production-intent on:

[Wikipedia]

[Google]

[Amazon]

Mass production, also known as flow production or continuous production, is the production of substantial amounts of

Mass production, also known as flow production or continuous production, is the production of substantial amounts of

Standardized parts and sizes and factory production techniques were developed in pre-industrial times; before the invention of

Standardized parts and sizes and factory production techniques were developed in pre-industrial times; before the invention of

The Navy was in a state of expansion that required 100,000 pulley blocks to be manufactured a year. Bentham had already achieved remarkable efficiency at the docks by introducing power-driven machinery and reorganising the dockyard system. Brunel, a pioneering engineer, and Maudslay, a pioneer of machine tool technology who had developed the first industrially practical

The Navy was in a state of expansion that required 100,000 pulley blocks to be manufactured a year. Bentham had already achieved remarkable efficiency at the docks by introducing power-driven machinery and reorganising the dockyard system. Brunel, a pioneering engineer, and Maudslay, a pioneer of machine tool technology who had developed the first industrially practical

. makingthemodernworld.org Mass production techniques were also used to rather limited extent to make clocks and watches, and to make small arms, though parts were usually non-interchangeable. Though produced on a very small scale, During

During

Mass production, also known as flow production or continuous production, is the production of substantial amounts of

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized

Standardization or standardisation is the process of implementing and developing technical standards based on the consensus of different parties that include firms, users, interest groups, standards organizations and governments. Standardization ...

products in a constant flow, including and especially on assembly line

An assembly line is a manufacturing process (often called a ''progressive assembly'') in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in seq ...

s. Together with job production

Job production, sometimes called jobbing or one-off production, involves producing custom work, such as a one-off product for a specific customer or a small batch of work in quantities usually less than those of mass-market products. Job producti ...

and batch production

Batch production is a method of manufacturing where the products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch prod ...

, it is one of the three main production methods.

The term ''mass production'' was popularized by a 1926 article in the ''Encyclopædia Britannica'' supplement that was written based on correspondence with Ford Motor Company

Ford Motor Company (commonly known as Ford) is an American multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. The company sells automobi ...

. ''The New York Times'' used the term in the title of an article that appeared before publication of the ''Britannica'' article.

The concepts of mass production are applied to various kinds of products: from fluids

In physics, a fluid is a liquid, gas, or other material that continuously deforms (''flows'') under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are substances which cannot resist any shear ...

and particulates handled in bulk (food

Food is any substance consumed by an organism for nutritional support. Food is usually of plant, animal, or fungal origin, and contains essential nutrients, such as carbohydrates, fats, proteins, vitamins, or minerals. The substance is inge ...

, fuel

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but ...

, chemicals

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., wit ...

and mined minerals

In geology and mineralogy, a mineral or mineral species is, broadly speaking, a solid chemical compound with a fairly well-defined chemical composition and a specific crystal structure that occurs naturally in pure form.John P. Rafferty, ed. (2 ...

), to parts and assemblies of parts (household appliances

A major appliance, also known as a large domestic appliance or large electric appliance or simply a large appliance, large domestic, or large electric, is a non-portable or semi-portable machine used for routine housekeeping tasks such as cookin ...

and automobiles

A car or automobile is a motor vehicle with wheels. Most definitions of ''cars'' say that they run primarily on roads, seat one to eight people, have four wheels, and mainly transport people instead of goods.

The year 1886 is regarded as ...

).

Some mass production techniques, such as standardized sizes and production lines, predate the Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

by many centuries; however, it was not until the introduction of machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

s and techniques to produce interchangeable parts were developed in the mid-19th century that modern mass production was possible.

Overview

Mass production involves making many copies of products, very quickly, using assembly line techniques to send partially complete products to workers who each work on an individual step, rather than having a worker work on a whole product from start to finish. Mass production of fluid matter typically involves pipes withcentrifugal pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic ...

s or screw conveyor

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "''flighting''", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyor ...

s (augers) to transfer raw materials or partially complete products between vessels. Fluid flow processes such as oil refining and bulk materials such as wood chips and pulp are automated using a system of process control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. I ...

which uses various instruments to measure variables such as temperature, pressure, volumetric and level, providing feedback.

Bulk materials such as coal, ores, grains and wood chips are handled by belt, chain, slat, pneumatic or screw

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to fa ...

conveyors, bucket elevator

A bucket elevator, also called a grain leg, is a mechanism for hauling flowable bulk materials (most often grain or fertilizer) vertically.

It consists of:

# Buckets to contain the material;

# A belt to carry the buckets and transmit the pull;

# ...

s and mobile equipment such as front-end loaders. Materials on pallets are handled with forklifts. Also used for handling heavy items like reels of paper, steel or machinery are electric overhead crane

An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of two parallel rails seated on longitudinal I-beams attached to opposite steel columns by means of brackets. ...

s, sometimes called bridge cranes because they span large factory bays.

Mass production is capital-intensive and energy-intensive, for it uses a high proportion of machinery and energy in relation to workers. It is also usually automated

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines ...

while total expenditure per unit of product is decreased. However, the machinery that is needed to set up a mass production line (such as robot

A robot is a machine—especially one programmable by a computer—capable of carrying out a complex series of actions automatically. A robot can be guided by an external control device, or the control may be embedded within. Robots may be c ...

s and machine press

A forming press, commonly shortened to press, is a machine tool that changes the shape of a work-piece by the application of pressure. The operator of a forming press is known as a press-tool setter, often shortened to tool-setter.

Presses ...

es) is so expensive that in order to attain profits there must be some assurance that the product is to be successful to.

One of the descriptions of mass production is that "the skill is built into the tool", which means that the worker using the tool may not need the skill. For example, in the 19th or early 20th century, this could be expressed as "the craftsmanship is in the workbench

A workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by ...

itself" (not the training of the worker). Rather than having a skilled worker measure every dimension of each part of the product against the plans or the other parts as it is being formed, there were jig

The jig ( ga, port, gd, port-cruinn) is a form of lively folk dance in compound metre, as well as the accompanying dance tune. It is most associated with Irish music and dance. It first gained popularity in 16th-century Ireland and parts of ...

s ready at hand to ensure that the part was made to fit this set-up. It had already been checked that the finished part would be to specifications to fit all the other finished parts—and it would be made more quickly, with no time spent on finishing the parts to fit one another. Later, once computerized control came about (for example, CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a p ...

), jigs were obviated, but it remained true that the skill (or knowledge) was built into the tool (or process, or documentation) rather than residing in the worker's head. This is the specialized capital required for mass production; each workbench and set of tools (or each CNC cell, or each fractionating column

A fractionating column or fractional column is an essential item used in the distillation of liquid mixtures to separate the mixture into its component parts, or fractions, based on the differences in volatilities. Fractionating columns are used in ...

) is different (fine-tuned to its task).

History

Pre-industrial

Standardized parts and sizes and factory production techniques were developed in pre-industrial times; before the invention of

Standardized parts and sizes and factory production techniques were developed in pre-industrial times; before the invention of machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

s the manufacture of precision parts, especially metal ones, was highly labour-intensive.

Crossbows

A crossbow is a ranged weapon using an elastic launching device consisting of a bow-like assembly called a ''prod'', mounted horizontally on a main frame called a ''tiller'', which is hand-held in a similar fashion to the stock of a long fire ...

made with bronze parts were produced in China

China, officially the People's Republic of China (PRC), is a country in East Asia. It is the world's most populous country, with a population exceeding 1.4 billion, slightly ahead of India. China spans the equivalent of five time zones and ...

during the Warring States period

The Warring States period () was an era in History of China#Ancient China, ancient Chinese history characterized by warfare, as well as bureaucratic and military reforms and consolidation. It followed the Spring and Autumn period and concluded ...

. The Qin Emperor unified China at least in part by equipping large armies with these weapons, which were equipped with a sophisticated trigger mechanism made of interchangeable parts. The Terracotta Army

The Terracotta Army is a collection of terracotta sculptures depicting the armies of Qin Shi Huang, the first emperor of China. It is a form of funerary art buried with the emperor in 210–209 BCE with the purpose of protecting the emperor in ...

guarding the Emperor's necropolis

A necropolis (plural necropolises, necropoles, necropoleis, necropoli) is a large, designed cemetery with elaborate tomb monuments. The name stems from the Ancient Greek ''nekropolis'', literally meaning "city of the dead".

The term usually im ...

is also believed to have been created through the use of standardized molds on an assembly line

An assembly line is a manufacturing process (often called a ''progressive assembly'') in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in seq ...

.

In ancient Carthage

Carthage () was a settlement in modern Tunisia that later became a city-state and then an empire. Founded by the Phoenicians in the ninth century BC, Carthage reached its height in the fourth century BC as one of the largest metropolises in t ...

, ships of war were mass-produced on a large scale at a moderate cost, allowing them to efficiently maintain their control of the Mediterranean

The Mediterranean Sea is a sea connected to the Atlantic Ocean, surrounded by the Mediterranean Basin and almost completely enclosed by land: on the north by Western and Southern Europe and Anatolia, on the south by North Africa, and on the e ...

. Many centuries later, the Republic of Venice

The Republic of Venice ( vec, Repùblega de Venèsia) or Venetian Republic ( vec, Repùblega Vèneta, links=no), traditionally known as La Serenissima ( en, Most Serene Republic of Venice, italics=yes; vec, Serenìsima Repùblega de Venèsia, ...

would follow Carthage in producing ships with prefabricated

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. The term is u ...

parts on an assembly line: the Venetian Arsenal

The Venetian Arsenal ( it, Arsenale di Venezia) is a complex of former shipyards and armories clustered together in the city of Venice in northern Italy. Owned by the state, the Arsenal was responsible for the bulk of the Venetian republic's ...

produced nearly one ship every day in what was effectively the world's first factory

A factory, manufacturing plant or a production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. T ...

, which at its height employed 16,000 people.

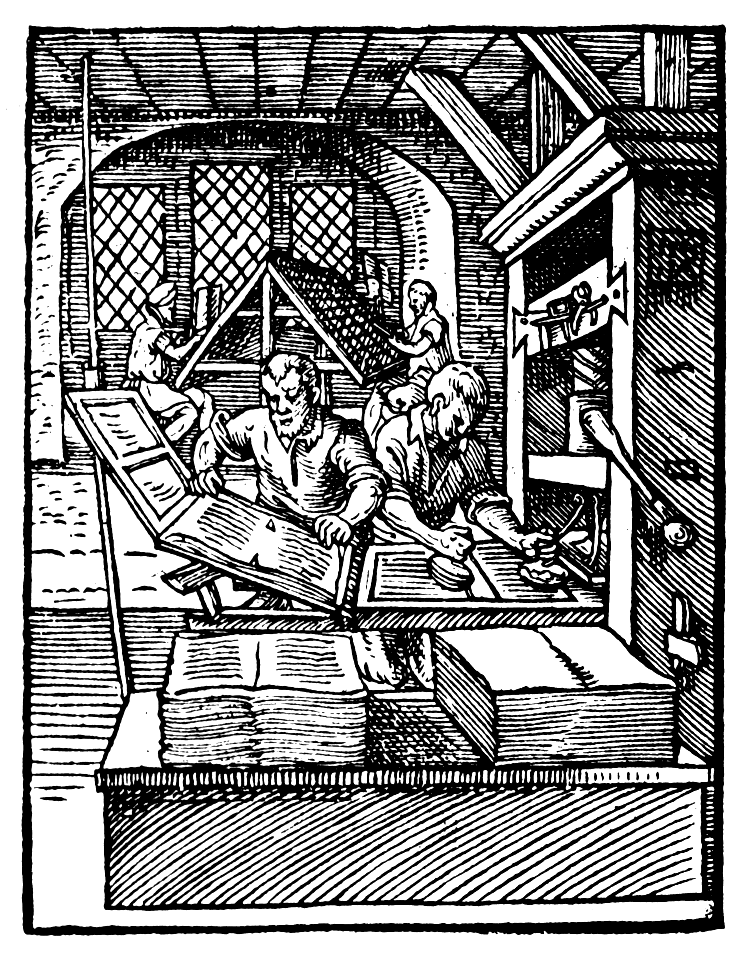

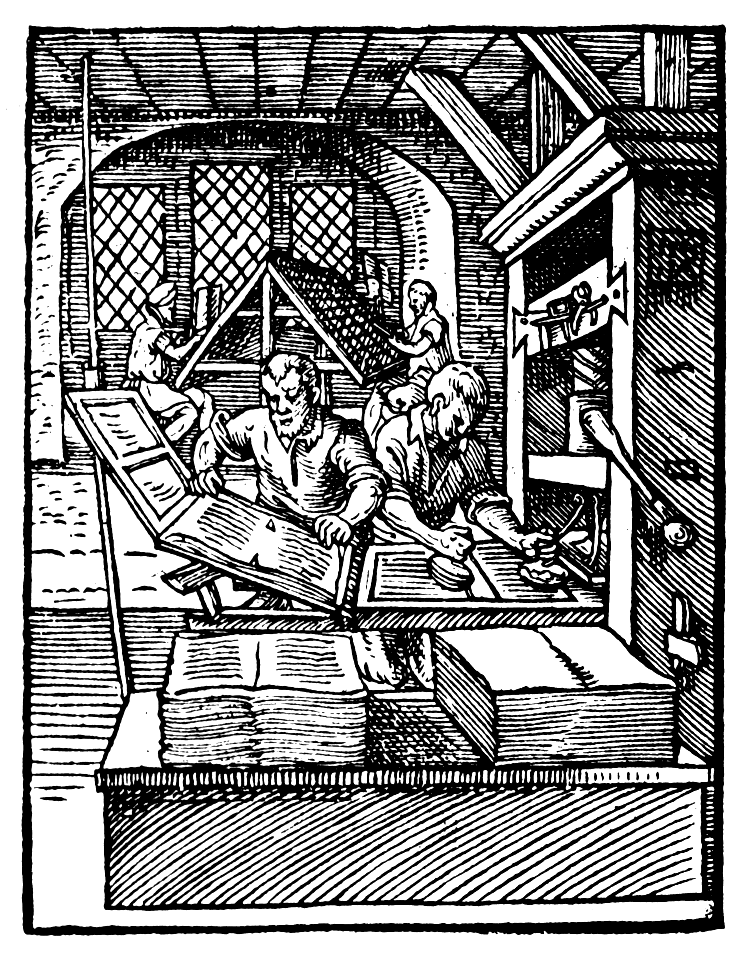

The invention of movable type

Movable type (US English; moveable type in British English) is the system and technology of printing and typography that uses movable components to reproduce the elements of a document (usually individual alphanumeric characters or punctuatio ...

has allowed for documents such as books to be mass produced. The first movable type system was invented in China by Bi Sheng

Bi Sheng (; 972–1051 AD) was a Chinese artisan, engineer, and inventor of the world's first movable type technology, with printing being one of the Four Great Inventions. Bi Sheng's system was made of Chinese porcelain and was invented betwee ...

, during the reign of the Song Dynasty

The Song dynasty (; ; 960–1279) was an imperial dynasty of China that began in 960 and lasted until 1279. The dynasty was founded by Emperor Taizu of Song following his usurpation of the throne of the Later Zhou. The Song conquered the rest ...

, where it was used to, among other things, issue paper money

A banknote—also called a bill (North American English), paper money, or simply a note—is a type of negotiable promissory note, made by a bank or other licensed authority, payable to the bearer on demand.

Banknotes were originally issued ...

. The oldest extant book produced using metal type

In typesetting, a sort or type is a block with a typographic character etched on it, which is lined up with others to print text. In movable-type printing, the sort or type is cast from a matrix mold and assembled by hand with other sorts be ...

is the ''Jikji

''Jikji'' () is the abbreviated title of a Korean Buddhist document whose title can be translated to "Anthology of Great Buddhist Priests' Zen Teachings".Johannes Gutenberg

Johannes Gensfleisch zur Laden zum Gutenberg (; – 3 February 1468) was a German inventor and Artisan, craftsman who introduced letterpress printing to Europe with his movable type, movable-type printing press. Though not the first of its ki ...

, through his invention of the printing press

A printing press is a mechanical device for applying pressure to an inked surface resting upon a printing, print medium (such as paper or cloth), thereby transferring the ink. It marked a dramatic improvement on earlier printing methods in wh ...

and production of the Gutenberg Bible

The Gutenberg Bible (also known as the 42-line Bible, the Mazarin Bible or the B42) was the earliest major book printed using mass-produced movable metal type in Europe. It marked the start of the "Gutenberg Revolution" and the age of printed b ...

, introduced movable type to Europe. Through this introduction, mass production in the European publishing industry was made commonplace, leading to a democratization of knowledge

The democratization of knowledge is the acquisition and spread of knowledge amongst a wider part of the population, not just privileged elites such as clergy and academics. Libraries, in particular public libraries, and modern digital technolog ...

, increased literacy and education, and the beginnings of modern science

Science is a systematic endeavor that builds and organizes knowledge in the form of testable explanations and predictions about the universe.

Science may be as old as the human species, and some of the earliest archeological evidence for ...

.

Jean-Baptiste de Gribeauval, a French artillery engineer, introduced the standardization of cannon design in the mid-18th century. He developed a 6-inch (150 mm) field howitzer whose gun barrel, carriage assembly and ammunition specifications were made uniform for all French cannons. The standardized interchangeable parts

Interchangeable parts are parts ( components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely r ...

of these cannons down to the nuts, bolts and screws made their mass production and repair easier than before.

Industrial

In theIndustrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

, simple mass production techniques were used at the Portsmouth Block Mills

The Portsmouth Block Mills form part of the Portsmouth Dockyard at Portsmouth, Hampshire, England, and were built during the Napoleonic Wars to supply the British Royal Navy with pulley blocks. They started the age of mass-production using ...

in England to make ships' pulley blocks for the Royal Navy

The Royal Navy (RN) is the United Kingdom's naval warfare force. Although warships were used by English and Scottish kings from the early medieval period, the first major maritime engagements were fought in the Hundred Years' War against F ...

in the Napoleonic Wars

The Napoleonic Wars (1803–1815) were a series of major global conflicts pitting the French Empire and its allies, led by Napoleon I, against a fluctuating array of European states formed into various coalitions. It produced a period of Fren ...

. It was achieved in 1803 by Marc Isambard Brunel

Sir Marc Isambard Brunel (, ; 25 April 1769 – 12 December 1849) was a French-British engineer who is most famous for the work he did in Britain. He constructed the Thames Tunnel and was the father of Isambard Kingdom Brunel.

Born in Franc ...

in cooperation with Henry Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were a ...

under the management of Sir Samuel Bentham

Sir Samuel Bentham (11 January 1757 – 31 May 1831) was a noted English mechanical engineer and naval architect credited with numerous innovations, particularly related to naval architecture, including weapons. He was the only surviving siblin ...

. The first unmistakable examples of manufacturing operations carefully designed to reduce production costs by specialized labour and the use of machines appeared in the 18th century in England.

screw-cutting lathe

A screw-cutting lathe is a machine (specifically, a lathe) capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotatin ...

in 1800 which standardized screw thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a ...

sizes for the first time which in turn allowed the application of interchangeable parts

Interchangeable parts are parts ( components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely r ...

, collaborated on plans to manufacture block-making machinery. By 1805, the dockyard had been fully updated with the revolutionary, purpose-built machinery at a time when products were still built individually with different components. A total of 45 machines were required to perform 22 processes on the blocks, which could be made into one of three possible sizes. The machines were almost entirely made of metal thus improving their accuracy and durability. The machines would make markings and indentations on the blocks to ensure alignment throughout the process. One of the many advantages of this new method was the increase in labour productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production proces ...

due to the less labour-intensive requirements of managing the machinery. Richard Beamish, assistant to Brunel's son and engineer, Isambard Kingdom Brunel

Isambard Kingdom Brunel (; 9 April 1806 – 15 September 1859) was a British civil engineer who is considered "one of the most ingenious and prolific figures in engineering history," "one of the 19th-century engineering giants," and "one ...

, wrote:

So that ten men, by the aid of this machinery, can accomplish with uniformity, celerity and ease, what formerly required the uncertain labour of one hundred and ten.By 1808, annual production from the 45 machines had reached 130,000 blocks and some of the equipment was still in operation as late as the mid-twentieth century."The Portsmouth blockmaking machinery"

. makingthemodernworld.org Mass production techniques were also used to rather limited extent to make clocks and watches, and to make small arms, though parts were usually non-interchangeable. Though produced on a very small scale,

Crimean War

The Crimean War, , was fought from October 1853 to February 1856 between Russia and an ultimately victorious alliance of the Ottoman Empire, France, the United Kingdom and Piedmont-Sardinia.

Geopolitical causes of the war included the de ...

gunboat engines designed and assembled by John Penn of Greenwich are recorded as the first instance of the application of mass production techniques (though not necessarily the assembly-line method) to marine engineering. In filling an Admiralty order for 90 sets to his high-pressure and high-revolution horizontal trunk engine

Trunk may refer to:

Biology

* Trunk (anatomy), synonym for torso

* Trunk (botany), a tree's central superstructure

* Trunk of corpus callosum, in neuroanatomy

* Elephant trunk, the proboscis of an elephant

Computing

* Trunk (software), in re ...

design, Penn produced them all in 90 days. He also used Whitworth Standard threads throughout. Prerequisites for the wide use of mass production were interchangeable parts

Interchangeable parts are parts ( components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely r ...

, machine tools

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

and power

Power most often refers to:

* Power (physics), meaning "rate of doing work"

** Engine power, the power put out by an engine

** Electric power

* Power (social and political), the ability to influence people or events

** Abusive power

Power may a ...

, especially in the form of electricity

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described ...

.

Some of the organizational management concepts needed to create 20th-century mass production, such as scientific management

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineer ...

, had been pioneered by other engineers (most of whom are not famous, but Frederick Winslow Taylor

Frederick Winslow Taylor (March 20, 1856 – March 21, 1915) was an American mechanical engineer. He was widely known for his methods to improve industrial efficiency. He was one of the first management consultants. In 1909, Taylor summed up hi ...

is one of the well-known ones), whose work would later be synthesized into fields such as industrial engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex process (engineering), processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, kno ...

, manufacturing engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

, operations research

Operations research ( en-GB, operational research) (U.S. Air Force Specialty Code: Operations Analysis), often shortened to the initialism OR, is a discipline that deals with the development and application of analytical methods to improve deci ...

, and management consultancy

Management consulting is the practice of providing consultant, consulting services to organizations to improve their performance management, performance or in any way to assist in achieving Goal#Goal setting management in organizations, organizatio ...

. Although after leaving the Henry Ford Company

The Henry Ford Company was an automobile manufacturer active from 1901 to 1902. Named for Henry Ford, it was his second company after the Detroit Automobile Company, which had been founded in 1899. The Henry Ford Company was founded November 190 ...

which was rebranded as Cadillac

The Cadillac Motor Car Division () is a division of the American automobile manufacturer General Motors (GM) that designs and builds luxury vehicles. Its major markets are the United States, Canada, and China. Cadillac models are distributed i ...

and later was awarded the Dewar Trophy

The Dewar Trophy was a cup donated in the early years of the twentieth century by Sir Thomas R. Dewar, M.P. a member of parliament of the United Kingdom (UK), to be awarded each year by the Royal Automobile Club (R. A .C.) of the United Kingdom "t ...

in 1908 for creating interchangeable mass-produced precision engine parts, Henry Ford

Henry Ford (July 30, 1863 – April 7, 1947) was an American industrialist, business magnate, founder of the Ford Motor Company, and chief developer of the assembly line technique of mass production. By creating the first automobile that mi ...

downplayed the role of Taylorism in the development of mass production at his company. However, Ford management performed time studies and experiments to mechanize their factory processes, focusing on minimizing worker movements. The difference is that while Taylor focused mostly on efficiency of the worker, Ford also substituted for labor by using machines, thoughtfully arranged, wherever possible.

In 1807, Eli Terry

Eli Terry Sr. (April 13, 1772 – February 24, 1852) was an inventor and clockmaker in Connecticut. He received a United States patent for a shelf clock mechanism. He introduced mass production to the art of clockmaking, which made clocks a ...

was hired to produce 4,000 wooden movement clocks in the Porter Contract. At this time, the annual yield for wooden clocks did not exceed a few dozen on average. Terry developed a milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

in 1795, in which he perfected Interchangeable parts

Interchangeable parts are parts ( components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely r ...

. In 1807, Terry developed a spindle cutting machine, which could produce multiple parts at the same time. Terry hired Silas Hoadley

Silas Hoadley (1786 – December 28, 1870) was an American clockmaker.

Biography

Hoadley was born in Bethany, Connecticut on January 31, 1786. He was a cousin of the architect and builder David Hoadley. He received little formal education befor ...

and Seth Thomas to work the Assembly line

An assembly line is a manufacturing process (often called a ''progressive assembly'') in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in seq ...

at the facilities. The Porter Contract was the first contract which called for mass production of clock movements in history. In 1815, Terry began mass-producing the first shelf clock. Chauncey Jerome

Chauncey Jerome (1793–1868) was an American clockmaker in the early 19th century. He made a fortune selling his clocks, and his business grew quickly. However, his company failed in 1856, and he died in poverty.

Early life

He was born in Cana ...

, an apprentice of Eli Terry mass-produced up to 20,000 brass clocks annually in 1840 when he invented the cheap 30-hour OG clock.

The United States Department of War

The United States Department of War, also called the War Department (and occasionally War Office in the early years), was the United States Cabinet department originally responsible for the operation and maintenance of the United States Army, a ...

sponsored the development of interchangeable parts for guns produced at the arsenals at Springfield, Massachusetts

Springfield is a city in the Commonwealth of Massachusetts, United States, and the seat of Hampden County. Springfield sits on the eastern bank of the Connecticut River near its confluence with three rivers: the western Westfield River, the ...

and Harpers Ferry

Harpers Ferry is a historic town in Jefferson County, West Virginia. It is located in the lower Shenandoah Valley. The population was 285 at the 2020 census. Situated at the confluence of the Potomac and Shenandoah rivers, where the U.S. stat ...

, Virginia (now West Virginia) in the early decades of the 19th century, finally achieving reliable interchangeability by about 1850. This period coincided with the development of machine tools

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

, with the armories designing and building many of their own. Some of the methods employed were a system of gauges for checking dimensions of the various parts and jigs

The jig ( ga, port, gd, port-cruinn) is a form of lively folk dance in compound metre, as well as the accompanying dance tune. It is most associated with Irish music and dance. It first gained popularity in 16th-century Ireland and parts of ...

and fixtures for guiding the machine tools and properly holding and aligning the work pieces. This system came to be known as ''armory practice'' or the ''American system of manufacturing

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient us ...

'', which spread throughout New England aided by skilled mechanics from the armories who were instrumental in transferring the technology to the sewing machines manufacturers and other industries such as machine tools, harvesting machines and bicycles. Singer Manufacturing Co., at one time the largest sewing machine manufacturer, did not achieve interchangeable parts until the late 1880s, around the same time Cyrus McCormick

Cyrus Hall McCormick (February 15, 1809 – May 13, 1884) was an American inventor and businessman who founded the McCormick Harvesting Machine Company, which later became part of the International Harvester Company in 1902. Originally from the ...

adopted modern manufacturing practices in making harvesting machines.

During

During World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposin ...

, The United States mass-produced many vehicles and weapons, such as ships (i.e. Liberty Ship

Liberty ships were a class of cargo ship built in the United States during World War II under the Emergency Shipbuilding Program. Though British in concept, the design was adopted by the United States for its simple, low-cost construction. Mass ...

s, Higgins boats

The landing craft, vehicle, personnel (LCVP) or Higgins boat was a landing craft used extensively by the Allied forces in amphibious landings in World War II. Typically constructed from plywood, this shallow-draft, barge-like boat could ferry ...

), aircraft (i.e. North American P-51 Mustang

The North American Aviation P-51 Mustang is an American long-range, single-seat fighter aircraft, fighter and fighter-bomber used during World War II and the Korean War, among other conflicts. The Mustang was designed in April 1940 by a team ...

, Consolidated B-24 Liberator

The Consolidated B-24 Liberator is an American heavy bomber, designed by Consolidated Aircraft of San Diego, California. It was known within the company as the Model 32, and some initial production aircraft were laid down as export models des ...

, Boeing B-29 Superfortress

The Boeing B-29 Superfortress is an American four-engined propeller-driven heavy bomber, designed by Boeing and flown primarily by the United States during World War II and the Korean War. Named in allusion to its predecessor, the B-17 Fl ...

), jeeps (i.e. Willys MB

The Willys MB and the Ford GPW, both formally called the U.S. Army Truck, -ton, 4×4, Command Reconnaissance, commonly known as the Willys Jeep, Jeep, or jeep, and sometimes referred to by its List of U.S. military vehicles by supply catalog ...

), trucks, tanks (i.e. M4 Sherman

}

The M4 Sherman, officially Medium Tank, M4, was the most widely used medium tank by the Military history of the United States during World War II, United States and Allies of World War II, Western Allies in World War II. The M4 Sherman prove ...

) and M2 Browning

The M2 machine gun or Browning .50 caliber machine gun (informally, "Ma Deuce") is a heavy machine gun that was designed towards the end of World War I by John Browning. Its design is similar to Browning's earlier M1919 Browning machine gun, w ...

and M1919 Browning machine gun

The M1919 Browning is a .30 caliber medium machine gun that was widely used during the 20th century, especially during World War II, the Korean War, and the Vietnam War. The M1919 saw service as a light infantry, coaxial, mounted, aircraft, and ...

s. Many vehicles, transported by ships have been shipped in parts and later assembled on-site.

For the ongoing energy transition, many wind turbine components and solar panels are being mass-produced. Wind turbines and solar panels are being used in respectively wind farm

A wind farm or wind park, also called a wind power station or wind power plant, is a group of wind turbines in the same location used Wind power, to produce electricity. Wind farms vary in size from a small number of turbines to several hundre ...

s and solar farms.

In addition, in the ongoing climate change mitigation

Climate change mitigation is action to limit climate change by reducing Greenhouse gas emissions, emissions of greenhouse gases or Carbon sink, removing those gases from the atmosphere. The recent rise in global average temperature is mostly caus ...

, large-scale carbon sequestration (through reforestation

Reforestation (occasionally, reafforestation) is the natural or intentional restocking of existing forests and woodlands (forestation) that have been depleted, usually through deforestation, but also after clearcutting.

Management

A debate ...

, blue carbon restoration, etc) has been proposed. Some projects (such as the Trillion Tree Campaign

The Trillion Tree Campaign is a project which aims to plant one trillion trees worldwide. It seeks to repopulate the world's trees and climate change mitigation, combat climate change as a Nature-based solutions, nature-based solution. The proje ...

) involve planting a very large amount of trees. In order to speed up such efforts, fast propagation of trees may be useful. Some automated machines have been produced to allow for fast (vegetative) plant propagation

Plant propagation is the process by which new plants grow from a variety of sources: seeds, cuttings, and other plant parts. Plant propagation can also refer to the man-made or natural dispersal of seeds.

Propagation typically occurs as a step i ...

.Also, for some plants that help to sequester carbon (such as seagrass

Seagrasses are the only flowering plants which grow in marine environments. There are about 60 species of fully marine seagrasses which belong to four families (Posidoniaceae, Zosteraceae, Hydrocharitaceae and Cymodoceaceae), all in the orde ...

), techniques have been developed to help speed up the process .

Mass production benefited from the development of materials such as inexpensive steel, high strength steel and plastics. Machining of metals was greatly enhanced with high-speed steel

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material.

It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in tha ...

and later very hard materials such as tungsten carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into ...

for cutting edges. Fabrication using steel components was aided by the development of electric welding and stamped steel parts, both which appeared in industry in about 1890. Plastics such as polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including bo ...

, polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a ...

and polyvinyl chloride (PVC) can be easily formed into shapes by extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex c ...

, blow molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

In general, there are three main types of blow molding: extrusion blow molding, injection ...

or injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

, resulting in very low cost manufacture of consumer products, plastic piping, containers and parts.

An influential article that helped to frame and popularize the 20th century's definition of mass production appeared in a 1926 ''Encyclopædia Britannica'' supplement. The article was written based on correspondence with Ford Motor Company and is sometimes credited as the first use of the term.

Factory electrification

Electrification

Electrification is the process of powering by electricity and, in many contexts, the introduction of such power by changing over from an earlier power source.

The broad meaning of the term, such as in the history of technology, economic histor ...

of factories began very gradually in the 1890s after the introduction of a practical DC motor

A DC motor is any of a class of rotary electrical motors that converts direct current (DC) electrical energy into mechanical energy. The most common types rely on the forces produced by induced magnetic fields due to flowing current in the coil ...

by Frank J. Sprague

Frank Julian Sprague (July 25, 1857 in Milford, Connecticut – October 25, 1934) was an American inventor who contributed to the development of the electric motor, electric railways, and electric elevators. His contributions were especially ...

and accelerated after the AC motor

An AC motor is an electric motor driven by an alternating current (AC). The AC motor commonly consists of two basic parts, an outside stator having coils supplied with alternating current to produce a rotating magnetic field, and an inside rotor ...

was developed by Galileo Ferraris

Galileo Ferraris (31 October 1847 – 7 February 1897) was an Italian university professor, physicist and electrical engineer, one of the pioneers of AC power system and inventor of the induction motor although he never patented his work. Many ...

, Nikola Tesla

Nikola Tesla ( ; ,"Tesla"

''

''

Westinghouse,  Mass production was popularized in the late 1910s and 1920s by Henry Ford's

Mass production was popularized in the late 1910s and 1920s by Henry Ford's

Mass production systems for items made of numerous parts are usually organized into

Mass production systems for items made of numerous parts are usually organized into

Mikhail Dolivo-Dobrovolsky

Mikhail Osipovich Dolivo-Dobrovolsky (russian: Михаи́л О́сипович Доли́во-Доброво́льский; german: Michail von Dolivo-Dobrowolsky or ''Michail Ossipowitsch Doliwo-Dobrowolski''; – ) was a Russian Empire ...

and others. Electrification of factories was fastest between 1900 and 1930, aided by the establishment of electric utilities with central stations and the lowering of electricity prices from 1914 to 1917.

Electric motors were several times more efficient than small steam engines because central station generation were more efficient than small steam engines and because line shaft

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to e ...

s and belts had high friction losses. Electric motors also allowed more flexibility in manufacturing and required less maintenance than line shafts and belts. Many factories saw a 30% increase in output simply from changing over to electric motors.

Electrification enabled modern mass production, as with Thomas Edison's iron ore processing plant (about 1893) that could process 20,000 tons of ore per day with two shifts, each of five men. At that time it was still common to handle bulk materials with shovels, wheelbarrows and small narrow-gauge rail cars, and for comparison, a canal digger in previous decades typically handled five tons per 12-hour day.

The biggest impact of early mass production was in manufacturing everyday items, such as at the Ball Brothers

The Ball brothers (Lucius, William, Edmund, Frank, and George) were five American industrialists and philanthropists who established a manufacturing business in New York and Indiana in the 1880s that was renamed the Ball Corporation in 1969. Th ...

Glass Manufacturing Company, which electrified its mason jar

A Mason jar, also known as a canning jar or fruit jar, is a glass jar used in home canning to preserve food. It was named after American tinsmith John Landis Mason, who patented it in 1858. The jar's mouth has a screw thread on its outer perime ...

plant in Muncie, Indiana

Muncie ( ) is an incorporated city and the county seat, seat of Delaware County, Indiana, Delaware County, Indiana. Previously known as Buckongahelas Town, named after the legendary Delaware Chief.http://www.delawarecountyhistory.org/history/docs ...

, U.S., around 1900. The new automated process used glass-blowing machines to replace 210 craftsman glass blowers and helpers. A small electric truck was used to handle 150 dozen bottles at a time where previously a hand truck would carry six dozen. Electric mixers replaced men with shovels handling sand and other ingredients that were fed into the glass furnace. An electric overhead crane replaced 36 day labor

Day labor (or day labour in Commonwealth spelling) is work done where the worker is hired and paid one day at a time, with no promise that more work will be available in the future. It is a form of contingent work.

Types

Day laborers (also kn ...

ers for moving heavy loads across the factory.

According to Henry Ford

Henry Ford (July 30, 1863 – April 7, 1947) was an American industrialist, business magnate, founder of the Ford Motor Company, and chief developer of the assembly line technique of mass production. By creating the first automobile that mi ...

:

The provision of a whole new system of electric generation emancipated industry from the leather belt andline shaft A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to e ..., for it eventually became possible to provide each tool with its own electric motor. This may seem only a detail of minor importance. In fact, modern industry could not be carried out with the belt and line shaft for a number of reasons. The motor enabled machinery to be arranged in the order of the work, and that alone has probably doubled the efficiency of industry, for it has cut out a tremendous amount of useless handling and hauling. The belt andline shaft A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to e ...were also tremendously wasteful – so wasteful indeed that no factory could be really large, for even the longest line shaft was small according to modern requirements. Also high speed tools were impossible under the old conditions – neither the pulleys nor the belts could stand modern speeds. Without high speed tools and the finer steels which they brought about, there could be nothing of what we call modern industry.

Mass production was popularized in the late 1910s and 1920s by Henry Ford's

Mass production was popularized in the late 1910s and 1920s by Henry Ford's Ford Motor Company

Ford Motor Company (commonly known as Ford) is an American multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. The company sells automobi ...

, which introduced electric motors to the then-well-known technique of chain or sequential production. Ford also bought or designed and built special purpose machine tools and fixtures such as multiple spindle drill presses

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to ...

that could drill every hole on one side of an engine block in one operation and a multiple head milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

that could simultaneously machine 15 engine blocks held on a single fixture. All of these machine tools were arranged systematically in the production flow and some had special carriages for rolling heavy items into machining position. Production of the Ford Model T

The Ford Model T is an automobile that was produced by Ford Motor Company from October 1, 1908, to May 26, 1927. It is generally regarded as the first affordable automobile, which made car travel available to middle-class Americans. The relati ...

used 32,000 machine tools.

Buildings

The process of prefabrication, wherein parts are created separately from the finished product, is at the core of all mass-produced construction. Early examples include movable structures reportedly utilized byAkbar the Great

Abu'l-Fath Jalal-ud-din Muhammad Akbar (25 October 1542 – 27 October 1605), popularly known as Akbar the Great ( fa, ), and also as Akbar I (), was the third Mughal emperor, who reigned from 1556 to 1605. Akbar succeeded his father, Hum ...

, and the chattel houses built by emancipated slaves on Barbados

Barbados is an island country in the Lesser Antilles of the West Indies, in the Caribbean region of the Americas, and the most easterly of the Caribbean Islands. It occupies an area of and has a population of about 287,000 (2019 estimate). ...

. The Nissen hut

A Nissen hut is a prefabricated steel structure for military use, especially as barracks, made from a half-cylindrical skin of corrugated iron. Designed during the First World War by the American-born, Canadian-British engineer and inventor Majo ...

, first used by the British during World War I

World War I (28 July 1914 11 November 1918), often abbreviated as WWI, was one of the deadliest global conflicts in history. Belligerents included much of Europe, the Russian Empire, the United States, and the Ottoman Empire, with fightin ...

, married prefabrication and mass production in a way that suited the needs of the military. The simple structures, which cost little and could be erected in just a couple of hours, were highly successful: over 100,000 Nissen huts were produced during World War I alone, and they would go on to serve in other conflicts and inspire a number of similar designs.

Following World War II, in the United States, William Levitt

William Jaird Levitt (February 11, 1907 – January 28, 1994) was an American real-estate developer and housing pioneer. As president of Levitt & Sons, he is widely credited as the father of modern American suburbia. He was named one of ''Time'' ...

pioneered the building of standardized tract house

Tract housing is a type of housing development in which multiple similar houses are built on a tract (area) of land that is subdivided into smaller lots. Tract housing developments are found in suburb developments that were modeled on the "Levi ...

s in 56 different locations around the country. These communities were dubbed Levittown

Levittown is the name of several large suburban housing developments created in the United States (including one in Puerto Rico) by William J. Levitt and his company Levitt & Sons. Built after World War II for returning white veterans and their ...

s, and they were able to be constructed quickly and cheaply through the leveraging of economies of scale

In microeconomics, economies of scale are the cost advantages that enterprises obtain due to their scale of operation, and are typically measured by the amount of output produced per unit of time. A decrease in cost per unit of output enables ...

, as well as the specialization of construction tasks in a process akin to an assembly line. This era also saw the invention of the mobile home

A mobile home (also known as a house trailer, park home, trailer, or trailer home) is a prefabricated structure, built in a factory on a permanently attached chassis before being transported to site (either by being towed or on a trailer). Us ...

, a small prefabricated house that can be transported cheaply on a truck bed.

In the modern industrialization of construction, mass production is often used for prefabrication of house components.

The use of assembly lines

Mass production systems for items made of numerous parts are usually organized into

Mass production systems for items made of numerous parts are usually organized into assembly line

An assembly line is a manufacturing process (often called a ''progressive assembly'') in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in seq ...

s. The assemblies pass by on a conveyor, or if they are heavy, hung from an overhead crane

An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of two parallel rails seated on longitudinal I-beams attached to opposite steel columns by means of brackets. ...

or monorail.

In a factory for a complex product, rather than one assembly line, there may be many auxiliary assembly lines feeding sub-assemblies (i.e. car engines or seats) to a backbone "main" assembly line. A diagram of a typical mass-production factory looks more like the skeleton of a fish than a single line.

Vertical integration

Vertical integration

In microeconomics, management and international political economy, vertical integration is a term that describes the arrangement in which the supply chain of a company is integrated and owned by that company. Usually each member of the suppl ...

is a business practice that involves gaining complete control over a product's production, from raw materials to final assembly.

In the age of mass production, this caused shipping and trade problems in that shipping systems were unable to transport huge volumes of finished automobiles (in Henry Ford's case) without causing damage, and also government policies imposed trade barriers on finished units.

Ford built the Ford River Rouge Complex with the idea of making the company's own iron and steel in the same large factory site where parts and car assembly took place. River Rouge also generated its own electricity.

Upstream vertical integration, such as to raw materials, is away from leading technology toward mature, low-return industries. Most companies chose to focus on their core business rather than vertical integration. This included buying parts from outside suppliers, who could often produce them as cheaply or cheaper.

Standard Oil

Standard Oil Company, Inc., was an American oil production, transportation, refining, and marketing company that operated from 1870 to 1911. At its height, Standard Oil was the largest petroleum company in the world, and its success made its co-f ...

, the major oil company in the 19th century, was vertically integrated partly because there was no demand for unrefined crude oil, but kerosene and some other products were in great demand. The other reason was that Standard Oil monopolized the oil industry. The major oil companies were, and many still are, vertically integrated, from production to refining and with their own retail stations, although some sold off their retail operations. Some oil companies also have chemical divisions.

Lumber and paper companies at one time owned most of their timber lands and sold some finished products such as corrugated boxes. The tendency has been to divest of timber lands to raise cash and to avoid property taxes.

Advantages and disadvantages

The economies of mass production come from several sources. The primary cause is a reduction of non-productive effort of all types. Incraft production

Craft production is manufacturing by hand, with or without the aid of tools. The term "craft production" describes manufacturing techniques that are used in handicraft trades. They were the common methods of manufacture in the pre-industrialized ...

, the craftsman must bustle about a shop, getting parts and assembling them. He must locate and use many tools many times for varying tasks. In mass production, each worker repeats one or a few related tasks that use the same tool to perform identical or near-identical operations on a stream of products. The exact tool and parts are always at hand, having been moved down the assembly line consecutively. The worker spends little or no time retrieving and/or preparing materials and tools, and so the time taken to manufacture a product using mass production is shorter than when using traditional methods.

The probability of human error

Human error refers to something having been done that was " not intended by the actor; not desired by a set of rules or an external observer; or that led the task or system outside its acceptable limits".Senders, J.W. and Moray, N.P. (1991) Human ...

and variation is also reduced, as tasks are predominantly carried out by machinery; error in operating such machinery has more far-reaching consequences. A reduction in labour costs, as well as an increased rate of production, enables a company to produce a larger quantity of one product at a lower cost than using traditional, non-linear methods.

However, mass production is inflexible because it is difficult to alter a design

A design is a plan or specification for the construction of an object or system or for the implementation of an activity or process or the result of that plan or specification in the form of a prototype, product, or process. The verb ''to design'' ...

or production

Production may refer to:

Economics and business

* Production (economics)

* Production, the act of manufacturing goods

* Production, in the outline of industrial organization, the act of making products (goods and services)

* Production as a stati ...

process after a production line

A production line is a set of sequential operations established in a factory where components are assembled to make a finished article or where materials are put through a refining process to produce an end-product that is suitable for onward c ...

is implemented. Also, all products produced on one production line will be identical or very similar, and introducing variety to satisfy individual tastes is not easy. However, some variety can be achieved by applying different finishes and decorations at the end of the production line if necessary. The starter cost for the machinery can be expensive so the producer must be sure it sells or the producers will lose a lot of money.

The Ford Model T produced tremendous affordable output but was not very good at responding to demand for variety, customization, or design changes. As a consequence Ford eventually lost market share to General Motors, who introduced annual model changes, more accessories and a choice of colors.

With each passing decade, engineers have found ways to increase the flexibility of mass production systems, driving down the lead time

A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on vari ...

s on new product development and allowing greater customization and variety of products.

Compared with other production methods, mass production can create new occupational hazard

An occupational hazard is a hazard experienced in the workplace. This encompasses many types of hazards, including chemical hazards, biological hazards (biohazards), psychosocial hazards, and physical hazards. In the United States, the Nation ...

s for workers. This is partly due to the need for workers to operate heavy machinery while also working close together with many other workers. Preventative safety measures, such as fire drills, as well as special training is therefore necessary to minimise the occurrence of industrial accidents

A work accident, workplace accident, occupational accident, or accident at work is a "discrete occurrence in the course of work" leading to physical or mental occupational injury. According to the International Labour Organization (ILO), more tha ...

.

Socioeconomic impacts

In the 1830s, French political thinker and historianAlexis de Tocqueville

Alexis Charles Henri Clérel, comte de Tocqueville (; 29 July 180516 April 1859), colloquially known as Tocqueville (), was a French aristocrat, diplomat, political scientist, political philosopher and historian. He is best known for his works ...

identified one of the key characteristics of America that would later make it so amenable to the development of mass production: the homogeneous consumer base. De Tocqueville wrote in his ''Democracy in America

(; published in two volumes, the first in 1835 and the second in 1840) is a classic French text by Alexis de Tocqueville. Its title literally translates to ''On Democracy in America'', but official English translations are usually simply entitl ...

'' (1835) that "The absence in the United States of those vast accumulations of wealth

Wealth is the abundance of Value (economics), valuable financial assets or property, physical possessions which can be converted into a form that can be used for financial transaction, transactions. This includes the core meaning as held in the ...

which favor the expenditures of large sums on articles of mere luxury... impact to the productions of American industry a character distinct from that of other countries' industries. roduction is geared towardarticles suited to the wants of the whole people".

Mass production improved productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production proces ...

, which was a contributing factor to economic growth and the decline in work week hours, alongside other factors such as transportation infrastructures (canals, railroads and highways) and agricultural mechanization. These factors caused the typical work week to decline from 70 hours in the early 19th century to 60 hours late in the century, then to 50 hours in the early 20th century and finally to 40 hours in the mid-1930s.

Mass production permitted great increases in total production. Using a European crafts system into the late 19th century it was difficult to meet demand for products such as sewing machines and animal powered mechanical harvesters

Harvester may refer to:

Agriculture and forestry

* Combine harvester, a machine commonly used to harvest grain crops

* Forage harvester, a machine used to harvest forage

* Harvester (forestry), a type of heavy vehicle employed in cut-to-length lo ...

. By the late 1920s many previously scarce goods were in good supply. One economist has argued that this constituted "overproduction" and contributed to high unemployment during the Great Depression

The Great Depression (19291939) was an economic shock that impacted most countries across the world. It was a period of economic depression that became evident after a major fall in stock prices in the United States. The economic contagio ...

. Say's law

In classical economics, Say's law, or the law of markets, is the claim that the production of a product creates demand for another product by providing something of value which can be exchanged for that other product. So, production is the source ...

denies the possibility of general overproduction

In economics, overproduction, oversupply, excess of supply or glut refers to excess of supply over demand of products being offered to the market. This leads to lower prices and/or unsold goods along with the possibility of unemployment.

The de ...

and for this reason classical economists deny that it had any role in the Great Depression.

Mass production allowed the evolution

Evolution is change in the heritable characteristics of biological populations over successive generations. These characteristics are the expressions of genes, which are passed on from parent to offspring during reproduction. Variation ...

of consumerism

Consumerism is a social and economic order that encourages the acquisition of goods and services in ever-increasing amounts. With the Industrial Revolution, but particularly in the 20th century, mass production led to overproduction—the supp ...

by lowering the unit cost

The unit cost is the price incurred by a company to produce, store and sell one unit of a particular product. Unit costs include all fixed costs and all variable costs

Variable costs are costs that change as the quantity of the good or service ...

of many goods used.

Mass production has been linked to the Fast Fashion Industry, often leaving the consumer with lower quality garments for a lower cost. Most fast-fashion clothing is mass-produced, which means it is typically made of cheap fabrics, such as polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natural ...

, and constructed poorly in order to keep short turnaround times to meet the demands of consumers and shifting trends.

See also

*Batch production

Batch production is a method of manufacturing where the products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch prod ...

* Craft production

Craft production is manufacturing by hand, with or without the aid of tools. The term "craft production" describes manufacturing techniques that are used in handicraft trades. They were the common methods of manufacture in the pre-industrialized ...

* Continuous production

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk ...

* Culture industry

The term culture industry (german: Kulturindustrie) was coined by the critical theorists Theodor Adorno (1903–1969) and Max Horkheimer (1895–1973), and was presented as critical vocabulary in the chapter "The Culture Industry: Enlightenment ...

* Fast-moving consumer goods

Fast-moving consumer goods (FMCG), also known as consumer packaged goods (CPG), are products that are sold quickly and at a relatively low cost. Examples include non-durable household goods such as packaged foods, beverages, toiletries, cand ...

* Fordism

Fordism is a manufacturing technology that serves as the basis of modern economic and social systems in industrialized, standardized mass production and mass consumption. The concept is named after Henry Ford. It is used in social, economic, and ...

* Ford Model T

The Ford Model T is an automobile that was produced by Ford Motor Company from October 1, 1908, to May 26, 1927. It is generally regarded as the first affordable automobile, which made car travel available to middle-class Americans. The relati ...

* Great Divergence

The Great Divergence or European miracle is the socioeconomic shift in which the Western world (i.e. Western Europe and the parts of the New World where its people became the dominant populations) overcame pre-modern growth constraints and eme ...

* Industrial engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex process (engineering), processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, kno ...

* Industrialisation

Industrialisation ( alternatively spelled industrialization) is the period of social and economic change that transforms a human group from an agrarian society into an industrial society. This involves an extensive re-organisation of an econo ...

* Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

* Instant manufacturing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer co ...

* Job production

Job production, sometimes called jobbing or one-off production, involves producing custom work, such as a one-off product for a specific customer or a small batch of work in quantities usually less than those of mass-market products. Job producti ...

* Just-in-time

* Lean manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing ( ...

* Licensed production Licensed production is the production under license of technology developed elsewhere. The licensee provides the licensor of a specific product with legal production rights, technical information, process technology, and any other proprietary compon ...

* Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a r ...

* Mass market

The term "mass market" refers to a market for goods produced on a large scale for a significant number of end consumers. The mass market differs from the niche market in that the former focuses on consumers with a wide variety of backgrounds with ...

* Mechanization

Mechanization is the process of changing from working largely or exclusively by hand or with animals to doing that work with machinery. In an early engineering text a machine is defined as follows:

In some fields, mechanization includes the ...

* Modular construction systems: identical components are easier to mass-produce

* Operations management

* Outline of industrial organization

The following outline is provided as an overview of and topical guide to industrial organization:

Industrial organization – describes the behavior of firms in the marketplace with regard to production, pricing, employment and other decisi ...

* Pilot plant

A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology. The knowledge obtained is then ...

* Cost-of-production theory of value

In economics, the cost-of-production theory of value is the theory that the price of an object or condition is determined by the sum of the cost of the resources that went into making it. The cost can comprise any of the factors of production (incl ...

* Scientific management

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineer ...

* Second Industrial Revolution

The Second Industrial Revolution, also known as the Technological Revolution, was a phase of rapid scientific discovery, standardization, mass production and industrialization from the late 19th century into the early 20th century. The Firs ...

* Technological revolution

A technological revolution is a period in which one or more technologies is replaced by another novel technology in a short amount of time. It is an era of accelerated technological progress characterized by new innovations whose rapid applic ...

* Technological unemployment

Technological unemployment is the loss of jobs caused by technological change. It is a key type of structural unemployment.

Technological change typically includes the introduction of labour-saving "mechanical-muscle" machines or more efficie ...

References

Further reading

* * Borth, Christy. ''Masters of Mass Production'', Bobbs-Merrill Company, Indianapolis, IN, 1945. * Herman, Arthur. ''Freedom's Forge: How American Business Produced Victory in World War II'', Random House, New York, NY, 2012. .External links

* * {{DEFAULTSORT:Mass Production History of science and technology in the United States Industrial processes Business economics Types of production Economic development