June 2010, when she gave the order to the Royal Canadian Navy as part of the celebration of their 100th anniversary.

Colonial Australia

Rum became an important trade good in the early period of the colony of

Rum became an important trade good in the early period of the colony of New South Wales

)

, nickname =

, image_map = New South Wales in Australia.svg

, map_caption = Location of New South Wales in AustraliaCoordinates:

, subdivision_type = Country

, subdivision_name = Australia

, established_title = Before federation

, es ...

. The value of rum was based upon the lack of coinage among the population of the colony, and due to the drink's ability to allow its consumer to temporarily forget about the lack of creature comforts available in the new colony. The value of rum was such that convict settlers could be induced to work the lands owned by officers of the New South Wales Corps. Due to rum's popularity among the settlers, the colony gained a reputation for drunkenness, though their alcohol consumption was less than levels commonly consumed in England at the time.

Australia

Australia, officially the Commonwealth of Australia, is a Sovereign state, sovereign country comprising the mainland of the Australia (continent), Australian continent, the island of Tasmania, and numerous List of islands of Australia, sma ...

was so far away from Britain

Britain most often refers to:

* The United Kingdom, a sovereign state in Europe comprising the island of Great Britain, the north-eastern part of the island of Ireland and many smaller islands

* Great Britain, the largest island in the United King ...

that the penal

Penal is a town in south Trinidad, Trinidad and Tobago. It lies south of San Fernando, Princes Town, and Debe, and north of Moruga, Morne Diablo and Siparia. It was originally a rice- and cocoa-producing area but is now a rapidly expanding and de ...

colony

In modern parlance, a colony is a territory subject to a form of foreign rule. Though dominated by the foreign colonizers, colonies remain separate from the administration of the original country of the colonizers, the ''metropole, metropolit ...

, established in 1788, faced severe food shortages, compounded by poor conditions for growing crops and the shortage of livestock. Eventually it was realized that it might be cheaper for India

India, officially the Republic of India (Hindi: ), is a country in South Asia. It is the seventh-largest country by area, the second-most populous country, and the most populous democracy in the world. Bounded by the Indian Ocean on the so ...

, instead of Britain, to supply the settlement of Sydney

Sydney ( ) is the capital city of the state of New South Wales, and the most populous city in both Australia and Oceania. Located on Australia's east coast, the metropolis surrounds Sydney Harbour and extends about towards the Blue Mountain ...

. By 1817, two out of every three ships which left Sydney went to Java or India, and cargoes from Bengal

Bengal ( ; bn, বাংলা/বঙ্গ, translit=Bānglā/Bôngô, ) is a geopolitical, cultural and historical region in South Asia, specifically in the eastern part of the Indian subcontinent at the apex of the Bay of Bengal, predom ...

fed and equipped the colony. Casks of Bengal Rum (which was reputed to be stronger than Jamaican Rum, and not so sweet) were brought back in the depths of nearly every ship from India. The cargoes were floated ashore clandestinely before the ships docked, by the Royal Marines

The Corps of Royal Marines (RM), also known as the Royal Marines Commandos, are the UK's special operations capable commando force, amphibious light infantry and also one of the five fighting arms of the Royal Navy. The Corps of Royal Marine ...

regiment which controlled the sales. It was against the direct orders of the governors, who had ordered the searching of every docking ship. British merchants in India grew wealthy through sending ships to Sydney "laden half with rice and half with bad spirits".

Rum was intimately involved in the only military takeover of an Australian government, known as the Rum Rebellion

The Rum Rebellion of 1808 was a ''coup d'état'' in the then-British penal colony of New South Wales, staged by the New South Wales Corps in order to depose Governor William Bligh. Australia's first and only military coup, the name derives from ...

. When William Bligh

Vice-Admiral William Bligh (9 September 1754 – 7 December 1817) was an officer of the Royal Navy and a colonial administrator. The mutiny on the HMS ''Bounty'' occurred in 1789 when the ship was under his command; after being set adrift i ...

became governor of the colony, he attempted to remedy the perceived problem with drunkenness by outlawing the use of rum as a medium of exchange. In response to Bligh's attempt to regulate the use of rum, in 1808, the New South Wales Corps marched with fixed bayonets to Government House and placed Bligh under arrest. The mutineers continued to control the colony until the arrival of Governor Lachlan Macquarie

Major-general (United Kingdom), Major General Lachlan Macquarie, Companion of the Order of the Bath, CB (; gd, Lachann MacGuaire; 31 January 1762 – 1 July 1824) was a British Army officer and colonial administrator from Scotland. Macquarie se ...

in 1810.

Asia

Commercial rum production was introduced intoTaiwan

Taiwan, officially the Republic of China (ROC), is a country in East Asia, at the junction of the East and South China Seas in the northwestern Pacific Ocean, with the People's Republic of China (PRC) to the northwest, Japan to the nort ...

along with commercial sugar production during the Japanese colonial period. Rum production continued under the Republic of China however it was neglected by Taiwan Tobacco and Liquor Corporation

Taiwan Tobacco and Liquor Corporation (TTL; ), is a state-owned manufacturer and distributor of cigarettes and alcohol, and also formerly (until 2002) a state-sanctioned alcohol beverage brewing and retailing monopoly, in Taiwan. Its most famou ...

which held the national liquor monopoly. The industry diversified after democratization and the de-monopolization of the Taiwanese alcoholic beverage industry.

Categorization

Dividing rum into meaningful groupings is complicated because no single standard exists for what constitutes rum. Instead, rum is defined by the varying rules and laws of the nations producing the spirit. The differences in definitions include issues such as spirit proof, minimum ageing, and even naming standards. Mexico requires rum be aged a minimum of eight months; the Dominican Republic, Panama and Venezuela require two years. Naming standards also vary. Argentina defines rums as white, gold, light, and extra light.Grenada

Grenada ( ; Grenadian Creole French: ) is an island country in the West Indies in the Caribbean Sea at the southern end of the Grenadines island chain. Grenada consists of the island of Grenada itself, two smaller islands, Carriacou and Pe ...

and Barbados

Barbados is an island country in the Lesser Antilles of the West Indies, in the Caribbean region of the Americas, and the most easterly of the Caribbean Islands. It occupies an area of and has a population of about 287,000 (2019 estimate). ...

uses the terms white, overproof, and matured, while the United States defines rum, rum liqueur, and flavored rum. In Australia, rum is divided into dark or red rum (underproof known as UP, overproof known as OP, and triple distilled) and white rum.

Despite these differences in standards and nomenclature, the following divisions are provided to help show the wide variety of rums produced.

Regional variations

Within the Caribbean, each island or production area has a unique style. For the most part, these styles can be grouped by the language traditionally spoken. Due to the overwhelming influence of Puerto Rican rum, most rum consumed in the United States is produced in the "Spanish-speaking" style.

* English-speaking areas are known for darker rums with a fuller taste that retains a greater amount of the underlying molasses flavor. Rums from the

Within the Caribbean, each island or production area has a unique style. For the most part, these styles can be grouped by the language traditionally spoken. Due to the overwhelming influence of Puerto Rican rum, most rum consumed in the United States is produced in the "Spanish-speaking" style.

* English-speaking areas are known for darker rums with a fuller taste that retains a greater amount of the underlying molasses flavor. Rums from the Bahamas

The Bahamas (), officially the Commonwealth of The Bahamas, is an island country within the Lucayan Archipelago of the West Indies in the Atlantic Ocean, North Atlantic. It takes up 97% of the Lucayan Archipelago's land area and is home to ...

, Antigua

Antigua ( ), also known as Waladli or Wadadli by the native population, is an island in the Lesser Antilles. It is one of the Leeward Islands in the Caribbean region and the main island of the country of Antigua and Barbuda. Antigua and Bar ...

, Trinidad and Tobago

Trinidad and Tobago (, ), officially the Republic of Trinidad and Tobago, is the southernmost island country in the Caribbean. Consisting of the main islands Trinidad and Tobago, and numerous much smaller islands, it is situated south of ...

, Grenada

Grenada ( ; Grenadian Creole French: ) is an island country in the West Indies in the Caribbean Sea at the southern end of the Grenadines island chain. Grenada consists of the island of Grenada itself, two smaller islands, Carriacou and Pe ...

, Barbados

Barbados is an island country in the Lesser Antilles of the West Indies, in the Caribbean region of the Americas, and the most easterly of the Caribbean Islands. It occupies an area of and has a population of about 287,000 (2019 estimate). ...

, Saint Lucia

Saint Lucia ( acf, Sent Lisi, french: Sainte-Lucie) is an island country of the West Indies in the eastern Caribbean. The island was previously called Iouanalao and later Hewanorra, names given by the native Arawaks and Caribs, two Amerindian ...

, Saint Vincent & the Grenadines

Saint Vincent and the Grenadines () is an island country in the Caribbean. It is located in the southeast Windward Islands of the Lesser Antilles, which lie in the West Indies at the southern end of the eastern border of the Caribbean Sea wh ...

, Belize

Belize (; bzj, Bileez) is a Caribbean and Central American country on the northeastern coast of Central America. It is bordered by Mexico to the north, the Caribbean Sea to the east, and Guatemala to the west and south. It also shares a wate ...

, Bermuda

)

, anthem = "God Save the King"

, song_type = National song

, song = " Hail to Bermuda"

, image_map =

, map_caption =

, image_map2 =

, mapsize2 =

, map_caption2 =

, subdivision_type = Sovereign state

, subdivision_name =

, e ...

, Saint Kitts

Saint Kitts, officially the Saint Christopher Island, is an island in the West Indies. The west side of the island borders the Caribbean Sea, and the eastern coast faces the Atlantic Ocean. Saint Kitts and the neighbouring island of Nevis cons ...

, the Demerara

Demerara ( nl, Demerary, ) is a historical region in the Guianas, on the north coast of South America, now part of the country of Guyana. It was a colony of the Dutch West India Company between 1745 and 1792 and a colony of the Dutch state fro ...

region of Guyana

Guyana ( or ), officially the Cooperative Republic of Guyana, is a country on the northern mainland of South America. Guyana is an indigenous word which means "Land of Many Waters". The capital city is Georgetown. Guyana is bordered by the ...

, and Jamaica

Jamaica (; ) is an island country situated in the Caribbean Sea. Spanning in area, it is the third-largest island of the Greater Antilles and the Caribbean (after Cuba and Hispaniola). Jamaica lies about south of Cuba, and west of His ...

are typical of this style. A version called "Rude Rum" or "John Crow Batty" is served in some places and it is reportedly much stronger in alcohol content being listed as one of the 10 strongest drinks in the world, while it might also contain other intoxicants."The drink that nearly knocked me out with one sniff"by Nick Davis, BBC News, 6 September 2015 The term, denoting home made, strong rum, appears in New Zealand since at least the early 19th century. Jamaican rum was granted

geographical indication

A geographical indication (GI) is a name or sign used on products which corresponds to a specific geographical location or origin (e.g., a town, region, or country). The use of a geographical indication, as an indication of the product's source, ...

protection in 2016.

* French-speaking areas are best known for their agricultural rums (''rhum agricole

Rhum agricole () is the French term for '' sugarcane juice rum'', a style of rum originally distilled in the French Caribbean islands from freshly squeezed sugarcane juice rather than molasses. ''Rhum'' is the term that typically distinguishes ...

''). These rums, being produced exclusively from sugar cane juice, retain a greater amount of the original flavor of the sugar cane and are generally more expensive than molasses-based rums. Rums from Haiti

Haiti (; ht, Ayiti ; French: ), officially the Republic of Haiti (); ) and formerly known as Hayti, is a country located on the island of Hispaniola in the Greater Antilles archipelago of the Caribbean Sea, east of Cuba and Jamaica, and ...

, Guadeloupe

Guadeloupe (; ; gcf, label=Antillean Creole, Gwadloup, ) is an archipelago and overseas department and region of France in the Caribbean. It consists of six inhabited islands—Basse-Terre, Grande-Terre, Marie-Galante, La Désirade, and the ...

, and Martinique

Martinique ( , ; gcf, label=Martinican Creole, Matinik or ; Kalinago: or ) is an island and an overseas department/region and single territorial collectivity of France. An integral part of the French Republic, Martinique is located in th ...

are typical of this style.

* Areas that had been formerly part of the Spanish Empire

The Spanish Empire ( es, link=no, Imperio español), also known as the Hispanic Monarchy ( es, link=no, Monarquía Hispánica) or the Catholic Monarchy ( es, link=no, Monarquía Católica) was a colonial empire governed by Spain and its prede ...

traditionally produce ''añejo'' rums with a fairly smooth taste. Rums from Colombia

Colombia (, ; ), officially the Republic of Colombia, is a country in South America with insular regions in North America—near Nicaragua's Caribbean coast—as well as in the Pacific Ocean. The Colombian mainland is bordered by the Car ...

, Cuba

Cuba ( , ), officially the Republic of Cuba ( es, República de Cuba, links=no ), is an island country comprising the island of Cuba, as well as Isla de la Juventud and several minor archipelagos. Cuba is located where the northern Caribbea ...

, the Dominican Republic

The Dominican Republic ( ; es, República Dominicana, ) is a country located on the island of Hispaniola in the Greater Antilles archipelago of the Caribbean region. It occupies the eastern five-eighths of the island, which it shares wit ...

, Guatemala

Guatemala ( ; ), officially the Republic of Guatemala ( es, República de Guatemala, links=no), is a country in Central America. It is bordered to the north and west by Mexico; to the northeast by Belize and the Caribbean; to the east by H ...

, Nicaragua

Nicaragua (; ), officially the Republic of Nicaragua (), is the largest country in Central America, bordered by Honduras to the north, the Caribbean to the east, Costa Rica to the south, and the Pacific Ocean to the west. Managua is the cou ...

, Panama

Panama ( , ; es, link=no, Panamá ), officially the Republic of Panama ( es, República de Panamá), is a transcontinental country spanning the southern part of North America and the northern part of South America. It is bordered by Cos ...

, the Philippines

The Philippines (; fil, Pilipinas, links=no), officially the Republic of the Philippines ( fil, Republika ng Pilipinas, links=no),

* bik, Republika kan Filipinas

* ceb, Republika sa Pilipinas

* cbk, República de Filipinas

* hil, Republ ...

, Puerto Rico

Puerto Rico (; abbreviated PR; tnq, Boriken, ''Borinquen''), officially the Commonwealth of Puerto Rico ( es, link=yes, Estado Libre Asociado de Puerto Rico, lit=Free Associated State of Puerto Rico), is a Caribbean island and Unincorporated ...

, and Venezuela

Venezuela (; ), officially the Bolivarian Republic of Venezuela ( es, link=no, República Bolivariana de Venezuela), is a country on the northern coast of South America, consisting of a continental landmass and many islands and islets in th ...

are typical of this style. Rum from the U.S. Virgin Islands is also of this style. The Canary Islands

The Canary Islands (; es, Canarias, ), also known informally as the Canaries, are a Spanish autonomous community and archipelago in the Atlantic Ocean, in Macaronesia. At their closest point to the African mainland, they are west of Morocc ...

produces a honey-based rum known as ''ron miel de Canarias'' which carries a protected geographical designation.

Cachaça

''Cachaça'' () is a distilled spirit made from fermented sugarcane juice. Also known as ''pinga'', ''caninha'', and other names, it is the most popular spirit among distilled alcoholic beverages in Brazil.Cavalcante, Messias Soares. Todos os no ...

is a spirit similar to rum that is produced in Brazil. Some countries, including the United States, classify cachaça as a type of rum. Seco, from Panama, is also a spirit similar to rum, but also similar to vodka

Vodka ( pl, wódka , russian: водка , sv, vodka ) is a clear distilled alcoholic beverage. Different varieties originated in Poland, Russia, and Sweden. Vodka is composed mainly of water and ethanol but sometimes with traces of impuritie ...

since it is triple distilled. Cachaca also comes from sugar cane

Mexico produces a number of brands of light and dark rum, as well as other less-expensive flavored and unflavored sugarcane-based liquors, such as ''aguardiente de caña'' and ''charanda

Charanda is an alcoholic spirit derived from sugarcane, similar to rum.

Typically the beverage is associated with the central portion of the State of Michoacán in Mexico, particularly the Purépecha-populated areas in the vicinity of the promin ...

''. Aguardiente is also the name for unaged distilled cane spirit in some, primarily Spanish-speaking countries, since their definition of rum includes at least two years of ageing in wood.

A spirit known as ''aguardiente

( Spanish), or ( Portuguese) ( eu, pattar; ca, aiguardent; gl, augardente), is a generic term for alcoholic beverages that contain between 29% and 60% alcohol by volume (ABV). It originates in the Iberian Peninsula (Portugal and Spain) and in ...

'', distilled from molasses and often infused with anise

Anise (; '), also called aniseed or rarely anix is a flowering plant in the family Apiaceae native to Eurasia.

The flavor and aroma of its seeds have similarities with some other spices and herbs, such as star anise, fennel, licorice, and ta ...

, with additional sugarcane juice added after distillation, is produced in Central America and northern South America.

In West Africa, and particularly in Liberia, 'cane juice' (also known as Liberian rum or simply ''CJ'' within Liberia itself) is a cheap, strong spirit distilled from sugarcane, which can be as strong as 43% ABV (86 proof). A refined cane spirit has also been produced in South Africa

South Africa, officially the Republic of South Africa (RSA), is the southernmost country in Africa. It is bounded to the south by of coastline that stretch along the South Atlantic and Indian Oceans; to the north by the neighbouring countri ...

since the 1950s, simply known as cane

Cane or caning may refer to:

*Walking stick or walking cane, a device used primarily to aid walking

*Assistive cane, a walking stick used as a mobility aid for better balance

*White cane, a mobility or safety device used by many people who are b ...

or "spook".

Within Europe, in the Czech Republic and Slovakia, a similar spirit made from sugar beet

A sugar beet is a plant whose root contains a high concentration of sucrose and which is grown commercially for sugar production. In plant breeding, it is known as the Altissima cultivar group of the common beet (''Beta vulgaris''). Together wi ...

is known as Tuzemak.

In Germany, a cheap substitute for genuine dark rum is called ''Rum-Verschnitt'' (literally: blended or "cut" rum). This drink is made of genuine dark rum (often high-ester rum from Jamaica), rectified spirit

Rectified spirit, also known as neutral spirits, rectified alcohol or ethyl alcohol of agricultural origin, is highly concentrated ethanol that has been purified by means of repeated distillation in a process called rectification. In some countr ...

, and water. Very often, caramel coloring

Caramel color or caramel coloring is a water-soluble food coloring. It is made by heat treatment of carbohydrates (sugars), in general in the presence of acids, alkalis, or salts, in a process called caramelization. It is more fully oxidized than ...

is used, too. The relative amount of genuine rum it contains can be quite low, since the legal minimum is at only 5%. In Austria

Austria, , bar, Östareich officially the Republic of Austria, is a country in the southern part of Central Europe, lying in the Eastern Alps. It is a federation of nine states, one of which is the capital, Vienna, the most populous ...

, a similar rum called ''Inländerrum'' or domestic rum is available. However, Austrian ''Inländerrum'' is always a spiced rum, such as the brand Stroh

Stroh Austria GmbH is an Austrian manufacturer of rum, especially spiced rums and high-proof rums used in warm drinks and cooking. The Stroh Rum brand is one of the best-known spirits from Austria. The name is widely used as a generic synonym f ...

; German ''Rum-Verschnitt'', in contrast, is never spiced or flavored.

Grades

The grades and variations used to describe rum depend on the location where a rum was produced. Despite these variations, the following terms are frequently used to describe various types of rum: * Dark rums, also known by their particular colour, such as brown, black, or red rums, are classes a grade darker than gold rums. They are usually made from caramelized sugar or molasses. They are generally aged longer, in heavily charred barrels, giving them much stronger flavors than either light or gold rums, and hints of spices can be detected, along with a strong molasses or caramel overtone. They commonly provide substance in rum drinks, as well as colour. In addition, dark rum is the type most commonly used in cooking. Most dark rums come from areas such asJamaica

Jamaica (; ) is an island country situated in the Caribbean Sea. Spanning in area, it is the third-largest island of the Greater Antilles and the Caribbean (after Cuba and Hispaniola). Jamaica lies about south of Cuba, and west of His ...

, Bahamas

The Bahamas (), officially the Commonwealth of The Bahamas, is an island country within the Lucayan Archipelago of the West Indies in the Atlantic Ocean, North Atlantic. It takes up 97% of the Lucayan Archipelago's land area and is home to ...

, Haiti

Haiti (; ht, Ayiti ; French: ), officially the Republic of Haiti (); ) and formerly known as Hayti, is a country located on the island of Hispaniola in the Greater Antilles archipelago of the Caribbean Sea, east of Cuba and Jamaica, and ...

, and Martinique

Martinique ( , ; gcf, label=Martinican Creole, Matinik or ; Kalinago: or ) is an island and an overseas department/region and single territorial collectivity of France. An integral part of the French Republic, Martinique is located in th ...

.

* Flavored rums are infused with flavors of fruits, such as banana

A banana is an elongated, edible fruit – botanically a berry – produced by several kinds of large herbaceous flowering plants in the genus ''Musa''. In some countries, bananas used for cooking may be called "plantains", distinguis ...

, mango

A mango is an edible stone fruit produced by the tropical tree ''Mangifera indica''. It is believed to have originated in the region between northwestern Myanmar, Bangladesh, and northeastern India. ''M. indica'' has been cultivated in South a ...

, orange

Orange most often refers to:

*Orange (fruit), the fruit of the tree species '' Citrus'' × ''sinensis''

** Orange blossom, its fragrant flower

*Orange (colour), from the color of an orange, occurs between red and yellow in the visible spectrum

* ...

, pineapple

The pineapple (''Ananas comosus'') is a tropical plant with an edible fruit; it is the most economically significant plant in the family Bromeliaceae. The pineapple is indigenous to South America, where it has been cultivated for many centuri ...

, coconut

The coconut tree (''Cocos nucifera'') is a member of the palm tree family ( Arecaceae) and the only living species of the genus ''Cocos''. The term "coconut" (or the archaic "cocoanut") can refer to the whole coconut palm, the seed, or the ...

, starfruit

Carambola, also known as star fruit, is the fruit of '' Averrhoa carambola'', a species of tree native to tropical Southeast Asia. The mildly poisonous fruit is commonly consumed in parts of Brazil, Southeast Asia, South Asia, the South Pacif ...

or lime

Lime commonly refers to:

* Lime (fruit), a green citrus fruit

* Lime (material), inorganic materials containing calcium, usually calcium oxide or calcium hydroxide

* Lime (color), a color between yellow and green

Lime may also refer to:

Botany ...

. These are generally less than 40% ABV (80 proof). They mostly serve to flavor similarly-themed tropical drinks but are also often drunk neat or with ice. This infusion of flavors occurs after fermentation and distillation. Various chemicals are added to the alcohol to simulate the tastes of food.

* Gold rums, also called "amber" rums, are medium-bodied rums that are generally aged. These gain their dark colour from aging in wooden barrel

A barrel or cask is a hollow cylindrical container with a bulging center, longer than it is wide. They are traditionally made of wooden staves and bound by wooden or metal hoops. The word vat is often used for large containers for liquids, ...

s (usually the charred, white oak

The genus ''Quercus'' contains about 500 species, some of which are listed here. The genus, as is the case with many large genera, is divided into subgenera and sections. Traditionally, the genus ''Quercus'' was divided into the two subgenera '' ...

barrels that are the byproduct of Bourbon whiskey

Bourbon () is a type of barrel-aged American whiskey made primarily from corn. The name derives from the French Bourbon dynasty, although the precise source of inspiration is uncertain; contenders include Bourbon County in Kentucky and Bourbo ...

). They have more flavor and are stronger-tasting than light rum, and can be considered midway between light rum and the darker varieties.

* Light rums, also referred to as "silver" or "white" rums, in general, have very little flavor aside from a general sweetness. Light rums are sometimes filtered after aging to remove any colour. The majority of light rums come from Puerto Rico

Puerto Rico (; abbreviated PR; tnq, Boriken, ''Borinquen''), officially the Commonwealth of Puerto Rico ( es, link=yes, Estado Libre Asociado de Puerto Rico, lit=Free Associated State of Puerto Rico), is a Caribbean island and Unincorporated ...

. Their milder flavors make them popular for use in mixed drinks, as opposed to drinking them straight. Light rums are included in some of the most popular cocktails including the Mojito

Mojito (; ) is a traditional Cuban punch. The cocktail often consists of five ingredients: white rum, sugar (traditionally sugar cane juice), lime juice, soda water, and mint. Its combination of sweetness, citrus, and herbaceous mint flavors is ...

and the Daiquiri

The daiquiri (; es, daiquirí ) is a cocktail whose main ingredients are rum, citrus juice (typically lime juice), and sugar or other sweetener.

The daiquiri is one of the six basic drinks listed in David A. Embury's classic ''The Fine Art o ...

.

* Overproof rums are much higher than the standard 40% ABV (80 proof), with many as high as 75% (150 proof) to 80% (160 proof) available. Two examples are Bacardi 151

Bacardi 151 is a discontinued brand of highly alcoholic rum made by Bacardi Limited of Hamilton, Bermuda. It is named for its alcohol concentration level of 151 U.S. proof, that is, 75.5% alcohol by volume. This is much higher than typical rum, ...

or Pitorro Pitorro is a distilled spirit from Puerto Rico, referred to as " moonshine rum." Pitorro is usually much stronger than commercial rum. At times its alcohol content surpasses 100 proof. It is often homemade and a part of traditional Puerto Rican holi ...

moonshine. They are usually used in mixed drinks.

* Premium rums, as with other sipping spirits such as Cognac

Cognac ( , also , ) is a variety of brandy named after the Communes of France, commune of Cognac, France. It is produced in the surrounding wine-growing region in the Departments of France, departments of Charente and Charente-Maritime.

Cog ...

and Scotch whisky

Scotch whisky (; sco, Scots whisky/whiskie, whusk(e)y; often simply called whisky or Scotch) is malt whisky or grain whisky (or a blend of the two), made in Scotland.

All Scotch whisky was originally made from malted barley. Commercial distil ...

, are in a special market category. These are generally from boutique brands that sell carefully produced and aged rums. They have more character and flavor than their "mixing" counterparts and are generally consumed straight.

* Spiced rums obtain their flavors through the addition of spices and, sometimes, caramel

Caramel ( or ) is an orange-brown confectionery product made by heating a range of sugars. It can be used as a flavoring in puddings and desserts, as a filling in bonbons, or as a topping for ice cream and custard.

The process of caramelizatio ...

. Most are darker in colour, and based on gold rums. Some are significantly darker, while many cheaper brands are made from inexpensive white rums and darkened with caramel colour. Among the spices added are cinnamon

Cinnamon is a spice obtained from the inner bark of several tree species from the genus ''Cinnamomum''. Cinnamon is used mainly as an aromatic condiment and flavouring additive in a wide variety of cuisines, sweet and savoury dishes, breakfa ...

, rosemary, absinthe/aniseed, pepper, cloves

Cloves are the aromatic flower buds of a tree in the family Myrtaceae, ''Syzygium aromaticum'' (). They are native to the Maluku Islands (or Moluccas) in Indonesia, and are commonly used as a spice, flavoring or fragrance in consumer products, s ...

, and cardamom

Cardamom (), sometimes cardamon or cardamum, is a spice made from the seeds of several plants in the genera ''Elettaria'' and ''Amomum'' in the family Zingiberaceae. Both genera are native to the Indian subcontinent and Indonesia. They are rec ...

.

Production method

Unlike some other spirits, rum has no defined production methods. Instead, rum production is based on traditional styles that vary between locations and distillers.Harvesting

Sugarcane

Sugarcane or sugar cane is a species of (often hybrid) tall, Perennial plant, perennial grass (in the genus ''Saccharum'', tribe Andropogoneae) that is used for sugar Sugar industry, production. The plants are 2–6 m (6–20 ft) tall with ...

is traditionally collected by sugarcane machete cutters who cut the cane near to the ground, where the largest concentration of sugars is found, before lopping off the green tips. A good cutter can cut three tons of cane per day on average, but this is a small fraction of what a machine can cut, therefore mechanised harvesting is now utilized.

Extraction

Sugarcane comprises around 63% to 73% water, 12% to 16% soluble sugar, 2% to 3% non-sugars, and 11% to 16% fiber. To extract the water and sugar juice, the harvested cane is cleaned, sliced into small lengths, and milled (pressed).Fermentation

Most rum is produced from molasses, which is made from sugarcane. A rum's quality is dependent on the quality and variety of the sugar cane that was used to create it. The sugar cane's quality depends on the soil type and climate that it was grown in. Within the Caribbean, much of this molasses is from Brazil.

A notable exception is the French-speaking islands, where sugarcane juice is the preferred base ingredient. In Brazil itself, the distilled alcoholic drink derived from cane juice is distinguished from rum and called ''

Most rum is produced from molasses, which is made from sugarcane. A rum's quality is dependent on the quality and variety of the sugar cane that was used to create it. The sugar cane's quality depends on the soil type and climate that it was grown in. Within the Caribbean, much of this molasses is from Brazil.

A notable exception is the French-speaking islands, where sugarcane juice is the preferred base ingredient. In Brazil itself, the distilled alcoholic drink derived from cane juice is distinguished from rum and called ''cachaça

''Cachaça'' () is a distilled spirit made from fermented sugarcane juice. Also known as ''pinga'', ''caninha'', and other names, it is the most popular spirit among distilled alcoholic beverages in Brazil.Cavalcante, Messias Soares. Todos os no ...

''.

Yeast

Yeasts are eukaryotic, single-celled microorganisms classified as members of the fungus kingdom. The first yeast originated hundreds of millions of years ago, and at least 1,500 species are currently recognized. They are estimated to constitut ...

and water are added to the base ingredient to start the fermentation process.

While some rum producers allow wild yeasts to perform the fermentation, most use specific strains of yeast to help provide a consistent taste and predictable fermentation time. Dunder

Dunder is the liquid left in a boiler after distilling a batch of rum. It is a traditional flavor source used in the fermentation of the wash of Jamaican rum. Similar in process to sour mash in Bourbon whiskey, it is a crucial step in achieving ...

, the yeast-rich foam from previous fermentations, is the traditional yeast source in Jamaica

Jamaica (; ) is an island country situated in the Caribbean Sea. Spanning in area, it is the third-largest island of the Greater Antilles and the Caribbean (after Cuba and Hispaniola). Jamaica lies about south of Cuba, and west of His ...

.

"The yeast employed will determine the final taste and aroma profile,"

says Jamaican master blender Joy Spence

The word joy refers to the emotion evoked by well-being, success, or good fortune, and is typically associated with feelings of intense, long lasting happiness.

Dictionary definitions

Dictionary definitions of joy typically include a sense of ...

.

Distillers that make lighter rums, such as Bacardi

Bacardi Limited (; ) is one of the largest privately held, family-owned spirits companies in the world. Originally known for its Bacardi brand of white rum, it now has a portfolio of more than 200 brands and labels. Founded in Cuba in 1862 an ...

, prefer to use faster-working yeasts.

Use of slower-working yeasts causes more ester

In chemistry, an ester is a compound derived from an oxoacid (organic or inorganic) in which at least one hydroxyl group () is replaced by an alkoxy group (), as in the substitution reaction of a carboxylic acid and an alcohol. Glycerides ar ...

s to accumulate during fermentation, allowing for a fuller-tasting rum.

Fermentation products like 2-ethyl-3-methyl butyric acid and esters like ethyl butyrate

Ethyl butyrate, also known as ethyl butanoate, or butyric ether, is an ester with the chemical formula CH3CH2CH2COOCH2CH3. It is soluble in propylene glycol, paraffin oil, and kerosene. It has a fruity odor, similar to pineapple, and is a key in ...

and ethyl hexanoate

Ethyl hexanoate is the ester resulting from the condensation of hexanoic acid and ethanol

Ethanol (abbr. EtOH; also called ethyl alcohol, grain alcohol, drinking alcohol, or simply alcohol) is an organic compound. It is an alcohol with ...

give rise to the sweet and fruitiness of rum.

Distillation

As with all other aspects of rum production, no standard method is used for distillation. While some producers work in batches usingpot still

A pot still is a type of distillation apparatus or still used to distill liquors such as whisky or brandy. In modern (post-1850s) practice, they are not used to produce rectified spirit, because they do not separate congeners from ethanol as eff ...

s, most rum production is done using column still

A column still, also called a continuous still, patent still or Coffey still is a variety of still consisting of two columns. Column stills can produce rectified spirit (95% ABV).

Description

The first column (called the analyzer) in a column s ...

distillation.

Pot still output contains more congeners than the output from column stills, so produces fuller-tasting rums.

Ageing and blending

Many countries require rum to beaged

Ageing ( BE) or aging ( AE) is the process of becoming older. The term refers mainly to humans, many other animals, and fungi, whereas for example, bacteria, perennial plants and some simple animals are potentially biologically immortal. In ...

for at least one year. This ageing is commonly performed in used bourbon Bourbon may refer to:

Food and drink

* Bourbon whiskey, an American whiskey made using a corn-based mash

* Bourbon barrel aged beer, a type of beer aged in bourbon barrels

* Bourbon biscuit, a chocolate sandwich biscuit

* A beer produced by Bras ...

casks, but may also be performed in other types of wooden casks or stainless steel tanks. The ageing process determines the colour of the rum. When aged in oak casks, it becomes dark, whereas rum aged in stainless steel tanks remains virtually colourless.

Due to the tropical climate, common to most rum-producing areas, rum matures at a much higher rate than is typical for whisky or brandy. An indication of this higher rate is the angels' share, or amount of product lost to evaporation

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidi ...

. While products aged in France or Scotland see about 2% loss each year, tropical rum producers may see as much as 10%.

After ageing, rum is normally blended to ensure a consistent flavour, the final step in the rum-making process. During blending, light rums may be filtered to remove any colour gained during ageing. For dark rums, caramel

Caramel ( or ) is an orange-brown confectionery product made by heating a range of sugars. It can be used as a flavoring in puddings and desserts, as a filling in bonbons, or as a topping for ice cream and custard.

The process of caramelizatio ...

may be added for colour.

There have been attempts to match the molecular composition of aged rum in significantly shorter time spans with artificial aging using heat and light.

In cuisine

Besidesrum punch

''Rum Punch'' is a 1992 novel written by Elmore Leonard. The novel was adapted into the film ''Jackie Brown'' (1997) by director Quentin Tarantino.

The characters Ordell Robbie, Louis Gara and Melanie Ralston first appeared in Leonard's novel ...

es, cocktails such as the Cuba libre