|

Grain Growth

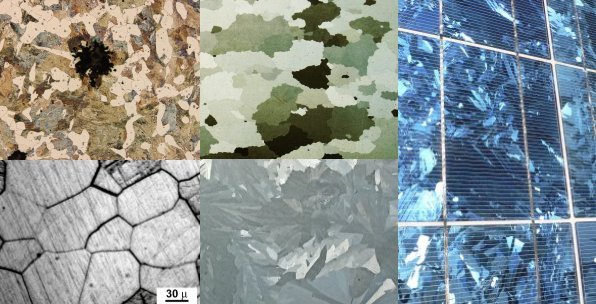

In materials science, grain growth is the increase in size of grains (crystallites) in a material at high temperature. This occurs when recovery and recrystallisation are complete and further reduction in the internal energy can only be achieved by reducing the total area of grain boundary. The term is commonly used in metallurgy but is also used in reference to ceramics and minerals. The behaviors of grain growth is analogous to the coarsening behaviors of grains, which implied that both of grain growth and coarsening may be dominated by the same physical mechanism. Importance of grain growth The practical performances of polycrystalline materials are strongly affected by the formed microstructure inside, which is mostly dominated by grain growth behaviors. For example, most materials exhibit the Hall–Petch effect at room-temperature and so display a higher yield stress when the grain size is reduced (assuming abnormal grain growth has not taken place). At high temperatures ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystallite

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains. Bacillite is a type of crystallite. It is rodlike with parallel longulites. Structure The orientation of crystallites can be random with no preferred direction, called random texture, or directed, possibly due to growth and processing conditions. While the structure of a ( single) crystal is highly ordered and its lattice is continuous and unbroken, amorphous materials, such as glass and many polymers, are non-crystalline and do not display any structures, as their constituents are not arranged in an ordered manner. Polycrystalline structures and paracrystalline phases are in-between these two extremes. Polycrystalline materials, or polycrystals, are solids that are composed of many crystallites of varying size and orientation. Most materials are polycrystalline, made of a large number crystallites held together by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Boundary

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional defects in the crystal structure, and tend to decrease the electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation of new phases from the solid. They are also important to many of the mechanisms of creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. High and low angle boundaries It is convenient to categorize grain boundaries according to the extent of misorientation between the two grains. ''Low-angle grain boundaries'' (''LAGB'') or ''subgrain boundaries'' are those with a misorientation less than about 15 degrees. Generally speaking they are composed o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dopants

A dopant, also called a doping agent, is a trace of impurity element that is introduced into a chemical material to alter its original electrical or optical properties. The amount of dopant necessary to cause changes is typically very low. When doped into crystalline substances, the dopant's atoms get incorporated into its crystal lattice. The crystalline materials are frequently either crystals of a semiconductor such as silicon and germanium for use in solid-state electronics, or transparent crystals for use in the production of various laser types; however, in some cases of the latter, noncrystalline substances such as glass can also be doped with impurities. In solid-state electronics using the proper types and amounts of dopants in semiconductors is what produces the p-type semiconductors and n-type semiconductors that are essential for making transistors and diodes. Transparent crystals Lasing media The procedure of doping tiny amounts of the metals chromium (Cr), ne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Clinker nodules produced by sintering Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Refractories

In materials science, a refractory material or refractory is a material that is resistant to decomposition by heat, pressure, or chemical attack, and retains strength and form at high temperatures. Refractories are polycrystalline, polyphase, inorganic, non-metallic, porous, and heterogeneous. They are typically composed of oxides or carbides, nitrides etc. of the following materials: silicon, aluminium, magnesium, calcium, boron, chromium and zirconium. ASTM C71 defines refractories as "...non-metallic materials having those chemical and physical properties that make them applicable for structures, or as components of systems, that are exposed to environments above ." Refractory materials are used in furnaces, kilns, incinerators, and reactors. Refractories are also used to make crucibles and moulds for casting glass and metals and for surfacing flame deflector systems for rocket launch structures. Today, the iron- and steel-industry and metal casting sectors use appro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zener Pinning

Zener pinning is the influence of a dispersion of fine particles on the movement of low- and high-angle grain boundaries through a polycrystalline material. Small particles act to prevent the motion of such boundaries by exerting a pinning pressure which counteracts the driving force pushing the boundaries. Zener pinning is very important in materials processing as it has a strong influence on recovery, recrystallization and grain growth. Origin of the pinning force A boundary is an imperfection in the crystal structure and as such is associated with a certain quantity of energy. When a boundary passes through an incoherent particle then the portion of boundary that would be inside the particle essentially ceases to exist. In order to move past the particle some new boundary must be created, and this is energetically unfavourable. While the region of boundary near the particle is pinned, the rest of the boundary continues trying to move forward under its own driving force. This r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abnormal Grain Growth

Abnormal or discontinuous grain growth, also referred to as exaggerated or secondary recrystallisation grain growth, is a grain growth phenomenon through which certain energetically favorable grains (crystallites) grow rapidly in a matrix of finer grains resulting in a bimodal grain size distribution. In ceramic materials this phenomenon can result in the formation of elongated prismatic, acicular (needle-like) grains in a densified matrix with implications for improved fracture toughness through the impedance of crack propagation. Mechanisms Abnormal grain growth (AGG) is encountered in metallic or ceramic systems exhibiting one or more of several characteristics. # Secondary phase inclusions, precipitates or impurities above a certain threshold concentration. # High anisotropy in interfacial energy (solid-liquid))or grain boundary energy (solid-solid) in bulk materials. # Highly anisotropic surface energy in thin film materials. # High chemical inequilibrium. Although ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mats Hillert

Mats Hillert (28 November 1924 – 2 November 2022) was a Swedish metallurgist who was an emeritus professor in metallography (physical metallurgy) at the Royal Institute of Technology (KTH).Thermodynamics and Phase Transformations - The Selected works of Mats Hillert. (2006) s. iii. A short presentation of Mats Hillert Hillert was born in Gothenburg on 28 November 1924. He graduated from Chalmers University of Technology in 1947 with a major in chemical engineering. After finishing his military service, he joined the Swedish Institute for Metals Research in 1948. He investigated his options for postgraduate studies related to his new area, and took additional physics courses at KTH. In 1953, he moved to the United States for postgraduate studies at the Massachusetts Institute of Technology, where he earned an Sc.D. in 1956, after which he returned to Sweden. He was made a professor at KTH in 1961. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ostwald Ripening

Ostwald ripening is a phenomenon observed in solid solutions or liquid sols that describes the change of an inhomogeneous structure over time, i.e., small crystals or sol particles dissolve, and redeposit onto larger crystals or sol particles. Dissolution of small crystals or sol particles and the redeposition of the dissolved species on the surfaces of larger crystals or sol particles was first described by Wilhelm Ostwald in 1896. For colloidal systems, Ostwald ripening is also found in water-in-oil emulsions, while flocculation is found in oil-in-water emulsions. Mechanism This thermodynamically-driven spontaneous process occurs because larger particles are more energetically favored than smaller particles. This stems from the fact that molecules on the surface of a particle are energetically less stable than the ones in the interior. Consider a cubic crystal of atoms: all the atoms inside are bonded to 6 neighbours and are quite stable, but atoms on the surface are onl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Evolution Of A Single Growing Grain

Evolution is change in the heritable characteristics of biological populations over successive generations. These characteristics are the expressions of genes, which are passed on from parent to offspring during reproduction. Variation tends to exist within any given population as a result of genetic mutation and recombination. Evolution occurs when evolutionary processes such as natural selection (including sexual selection) and genetic drift act on this variation, resulting in certain characteristics becoming more common or more rare within a population. The evolutionary pressures that determine whether a characteristic is common or rare within a population constantly change, resulting in a change in heritable characteristics arising over successive generations. It is this process of evolution that has given rise to biodiversity at every level of biological organisation, including the levels of species, individual organisms, and molecules. The theory of evolution by nat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |