Sinters on:

[Wikipedia]

[Google]

[Amazon]

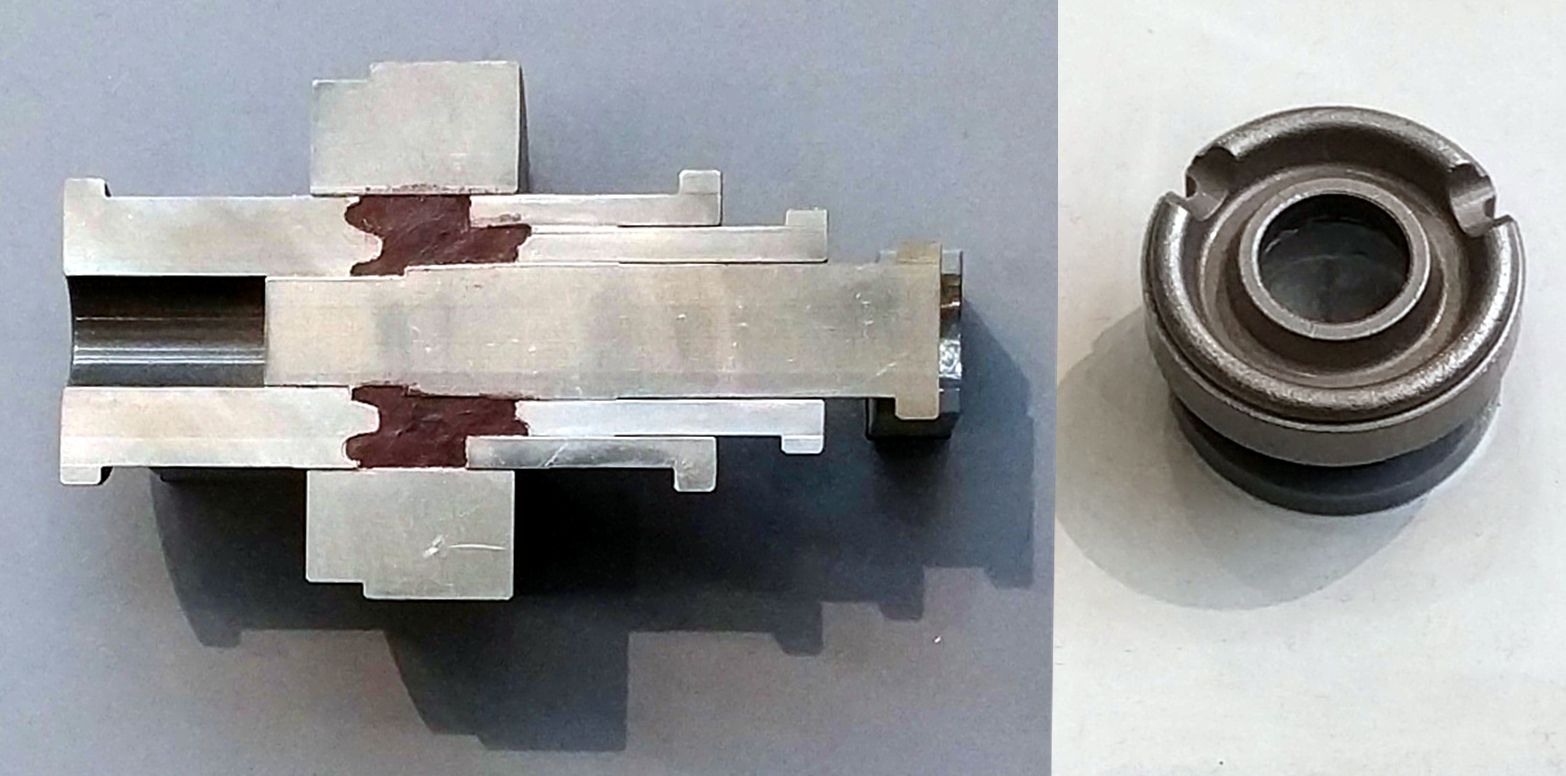

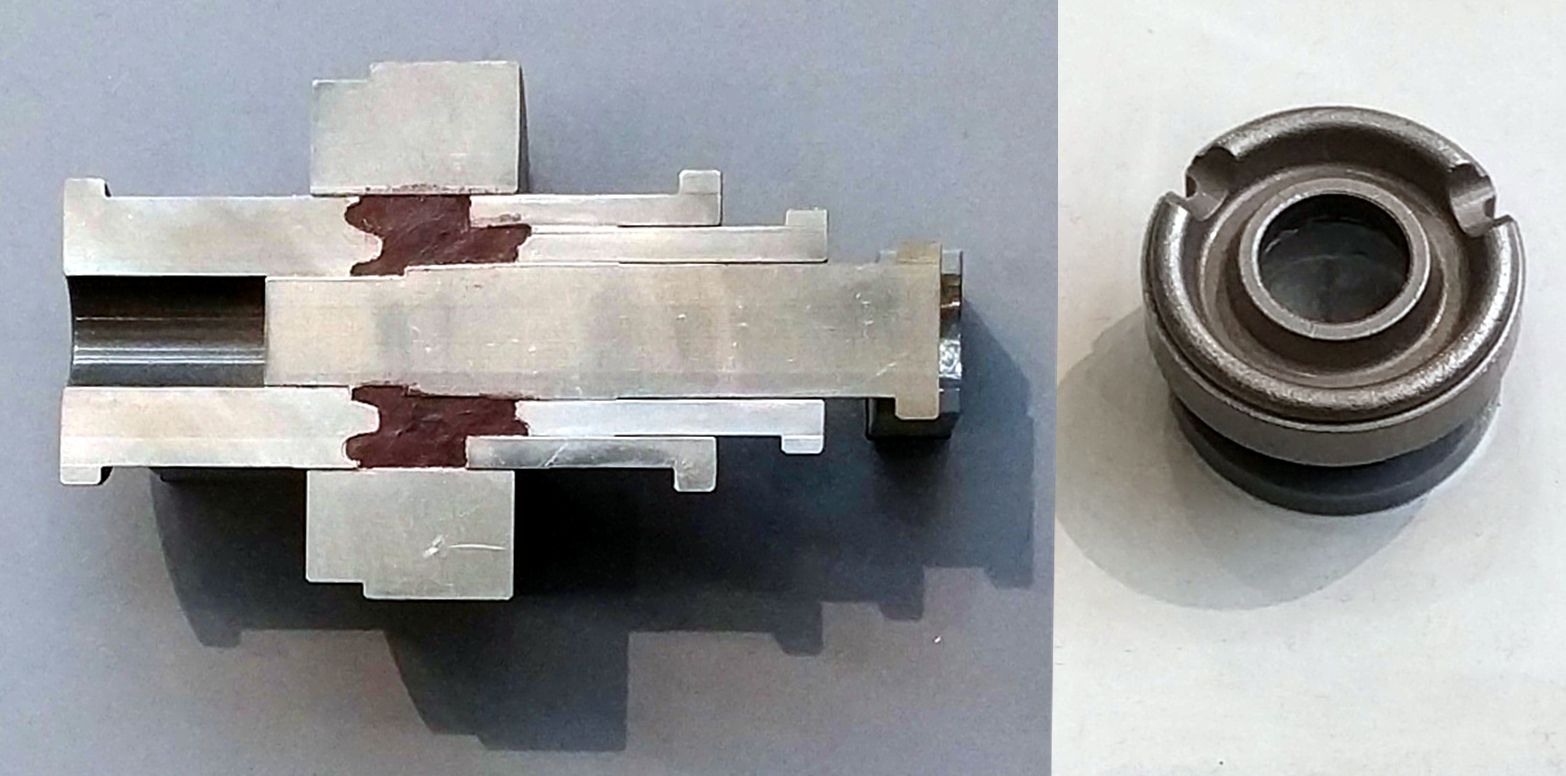

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of

Sintering is generally considered successful when the process reduces

Sintering is generally considered successful when the process reduces

Most, if not all, metals can be sintered. This applies especially to pure metals produced in vacuum which suffer no surface contamination. Sintering under atmospheric pressure requires the use of a protective gas, quite often

Most, if not all, metals can be sintered. This applies especially to pure metals produced in vacuum which suffer no surface contamination. Sintering under atmospheric pressure requires the use of a protective gas, quite often

Particle-Particle-Sintering – a 3D lattice kinetic Monte Carlo simulation

{{Authority control Industrial processes Metalworking Plastics industry Metallurgical processes

liquefaction

In materials science, liquefaction is a process that generates a liquid from a solid or a gas or that generates a non-liquid phase which behaves in accordance with fluid dynamics.

It occurs both naturally and artificially. As an example of the ...

.

Sintering happens as part of a manufacturing process used with metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typicall ...

s, ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain ...

s, plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptab ...

s, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depends ...

of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten

Tungsten, or wolfram, is a chemical element with the symbol W and atomic number 74. Tungsten is a rare metal found naturally on Earth almost exclusively as compounds with other elements. It was identified as a new element in 1781 and first isolat ...

and molybdenum

Molybdenum is a chemical element with the symbol Mo and atomic number 42 which is located in period 5 and group 6. The name is from Neo-Latin ''molybdaenum'', which is based on Ancient Greek ', meaning lead, since its ores were confused with lea ...

. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compacting of snowfall to a glacier, or the forming of a hard snowball by pressing loose snow together.

The material produced by sintering is called ''sinter''. The word ''sinter'' comes from the Middle High German

Middle High German (MHG; german: Mittelhochdeutsch (Mhd.)) is the term for the form of German spoken in the High Middle Ages. It is conventionally dated between 1050 and 1350, developing from Old High German and into Early New High German. High ...

, a cognate

In historical linguistics, cognates or lexical cognates are sets of words in different languages that have been inherited in direct descent from an etymology, etymological ancestor in a proto-language, common parent language. Because language c ...

of English '' cinder''.

General sintering

Sintering is generally considered successful when the process reduces

Sintering is generally considered successful when the process reduces porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

and enhances properties such as strength, electrical conductivity

Electrical resistivity (also called specific electrical resistance or volume resistivity) is a fundamental property of a material that measures how strongly it resists electric current. A low resistivity indicates a material that readily allow ...

, translucency and thermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

. In some special cases, sintering is carefully applied to enhance the strength of a material while preserving porosity (e.g. in filters or catalysts, where gas absorbency is a priority). During the firing process, atomic diffusion drives powder surface elimination in different stages, starting at the formation of necks between powders to final elimination of small pores at the end of the process.

The driving force for densification is the change in free energy from the decrease in surface area and lowering of the surface free energy by the replacement of solid-vapor interfaces. It forms new but lower-energy solid-solid interfaces with a net decrease in total free energy. On a microscopic scale, material transfer is affected by the change in pressure and differences in free energy across the curved surface. If the size of the particle is small (and its curvature is high), these effects become very large in magnitude. The change in energy is much higher when the radius of curvature is less than a few micrometers, which is one of the main reasons why much ceramic technology is based on the use of fine-particle materials.

The ratio of bond area to particle size is a determining factor for properties such as strength and electrical conductivity. To yield the desired bond area, temperature and initial grain size are precisely controlled over the sintering process. At steady state, the particle radius and the vapor pressure are proportional to (p0)2/3 and to (p0)1/3, respectively.

The source of power for solid-state processes is the change in free or chemical potential energy between the neck and the surface of the particle. This energy creates a transfer of material through the fastest means possible; if transfer were to take place from the particle volume or the grain boundary between particles, particle count would decrease and pores would be destroyed. Pore elimination is fastest in samples with many pores of uniform size because the boundary diffusion distance is smallest. during the latter portions of the process, boundary and lattice diffusion from the boundary become important.

Control of temperature is very important to the sintering process, since grain-boundary diffusion and volume diffusion rely heavily upon temperature, particle size, particle distribution, material composition, and often other properties of the sintering environment itself.

Ceramic sintering

Sintering is part of the firing process used in the manufacture ofpottery

Pottery is the process and the products of forming vessels and other objects with clay and other ceramic materials, which are fired at high temperatures to give them a hard and durable form. Major types include earthenware, stoneware and por ...

and other ceramic objects. These objects are made from substances such as glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of ...

, alumina, zirconia

Zirconium dioxide (), sometimes known as zirconia (not to be confused with zircon), is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral baddeleyite. A dopant stabi ...

, silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one ...

, magnesia, lime

Lime commonly refers to:

* Lime (fruit), a green citrus fruit

* Lime (material), inorganic materials containing calcium, usually calcium oxide or calcium hydroxide

* Lime (color), a color between yellow and green

Lime may also refer to:

Botany ...

, beryllium oxide, and ferric oxide

Iron(III) oxide or ferric oxide is the inorganic compound with the formula Fe2O3. It is one of the three main oxides of iron, the other two being iron(II) oxide (FeO), which is rare; and iron(II,III) oxide (Fe3O4), which also occurs naturally a ...

. Some ceramic raw materials have a lower affinity

Affinity may refer to:

Commerce, finance and law

* Affinity (law), kinship by marriage

* Affinity analysis, a market research and business management technique

* Affinity Credit Union, a Saskatchewan-based credit union

* Affinity Equity Partn ...

for water and a lower plasticity index than clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolin, Al2 Si2 O5( OH)4).

Clays develop plasticity when wet, due to a molecular film of water surrounding the clay par ...

, requiring organic additives in the stages before sintering. The general procedure of creating ceramic objects via sintering of powders includes:

* mixing water, binder, deflocculant

Flocculation, in the field of chemistry, is a process by which colloidal particles come out of suspension to sediment under the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from p ...

, and unfired ceramic powder to form a slurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pu ...

* spray-drying the slurry

* putting the spray dried powder into a mold and pressing it to form a green body (an unsintered ceramic item)

* heating the green body at low temperature to burn off the binder

* sintering at a high temperature to fuse the ceramic particles together.

All the characteristic temperatures associated with phase transformation, glass transitions, and melting points, occurring during a sinterisation cycle of a particular ceramics formulation (i.e., tails and frits) can be easily obtained by observing the expansion-temperature curves during optical dilatometer An optical dilatometer is a non-contact device able to measure thermal expansions or sintering kinetics of any kind of materials, unlike traditional push rod dilatometer, it can push up to the dilatometric softening of the specimen. It is a device f ...

thermal analysis. In fact, sinterisation is associated with a remarkable shrinkage of the material because glass phases flow once their transition temperature is reached, and start consolidating the powdery structure and considerably reducing the porosity of the material.

Sintering is performed at high temperature. Additionally, a second and/or third external force (such as pressure, electrical current) could be used. A commonly used second external force is pressure. Sintering performed by only heating is generally termed "pressureless sintering", which is possible with graded metal-ceramic composites, utilising a nanoparticle sintering aid and bulk molding technology. A variant used for 3D shapes is called hot isostatic pressing

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.

The process can be used to pro ...

.

To allow efficient stacking of product in the furnace during sintering and to prevent parts sticking together, many manufacturers separate ware using ceramic powder separator sheets. These sheets are available in various materials such as alumina, zirconia and magnesia. They are additionally categorized by fine, medium and coarse particle sizes. By matching the material and particle size to the ware being sintered, surface damage and contamination can be reduced while maximizing furnace loading.

Sintering of metallic powders

endothermic gas

Endothermic gas is a gas that inhibits or reverses oxidation on the surfaces it is in contact with. This gas is the product of incomplete combustion in a controlled environment. An example mixture is hydrogen gas (H2), nitrogen gas (N2), and carbo ...

. Sintering, with subsequent reworking, can produce a great range of material properties. Changes in density, alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, ...

ing, and heat treatments can alter the physical characteristics of various products. For instance, the Young's modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied leng ...

''En'' of sintered iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in f ...

powders remains somewhat insensitive to sintering time, alloying, or particle size in the original powder for lower sintering temperatures, but depends upon the density of the final product:

where ''D'' is the density, ''E'' is Young's modulus and ''d'' is the maximum density of iron.

Sintering is static when a metal powder under certain external conditions may exhibit coalescence, and yet reverts to its normal behavior when such conditions are removed. In most cases, the density of a collection of grains increases as material flows into voids, causing a decrease in overall volume. Mass movements that occur during sintering consist of the reduction of total porosity by repacking, followed by material transport due to evaporation

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidi ...

and condensation

Condensation is the change of the state of matter from the gas phase into the liquid phase, and is the reverse of vaporization. The word most often refers to the water cycle. It can also be defined as the change in the state of water vapor to ...

from diffusion

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical p ...

. In the final stages, metal atoms move along crystal boundaries to the walls of internal pores, redistributing mass from the internal bulk of the object and smoothing pore walls. Surface tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension is what allows objects with a higher density than water such as razor blades and insects (e.g. water striders) to f ...

is the driving force for this movement.

A special form of sintering (which is still considered part of powder metallurgy) is liquid-state sintering in which at least one but not all elements are in a liquid state. Liquid-state sintering is required for making cemented carbide

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of carbide cemented into a composite by a binder metal. Cemented carbides commonly use ...

and tungsten carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into ...

.

Sintered bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals, such as phosphorus, or metalloids such ...

in particular is frequently used as a material for bearings, since its porosity allows lubricants to flow through it or remain captured within it. Sintered copper may be used as a wicking structure in certain types of heat pipe construction, where the porosity allows a liquid agent to move through the porous material via capillary action. For materials that have high melting points such as molybdenum

Molybdenum is a chemical element with the symbol Mo and atomic number 42 which is located in period 5 and group 6. The name is from Neo-Latin ''molybdaenum'', which is based on Ancient Greek ', meaning lead, since its ores were confused with lea ...

, tungsten

Tungsten, or wolfram, is a chemical element with the symbol W and atomic number 74. Tungsten is a rare metal found naturally on Earth almost exclusively as compounds with other elements. It was identified as a new element in 1781 and first isolat ...

, rhenium, tantalum

Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as ''tantalium'', it is named after Tantalus, a villain in Greek mythology. Tantalum is a very hard, ductile, lustrous, blue-gray transition metal that is ...

, osmium

Osmium (from Greek grc, ὀσμή, osme, smell, label=none) is a chemical element with the symbol Os and atomic number 76. It is a hard, brittle, bluish-white transition metal in the platinum group that is found as a trace element in alloys, mos ...

and carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent

In chemistry, the valence (US spelling) or valency (British spelling) of an element is the measure of its combining capacity with o ...

, sintering is one of the few viable manufacturing processes. In these cases, very low porosity is desirable and can often be achieved.

Sintered metal powder is used to make frangible shotgun shells called breaching round

A breaching round or slug-shot is a shotgun shell specially made for door breaching. It is typically fired at a range of 6 inches (15 cm) or less, aimed at the hinges or the area between the doorknob and lock and doorjamb, and is designed to d ...

s, as used by military and SWAT teams to quickly force entry into a locked room. These shotgun shells are designed to destroy door deadbolts, locks and hinges without risking lives by ricocheting or by flying on at lethal speed through the door. They work by destroying the object they hit and then dispersing into a relatively harmless powder.

Sintered bronze and stainless steel are used as filter materials in applications requiring high temperature resistance while retaining the ability to regenerate the filter element. For example, sintered stainless steel elements are employed for filtering steam in food and pharmaceutical applications, and sintered bronze in aircraft hydraulic systems.

Sintering of powders containing precious metals such as silver

Silver is a chemical element with the Symbol (chemistry), symbol Ag (from the Latin ', derived from the Proto-Indo-European wikt:Reconstruction:Proto-Indo-European/h₂erǵ-, ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, whi ...

and gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile met ...

is used to make small jewelry items. Evaporative self-assembly of colloidal silver nanocubes into supercrystals has been shown to allow the sintering of electrical joints at temperatures lower than 200°C.Advantages

Particular advantages of the powder technology include: # Very high levels of purity and uniformity in starting materials # Preservation of purity, due to the simpler subsequentfabrication

Fabrication may refer to:

* Manufacturing, specifically the crafting of individual parts as a solo product or as part of a larger combined product.

Processes in arts, crafts and manufacturing

*Semiconductor device fabrication, the process used t ...

process (fewer steps) that it makes possible

# Stabilization of the details of repetitive operations, by control of grain

A grain is a small, hard, dry fruit (caryopsis) – with or without an attached hull layer – harvested for human or animal consumption. A grain crop is a grain-producing plant. The two main types of commercial grain crops are cereals and legum ...

size during the input stages

# Absence of binding contact between segregated powder particles – or "inclusions" (called stringering) – as often occurs in melting processes

# No deformation needed to produce directional elongation of grains

# Capability to produce materials of controlled, uniform porosity.

# Capability to produce nearly net-shaped objects.

# Capability to produce materials which cannot be produced by any other technology.

# Capability to fabricate high-strength material like turbine blades.

# After sintering the mechanical strength to handling becomes higher.

The literature contains many references on sintering dissimilar materials to produce solid/solid-phase compounds or solid/melt mixtures at the processing stage. Almost any substance can be obtained in powder form, through either chemical, mechanical or physical processes, so basically any material can be obtained through sintering. When pure elements are sintered, the leftover powder is still pure, so it can be recycled.

Disadvantages

Particular disadvantages of the powder technology include: # 100% sintered (iron ore) cannot be charged in the blast furnace # sintering cannot create uniform sizes # micro- and nanostructures produced before sintering are often destroyed.Plastics sintering

Plastic materials are formed by sintering for applications that require materials of specific porosity. Sintered plastic porous components are used in filtration and to control fluid and gas flows. Sintered plastics are used in applications requiring caustic fluid separation processes such as the nibs in whiteboard markers, inhaler filters, and vents for caps and liners on packaging materials. Sintered ultra high molecular weight polyethylene materials are used as ski and snowboard base materials. The porous texture allows wax to be retained within the structure of the base material, thus providing a more durable wax coating.Liquid phase sintering

For materials that are difficult to sinter, a process calledliquid phase sintering Liquid phase sintering is a sintering technique that uses a liquid phase to accelerate the interparticle bonding of the solid phase. In addition to rapid initial particle rearrangement due to capillary forces, mass transport through liquid is genera ...

is commonly used. Materials for which liquid phase sintering is common are Si3N4, WC, SiC

The Latin adverb ''sic'' (; "thus", "just as"; in full: , "thus was it written") inserted after a quoted word or passage indicates that the quoted matter has been transcribed or translated exactly as found in the source text, complete with any e ...

, and more. Liquid phase sintering is the process of adding an additive to the powder which will melt before the matrix phase. The process of liquid phase sintering has three stages:

*rearrangement – As the liquid melts capillary action will pull the liquid into pores and also cause grains to rearrange into a more favorable packing arrangement.

*solution-precipitation – In areas where capillary pressures are high (particles are close together) atoms will preferentially go into solution and then precipitate in areas of lower chemical potential where particles are not close or in contact. This is called contact flattening. This densifies the system in a way similar to grain boundary diffusion in solid state sintering. Ostwald ripening will also occur where smaller particles will go into solution preferentially and precipitate on larger particles leading to densification.

*final densification – densification of solid skeletal network, liquid movement from efficiently packed regions into pores.

For liquid phase sintering to be practical the major phase should be at least slightly soluble in the liquid phase and the additive should melt before any major sintering of the solid particulate network occurs, otherwise rearrangement of grains will not occur. Liquid phase sintering was successfully applied to improve grain growth of thin semiconductor layers from nanoparticle precursor films.

Electric current assisted sintering

These techniques employ electric currents to drive or enhance sintering. English engineer A. G. Bloxam registered in 1906 the firstpatent

A patent is a type of intellectual property that gives its owner the legal right to exclude others from making, using, or selling an invention for a limited period of time in exchange for publishing an enabling disclosure of the invention."A p ...

on sintering powders using direct current

Direct current (DC) is one-directional flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor such as a wire, but can also flow through semiconductors, insulators, or even ...

in vacuum

A vacuum is a space devoid of matter. The word is derived from the Latin adjective ''vacuus'' for "vacant" or "void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressure. Physicists often dis ...

. The primary purpose of his inventions was the industrial scale production of filaments for incandescent lamp

An incandescent light bulb, incandescent lamp or incandescent light globe is an electric light with a wire filament heated until it glows. The filament is enclosed in a glass bulb with a vacuum or inert gas to protect the filament from oxid ...

s by compacting tungsten

Tungsten, or wolfram, is a chemical element with the symbol W and atomic number 74. Tungsten is a rare metal found naturally on Earth almost exclusively as compounds with other elements. It was identified as a new element in 1781 and first isolat ...

or molybdenum

Molybdenum is a chemical element with the symbol Mo and atomic number 42 which is located in period 5 and group 6. The name is from Neo-Latin ''molybdaenum'', which is based on Ancient Greek ', meaning lead, since its ores were confused with lea ...

particles. The applied current was particularly effective in reducing surface oxide

An oxide () is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O2– (molecular) ion. with oxygen in the oxidation state of −2. Most of the E ...

s that increased the emissivity of the filaments.

In 1913, Weintraub and Rush patented a modified sintering method which combined electric current with pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

. The benefits of this method were proved for the sintering of refractory metals

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear. The expression is mostly used in the context of materials science, metallurgy and engineering. The definition of which elements belong to this group diff ...

as well as conductive carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of the ...

or nitride powders. The starting boron

Boron is a chemical element with the symbol B and atomic number 5. In its crystalline form it is a brittle, dark, lustrous metalloid; in its amorphous form it is a brown powder. As the lightest element of the ''boron group'' it has th ...

–carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent

In chemistry, the valence (US spelling) or valency (British spelling) of an element is the measure of its combining capacity with o ...

or silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic tab ...

–carbon powders were placed in an electrically insulating tube and compressed by two rods which also served as electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or air). Electrodes are essential parts of batteries that can consist of a variety of materials de ...

s for the current. The estimated sintering temperature was 2000 °C.

In the United States, sintering was first patented by Duval d’Adrian in 1922. His three-step process aimed at producing heat-resistant blocks from such oxide materials as zirconia

Zirconium dioxide (), sometimes known as zirconia (not to be confused with zircon), is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the mineral baddeleyite. A dopant stabi ...

, thoria

''Thoria'' is a genus of shield bugs in the tribe Podopini

Podopinae, known as turtle bugs, are a subfamily of the insect family Pentatomidae. The type genus is '' Podops''.

Tribes and Genera

''BioLib'' lists: Brachycerocorini

Auth. Davidova ...

or tantalia. The steps were: (i) molding the powder; (ii) annealing it at about 2500 °C to make it conducting; (iii) applying current-pressure sintering as in the method by Weintraub and Rush.

Sintering that uses an arc

ARC may refer to:

Business

* Aircraft Radio Corporation, a major avionics manufacturer from the 1920s to the '50s

* Airlines Reporting Corporation, an airline-owned company that provides ticket distribution, reporting, and settlement services

* ...

produced via a capacitance

Capacitance is the capability of a material object or device to store electric charge. It is measured by the change in charge in response to a difference in electric potential, expressed as the ratio of those quantities. Commonly recognized are ...

discharge to eliminate oxides before direct current heating, was patented by G. F. Taylor in 1932. This originated sintering methods employing pulsed or alternating current

Alternating current (AC) is an electric current which periodically reverses direction and changes its magnitude continuously with time in contrast to direct current (DC) which flows only in one direction. Alternating current is the form in whic ...

, eventually superimposed to a direct current. Those techniques have been developed over many decades and summarized in more than 640 patents.

Of these technologies the most well known is resistance sintering (also called hot pressing

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat a ...

) and spark plasma sintering Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique.

The main characteristic of SPS is that the pulsed or u ...

, while electro sinter forging Electro sinter forging (ESF) is an industrial single electromagnetic pulse sintering technique to rapidly produce a wide range of small components in metals, alloys, intermetallics, semiconductors, and composite material, composites. ESF was invent ...

is the latest advancement in this field.

Spark plasma sintering

Inspark plasma sintering Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique.

The main characteristic of SPS is that the pulsed or u ...

(SPS), external pressure and an electric field are applied simultaneously to enhance the densification of the metallic/ceramic powder compacts. However, after commercialization it was determined there is no plasma, so the proper name is spark sintering as coined by Lenel. The electric field driven densification supplements sintering with a form of hot pressing, to enable lower temperatures and taking less time than typical sintering. For a number of years, it was speculated that the existence of sparks or plasma between particles could aid sintering; however, Hulbert and coworkers systematically proved that the electric parameters used during spark plasma sintering make it (highly) unlikely. In light of this, the name "spark plasma sintering" has been rendered obsolete. Terms such as field assisted sintering technique (FAST), electric field assisted sintering (EFAS), and direct current sintering (DCS) have been implemented by the sintering community. Using a direct current

Direct current (DC) is one-directional flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor such as a wire, but can also flow through semiconductors, insulators, or even ...

(DC) pulse as the electric current, spark plasma, spark impact pressure, joule heating, and an electrical field diffusion effect would be created. By modifying the graphite die design and its assembly, it is possible to perform pressureless sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

in spark plasma sintering facility. This modified die design setup is reported to synergize the advantages of both conventional pressureless sintering and spark plasma sintering techniques.

Electro sinter forging

Electro sinter forging Electro sinter forging (ESF) is an industrial single electromagnetic pulse sintering technique to rapidly produce a wide range of small components in metals, alloys, intermetallics, semiconductors, and composite material, composites. ESF was invent ...

is an electric current assisted sintering (ECAS) technology originated from capacitor discharge sintering. It is used for the production of diamond metal matrix composites and is under evaluation for the production of hard metals, nitinol and other metals and intermetallics. It is characterized by a very low sintering time, allowing machines to sinter at the same speed as a compaction press.

Pressureless sintering

Pressureless sintering is the sintering of a powder compact (sometimes at very high temperatures, depending on the powder) without applied pressure. This avoids density variations in the final component, which occurs with more traditional hot pressing methods. The powder compact (if a ceramic) can be created byslip casting

Slip casting, or slipcasting, is a ceramic forming technique for pottery and other ceramics, especially for shapes not easily made on a wheel. In this method, a liquid clay body slip (usually mixed in a blunger) is poured into plaster moul ...

, injection moulding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

, and cold isostatic pressing. After presintering, the final green compact can be machined to its final shape before being sintered.

Three different heating schedules can be performed with pressureless sintering: constant-rate of heating (CRH), rate-controlled sintering (RCS), and two-step sintering (TSS). The microstructure and grain size of the ceramics may vary depending on the material and method used.

Constant-rate of heating (CRH), also known as temperature-controlled sintering, consists of heating the green compact at a constant rate up to the sintering temperature. Experiments with zirconia have been performed to optimize the sintering temperature and sintering rate for CRH method. Results showed that the grain sizes were identical when the samples were sintered to the same density, proving that grain size is a function of specimen density rather than CRH temperature mode.

In rate-controlled sintering (RCS), the densification rate in the open-porosity phase is lower than in the CRH method. By definition, the relative density, ρrel, in the open-porosity phase is lower than 90%. Although this should prevent separation of pores from grain boundaries, it has been proven statistically that RCS did not produce smaller grain sizes than CRH for alumina, zirconia, and ceria samples.

Two-step sintering (TSS) uses two different sintering temperatures. The first sintering temperature should guarantee a relative density higher than 75% of theoretical sample density. This will remove supercritical pores from the body. The sample will then be cooled down and held at the second sintering temperature until densification is completed. Grains of cubic zirconia and cubic strontium titanate were significantly refined by TSS compared to CRH. However, the grain size changes in other ceramic materials, like tetragonal zirconia and hexagonal alumina, were not statistically significant.

Microwave sintering

Inmicrowave

Microwave is a form of electromagnetic radiation with wavelengths ranging from about one meter to one millimeter corresponding to frequencies between 300 MHz and 300 GHz respectively. Different sources define different frequency ran ...

sintering, heat is sometimes generated internally within the material, rather than via surface radiative heat transfer from an external heat source. Some materials fail to couple and others exhibit run-away behavior, so it is restricted in usefulness. A benefit of microwave sintering is faster heating for small loads, meaning less time is needed to reach the sintering temperature, less heating energy is required and there are improvements in the product properties.

A failing of microwave sintering is that it generally sinters only one compact at a time, so overall productivity turns out to be poor except for situations involving one of a kind sintering, such as for artists. As microwaves can only penetrate a short distance in materials with a high conductivity and a high permeability, microwave sintering requires the sample to be delivered in powders with a particle size around the penetration depth of microwaves in the particular material. The sintering process and side-reactions run several times faster during microwave sintering at the same temperature, which results in different properties for the sintered product.

This technique is acknowledged to be quite effective in maintaining fine grains/nano sized grains in sintered bioceramics

Bioceramics and bioglasses are ceramic materials that are biocompatible. Bioceramics are an important subset of biomaterials.J. F. Shackelford (editor)(1999) ''MSF bioceramics applications of ceramic and glass materials in medicine'' Bioceramics r ...

. Magnesium phosphates and calcium phosphates are the examples which have been processed through the microwave sintering technique.

Densification, vitrification and grain growth

Sintering in practice is the control of both densification and grain growth. Densification is the act of reducing porosity in a sample, thereby making it denser. Grain growth is the process of grain boundary motion and Ostwald ripening to increase the average grain size. Many properties (mechanical strength

The field of strength of materials, also called mechanics of materials, typically refers to various methods of calculating the stresses and strains in structural members, such as beams, columns, and shafts. The methods employed to predict the re ...

, electrical breakdown strength, etc.) benefit from both a high relative density

Density (volumetric mass density or specific mass) is the substance's mass per unit of volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' can also be used. Mathematical ...

and a small grain size. Therefore, being able to control these properties during processing is of high technical importance. Since densification of powders requires high temperatures, grain growth naturally occurs during sintering. Reduction of this process is key for many engineering ceramics. Under certain conditions of chemistry and orientation, some grains may grow rapidly at the expense of their neighbours during sintering. This phenomenon, known as abnormal grain growth (AGG), results in a bimodal grain size distribution that has consequences for the mechanical, dielectric and thermal performance of the sintered material.

For densification to occur at a quick pace it is essential to have (1) an amount of liquid phase that is large in size, (2) a near complete solubility of the solid in the liquid, and (3) wetting of the solid by the liquid. The power behind the densification is derived from the capillary pressure of the liquid phase located between the fine solid particles. When the liquid phase wets the solid particles, each space between the particles becomes a capillary in which a substantial capillary pressure is developed. For submicrometre particle sizes, capillaries with diameters in the range of 0.1 to 1 micrometres develop pressures in the range of to for silicate liquids and in the range of to for a metal such as liquid cobalt.

Densification requires constant capillary pressure In fluid statics, capillary pressure () is the pressure between two immiscible fluids in a thin tube (see capillary action), resulting from the interactions of forces between the fluids and solid walls of the tube. Capillary pressure can serve as bo ...

where just solution-precipitation material transfer would not produce densification. For further densification, additional particle movement while the particle undergoes grain-growth and grain-shape changes occurs. Shrinkage would result when the liquid slips between particles and increases pressure at points of contact causing the material to move away from the contact areas, forcing particle centers to draw near each other.

The sintering of liquid-phase materials involves a fine-grained solid phase to create the needed capillary pressures proportional to its diameter, and the liquid concentration must also create the required capillary pressure within range, else the process ceases. The vitrification rate is dependent upon the pore size, the viscosity and amount of liquid phase present leading to the viscosity of the overall composition, and the surface tension. Temperature dependence for densification controls the process because at higher temperatures viscosity decreases and increases liquid content. Therefore, when changes to the composition and processing are made, it will affect the vitrification process.

Sintering mechanisms

Sintering occurs by diffusion of atoms through the microstructure. This diffusion is caused by a gradient of chemical potential – atoms move from an area of higher chemical potential to an area of lower chemical potential. The different paths the atoms take to get from one spot to another are the sintering mechanisms. The six common mechanisms are: * surface diffusion – diffusion of atoms along the surface of a particle * vapor transport – evaporation of atoms which condense on a different surface * lattice diffusion from surface – atoms from surface diffuse through lattice * lattice diffusion from grain boundary – atom from grain boundary diffuses through lattice * grain boundary diffusion – atoms diffuse along grain boundary * plastic deformation – dislocation motion causes flow of matter. Also, one must distinguish between densifying and non-densifying mechanisms. 1–3 above are non-densifying – they take atoms from the surface and rearrange them onto another surface or part of the same surface. These mechanisms simply rearrange matter inside of porosity and do not cause pores to shrink. Mechanisms 4–6 are densifying mechanisms – atoms are moved from the bulk to the surface of pores, thereby eliminating porosity and increasing the density of the sample.Grain growth

Agrain boundary

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional defects in the crystal structure, and tend to decrease the electrical and thermal ...

(GB) is the transition area or interface between adjacent crystallites (or grains) of the same chemical and lattice composition, not to be confused with a phase boundary

Phase or phases may refer to:

Science

*State of matter, or phase, one of the distinct forms in which matter can exist

*Phase (matter), a region of space throughout which all physical properties are essentially uniform

*Phase space, a mathematica ...

. The adjacent grains do not have the same orientation of the lattice, thus giving the atoms in GB shifted positions relative to the lattice in the crystal

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macros ...

s. Due to the shifted positioning of the atoms in the GB they have a higher energy state when compared with the atoms in the crystal lattice of the grains. It is this imperfection that makes it possible to selectively etch the GBs when one wants the microstructure to be visible.

Striving to minimize its energy leads to the coarsening of the microstructure to reach a metastable state within the specimen. This involves minimizing its GB area and changing its topological structure to minimize its energy. This grain growth can either be normal or abnormal, a normal grain growth is characterized by the uniform growth and size of all the grains in the specimen. Abnormal grain growth is when a few grains grow much larger than the remaining majority.

Grain boundary energy/tension

The atoms in the GB are normally in a higher energy state than their equivalent in the bulk material. This is due to their more stretched bonds, which gives rise to a GB tension . This extra energy that the atoms possess is called the grain boundary energy, . The grain will want to minimize this extra energy, thus striving to make the grain boundary area smaller and this change requires energy. “Or, in other words, a force has to be applied, in the plane of the grain boundary and acting along a line in the grain-boundary area, in order to extend the grain-boundary area in the direction of the force. The force per unit length, i.e. tension/stress, along the line mentioned is σGB. On the basis of this reasoning it would follow that: with dA as the increase of grain-boundary area per unit length along the line in the grain-boundary area considered.” g 478/sup> The GB tension can also be thought of as the attractive forces between the atoms at the surface and the tension between these atoms is due to the fact that there is a larger interatomic distance between them at the surface compared to the bulk (i.e.surface tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension is what allows objects with a higher density than water such as razor blades and insects (e.g. water striders) to f ...

). When the surface area becomes bigger the bonds stretch more and the GB tension increases. To counteract this increase in tension there must be a transport of atoms to the surface keeping the GB tension constant. This diffusion of atoms accounts for the constant surface tension in liquids. Then the argument,

holds true. For solids, on the other hand, diffusion of atoms to the surface might not be sufficient and the surface tension can vary with an increase in surface area.

For a solid, one can derive an expression for the change in Gibbs free energy, dG, upon the change of GB area, dA. dG is given by

which gives

is normally expressed in units of while is normally expressed in units of since they are different physical properties.

Mechanical equilibrium

In a two-dimensionalisotropic material

Isotropy is uniformity in all orientations; it is derived . Precise definitions depend on the subject area. Exceptions, or inequalities, are frequently indicated by the prefix ' or ', hence ''anisotropy''. ''Anisotropy'' is also used to describe ...

the grain boundary tension would be the same for the grains. This would give angle of 120° at GB junction where three grains meet. This would give the structure a hexagonal

In geometry, a hexagon (from Greek , , meaning "six", and , , meaning "corner, angle") is a six-sided polygon. The total of the internal angles of any simple (non-self-intersecting) hexagon is 720°.

Regular hexagon

A '' regular hexagon'' has ...

pattern which is the metastable state (or mechanical equilibrium) of the 2D specimen. A consequence of this is that, to keep trying to be as close to the equilibrium as possible, grains with fewer sides than six will bend the GB to try keep the 120° angle between each other. This results in a curved boundary with its curvature

In mathematics, curvature is any of several strongly related concepts in geometry. Intuitively, the curvature is the amount by which a curve deviates from being a straight line, or a surface deviates from being a plane.

For curves, the canonic ...

towards itself. A grain with six sides will, as mentioned, have straight boundaries, while a grain with more than six sides will have curved boundaries with its curvature away from itself. A grain with six boundaries (i.e. hexagonal structure) is in a metastable state (i.e. local equilibrium) within the 2D structure. In three dimensions structural details are similar but much more complex and the metastable structure for a grain is a non-regular 14-sided polyhedra with doubly curved faces. In practice all arrays of grains are always unstable and thus always grow until prevented by a counterforce.

Grains strive to minimize their energy, and a curved boundary has a higher energy than a straight boundary. This means that the grain boundary will migrate towards the curvature. The consequence of this is that grains with less than 6 sides will decrease in size while grains with more than 6 sides will increase in size.

Grain growth occurs due to motion of atoms across a grain boundary. Convex surfaces have a higher chemical potential than concave surfaces, therefore grain boundaries will move toward their center of curvature. As smaller particles tend to have a higher radius of curvature and this results in smaller grains losing atoms to larger grains and shrinking. This is a process called Ostwald ripening. Large grains grow at the expense of small grains.

Grain growth in a simple model is found to follow:

Here ''G'' is final average grain size, ''G0'' is the initial average grain size, ''t'' is time, ''m'' is a factor between 2 and 4, and ''K'' is a factor given by:

Here ''Q'' is the molar activation energy, ''R'' is the ideal gas constant, ''T'' is absolute temperature, and ''K0'' is a material dependent factor. In most materials the sintered grain size is proportion to the inverse square root of the fractional porosity, implying that pores are the most effective retardant for grain growth during sintering.

Reducing grain growth

;Solute ions If adopant

A dopant, also called a doping agent, is a trace of impurity element that is introduced into a chemical material to alter its original electrical or optical properties. The amount of dopant necessary to cause changes is typically very low. When ...

is added to the material (example: Nd in BaTiO3) the impurity will tend to stick to the grain boundaries. As the grain boundary tries to move (as atoms jump from the convex to concave surface) the change in concentration of the dopant at the grain boundary will impose a drag on the boundary. The original concentration of solute around the grain boundary will be asymmetrical in most cases. As the grain boundary tries to move, the concentration on the side opposite of motion will have a higher concentration and therefore have a higher chemical potential. This increased chemical potential will act as a backforce to the original chemical potential gradient that is the reason for grain boundary movement. This decrease in net chemical potential will decrease the grain boundary velocity and therefore grain growth.

;Fine second phase particles

If particles of a second phase which are insoluble in the matrix phase are added to the powder in the form of a much finer powder, then this will decrease grain boundary movement. When the grain boundary tries to move past the inclusion diffusion of atoms from one grain to the other, it will be hindered by the insoluble particle. This is because it is beneficial for particles to reside in the grain boundaries and they exert a force in opposite direction compared to grain boundary migration. This effect is called the Zener effect after the man who estimated this drag force to

where r is the radius of the particle and λ the interfacial energy of the boundary if there are N particles per unit volume their volume fraction f is

assuming they are randomly distributed. A boundary of unit area will intersect all particles within a volume of 2r which is 2Nr particles. So the number of particles n intersecting a unit area of grain boundary is:

Now, assuming that the grains only grow due to the influence of curvature, the driving force of growth is where (for homogeneous grain structure) R approximates to the mean diameter of the grains. With this the critical diameter that has to be reached before the grains ceases to grow:

This can be reduced to

so the critical diameter of the grains is dependent on the size and volume fraction of the particles at the grain boundaries.

It has also been shown that small bubbles or cavities can act as inclusion

More complicated interactions which slow grain boundary motion include interactions of the surface energies of the two grains and the inclusion and are discussed in detail by C.S. Smith.

Sintering of catalysts

Sintering is an important cause for loss ofcatalytic activity

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recyc ...

, especially on supported metal catalysts. It decreases the surface area of the catalyst and changes the surface structure. For a porous catalytic surface, the pores may collapse due to sintering, resulting in loss of surface area. Sintering is in general an irreversible process.

Small catalyst particles have the highest possible relative surface area and high reaction temperature, both factors that generally increase the reactivity of a catalyst. However, these factors are also the circumstances under which sintering occurs. Specific materials may also increase the rate of sintering. On the other hand, by alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, ...

ing catalysts with other materials, sintering can be reduced. Rare-earth metals

The rare-earth elements (REE), also called the rare-earth metals or (in context) rare-earth oxides or sometimes the lanthanides (yttrium and scandium are usually included as rare earths), are a set of 17 nearly-indistinguishable lustrous silve ...

in particular have been shown to reduce sintering of metal catalysts when alloyed.

For many supported metal catalysts, sintering starts to become a significant effect at temperatures over . Catalysts that operate at higher temperatures, such as a car catalyst, use structural improvements to reduce or prevent sintering. These improvements are in general in the form of a support made from an inert and thermally stable material such as silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one ...

, carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent

In chemistry, the valence (US spelling) or valency (British spelling) of an element is the measure of its combining capacity with o ...

or alumina.

See also

* * * * * * * * * *, arapid prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

Construction of the part or assembly is usually done using 3D printin ...

technology, that includes Direct Metal Laser Sintering (DMLS).

*

* – a pioneer of sintering methods

*

References

Further reading

* * * *External links

Particle-Particle-Sintering – a 3D lattice kinetic Monte Carlo simulation

{{Authority control Industrial processes Metalworking Plastics industry Metallurgical processes