Industrial wastewater treatment describes the processes used for

treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a

sanitary sewer or to a

surface water

Surface water is water located on top of land forming terrestrial (inland) waterbodies, and may also be referred to as ''blue water'', opposed to the seawater and waterbodies like the ocean.

The vast majority of surface water is produced by prec ...

in the environment. Some industrial facilities generate wastewater that can be treated in

sewage treatment plants

Sewage treatment (or domestic wastewater treatment, municipal wastewater treatment) is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding envir ...

. Most industrial processes, such as

petroleum refineries

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefie ...

, chemical and

petrochemical

Petrochemicals (sometimes abbreviated as petchems) are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sou ...

plants have their own specialized facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the regulations regarding disposal of wastewaters into

sewers or into rivers, lakes or

ocean

The ocean (also the sea or the world ocean) is the body of salt water that covers approximately 70.8% of the surface of Earth and contains 97% of Earth's water. An ocean can also refer to any of the large bodies of water into which the wo ...

s.

This applies to industries that generate wastewater with high concentrations of organic matter (e.g. oil and grease), toxic pollutants (e.g. heavy metals,

volatile organic compounds) or nutrients such as

ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogenous was ...

. Some industries install a pre-treatment system to remove some pollutants (e.g., toxic compounds), and then discharge the partially treated wastewater to the municipal sewer system.

Most industries produce some

wastewater. Recent trends have been to minimize such production or to recycle treated wastewater within the production process. Some industries have been successful at redesigning their manufacturing processes to reduce or eliminate pollutants. Sources of industrial wastewater include battery manufacturing, chemical manufacturing, electric power plants,

food industry

The food industry is a complex, global network of diverse businesses that supplies most of the food consumed by the world's population. The food industry today has become highly diversified, with manufacturing ranging from small, traditiona ...

, iron and steel industry, metal working, mines and quarries, nuclear industry,

oil and gas extraction

Petroleum is a fossil fuel that can be drawn from beneath the earth's surface. Reservoirs of petroleum was formed through the mixture of plants, algae, and sediments in shallow seas under high pressure. Petroleum is mostly recovered from oil dr ...

,

petroleum refining and

petrochemicals

Petrochemicals (sometimes abbreviated as petchems) are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sou ...

, pharmaceutical manufacturing,

pulp and paper industry

The pulp and paper industry comprises companies that use wood as raw material and produce pulp, paper, paperboard and other cellulose-based products.

Manufacturing process

The pulp is fed to a paper machine where it is formed as a paper web an ...

, smelters,

textile mill

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods ...

s, industrial

oil contamination, water treatment and

wood preserving. Treatment processes include brine treatment, solids removal (e.g. chemical precipitation, filtration), oils and grease removal, removal of biodegradable organics, removal of other organics, removal of acids and alkalis, and removal of toxic materials.

Types

Industrial facilities may generate the following industrial wastewater flows:

* Manufacturing process wastestreams, which can include

conventional pollutant A conventional pollutant is a term used in the USA to describe a water pollutant that is amenable to treatment by a municipal sewage treatment plant. A basic list of conventional pollutants is defined in the U.S. Clean Water Act. The list has been ...

s (i.e. controllable with

secondary treatment systems),

toxic

Toxicity is the degree to which a chemical substance or a particular mixture of substances can damage an organism. Toxicity can refer to the effect on a whole organism, such as an animal, bacterium, or plant, as well as the effect on a subst ...

pollutants (e.g. solvents, heavy metals), and other harmful compounds such as

nutrients

A nutrient is a substance used by an organism to survive, grow, and reproduce. The requirement for dietary nutrient intake applies to animals, plants, fungi, and protists. Nutrients can be incorporated into cells for metabolic purposes or excret ...

* Non-process wastestreams:

boiler blowdown Boiler blowdown is water intentionally wasted from a boiler to avoid concentration of impurities during continuing evaporation of steam. The water is blown out of the boiler with some force by steam pressure within the boiler. Bottom blowdown used ...

and

cooling water

Cooling tower and water discharge of a nuclear power plant

Water cooling is a method of heat removal from components and industrial equipment. Evaporative cooling using water is often more efficient than air cooling. Water is inexpensive and non ...

, which produce

thermal pollution

Thermal pollution, sometimes called "thermal enrichment", is the degradation of water quality by any process that changes ambient water temperature. Thermal pollution is the rise or fall in the temperature of a natural body of water caused by hum ...

and other pollutants

*

Industrial site drainage, generated both by manufacturing facilities, service industries and energy and mining sites

* Wastestreams from the energy and mining sectors:

acid mine drainage,

produced water

Produced water is a term used in the oil industry or geothermal industry to describe water that is produced as a byproduct during the extraction of Petroleum, oil and natural gas, or used as a medium for heat extraction. Produced water is the kind ...

from oil and gas extraction,

radionuclide

A radionuclide (radioactive nuclide, radioisotope or radioactive isotope) is a nuclide that has excess nuclear energy, making it unstable. This excess energy can be used in one of three ways: emitted from the nucleus as gamma radiation; transfer ...

s

* Wastestreams that are by-products of treatment or cooling processes:

backwashing (water treatment)

In terms of water treatment, including water purification and sewage treatment, backwashing refers to pumping water backwards through the filters media, sometimes including intermittent use of compressed air during the process. Backwashing is ...

,

brine

Brine is a high-concentration solution of salt (NaCl) in water (H2O). In diverse contexts, ''brine'' may refer to the salt solutions ranging from about 3.5% (a typical concentration of seawater, on the lower end of that of solutions used for br ...

.

Contaminants

Industrial sectors

The specific pollutants generated and the resultant effluent concentrations can vary widely among the industrial sectors.

Battery manufacturing

Battery

Battery most often refers to:

* Electric battery, a device that provides electrical power

* Battery (crime), a crime involving unlawful physical contact

Battery may also refer to:

Energy source

*Automotive battery, a device to provide power t ...

manufacturers specialize in fabricating small devices for electronics and portable equipment (e.g., power tools), or larger, high-powered units for cars, trucks and other motorized vehicles. Pollutants generated at manufacturing plants includes cadmium, chromium, cobalt, copper, cyanide, iron, lead, manganese, mercury, nickel, silver, zinc, oil and grease.

Centralized waste treatment

A centralized waste treatment (CWT) facility processes liquid or solid industrial wastes generated by off-site manufacturing facilities. A manufacturer may send its wastes to a CWT plant, rather than perform treatment on site, due to constraints such as limited land availability, difficulty in designing and operating an on-site system, or limitations imposed by environmental regulations and permits. A manufacturer may determine that using a CWT is more cost-effective than treating the waste itself; this is often the case where the manufacturer is a small business.

CWT plants often receive wastes from a wide variety of manufacturers, including chemical plants, metal fabrication and finishing; and used oil and petroleum products from various manufacturing sectors. The wastes may be classified as

hazardous, have high pollutant concentrations or otherwise be difficult to treat. In 2000 the

U.S. Environmental Protection Agency published wastewater regulations for CWT facilities in the US.

Chemical manufacturing

Organic chemicals manufacturing

The specific pollutants discharged by

organic chemical manufacturers vary widely from plant to plant, depending on the types of products manufactured, such as bulk organic chemicals, resins, pesticides, plastics, or synthetic fibers. Some of the organic compounds that may be discharged are

benzene

Benzene is an organic chemical compound with the molecular formula C6H6. The benzene molecule is composed of six carbon atoms joined in a planar ring with one hydrogen atom attached to each. Because it contains only carbon and hydrogen atoms, ...

,

chloroform

Chloroform, or trichloromethane, is an organic compound with chemical formula, formula Carbon, CHydrogen, HChlorine, Cl3 and a common organic solvent. It is a colorless, strong-smelling, dense liquid produced on a large scale as a precursor to ...

,

naphthalene

Naphthalene is an organic compound with formula . It is the simplest polycyclic aromatic hydrocarbon, and is a white crystalline solid with a characteristic odor that is detectable at concentrations as low as 0.08 ppm by mass. As an aromati ...

,

phenol

Phenol (also called carbolic acid) is an aromatic organic compound with the molecular formula . It is a white crystalline solid that is volatile. The molecule consists of a phenyl group () bonded to a hydroxy group (). Mildly acidic, it req ...

s,

toluene and

vinyl chloride.

Biochemical oxygen demand (BOD), which is a gross measurement of a range of organic pollutants, may be used to gauge the effectiveness of a biological wastewater treatment system, and is used as a regulatory parameter in some discharge permits. Metal pollutant discharges may include

chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

,

copper,

lead,

nickel and

zinc.

Inorganic chemicals manufacturing

The

inorganic chemicals

In chemistry, an inorganic compound is typically a chemical compound that lacks carbon–hydrogen bonds, that is, a compound that is not an organic compound. The study of inorganic compounds is a subfield of chemistry known as ''inorganic chemistr ...

sector covers a wide variety of products and processes, although an individual plant may produce a narrow range of products and pollutants. Products include aluminum compounds; calcium carbide and calcium chloride; hydrofluoric acid; potassium compounds; borax; chrome and fluorine-based compounds; cadmium and zinc-based compounds. The pollutants discharged vary by product sector and individual plant, and may include arsenic, chlorine, cyanide, fluoride; and heavy metals such as chromium, copper, iron, lead, mercury, nickel and zinc.

Electric power plants

Fossil-fuel power station

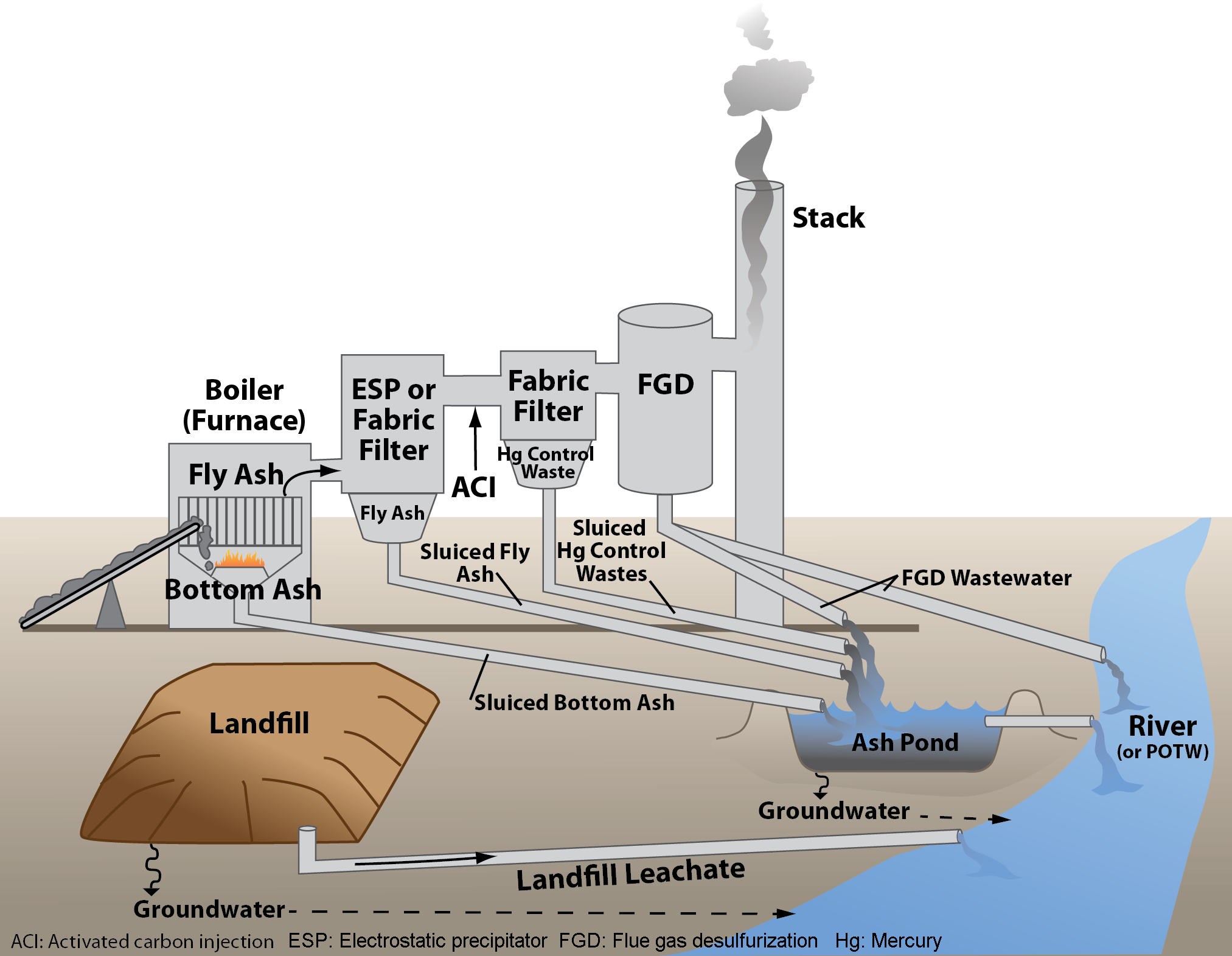

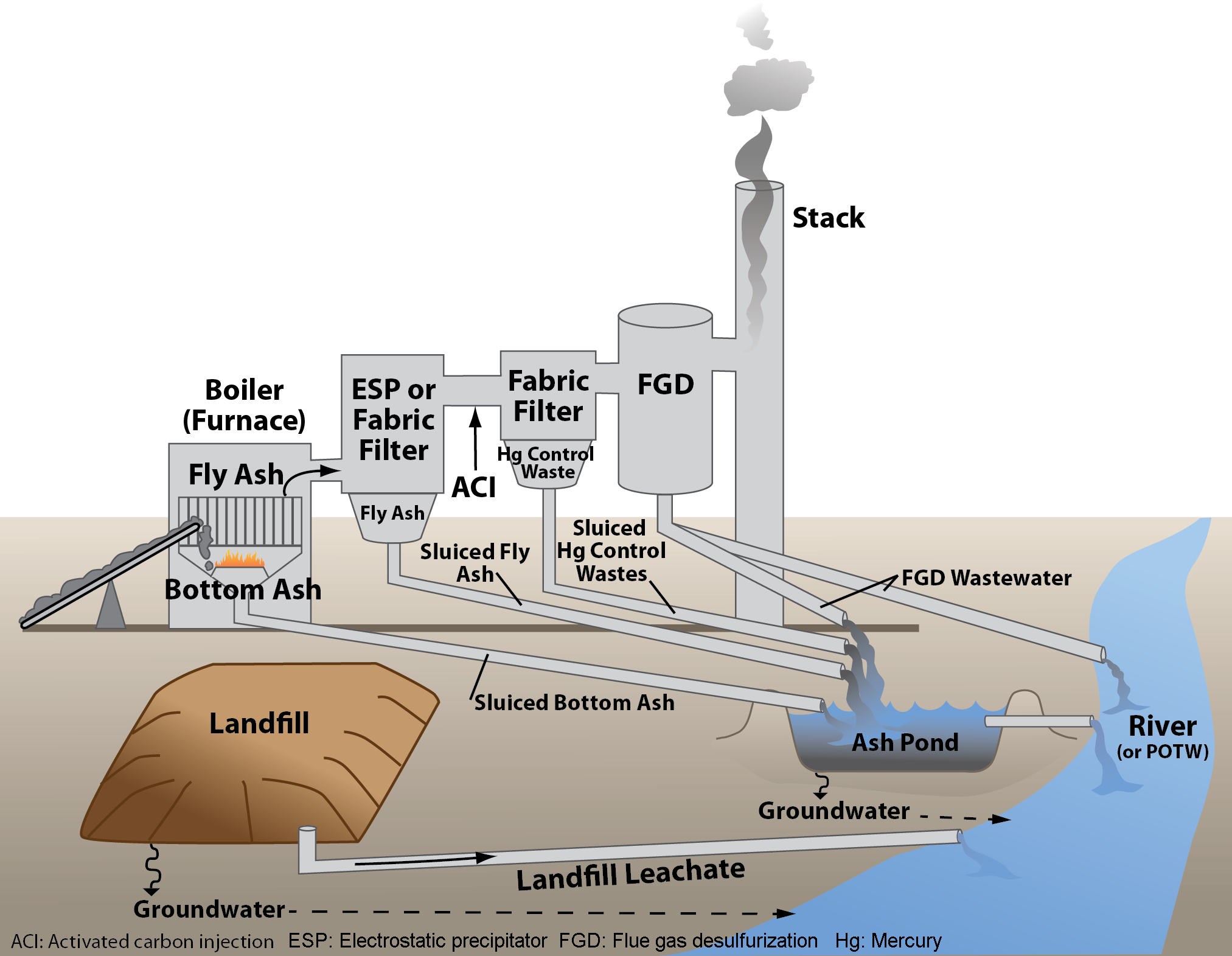

Fossil-fuel power stations, particularly

coal-fired plants, are a major source of industrial wastewater. Many of these plants discharge wastewater with significant levels of metals such as

lead,

mercury

Mercury commonly refers to:

* Mercury (planet), the nearest planet to the Sun

* Mercury (element), a metallic chemical element with the symbol Hg

* Mercury (mythology), a Roman god

Mercury or The Mercury may also refer to:

Companies

* Merc ...

,

cadmium and

chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

, as well as

arsenic,

selenium and

nitrogen compounds (

nitrate

Nitrate is a polyatomic ion

A polyatomic ion, also known as a molecular ion, is a covalent bonded set of two or more atoms, or of a metal complex, that can be considered to behave as a single unit and that has a net charge that is not zer ...

s and

nitrite

The nitrite polyatomic ion, ion has the chemical formula . Nitrite (mostly sodium nitrite) is widely used throughout chemical and pharmaceutical industries. The nitrite anion is a pervasive intermediate in the nitrogen cycle in nature. The name ...

s). Wastewater streams include

flue-gas desulfurization

Flue-gas desulfurization (FGD) is a set of technologies used to remove sulfur dioxide () from exhaust flue gases of fossil-fuel power plants, and from the emissions of other sulfur oxide emitting processes such as waste incineration.

Methods

...

,

fly ash

Fly ash, flue ash, coal ash, or pulverised fuel ash (in the UK) plurale tantum: coal combustion residuals (CCRs)is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coal-fired ...

,

bottom ash

Bottom ash is part of the non-combustible residue of combustion in a power plant, boiler, furnace or incinerator. In an industrial context, it has traditionally referred to coal combustion and comprises traces of combustibles embedded in formin ...

and

flue gas mercury control. Plants with air pollution controls such as

wet scrubbers typically transfer the captured pollutants to the wastewater stream.

s, a type of surface impoundment, are a widely used treatment technology at coal-fired plants. These ponds use gravity to

settle out large particulates (measured as

total suspended solids) from power plant wastewater. This technology does not treat dissolved pollutants. Power stations use additional technologies to control pollutants, depending on the particular wastestream in the plant. These include dry ash handling, closed-loop ash recycling,

chemical precipitation, biological treatment (such as an

activated sludge process), membrane systems, and evaporation-crystallization systems.

Technological advancements in

ion-exchange membranes and

electrodialysis systems has enabled high efficiency treatment of

flue-gas desulfurization

Flue-gas desulfurization (FGD) is a set of technologies used to remove sulfur dioxide () from exhaust flue gases of fossil-fuel power plants, and from the emissions of other sulfur oxide emitting processes such as waste incineration.

Methods

...

wastewater to meet recent EPA discharge limits. The treatment approach is similar for other highly scaling industrial wastewaters.

Food industry

Wastewater generated from agricultural and

food processing

Food processing is the transformation of agricultural products into food, or of one form of food into other forms. Food processing includes many forms of processing foods, from grinding grain to make raw flour to home cooking to complex industr ...

operations has distinctive characteristics that set it apart from common municipal wastewater managed by public or private

sewage treatment plants throughout the world: it is

biodegradable

Biodegradation is the breakdown of organic matter by microorganisms, such as bacteria and fungi. It is generally assumed to be a natural process, which differentiates it from composting. Composting is a human-driven process in which biodegradati ...

and non-toxic, but has high Biological Oxygen Demand (BOD) and

suspended solids

Suspended solids refers to small solid particles which remain in suspension in water as a colloid or due to motion of the water. Suspended solids can be removed by sedimentation if their size or density is comparatively large, or by filtration. It ...

(SS). The constituents of food and agriculture wastewater are often complex to predict, due to the differences in BOD and

pH in effluents from vegetable, fruit, and meat products and due to the seasonal nature of food processing and post-harvesting.

Processing of food from raw materials requires large volumes of high grade water. Vegetable washing generates waters with high loads of

particulate matter

Particulates – also known as atmospheric aerosol particles, atmospheric particulate matter, particulate matter (PM) or suspended particulate matter (SPM) – are microscopic particles of solid or liquid matter suspended in the air. The ter ...

and some dissolved

organic matter

Organic matter, organic material, or natural organic matter refers to the large source of carbon-based compounds found within natural and engineered, terrestrial, and aquatic environments. It is matter composed of organic compounds that have c ...

. It may also contain surfactants and pesticides.

Aquaculture

Aquaculture (less commonly spelled aquiculture), also known as aquafarming, is the controlled cultivation ("farming") of aquatic organisms such as fish, crustaceans, mollusks, algae and other organisms of value such as aquatic plants (e.g. lot ...

facilities (fish farms) often discharge large amounts of nitrogen and phosphorus, as well as suspended solids. Some facilities use drugs and pesticides, which may be present in the wastewater.

Dairy processing plants generate

conventional pollutant A conventional pollutant is a term used in the USA to describe a water pollutant that is amenable to treatment by a municipal sewage treatment plant. A basic list of conventional pollutants is defined in the U.S. Clean Water Act. The list has been ...

s (BOD, SS).

Animal slaughter and processing produces organic waste from body fluids, such as

blood, and

gut contents. Pollutants generated include BOD, SS,

coliform bacteria, oil and grease,

organic nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at seventh ...

and

ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogenous was ...

.

Processing food for sale produces wastes generated from cooking which are often rich in plant organic material and may also contain

salt,

flavourings,

colouring material and

acid

In computer science, ACID ( atomicity, consistency, isolation, durability) is a set of properties of database transactions intended to guarantee data validity despite errors, power failures, and other mishaps. In the context of databases, a sequ ...

s or

alkali

In chemistry, an alkali (; from ar, القلوي, al-qaly, lit=ashes of the saltwort) is a basic, ionic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a ...

. Large quantities of fats, oil and grease ("FOG") may also be present, which in sufficient concentrations can clog sewer lines. Some municipalities require restaurants and food processing businesses to use

grease interceptor

A grease trap (also known as grease interceptor, grease recovery device, grease capsule and grease converter) is a plumbing device (a type of trap) designed to intercept most greases and solids before they enter a wastewater disposal system. Co ...

s and regulate the disposal of FOG in the sewer system.

Food processing activities such as plant cleaning, material conveying, bottling, and product washing create wastewater. Many food processing facilities require on-site treatment before operational wastewater can be land applied or discharged to a waterway or a sewer system. High suspended solids levels of organic particles increase BOD and can result in significant sewer surcharge fees. Sedimentation, wedgewire screening, or rotating belt filtration (microscreening) are commonly used methods to reduce suspended organic solids loading prior to discharge.

Iron and steel industry

The

production of iron from its ores involves powerful

reduction reactions in blast furnaces. Cooling waters are inevitably contaminated with products especially

ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogenous was ...

and

cyanide

Cyanide is a naturally occurring, rapidly acting, toxic chemical that can exist in many different forms.

In chemistry, a cyanide () is a chemical compound that contains a functional group. This group, known as the cyano group, consists of a ...

. Production of

coke from coal in coking plants also requires

water cooling and the use of water in by-products separation. Contamination of waste streams includes gasification products such as

benzene

Benzene is an organic chemical compound with the molecular formula C6H6. The benzene molecule is composed of six carbon atoms joined in a planar ring with one hydrogen atom attached to each. Because it contains only carbon and hydrogen atoms, ...

,

naphthalene

Naphthalene is an organic compound with formula . It is the simplest polycyclic aromatic hydrocarbon, and is a white crystalline solid with a characteristic odor that is detectable at concentrations as low as 0.08 ppm by mass. As an aromati ...

,

anthracene, cyanide, ammonia,

phenol

Phenol (also called carbolic acid) is an aromatic organic compound with the molecular formula . It is a white crystalline solid that is volatile. The molecule consists of a phenyl group () bonded to a hydroxy group (). Mildly acidic, it req ...

s,

cresols together with a range of more complex

organic compounds known collectively as

polycyclic aromatic hydrocarbons (PAH).

The conversion of iron or steel into sheet, wire or rods requires hot and cold mechanical transformation stages frequently employing water as a lubricant and coolant. Contaminants include

hydraulic oils,

tallow and particulate solids. Final treatment of iron and steel products before onward sale into manufacturing includes ''pickling'' in strong mineral acid to remove rust and prepare the surface for

tin or

chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

plating or for other surface treatments such as

galvanisation or

paint

Paint is any pigmented liquid, liquefiable, or solid mastic composition that, after application to a substrate in a thin layer, converts to a solid film. It is most commonly used to protect, color, or provide texture. Paint can be made in many ...

ing. The two acids commonly used are

hydrochloric acid and

sulfuric acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid ( Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with the molecular formu ...

. Wastewaters include acidic rinse waters together with waste acid. Although many plants operate acid recovery plants (particularly those using hydrochloric acid), where the mineral acid is boiled away from the iron salts, there remains a large volume of highly acid

ferrous sulfate or

ferrous chloride to be disposed of. Many steel industry wastewaters are contaminated by hydraulic oil, also known as ''soluble oil.''

Metal working

Many industries perform work on metal feedstocks (e.g. sheet metal,

ingots) as they fabricate their final products. The industries include automobile, truck and aircraft manufacturing; tools and hardware manufacturing; electronic equipment and office machines; ships and boats; appliances and other household products; and stationary industrial equipment (e.g. compressors, pumps, boilers). Typical processes conducted at these plants include

grinding,

machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

,

coating and painting,

chemical etching and milling,

solvent degreasing Solvent degreasing is a process used to prepare a part for further operations such as electroplating or painting. Typically it uses petroleum, chlorine, dry ice or alcohol based solvents to dissolve the machining fluids and other contaminants t ...

,

electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be ...

and

anodizing. Wastewater generated from these industries may contain heavy metals such as cadmium, chromium, copper, lead, nickel, silver and zinc; cyanide and various organic chemical solvents; and oil and grease.

Mines and quarries

The principal waste-waters associated with

mine

Mine, mines, miners or mining may refer to:

Extraction or digging

* Miner, a person engaged in mining or digging

*Mining, extraction of mineral resources from the ground through a mine

Grammar

*Mine, a first-person English possessive pronoun

...

s and

quarries are slurries of rock particles in water. These arise from rainfall washing exposed surfaces and haul roads and also from rock washing and grading processes. Volumes of water can be very high, especially rainfall related arisings on large sites.

Some specialized separation operations, such as

coal washing to separate coal from native rock using

density gradients, can produce wastewater contaminated by fine particulate

haematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . ...

and

surfactants.

Oils and hydraulic oils are also common contaminants.

Wastewater from metal mines and ore recovery plants are inevitably contaminated by the minerals present in the native rock formations. Following crushing and extraction of the desirable materials, undesirable materials may enter the wastewater stream. For metal mines, this can include unwanted metals such as

zinc and other materials such as

arsenic. Extraction of high value metals such as

gold and

silver may generate

slime

Slime may refer to:

Biology

* Slime mold, a broad term often referring to roughly six groups of Eukaryotes

* Biofilm, an aggregate of microorganisms in which cells adhere to each other and/or to a surface

* Slimy (fish), also known as the pony ...

s containing very fine particles in where physical removal of contaminants becomes particularly difficult.

Additionally, the geologic formations that harbour economically valuable metals such as

copper and gold very often consist of sulphide-type ores. The processing entails grinding the rock into fine particles and then extracting the desired metal(s), with the leftover rock being known as tailings. These tailings contain a combination of not only undesirable leftover metals, but also sulphide components which eventually form sulphuric acid upon the exposure to air and water that inevitably occurs when the tailings are disposed of in large impoundments. The resulting

acid mine drainage, which is often rich in heavy metals (because acids dissolve metals), is one of the many

environmental impacts of mining.

Nuclear industry

The waste production from the nuclear and radio-chemicals industry is dealt with as ''

Radioactive waste.''

Researchers have looked at the bioaccumulation of

strontium

Strontium is the chemical element with the symbol Sr and atomic number 38. An alkaline earth metal, strontium is a soft silver-white yellowish metallic element that is highly chemically reactive. The metal forms a dark oxide layer when it is ex ...

by ''

Scenedesmus spinosus'' (

algae

Algae (; singular alga ) is an informal term for a large and diverse group of photosynthetic eukaryotic organisms. It is a polyphyletic grouping that includes species from multiple distinct clades. Included organisms range from unicellular mic ...

) in simulated wastewater. The study claims a highly selective

biosorption capacity for strontium of S. spinosus, suggesting that it may be appropriate for use of nuclear wastewater.

Oil and gas extraction

Oil and gas well operations generate

produced water

Produced water is a term used in the oil industry or geothermal industry to describe water that is produced as a byproduct during the extraction of Petroleum, oil and natural gas, or used as a medium for heat extraction. Produced water is the kind ...

, which may contain oils, toxic metals (e.g.

arsenic,

cadmium,

chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

, mercury, lead), salts, organic chemicals and solids. Some produced water contains traces of

naturally occurring radioactive material.

Offshore oil

Offshore drilling is a mechanical process where a wellbore is drilled below the seabed. It is typically carried out in order to explore for and subsequently extract petroleum that lies in rock formations beneath the seabed. Most commonly, the te ...

and gas platforms also generate deck drainage, domestic waste and sanitary waste. During the drilling process, well sites typically discharge

drill cuttings

Drill cuttings are broken bits of solid material removed from a borehole drilled by rotary, percussion, or auger methods and brought to the surface in the drilling mud. Boreholes drilled in this way include oil or gas wells, water wells, a ...

and

drilling mud

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also us ...

(drilling fluid).

Petroleum refining and petrochemicals

Pollutants discharged at

petroleum refineries

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefie ...

and

petrochemical

Petrochemicals (sometimes abbreviated as petchems) are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sou ...

plants include

conventional pollutant A conventional pollutant is a term used in the USA to describe a water pollutant that is amenable to treatment by a municipal sewage treatment plant. A basic list of conventional pollutants is defined in the U.S. Clean Water Act. The list has been ...

s (BOD, oil and grease,

suspended solids

Suspended solids refers to small solid particles which remain in suspension in water as a colloid or due to motion of the water. Suspended solids can be removed by sedimentation if their size or density is comparatively large, or by filtration. It ...

), ammonia, chromium, phenols and sulfides.

Pharmaceutical manufacturing

Pharmaceutical plants typically generate a variety of process wastewaters, including solvents, spent acid and caustic solutions, water from chemical reactions, product wash water, condensed steam, blowdown from air pollution control scrubbers, and equipment washwater. Non-process wastewaters typically include cooling water and site runoff. Pollutants generated by the industry include

acetone, ammonia, benzene, BOD, chloroform, cyanide,

ethanol,

ethyl acetate,

isopropanol

Isopropyl alcohol (IUPAC name propan-2-ol and also called isopropanol or 2-propanol) is a colorless, flammable organic compound with a pungent alcoholic odor. As an isopropyl group linked to a hydroxyl group (chemical formula ) it is the simple ...

,

methylene chloride,

methanol

Methanol (also called methyl alcohol and wood spirit, amongst other names) is an organic chemical and the simplest aliphatic alcohol, with the formula C H3 O H (a methyl group linked to a hydroxyl group, often abbreviated as MeOH). It is a ...

, phenol and toluene. Treatment technologies used include advanced biological treatment (e.g. activated sludge with nitrification),

multimedia filtration, cyanide destruction (e.g.

hydrolysis),

steam stripping and wastewater recycling.

Pulp and paper industry

Effluent from the

pulp and paper industry

The pulp and paper industry comprises companies that use wood as raw material and produce pulp, paper, paperboard and other cellulose-based products.

Manufacturing process

The pulp is fed to a paper machine where it is formed as a paper web an ...

is generally high in

suspended solids

Suspended solids refers to small solid particles which remain in suspension in water as a colloid or due to motion of the water. Suspended solids can be removed by sedimentation if their size or density is comparatively large, or by filtration. It ...

and BOD. Plants that

bleach wood pulp for paper making may generate

chloroform

Chloroform, or trichloromethane, is an organic compound with chemical formula, formula Carbon, CHydrogen, HChlorine, Cl3 and a common organic solvent. It is a colorless, strong-smelling, dense liquid produced on a large scale as a precursor to ...

,

dioxins

Dioxin may refer to:

* 1,2-Dioxin or 1,4-Dioxin, two unsaturated heterocyclic 6-membered rings where two carbon atoms have been replaced by oxygen atoms, giving the molecular formula C4H4O2

*Dibenzo-1,4-dioxin, the parent compound also known as ...

(including

2,3,7,8-TCDD

2,3,7,8-Tetrachlorodibenzo-''p-''dioxin (TCDD) is a polychlorinated dibenzo''-p-''dioxin (sometimes shortened, though inaccurately, to simply 'dioxin')Tuomisto, Jouko (2019) Dioxins and dioxin-like compounds: toxicity in humans and animals, s ...

),

furans, phenols and

chemical oxygen demand (COD).

Stand-alone paper mills using imported pulp may only require simple primary treatment, such as

sedimentation or

dissolved air flotation. Increased BOD or COD loadings, as well as organic pollutants, may require biological treatment such as

activated sludge or

upflow anaerobic sludge blanket reactors. For mills with high inorganic loadings like salt, tertiary treatments may be required, either general membrane treatments like

ultrafiltration or

reverse osmosis

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pre ...

or treatments to remove specific contaminants, such as nutrients.

Smelters

The pollutants discharged by nonferrous

smelters

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a ch ...

vary with the base metal ore.

Bauxite smelters generate

phenols but typically use

settling basin

A settling basin, settling pond or decant pond is an earthen or concrete structure using sedimentation to remove settleable matter and turbidity from wastewater. The basins are used to control water pollution in diverse industries such as agricult ...

s and evaporation to manage these wastes, with no need to routinely discharge wastewater.

smelters typically discharge

fluoride

Fluoride (). According to this source, is a possible pronunciation in British English. is an inorganic, monatomic anion of fluorine, with the chemical formula (also written ), whose salts are typically white or colorless. Fluoride salts typ ...

,

benzo(a)pyrene

Benzo 'a''yrene (B''a''P or B ) is a polycyclic aromatic hydrocarbon and the result of incomplete combustion of organic matter at temperatures between and . The ubiquitous compound can be found in coal tar, tobacco smoke and many foods, espec ...

,

antimony and

nickel, as well as aluminum. Copper smelters typically generate

cadmium, lead, zinc, arsenic and nickel, in addition to copper, in their wastewater. Lead smelters discharge lead and zinc. Nickel and cobalt smelters discharge ammonia and copper in addition to the base metals. Zinc smelters discharge arsenic, cadmium, copper, lead, selenium and zinc.

Typical treatment processes used in the industry are chemical precipitation, sedimentation and filtration.

Textile mills

Textile mills, including

carpet manufacturers, generate wastewater from a wide variety of processes, including

cleaning

Cleaning is the process of removing unwanted substances, such as dirt, infectious agents, and other impurities, from an object or environment. Cleaning is often performed for aesthetic, hygienic, functional, environmental, or safety purposes. Cl ...

and finishing,

yarn manufacturing and fabric finishing (such as

bleaching,

dyeing,

resin treatment,

waterproofing and

retardant flameproofing). Pollutants generated by textile mills include BOD, SS, oil and grease, sulfide, phenols and chromium.

Insecticide

Insecticides are substances used to kill insects. They include ovicides and larvicides used against insect eggs and larvae, respectively. Insecticides are used in agriculture, medicine, industry and by consumers. Insecticides are claimed to b ...

residues in fleeces are a particular problem in treating waters generated in wool processing. Animal fats may be present in the wastewater, which if not contaminated, can be recovered for the production of tallow or further rendering.

Textile dyeing plants generate wastewater that contain synthetic (e.g., reactive dyes, acid dyes, basic dyes, disperse dyes, vat dyes, sulphur dyes, mordant dyes, direct dyes, ingrain dyes, solvent dyes, pigment dyes) and natural dyestuff, gum thickener (guar) and various wetting agents, pH buffers and dye retardants or accelerators. Following treatment with polymer-based flocculants and settling agents, typical monitoring parameters include BOD, COD, color (ADMI), sulfide, oil and grease, phenol,

TSS and heavy metals (chromium,

zinc, lead, copper).

Industrial oil contamination

Industrial applications where oil enters the wastewater stream may include vehicle wash bays, workshops, fuel storage depots, transport hubs and power generation. Often the wastewater is discharged into local sewer or trade waste systems and must meet local environmental specifications. Typical contaminants can include solvents, detergents, grit, lubricants and hydrocarbons.

Water treatment

Many industries have a need to treat water to obtain very high quality water for their processes. This might include pure chemical synthesis or boiler feed water. Also, some water treatment processes produce organic and mineral sludges from

filtration

Filtration is a physical separation process that separates solid matter and fluid from a mixture using a ''filter medium'' that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter ...

and

sedimentation which require treatment.

Ion exchange using natural or synthetic resins removes

calcium,

magnesium and

carbonate ions from water, typically replacing them with

sodium,

chloride,

hydroxyl and/or other ions. Regeneration of ion-exchange columns with strong acids and alkalis produces a wastewater rich in hardness ions which are readily precipitated out, especially when in admixture with other wastewater constituents.

Wood preserving

Wood preserving

Wood easily degrades without sufficient preservation. Apart from structural wood preservation measures, there are a number of different chemical preservatives and processes (also known as "timber treatment", "lumber treatment" or "pressure treat ...

plants generate conventional and toxic pollutants, including arsenic, COD, copper, chromium, abnormally high or low pH, phenols, suspended solids, oil and grease.

Treatment methods

The various types of contamination of wastewater require a variety of strategies to remove the contamination.

Most industrial processes, such as

petroleum refineries

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefie ...

, chemical and

petrochemical

Petrochemicals (sometimes abbreviated as petchems) are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sou ...

plants have onsite facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the regulations regarding disposal of wastewaters into sewers or into rivers, lakes or oceans.

s are being used in an increasing number of cases as they provided high quality and productive on-site treatment. Other industrial processes that produce a lot of waste-waters such as

paper and pulp production

The pulp and paper industry comprises companies that use wood as raw material and produce Pulp (paper), pulp, paper, paperboard and other cellulose-based products.

Manufacturing process

The pulp is fed to a paper machine where it is formed as ...

have created environmental concern, leading to development of processes to recycle water use within plants before they have to be cleaned and disposed.

An industrial wastewater treatment plant may include one or more of the following rather than the conventional treatment sequence of sewage treatment plants:

* An

API oil-water separator, for removing separate phase oil from wastewater.

* A

clarifier

Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation. A clarifier is generally used to remove solid particulates or suspended solids from liquid for clarification and/or thi ...

, for removing solids from wastewater.

[Kemmer, Frank N. (1979). ''The Nalco Water Handbook''. New York: McGraw-Hill Book Company. .]

* A

roughing filter, to reduce the

biochemical oxygen demand of wastewater.

* A

carbon filtration

Carbon filtering is a method of filtering that uses a bed of activated carbon to remove impurities from a fluid using adsorption.

Mechanism

Carbon filtering works by adsorption, in which pollutants in the fluid to be treated are trapped inside th ...

plant, to remove toxic dissolved organic compounds from wastewater.

* An advanced

electrodialysis reversal

Electrodialysis reversal (EDR) is an electrodialysis reversal water desalination membrane process that has been commercially used since the early 1960s. An electric current migrates dissolved salt ions, including fluorides, nitrates and sulfate ...

(EDR) system with

ion-exchange membranes.

Brine treatment

Brine

Brine is a high-concentration solution of salt (NaCl) in water (H2O). In diverse contexts, ''brine'' may refer to the salt solutions ranging from about 3.5% (a typical concentration of seawater, on the lower end of that of solutions used for br ...

treatment involves removing dissolved

salt ion

Salt is a mineral composed primarily of sodium chloride (NaCl), a chemical compound belonging to the larger class of salts; salt in the form of a natural crystalline mineral is known as rock salt or halite. Salt is present in vast quantit ...

s from the waste stream. Although similarities to seawater or brackish water

desalination

Desalination is a process that takes away mineral components from saline water. More generally, desalination refers to the removal of salts and minerals from a target substance, as in Soil salinity control, soil desalination, which is an issue f ...

exist, industrial brine treatment may contain unique combinations of dissolved ions, such as hardness ions or other metals, necessitating specific processes and equipment.

Brine treatment systems are typically optimized to either reduce the volume of the final discharge for more economic disposal (as disposal costs are often based on volume) or maximize the recovery of fresh water or salts. Brine treatment systems may also be optimized to reduce electricity consumption, chemical usage, or physical footprint.

Brine treatment is commonly encountered when treating cooling tower blowdown,

produced water

Produced water is a term used in the oil industry or geothermal industry to describe water that is produced as a byproduct during the extraction of Petroleum, oil and natural gas, or used as a medium for heat extraction. Produced water is the kind ...

from

steam-assisted gravity drainage Steam-assisted gravity drainage (SAGD; "Sag-D") is an enhanced oil recovery technology for producing heavy crude oil and bitumen. It is an advanced form of steam stimulation in which a pair of horizontal wells is drilled into the oil reservoir, on ...

(SAGD), produced water from

natural gas extraction such as

coal seam gas, frac flowback water,

acid mine or acid rock drainage, reverse osmosis reject,

chlor-alkali wastewater, pulp and paper mill effluent, and waste streams from food and beverage processing.

Brine treatment technologies may include: membrane filtration processes, such as

reverse osmosis

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pre ...

;

ion-exchange

Ion exchange is a reversible interchange of one kind of ion present in an insoluble solid with another of like charge present in a solution surrounding the solid with the reaction being used especially for softening or making water demineralised, ...

processes such as

electrodialysis or

weak acid cation exchange; or evaporation processes, such as brine concentrators and

crystallizers employing

mechanical vapour recompression Mechanical vapor recompression (MVR) is an energy recovery process which can be used to recycle waste heat to improve efficiency. Typically, the compressed vapor is fed back to help heat the mother liquor in order to produce more vapor or steam.

Ap ...

and steam. Due to the ever increasing discharge standards, there has been an emergence of the use of

advance oxidation processes for the treatment of brine. Some notable examples such as

Fenton's oxidation and

ozonation have been employed for degradation of recalcitrant compounds in brine from industrial plants.

Reverse osmosis may not be viable for brine treatment, due to the potential for fouling caused by hardness salts or organic contaminants, or damage to the reverse osmosis membranes from

hydrocarbons.

Evaporation processes are the most widespread for brine treatment as they enable the highest degree of concentration, as high as solid salt. They also produce the highest purity effluent, even distillate-quality. Evaporation processes are also more tolerant of organics, hydrocarbons, or hardness salts. However, energy consumption is high and corrosion may be an issue as the prime mover is concentrated salt water. As a result, evaporation systems typically employ

titanium or

duplex stainless steel materials.

Brine management

Brine management examines the broader context of brine treatment and may include consideration of government policy and regulations,

corporate sustainability, environmental impact, recycling, handling and transport, containment, centralized compared to on-site treatment, avoidance and reduction, technologies, and economics. Brine management shares some issues with

leachate management and more general

waste management. In the recent years, there has been greater prevalence in brine management due to global push for zero liquid discharge (ZLD)/minimal liquid discharge (MLD). In ZLD/MLD techniques, a closed water cycle is used to minimize water discharges from a system for

water reuse. This concept has been gaining traction in recent years, due to increased water discharges and recent advancement in membrane technology.

Solids removal

Most solids can be removed using simple sedimentation techniques with the solids recovered as

slurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pu ...

or sludge. Very fine solids and solids with densities close to the density of water pose special problems. In such case filtration or

ultrafiltration may be required. Although

flocculation may be used, using

alum

An alum () is a type of chemical compound, usually a hydrated double salt, double sulfate salt (chemistry), salt of aluminium with the general chemical formula, formula , where is a valence (chemistry), monovalent cation such as potassium or a ...

salts or the addition of

polyelectrolytes. Wastewater from industrial food processing often requires on-site treatment before it can be discharged to prevent or reduce sewer surcharge fees. The type of industry and specific operational practices determine what types of wastewater is generated and what type of treatment is required. Reducing solids such as waste product, organic materials, and sand is often a goal of industrial wastewater treatment. Some common ways to reduce solids include primary sedimentation (clarification),

dissolved air flotation (DAF), belt filtration (microscreening), and drum screening.

Oils and grease removal

The effective removal of oils and grease is dependent on the characteristics of the oil in terms of its suspension state and droplet size, which will in turn affect the choice of separator technology. Oil in industrial waste water may be free light oil, heavy oil, which tends to sink, and emulsified oil, often referred to as soluble oil. Emulsified or soluble oils will typically required "cracking" to free the oil from its emulsion. In most cases this is achieved by lowering the pH of the water matrix.

Most separator technologies will have an optimum range of oil droplet sizes that can be effectively treated. Each separator technology will have its own performance curve outlining optimum performance based on oil droplet size. the most common separators are gravity tanks or pits, API oil-water separators or plate packs, chemical treatment via dissolved air flotations, centrifuges, media filters and hydrocyclones.

Analyzing the oily water to determine droplet size can be performed with a video particle analyser.

API oil-water separators

Hydrocyclone oil separators

Hydrocyclone oil separators operate on the process where wastewater enters the cyclone chamber and is spun under extreme centrifugal forces more than 1000 times the force of gravity. This force causes the water and oil droplets to separate. The separated oil is discharged from one end of the cyclone where treated water is discharged through the opposite end for further treatment, filtration or discharge.

Removal of biodegradable organics

Biodegradable organic material of plant or animal origin is usually possible to treat using extended conventional

sewage treatment processes such as

activated sludge or

trickling filter.

Activated sludge process

Trickling filter process

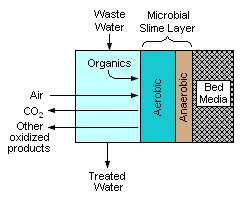

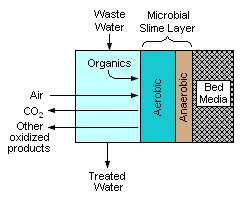

A trickling filter consists of a bed of

A trickling filter consists of a bed of rocks

In geology, rock (or stone) is any naturally occurring solid mass or aggregate of minerals or mineraloid matter. It is categorized by the minerals included, its chemical composition, and the way in which it is formed. Rocks form the Earth's ...

, gravel

Gravel is a loose aggregation of rock fragments. Gravel occurs naturally throughout the world as a result of sedimentary and erosive geologic processes; it is also produced in large quantities commercially as crushed stone.

Gravel is classifi ...

, slag

Slag is a by-product of smelting (pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-prod ...

, peat moss, or plastic media over which wastewater flows downward and contacts a layer (or film) of microbial

A microorganism, or microbe,, ''mikros'', "small") and ''organism'' from the el, ὀργανισμός, ''organismós'', "organism"). It is usually written as a single word but is sometimes hyphenated (''micro-organism''), especially in olde ...

slime covering the bed media. Aerobic conditions are maintained by forced air flowing through the bed or by natural convection of air. The process involves adsorption of organic compounds in the wastewater by the microbial slime layer, diffusion of air into the slime layer to provide the oxygen required for the biochemical oxidation of the organic compounds. The end products include carbon dioxide gas, water and other products of the oxidation. As the slime layer thickens, it becomes difficult for the air to penetrate the layer and an inner anaerobic layer is formed.

Removal of other organics

Synthetic organic materials including solvents, paints, pharmaceuticals, pesticides, products from coke production and so forth can be very difficult to treat. Treatment methods are often specific to the material being treated. Methods include advanced oxidation processing, distillation, adsorption, ozonation, vitrification, incineration, chemical immobilisation or landfill disposal. Some materials such as some detergents may be capable of biological degradation and in such cases, a modified form of wastewater treatment can be used.

Removal of acids and alkalis

Acids and alkalis can usually be neutralised under controlled conditions. Neutralisation frequently produces a precipitate that will require treatment as a solid residue that may also be toxic. In some cases, gases may be evolved requiring treatment for the gas stream. Some other forms of treatment are usually required following neutralisation.

Waste streams rich in hardness ions as from de-ionisation processes can readily lose the hardness ions in a buildup of precipitated calcium and magnesium salts. This precipitation process can cause severe ''furring'' of pipes and can, in extreme cases, cause the blockage of disposal pipes. A 1-metre diameter industrial marine discharge pipe serving a major chemicals complex was blocked by such salts in the 1970s. Treatment is by concentration of de-ionisation waste waters and disposal to landfill or by careful pH management of the released wastewater.

Removal of toxic materials

Toxic materials including many organic materials, metals (such as zinc, silver, cadmium, thallium, etc.) acids, alkalis, non-metallic elements (such as arsenic or selenium) are generally resistant to biological processes unless very dilute. Metals can often be precipitated out by changing the pH or by treatment with other chemicals. Many, however, are resistant to treatment or mitigation and may require concentration followed by landfilling or recycling. Dissolved organics can be ''incinerated'' within the wastewater by the advanced oxidation process.

Smart capsules

Molecular encapsulation

In supramolecular chemistry, molecular encapsulation is the confinement of a guest molecule inside the cavity of a supramolecular host molecule (molecular capsule, molecular container or cage compounds). Examples of supramolecular host molecule ...

is a technology that has the potential to provide a system for the recyclable removal of lead and other ions from polluted sources. Nano-, micro- and milli- capsules, with sizes in the ranges 10 nm–1μm,1μm–1mm and >1mm, respectively, are particles that have an active reagent (core) surrounded by a carrier (shell).There are three types of capsule under investigation: alginate-based capsules, carbon nanotubes, polymer swelling capsules. These capsules provide a possible means for the remediation of contaminated water.

Removal of thermal pollution

To remove heat from wastewater generated by power plants or manufacturing plants

A factory, manufacturing plant or a production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. Th ...

, and thus to reduce thermal pollution

Thermal pollution, sometimes called "thermal enrichment", is the degradation of water quality by any process that changes ambient water temperature. Thermal pollution is the rise or fall in the temperature of a natural body of water caused by hum ...

, the following technologies are used:

*cooling pond

A cooling pond is a man-made body of water primarily formed for the purpose of cooling heated water and/or to store and supply cooling water to a nearby power plant or industrial facility such as a petroleum refinery, pulp and paper mill, chemica ...

s, engineered bodies of water designed for cooling by evaporation

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidi ...

, convection, and radiation

In physics, radiation is the emission or transmission of energy in the form of waves or particles through space or through a material medium. This includes:

* ''electromagnetic radiation'', such as radio waves, microwaves, infrared, visi ...

* cooling towers, which transfer waste heat to the atmosphere

An atmosphere () is a layer of gas or layers of gases that envelop a planet, and is held in place by the gravity of the planetary body. A planet retains an atmosphere when the gravity is great and the temperature of the atmosphere is low. A s ...

through evaporation

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidi ...

or heat transfer

* cogeneration, a process where waste heat is recycled for domestic or industrial heating purposes.

Other disposal methods

Some facilities such as oil and gas wells may be permitted to pump their wastewater underground through injection wells. However, wastewater injection has been linked to induced seismicity

Induced seismicity is typically minor earthquakes and tremors that are caused by human activity that alters the stresses and strains on Earth's crust. Most induced seismicity is of a low magnitude. A few sites regularly have larger quakes, such a ...

.

Costs and trade waste charges

Disposal of wastewaters from an industrial plant is a difficult and costly problem. Although economies of scale may favor use of a large municipal sewage treatment plant for disposal of small volumes of industrial wastewater, industrial wastewater treatment and disposal may be less expensive than correctly apportioned costs for larger volumes of industrial wastewater not requiring the conventional sewage treatment sequence of a small municipal sewage treatment plant.

Society and culture

Global goals

The international community

The international community is an imprecise phrase used in geopolitics and international relations to refer to a broad group of people and governments of the world.

As a rhetorical term

Aside from its use as a general descriptor, the term is ...

has defined the treatment of industrial wastewater as an important part of sustainable development

Sustainable development is an organizing principle for meeting human development goals while also sustaining the ability of natural systems to provide the natural resources and ecosystem services on which the economy and society depend. The des ...

by including it in Sustainable Development Goal 6

Sustainable Development Goal 6 (SDG 6 or Global Goal 6) is about "clean water and sanitation for all". It is one of 17 Sustainable Development Goals established by the United Nations General Assembly in 2015, the official wording is: "Ensure ava ...

. Target 6.3 of this goal is to "By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals

Dangerous goods, abbreviated DG, are substances that when transported are a risk to health, safety, property or the environment. Certain dangerous goods that pose risks even when not being transported are known as hazardous materials ( syllabi ...

and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally". One of the indicators for this target is the "proportion of domestic and industrial wastewater flows safely treated".[Ritchie, Roser, Mispy, Ortiz-Ospina.]

Measuring progress towards the Sustainable Development Goals, Goal 6

''SDG-Tracker.org, website'' (2018).

See also

* Best management practice for water pollution (BMP)

* List of waste water treatment technologies

* Purified water (for industrial use)

* Water purification (for drinking water)

References

Further reading

*

External links

Water Environment Federation

- Professional society

Industrial Wastewater Treatment Technology Database

- EPA

{{waste

Waste treatment technology

Sewerage

Industrial processes

Water pollution

Sanitation

cs:Čištění odpadních vod

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a  Fossil-fuel power stations, particularly coal-fired plants, are a major source of industrial wastewater. Many of these plants discharge wastewater with significant levels of metals such as lead,

Fossil-fuel power stations, particularly coal-fired plants, are a major source of industrial wastewater. Many of these plants discharge wastewater with significant levels of metals such as lead,  Wastewater generated from agricultural and

Wastewater generated from agricultural and  Effluent from the

Effluent from the  The various types of contamination of wastewater require a variety of strategies to remove the contamination. Most industrial processes, such as

The various types of contamination of wastewater require a variety of strategies to remove the contamination. Most industrial processes, such as