Module (gears) on:

[Wikipedia]

[Google]

[Amazon]

A gear or gearwheel is a rotating machine part typically used to transmit

A gear or gearwheel is a rotating machine part typically used to transmit

in the ''Oxford Learner's Dictionary'' online. Accessed on 2024-07-29.Definition of "cog"

in the ''Merriam-Webster Dictionary'' online. Accessed on 2024-07-29.Definition of "cog"

in the ''Cambridge Dictionary Plus'' online. Accessed on 2024-07-29. or the whole gear.Definition of "cog"

in the ''Collins English Dictionary'' online. Accessed on 2024-07-29. Two or more meshing gears are called a Gears are among the most common mechanical parts. They come in a great variety of shapes and materials, and are used for many different functions and applications. Diameters may range from a few μm in micromachines,Shuailong Zhang, Mohamed Elsayed, Ran Peng,

Yujie Chen (2021): "Reconfigurable multi-component micromachines driven by optoelectronic tweezers". ''Nature Communications'', volume 12, issue 1. to a few mm in

Gears are among the most common mechanical parts. They come in a great variety of shapes and materials, and are used for many different functions and applications. Diameters may range from a few μm in micromachines,Shuailong Zhang, Mohamed Elsayed, Ran Peng,

Yujie Chen (2021): "Reconfigurable multi-component micromachines driven by optoelectronic tweezers". ''Nature Communications'', volume 12, issue 1. to a few mm in

"MY GEAR is Bigger than YOUR GEAR: Industry Battles it Out for World's Largest Gear Title"

Online article from ''Gear Technology'' magazine

Archived on 2024-07-30

Other types of parts that are somewhat similar in shape and function to gears include the

On the Origin of Clockwork, Perpetual Motion Devices, and the Compass

p.84 (Zhan Guo times – Late East

''Economic History of Medieval India, 1200-1500'', page 53

The gears of the Antikythera mechanism are made of

The gears of the Antikythera mechanism are made of  Still, because of cost or other considerations, some early metal gears had wooden cogs, each tooth forming a type of specialised 'through' mortise and tenon joint

More recently

Still, because of cost or other considerations, some early metal gears had wooden cogs, each tooth forming a type of specialised 'through' mortise and tenon joint

More recently  In spite of the advantages of metal and plastic, wood continued to be used for large gears until a couple of centuries ago, because of cost, weight, tradition, or other considerations. In 1967 the Thompson Manufacturing Company of

In spite of the advantages of metal and plastic, wood continued to be used for large gears until a couple of centuries ago, because of cost, weight, tradition, or other considerations. In 1967 the Thompson Manufacturing Company of

The gears in a matching pair are said to be ''skew'' if their axes of rotation are skew lines -- neither parallel nor intersecting.

In this case, the best shape for each pitch surface is neither cylindrical nor conical but a portion of a

The gears in a matching pair are said to be ''skew'' if their axes of rotation are skew lines -- neither parallel nor intersecting.

In this case, the best shape for each pitch surface is neither cylindrical nor conical but a portion of a

A gear is said to be ''external'' if its teeth are directed generally away from the rotation axis, and ''internal'' otherwise. In a pair of matching wheels, only one of them (the larger one) may be internal.

A gear is said to be ''external'' if its teeth are directed generally away from the rotation axis, and ''internal'' otherwise. In a pair of matching wheels, only one of them (the larger one) may be internal.

In a ''helical'' or ''dry fixed'' gear the tooth walls are not parallel to the axis of rotation, but are set at an angle. An imaginary pitch surface (cylinder, cone, or hyperboloid, depending on the relative axis positions) intersects each tooth face along an arc of a

In a ''helical'' or ''dry fixed'' gear the tooth walls are not parallel to the axis of rotation, but are set at an angle. An imaginary pitch surface (cylinder, cone, or hyperboloid, depending on the relative axis positions) intersects each tooth face along an arc of a  The angled teeth engage more gradually than do spur gear teeth, causing them to run more smoothly and quietly. With parallel helical gears, each pair of teeth first make contact at a single point at one side of the gear wheel; a moving curve of contact then grows gradually across the tooth face to a maximum, then recedes until the teeth break contact at a single point on the opposite side. In spur gears, teeth suddenly meet at a line contact across their entire width, causing stress and noise. Spur gears make a characteristic whine at high speeds. For this reason spur gears are used in low-speed applications and in situations where noise control is not a problem, and helical gears are used in high-speed applications, large power transmission, or where noise abatement is important. The speed is considered high when the pitch line velocity exceeds 25 m/s.

A disadvantage of helical gears is a resultant

The angled teeth engage more gradually than do spur gear teeth, causing them to run more smoothly and quietly. With parallel helical gears, each pair of teeth first make contact at a single point at one side of the gear wheel; a moving curve of contact then grows gradually across the tooth face to a maximum, then recedes until the teeth break contact at a single point on the opposite side. In spur gears, teeth suddenly meet at a line contact across their entire width, causing stress and noise. Spur gears make a characteristic whine at high speeds. For this reason spur gears are used in low-speed applications and in situations where noise control is not a problem, and helical gears are used in high-speed applications, large power transmission, or where noise abatement is important. The speed is considered high when the pitch line velocity exceeds 25 m/s.

A disadvantage of helical gears is a resultant

3D animation of helical gears (parallel axis)

3D animation of helical gears (crossed axis)

''Worms'' resemble

''Worms'' resemble

Another criterion to classify gears is the ''tooth profile'', the shape of the cross-section of a tooth face by an imaginary cut perpendicular to the pitch surface, such as the transverse, normal, or axial plane.

The tooth profile is crucial for the smoothness and uniformity of the movement of matching gears, as well as for the

Another criterion to classify gears is the ''tooth profile'', the shape of the cross-section of a tooth face by an imaginary cut perpendicular to the pitch surface, such as the transverse, normal, or axial plane.

The tooth profile is crucial for the smoothness and uniformity of the movement of matching gears, as well as for the

The teeth of antique or artisanal gears that were cut by hand from sheet material, like those in the Antikhytera mechanism, generally had simple profiles, such as triangles.

The teeth of larger gears — such as used in windmills — were usually pegs with simple shapes like cylinders,

The teeth of antique or artisanal gears that were cut by hand from sheet material, like those in the Antikhytera mechanism, generally had simple profiles, such as triangles.

The teeth of larger gears — such as used in windmills — were usually pegs with simple shapes like cylinders,

A ''cage gear'', also called a ''lantern gear'' or ''lantern pinion'', is one of those artisanal gears having cylindrical rods for teeth, parallel to the axle and arranged in a circle around it, much as the bars on a round bird cage or lantern. The assembly is held together by disks at each end, into which the tooth rods and axle are set. Cage gears are more efficient than solid pinions, and dirt can fall through the rods rather than becoming trapped and increasing wear. They can be constructed with very simple tools as the teeth are not formed by cutting or milling, but rather by drilling holes and inserting rods.

Sometimes used in clocks, a cage gear should always be driven by a gearwheel, not used as the driver. The cage gear was not initially favoured by conservative clock makers. It became popular in turret clocks where dirty working conditions were most commonplace. Domestic American clock movements often used them.

A ''cage gear'', also called a ''lantern gear'' or ''lantern pinion'', is one of those artisanal gears having cylindrical rods for teeth, parallel to the axle and arranged in a circle around it, much as the bars on a round bird cage or lantern. The assembly is held together by disks at each end, into which the tooth rods and axle are set. Cage gears are more efficient than solid pinions, and dirt can fall through the rods rather than becoming trapped and increasing wear. They can be constructed with very simple tools as the teeth are not formed by cutting or milling, but rather by drilling holes and inserting rods.

Sometimes used in clocks, a cage gear should always be driven by a gearwheel, not used as the driver. The cage gear was not initially favoured by conservative clock makers. It became popular in turret clocks where dirty working conditions were most commonplace. Domestic American clock movements often used them.

For non-parallel axes with non-straight tooth cuts, the best tooth profile is one of several spiral bevel gear shapes. These include Gleason types (circular arc with non-constant tooth depth), Oerlikon and Curvex types (circular arc with constant tooth depth), Klingelnberg Cyclo-Palloid (Epicycloid with constant tooth depth) or Klingelnberg Palloid..

The tooth faces in these gear types are not involute cylinders or cones but patches of octoidal surfaces. Manufacturing such tooth faces may require a 5-axis

For non-parallel axes with non-straight tooth cuts, the best tooth profile is one of several spiral bevel gear shapes. These include Gleason types (circular arc with non-constant tooth depth), Oerlikon and Curvex types (circular arc with constant tooth depth), Klingelnberg Cyclo-Palloid (Epicycloid with constant tooth depth) or Klingelnberg Palloid..

The tooth faces in these gear types are not involute cylinders or cones but patches of octoidal surfaces. Manufacturing such tooth faces may require a 5-axis

A ''rack'' is a toothed bar or rod that can be thought of as a sector gear with an infinitely large

A ''rack'' is a toothed bar or rod that can be thought of as a sector gear with an infinitely large

In epicyclic gearing, one or more of the gear

In epicyclic gearing, one or more of the gear

Non-circular gears are designed for special purposes. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and maximum

Non-circular gears are designed for special purposes. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and maximum

A ''harmonic gear'' or '' strain wave gear'' is a specialized gearing mechanism often used in industrial

A ''harmonic gear'' or '' strain wave gear'' is a specialized gearing mechanism often used in industrial

; Rotational

; Rotational

File:Contact line.jpg, Line of contact

File:Action path.jpg, Path of action

File:Action line.jpg, Line of action

File:Action plane.jpg, Plane of action

File:Contact lines.jpg, Lines of contact (helical gear)

File:Action arc.jpg, Arc of action

File:Action length.jpg, Length of action

File:Limit diameter.jpg, Limit diameter

File:Face advance.svg, Face advance

File:Action zone.jpg, Zone of action

; Point of contact : Any point at which two tooth profiles touch each other.

; Line of contact : A line or curve along which two tooth surfaces are tangent to each other.

; Path of action : The locus of successive contact points between a pair of gear teeth, during the phase of engagement. For conjugate gear teeth, the path of action passes through the pitch point. It is the trace of the surface of action in the plane of rotation.

; Line of action : The path of action for involute gears. It is the straight line passing through the pitch point and tangent to both base circles.

; Surface of action : The imaginary surface in which contact occurs between two engaging tooth surfaces. It is the summation of the paths of action in all sections of the engaging teeth.

; Plane of action: The surface of action for involute, parallel axis gears with either spur or helical teeth. It is tangent to the base cylinders.

; Zone of action (contact zone) : For involute, parallel-axis gears with either spur or helical teeth, is the rectangular area in the plane of action bounded by the length of action and the effective face width.

; Path of contact: The curve on either tooth surface along which theoretical single point contact occurs during the engagement of gears with crowned tooth surfaces or gears that normally engage with only single point contact.

; Length of action: The distance on the line of action through which the point of contact moves during the action of the tooth profile.

; Arc of action, ''Qt'' : The arc of the pitch circle through which a tooth profile moves from the beginning to the end of contact with a mating profile.

; Arc of approach, ''Qa'' : The arc of the pitch circle through which a tooth profile moves from its beginning of contact until the point of contact arrives at the pitch point.

; Arc of recess, ''Qr'' : The arc of the pitch circle through which a tooth profile moves from contact at the pitch point until contact ends.

; Contact ratio, ''mc'' or ''ε'' : The number of angular pitches through which a tooth surface rotates from the beginning to the end of contact. In a simple way, it can be defined as a measure of the average number of teeth in contact during the period during which a tooth comes and goes out of contact with the mating gear.

; Transverse contact ratio, ''mp'' or ''εα'' : The contact ratio in a transverse plane. It is the ratio of the angle of action to the angular pitch. For involute gears it is most directly obtained as the ratio of the length of action to the base pitch.

; Face contact ratio, ''mF'' or ''εβ'' : The contact ratio in an axial plane, or the ratio of the face width to the axial pitch. For bevel and hypoid gears it is the ratio of face advance to circular pitch.

; Total contact ratio, ''mt'' or ''εγ'' : The sum of the transverse contact ratio and the face contact ratio.

::

::

; Modified contact ratio, ''mo'' : For bevel gears, the square root of the sum of the squares of the transverse and face contact ratios.

::

; Limit diameter : Diameter on a gear at which the line of action intersects the maximum (or minimum for internal pinion) addendum circle of the mating gear. This is also referred to as the start of active profile, the start of contact, the end of contact, or the end of active profile.

; Start of active profile (SAP) : Intersection of the limit diameter and the involute profile.

; Face advance : Distance on a pitch circle through which a helical or spiral tooth moves from the position at which contact begins at one end of the tooth trace on the pitch surface to the position where contact ceases at the other end.

File:Tooth thickness.jpg, Tooth thickness

File:Thickness relationships.jpg, Thickness relationships

File:Chordial thickness.svg, Chordal thickness

File:Pin measurement.jpg, Tooth thickness measurement over pins

File:Span measurement.jpg, Span measurement

File:Addendum teeth.jpg, Long and short addendum teeth

; Circular thickness : Length of arc between the two sides of a gear tooth, on the specified datum circle.

; Transverse circular thickness : Circular thickness in the transverse plane.

; Normal circular thickness : Circular thickness in the normal plane. In a helical gear it may be considered as the length of arc along a normal helix.

; Axial thickness: In helical gears and worms, tooth thickness in an axial cross section at the standard pitch diameter.

; Base circular thickness: In involute teeth, length of arc on the base circle between the two involute curves forming the profile of a tooth.

; Normal chordal thickness: Length of the chord that subtends a circular thickness arc in the plane normal to the pitch helix. Any convenient measuring diameter may be selected, not necessarily the standard pitch diameter.

; Chordal addendum (chordal height) : Height from the top of the tooth to the chord subtending the circular thickness arc. Any convenient measuring diameter may be selected, not necessarily the standard pitch diameter.

; Profile shift : Displacement of the basic rack datum line from the reference cylinder, made non-dimensional by dividing by the normal module. It is used to specify the tooth thickness, often for zero backlash.

; Rack shift : Displacement of the tool datum line from the reference cylinder, made non-dimensional by dividing by the normal module. It is used to specify the tooth thickness.

; Measurement over pins : Measurement of the distance taken over a pin positioned in a tooth space and a reference surface. The reference surface may be the reference axis of the gear, a datum surface or either one or two pins positioned in the tooth space or spaces opposite the first. This measurement is used to determine tooth thickness.

; Span measurement : Measurement of the distance across several teeth in a normal plane. As long as the measuring device has parallel measuring surfaces that contact on an unmodified portion of the involute, the measurement wis along a line tangent to the base cylinder. It is used to determine tooth thickness.

; Modified addendum teeth : Teeth of engaging gears, one or both of which have non-standard addendum.

; Full-depth teeth : Teeth in which the working depth equals 2.000 divided by the normal diametral pitch.

; Stub teeth : Teeth in which the working depth is less than 2.000 divided by the normal diametral pitch.

; Equal addendum teeth : Teeth in which two engaging gears have equal addendums.

; Long and short-addendum teeth : Teeth in which the addendums of two engaging gears are unequal.

; Undercut : An undercut is a condition in generated gear teeth when any part of the fillet curve lies inside of a line drawn tangent to the working profile at its point of juncture with the fillet. Undercut may be deliberately introduced to facilitate finishing operations. With undercut the fillet curve intersects the working profile. Without undercut the fillet curve and the working profile have a common tangent.

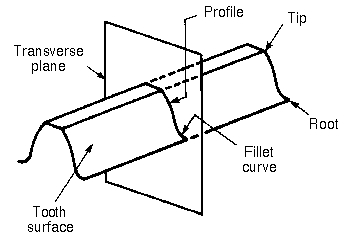

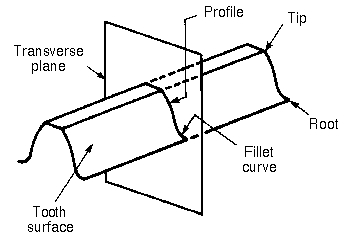

; Root fillet : or fillet curve, the concave portion of the tooth profile where it joins the bottom of the tooth space. 2

; Undercut : An undercut is a condition in generated gear teeth when any part of the fillet curve lies inside of a line drawn tangent to the working profile at its point of juncture with the fillet. Undercut may be deliberately introduced to facilitate finishing operations. With undercut the fillet curve intersects the working profile. Without undercut the fillet curve and the working profile have a common tangent.

; Root fillet : or fillet curve, the concave portion of the tooth profile where it joins the bottom of the tooth space. 2

File:Pitches.svg, Pitch

File:Tooth pitches.jpg, Tooth pitch

File:Base pitch.jpg, Base pitch relationships

File:Principal pitches.jpg, Principal pitches

; Circular pitch, ''p'' : Arc distance along a specified pitch circle or pitch line between corresponding profiles of adjacent teeth.

; Transverse circular pitch, ''p''t : Circular pitch in the transverse plane.

; Normal circular pitch, ''p''n, ''p''e : Circular pitch in the normal plane, and also the length of the arc along the normal pitch helix between helical teeth or threads.

; Axial pitch, ''p''x : Linear pitch in an axial plane and in a pitch surface. In helical gears and worms, axial pitch has the same value at all diameters. In gearing of other types, axial pitch may be confined to the pitch surface and may be a circular measurement. The term axial pitch is preferred to the term linear pitch. The axial pitch of a helical worm and the circular pitch of its worm gear are the same.

; Normal base pitch, ''p''N, ''p''bn :An involute helical gear is the base pitch in the normal plane. It is the normal distance between parallel helical involute surfaces on the plane of action in the normal plane, or is the length of arc on the normal base helix. It is a constant distance in any helical involute gear.

; Transverse base pitch, ''p''b, ''p''bt : In an involute gear, the pitch is on the base circle or along the line of action. Corresponding sides of involute gear teeth are parallel curves, and the base pitch is the constant and fundamental distance between them along a common normal in a transverse plane.

; Diametral pitch (transverse), ''P''d : Ratio of the number of teeth to the standard pitch diameter in inches.

::

; Normal diametral pitch, ''P''nd : Value of diametral pitch in a normal plane of a helical gear or worm.

::

; Angular pitch, ''θ''N, ''τ'' : Angle subtended by the circular pitch, usually expressed in radians.

:: degrees or radians

The gear mechanism was previously considered exclusively artificial, but as early as 1957, gears had been recognized in the hind legs of various species of

The gear mechanism was previously considered exclusively artificial, but as early as 1957, gears had been recognized in the hind legs of various species of

"Wheels That Can't Slip."

''Popular Science'', February 1945, pp. 120–125.

Geararium. Museum of gears and toothed wheels

- antique and vintage gears, sprockets, ratchets and other gear-related objects.

Kinematic Models for Design Digital Library (KMODDL)

- movies and photos of hundreds of working models at Cornell University

Short historical account on the application of analytical geometry to the form of gear teethMathematical Tutorial for Gearing (Relating to Robotics)American Gear Manufacturers AssociationGear Technology, the Journal of Gear Manufacturing

{{Kinematic pair Tribology Articles containing video clips

A gear or gearwheel is a rotating machine part typically used to transmit

A gear or gearwheel is a rotating machine part typically used to transmit rotational motion

Rotation or rotational/rotary motion is the circular movement of an object around a central line, known as an ''axis of rotation''. A plane figure can rotate in either a clockwise or counterclockwise sense around a perpendicular axis interse ...

and/or torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. Wh ...

by means of a series of teeth that engage with compatible teeth of another gear or other part. The teeth can be integral saliences or cavities machined on the part, or separate pegs inserted into it. In the latter case, the gear is usually called a cogwheel. A cog may be one of those pegsDefinition of "cog"in the ''Oxford Learner's Dictionary'' online. Accessed on 2024-07-29.Definition of "cog"

in the ''Merriam-Webster Dictionary'' online. Accessed on 2024-07-29.Definition of "cog"

in the ''Cambridge Dictionary Plus'' online. Accessed on 2024-07-29. or the whole gear.Definition of "cog"

in the ''Collins English Dictionary'' online. Accessed on 2024-07-29. Two or more meshing gears are called a

gear train

A gear train or gear set is a machine element of a mechanical system formed by mounting two or more gears on a frame such that the teeth of the gears engage.

Gear teeth are designed to ensure the pitch circles of engaging gears roll on each oth ...

.

The smaller member of a pair of meshing gears is often called pinion. Most commonly, gears and gear trains can be used to trade torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. Wh ...

for rotational speed

Rotational frequency, also known as rotational speed or rate of rotation (symbols ''ν'', lowercase Greek nu, and also ''n''), is the frequency of rotation of an object around an axis.

Its SI unit is the reciprocal seconds (s−1); other com ...

between two axle

An axle or axletree is a central shaft for a rotation, rotating wheel and axle, wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In ...

s or other rotating parts and/or to change the axis of rotation and/or to invert the sense of rotation. A gear may also be used to transmit linear force

In physics, a force is an influence that can cause an Physical object, object to change its velocity unless counterbalanced by other forces. In mechanics, force makes ideas like 'pushing' or 'pulling' mathematically precise. Because the Magnitu ...

and/or linear motion

Linear motion, also called rectilinear motion, is one-dimensional motion along a straight line, and can therefore be described mathematically using only one spatial dimension. The linear motion can be of two types: uniform linear motion, with ...

to a rack, a straight bar with a row of compatible teeth.

Gears are among the most common mechanical parts. They come in a great variety of shapes and materials, and are used for many different functions and applications. Diameters may range from a few μm in micromachines,Shuailong Zhang, Mohamed Elsayed, Ran Peng,

Yujie Chen (2021): "Reconfigurable multi-component micromachines driven by optoelectronic tweezers". ''Nature Communications'', volume 12, issue 1. to a few mm in

Gears are among the most common mechanical parts. They come in a great variety of shapes and materials, and are used for many different functions and applications. Diameters may range from a few μm in micromachines,Shuailong Zhang, Mohamed Elsayed, Ran Peng,

Yujie Chen (2021): "Reconfigurable multi-component micromachines driven by optoelectronic tweezers". ''Nature Communications'', volume 12, issue 1. to a few mm in watch

A watch is a timepiece carried or worn by a person. It is designed to maintain a consistent movement despite the motions caused by the person's activities. A wristwatch is worn around the wrist, attached by a watch strap or another type of ...

es and toys to over 10 metre

The metre (or meter in US spelling; symbol: m) is the base unit of length in the International System of Units (SI). Since 2019, the metre has been defined as the length of the path travelled by light in vacuum during a time interval of of ...

s in some mining equipment.Matthew Jaster (2013)"MY GEAR is Bigger than YOUR GEAR: Industry Battles it Out for World's Largest Gear Title"

Online article from ''Gear Technology'' magazine

Archived on 2024-07-30

Other types of parts that are somewhat similar in shape and function to gears include the

sprocket

A sprocket, sprocket-wheel or chainwheel is a profiled wheel

A wheel is a rotating component (typically circular in shape) that is intended to turn on an axle Bearing (mechanical), bearing. The wheel is one of the key components of the whe ...

, which is meant to engage with a link chain

A chain is a wikt:series#Noun, serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression (physics), compression but line (g ...

instead of another gear, and the timing pulley, meant to engage a timing belt. Most gears are round and have equal teeth, designed to operate as smoothly as possible; but there are several applications for non-circular gear

A non-circular gear (NCG) is a special gear design with special characteristics and purpose. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and with maximum Mechanical efficiency, effic ...

s, and the Geneva drive

The Geneva drive or Geneva mechanism is a gear mechanism that translates a continuous rotation movement into intermittent rotary motion.

The ''rotating drive'' wheel is usually equipped with a pin that reaches into a slot located in the other ...

has an extremely uneven operation, by design.

Gears can be seen as instances of the basic lever

A lever is a simple machine consisting of a beam (structure), beam or rigid rod pivoted at a fixed hinge, or '':wikt:fulcrum, fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, l ...

"machine". When a small gear drives a larger one, the mechanical advantage

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. The device trades off input forces against movement to obtain a desired amplification in the output force. The model for ...

of this ideal lever causes the torque ''T'' to increase but the rotational speed

Rotational frequency, also known as rotational speed or rate of rotation (symbols ''ν'', lowercase Greek nu, and also ''n''), is the frequency of rotation of an object around an axis.

Its SI unit is the reciprocal seconds (s−1); other com ...

''ω'' to decrease. The opposite effect is obtained when a large gear drives a small one. The changes are proportional to the ''gear ratio'' ''r'', the ratio of the tooth counts: namely, , and . Depending on the geometry of the pair, the sense of rotation may also be inverted (from clockwise to anti-clockwise, or vice versa).

Most vehicles have a transmission or "gearbox" containing a set of gears that can be meshed in multiple configurations. The gearbox lets the operator vary the torque that is applied to the wheels without changing the engine's speed. Gearboxes are used also in many other machines, such as lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the w ...

s and conveyor belts. In all those cases, terms like "first gear", "high gear", and "reverse gear" refer to the overall torque ratios of different meshing configurations, rather than to specific physical gears. These terms may be applied even when the vehicle does not actually contain gears, as in a continuously variable transmission

A continuously variable transmission (CVT) is an automated Transmission (mechanical device), transmission that can change through a continuous range of gear ratios, typically resulting in better fuel economy in gasoline applications. This contr ...

.

History

The oldest functioning gears by far are not man made, but are seen in the hind legs of the nymphs of the planthopper insect '' Issus coleoptratus''. The earliest man-made gears that have not been lost or destroyed date to 4th century BCChina

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

Derek J. de Solla Price

Derek John de Solla Price (22 January 1922 – 3 September 1983) was a British physicist, history of science, historian of science, and information science, information scientist. He was known for his investigation of the Antikythera mechanism, ...

On the Origin of Clockwork, Perpetual Motion Devices, and the Compass

p.84 (Zhan Guo times – Late East

Zhou dynasty

The Zhou dynasty ( ) was a royal dynasty of China that existed for 789 years from until 256 BC, the longest span of any dynasty in Chinese history. During the Western Zhou period (771 BC), the royal house, surnamed Ji, had military ...

), which have been preserved at the Luoyang Museum of Henan Province, China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

.

In Europe, Aristotle

Aristotle (; 384–322 BC) was an Ancient Greek philosophy, Ancient Greek philosopher and polymath. His writings cover a broad range of subjects spanning the natural sciences, philosophy, linguistics, economics, politics, psychology, a ...

mentions gears around 330 BC, as wheel drives in windlasses. He observed that the direction of rotation is reversed when one gear wheel drives another gear wheel. Philon of Byzantium was one of the first who used gears in water raising devices. Gears appear in works connected to Hero of Alexandria

Hero of Alexandria (; , , also known as Heron of Alexandria ; probably 1st or 2nd century AD) was a Greek mathematician and engineer who was active in Alexandria in Egypt during the Roman era. He has been described as the greatest experimental ...

, in Roman Egypt

Roman Egypt was an imperial province of the Roman Empire from 30 BC to AD 642. The province encompassed most of modern-day Egypt except for the Sinai. It was bordered by the provinces of Crete and Cyrenaica to the west and Judaea, ...

circa AD 50, but can be traced back to the mechanics of the Library of Alexandria

The Great Library of Alexandria in Alexandria, Egypt, was one of the largest and most significant libraries of the ancient world. The library was part of a larger research institution called the Mouseion, which was dedicated to the Muses, ...

in 3rd-century BC Ptolemaic Egypt Ptolemaic is the adjective formed from the name Ptolemy, and may refer to:

Pertaining to the Ptolemaic dynasty

* Ptolemaic dynasty, the Macedonian Greek dynasty that ruled Egypt founded in 305 BC by Ptolemy I Soter

*Ptolemaic Kingdom

Pertaining ...

, and were greatly developed by the Greek polymath

A polymath or polyhistor is an individual whose knowledge spans many different subjects, known to draw on complex bodies of knowledge to solve specific problems. Polymaths often prefer a specific context in which to explain their knowledge, ...

Archimedes

Archimedes of Syracuse ( ; ) was an Ancient Greece, Ancient Greek Greek mathematics, mathematician, physicist, engineer, astronomer, and Invention, inventor from the ancient city of Syracuse, Sicily, Syracuse in History of Greek and Hellenis ...

(287–212 BC). The earliest surviving gears in Europe were found in the Antikythera mechanism

The Antikythera mechanism ( , ) is an Ancient Greece, Ancient Greek hand-powered orrery (model of the Solar System). It is the oldest known example of an Analog computer, analogue computer. It could be used to predict astronomy, astronomical ...

an example of a very early and intricate geared device, designed to calculate astronomical

Astronomy is a natural science that studies celestial objects and the phenomena that occur in the cosmos. It uses mathematics, physics, and chemistry in order to explain their origin and their overall evolution. Objects of interest include ...

positions of the sun, moon, and planets, and predict eclipse

An eclipse is an astronomical event which occurs when an astronomical object or spacecraft is temporarily obscured, by passing into the shadow of another body or by having another body pass between it and the viewer. This alignment of three ...

s. Its time of construction is now estimated between 150 and 100 BC.

The Chinese engineer Ma Jun (–265) described a south-pointing chariot

The south-pointing chariot (or carriage) was an ancient Chinese two-wheeled vehicle that carried a movable pointer to indicate the south, no matter how the chariot turned. Usually, the pointer took the form of a doll or figure with an outstretch ...

. A set of differential gears connected to the wheels and to a pointer on top of the chariot kept the direction of latter unchanged as the chariot turned.

Another early surviving example of geared mechanism is a complex calendrical device showing the phase of the Moon, the day of the month and the places of the Sun and the Moon in the Zodiac was invented in the Byzantine empire in the early 6th century.

Geared mechanical water clocks were built in China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

by 725.

Around 1221, a geared astrolabe

An astrolabe (; ; ) is an astronomy, astronomical list of astronomical instruments, instrument dating to ancient times. It serves as a star chart and Model#Physical model, physical model of the visible celestial sphere, half-dome of the sky. It ...

was built in Isfahan

Isfahan or Esfahan ( ) is a city in the Central District (Isfahan County), Central District of Isfahan County, Isfahan province, Iran. It is the capital of the province, the county, and the district. It is located south of Tehran. The city ...

showing the position of the moon

The Moon is Earth's only natural satellite. It Orbit of the Moon, orbits around Earth at Lunar distance, an average distance of (; about 30 times Earth diameter, Earth's diameter). The Moon rotation, rotates, with a rotation period (lunar ...

in the zodiac

The zodiac is a belt-shaped region of the sky that extends approximately 8° north and south celestial latitude of the ecliptic – the apparent path of the Sun across the celestial sphere over the course of the year. Within this zodiac ...

and its phase, and the number of days since new moon.

The worm gear

A worm drive is a gear train, gear arrangement in which a worm (which is a gear in the form of a Screw thread, screw) meshes with a worm wheel (which is similar in appearance to a spur gear). Its main purpose is to translate the motion of two p ...

was invented in the Indian subcontinent

The Indian subcontinent is a physiographic region of Asia below the Himalayas which projects into the Indian Ocean between the Bay of Bengal to the east and the Arabian Sea to the west. It is now divided between Bangladesh, India, and Pakista ...

, for use in roller cotton gin

A cotton gin—meaning "cotton engine"—is a machine that quickly and easily separates cotton fibers from their seeds, enabling much greater productivity than manual cotton separation.. Reprinted by McGraw-Hill, New York and London, 1926 (); ...

s, some time during the 13th–14th centuries.Irfan Habib

Irfan Habib (born 10 August 1931) is an Indian historian of ancient and medieval India, following the methodology of Marxist historiography in his contributions to economic history. He is known for his strong stance against Hindutva. He has au ...

''Economic History of Medieval India, 1200-1500'', page 53

Pearson Education

Pearson Education, known since 2011 as simply Pearson, is the educational publishing and services subsidiary of the international corporation Pearson plc. The subsidiary was formed in 1998, when Pearson plc acquired Simon & Schuster's educatio ...

A complex astronomical clock, called the Astrarium, was built between 1348 and 1364 by Giovanni Dondi dell'Orologio. It had seven faces and 107 moving parts; it showed the positions of the sun, the moon and the five planets then known, as well as religious feast days. The Salisbury Cathedral clock, built in 1386, it is the world's oldest still working geared mechanical clock.

Differential gears were used by the British clock maker Joseph Williamson in 1720.

Etymology

The word ''gear'' is probably fromOld Norse

Old Norse, also referred to as Old Nordic or Old Scandinavian, was a stage of development of North Germanic languages, North Germanic dialects before their final divergence into separate Nordic languages. Old Norse was spoken by inhabitants ...

''gørvi'' (plural ''gørvar'') 'apparel, gear,' related to ''gøra'', ''gørva'' 'to make, construct, build; set in order, prepare,' a common verb in Old Norse, "used in a wide range of situations from writing a book to dressing meat". In this context, the meaning of 'toothed wheel in machinery' first attested 1520s; specific mechanical sense of 'parts by which a motor communicates motion' is from 1814; specifically of a vehicle (bicycle, automobile, etc.) by 1888.

A ''cog'' is a tooth on a wheel. From Middle English

Middle English (abbreviated to ME) is a form of the English language that was spoken after the Norman Conquest of 1066, until the late 15th century. The English language underwent distinct variations and developments following the Old English pe ...

cogge, from Old Norse

Old Norse, also referred to as Old Nordic or Old Scandinavian, was a stage of development of North Germanic languages, North Germanic dialects before their final divergence into separate Nordic languages. Old Norse was spoken by inhabitants ...

(compare Norwegian ''kugg'' ('cog'), Swedish ''kugg'', ''kugge'' ('cog, tooth')), from Proto-Germanic

Proto-Germanic (abbreviated PGmc; also called Common Germanic) is the linguistic reconstruction, reconstructed proto-language of the Germanic languages, Germanic branch of the Indo-European languages.

Proto-Germanic eventually developed from ...

*''kuggō'' (compare Dutch ''kogge'' (' cogboat'), German ''Kock''), from Proto-Indo-European

Proto-Indo-European (PIE) is the reconstructed common ancestor of the Indo-European language family. No direct record of Proto-Indo-European exists; its proposed features have been derived by linguistic reconstruction from documented Indo-Euro ...

*''gugā'' ('hump, ball') (compare Lithuanian ''gugà'' ('pommel, hump, hill'), from PIE *''gēw-'' ('to bend, arch'). First used c. 1300 in the sense of 'a wheel having teeth or cogs; late 14c., 'tooth on a wheel'; cog-wheel, early 15c.

Materials

The gears of the Antikythera mechanism are made of

The gears of the Antikythera mechanism are made of bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloid ...

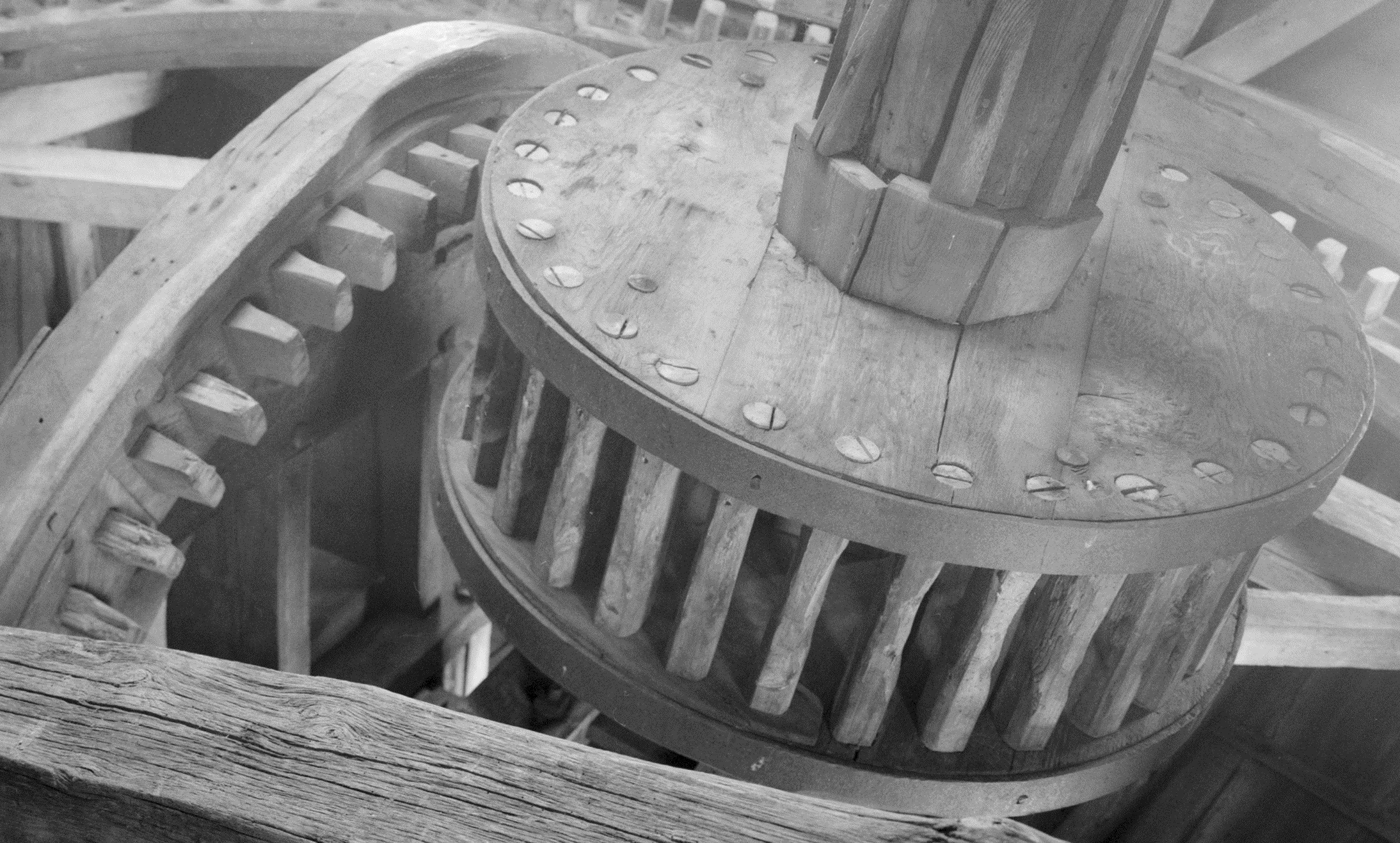

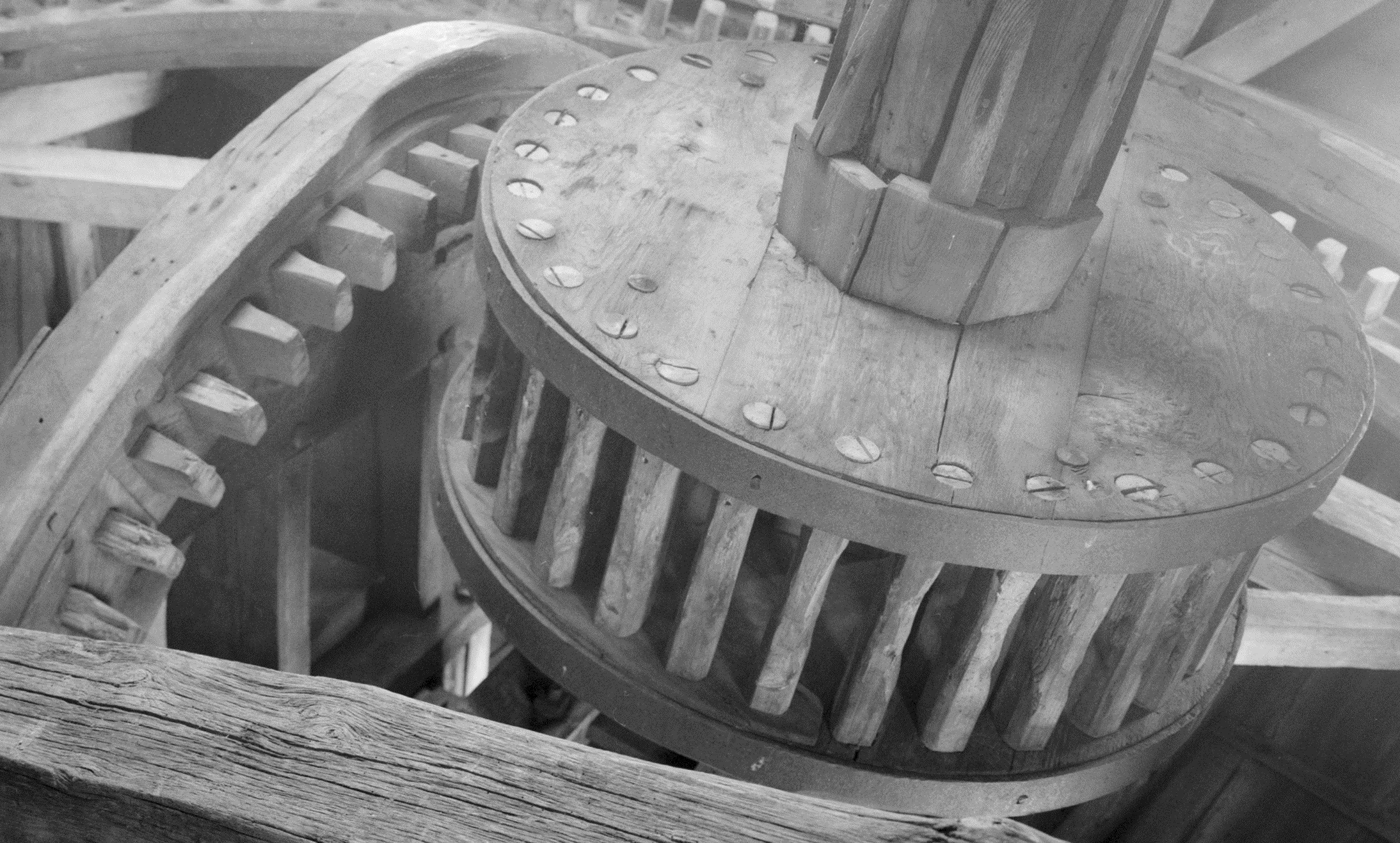

, and the earliest surviving Chinese gears are made of iron. These metals, as well as tin, have been generally used for clocks and similar mechanisms to this day.

Historically, large gears, such as those used in flour mills, were commonly made of wood rather than metal. They were cogwheels, made by inserting a series of wooden pegs or cogs around the rim of a wheel. The cogs were often made of maple

''Acer'' is a genus of trees and shrubs commonly known as maples. The genus is placed in the soapberry family Sapindaceae.Stevens, P. F. (2001 onwards). Angiosperm Phylogeny Website. Version 9, June 2008 nd more or less continuously updated si ...

wood.

Wooden gears have been gradually replaced by ones made or metal, such as cast iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its car ...

at first, then steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

and aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

. Steel is most commonly used because of its high strength-to-weight ratio and low cost. Aluminum is not as strong as steel for the same geometry, but is lighter and easier to machine. Powder metallurgy

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes are sometimes used to reduce or eliminate the need for subtractive manufacturing, subtractive processes in ma ...

may be used with alloys that cannot be easily cast or machined.

Still, because of cost or other considerations, some early metal gears had wooden cogs, each tooth forming a type of specialised 'through' mortise and tenon joint

More recently

Still, because of cost or other considerations, some early metal gears had wooden cogs, each tooth forming a type of specialised 'through' mortise and tenon joint

More recently engineering plastic

Engineering plastics are a group of plastic materials that have better mechanical or thermal properties than the more widely used commodity plastics (such as polystyrene, polyvinyl chloride, polypropylene and polyethylene).

Engineering plastic ...

s and composite materials

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a ...

have been replacing metals in many applications, especially those with moderate speed and torque. They are not as strong as steel, but are cheaper, can be mass-manufactured by injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

, and don't need lubrication. Plastic gears can even be intentionally designed to be the weakest part in a mechanism, so that in case of jamming they will fail first and thus avoid damage to more expensive parts. Such "sacrificial" gears may be a simpler alternative to other overload-protection devices such as clutches and torque-limited or current-limited motors.

In spite of the advantages of metal and plastic, wood continued to be used for large gears until a couple of centuries ago, because of cost, weight, tradition, or other considerations. In 1967 the Thompson Manufacturing Company of

In spite of the advantages of metal and plastic, wood continued to be used for large gears until a couple of centuries ago, because of cost, weight, tradition, or other considerations. In 1967 the Thompson Manufacturing Company of Lancaster, New Hampshire

Lancaster is a town located along the Connecticut River in Coös County, New Hampshire, United States. The town is named after the city of Lancaster in England. As of the 2020 census, the town population was 3,218, the second largest in the cou ...

still had a very active business in supplying tens of thousands of maple gear teeth per year, mostly for use in paper mill

A paper mill is a factory devoted to making paper from vegetable fibres such as wood pulp, old rags, and other ingredients. Prior to the invention and adoption of the Fourdrinier machine and other types of paper machine that use an endless belt ...

s and grist mills, some dating back over 100 years.

Manufacture

The most common techniques for gear manufacturing are dies,sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is usually defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural ...

, and investment casting; injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

; powder metallurgy

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes are sometimes used to reduce or eliminate the need for subtractive manufacturing, subtractive processes in ma ...

; blanking; and gear cutting.

As of 2014, an estimated 80% of all gearing produced worldwide is produced by net shape molding. Molded gearing is usually powder metallurgy, plastic injection, or metal die casting. Gears produced by powder metallurgy often require a sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plas ...

step after they are removed from the mold. Cast gears require gear cutting or other machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

to shape the teeth to the necessary precision. The most common form of gear cutting is hobbing, but gear shaping

Gear shaping is a machining process for creating teeth on a gear using a cutter. Gear shaping is a convenient and versatile method of gear cutting. It involves continuous, same-plane rotational cutting of gear.

Process theory

The types of cutt ...

, milling

Milling may refer to:

* Milling (minting), forming narrow ridges around the edge of a coin

* Milling (grinding), breaking solid materials into smaller pieces by grinding, crushing, or cutting in a mill

* Milling (machining), a process of using ro ...

, and broaching may be used instead.

Metal gears intended for heavy duty operation, such as in the transmissions of cars and trucks, the teeth are heat treated to make them hard and more wear resistant while leaving the core soft but tough. For large gears that are prone to warp, a quench press is used.

Gears can be made by 3D printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

; however, this alternative is typically used only for prototypes or very limited production quantities, because of its high cost, low accuracy, and relatively low strength of the resulting part.

Comparison with other drive mechanisms

Besides gear trains, other alternative methods of transmitting torque between non-coaxial parts includelink chain

A chain is a wikt:series#Noun, serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression (physics), compression but line (g ...

s driven by sprockets, friction drives, belts and pulleys, hydraulic couplings, and timing belts.

One major advantage of gears is that their rigid body and the snug interlocking of the teeth ensure precise tracking of the rotation across the gear train, limited only by backlash and other mechanical defects. For this reason they are favored in precision applications such as watches. Gear trains also can have fewer separate parts (only two) and have minimal power loss, minimal wear, and long life. Gears are also often the most efficient and compact way of transmitting torque between two non-parallel axes.

On the other hand, gears are more expensive to manufacture, may require periodic lubrication, and may have greater mass and rotational inertia

The moment of inertia, otherwise known as the mass moment of inertia, angular/rotational mass, second moment of mass, or most accurately, rotational inertia, of a rigid body is defined relatively to a rotational axis. It is the ratio between ...

than the equivalent pulleys. More importantly, the distance between the axes of matched gears is limited and cannot be changed once they are manufactured. There are also applications where slippage under overload or transients (as occurs with belts, hydraulics, and friction wheels) is not only acceptable but desirable.

Ideal gear model

For basic analysis purposes, each gear can be idealized as a perfectlyrigid body

In physics, a rigid body, also known as a rigid object, is a solid body in which deformation is zero or negligible, when a deforming pressure or deforming force is applied on it. The distance between any two given points on a rigid body rema ...

that, in normal operation, turns around a ''rotation axis'' that is fixed in space, without sliding along it. Thus, each point of the gear can move only along a circle that is perpendicular to its axis and centered on it. At any moment ''t'', all points of the gear will be rotating around that axis with the same angular speed

In physics, angular frequency (symbol ''ω''), also called angular speed and angular rate, is a scalar measure of the angle rate (the angle per unit time) or the temporal rate of change of the phase argument of a sinusoidal waveform or sine f ...

''ω''(''t''), in the same sense. The speed need not be constant over time.

The ''action surface'' of the gear consists of all points of its surface that, in normal operation, may contact the matching gear with positive pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and eve ...

. All other parts of the surface are irrelevant (except that they cannot be crossed by any part of the matching gear). In a gear with ''N'' teeth, the working surface has ''N''-fold rotational symmetry

Rotational symmetry, also known as radial symmetry in geometry, is the property a shape (geometry), shape has when it looks the same after some rotation (mathematics), rotation by a partial turn (angle), turn. An object's degree of rotational s ...

about the axis, meaning that it is congruent

Congruence may refer to:

Mathematics

* Congruence (geometry), being the same size and shape

* Congruence or congruence relation, in abstract algebra, an equivalence relation on an algebraic structure that is compatible with the structure

* In modu ...

with itself when the gear rotates by of a turn.

If the gear is meant to transmit or receive torque with a definite sense only (clockwise or counterclockwise with respect to some reference viewpoint), the action surface consists of ''N'' separate patches, the ''tooth faces''; which have the same shape and are positioned in the same way relative to the axis, spaced turn apart.

If the torque on each gear may have both senses, the action surface will have two sets of ''N'' tooth faces; each set will be effective only while the torque has one specific sense, and the two sets can be analyzed independently of the other. However, in this case the gear usually has also "flip over" symmetry, so that the two sets of tooth faces are congruent after the gear is flipped. This arrangement ensures that the two gears are firmly locked together, at all times, with no backlash

Backlash may refer to:

Literature

* '' Backlash: The Undeclared War Against American Women'', a 1991 book by Susan Faludi

* ''Backlash'' (Star Wars novel), a 2010 novel by Aaron Allston

* Backlash (Marc Slayton), a comic book character from ...

.

During operation, each point ''p'' of each tooth face will at some moment contact a tooth face of the matching gear at some point ''q'' of one of its tooth faces. At that moment and at those points, the two faces must have the same perpendicular direction but opposite orientation. But since the two gears are rotating around different axes, the points ''p'' and ''q'' are moving along different circles; therefore, the contact cannot last more than one instant, and ''p'' will then either slide across the other face, or stop contacting it altogether.

On the other hand, at any given moment there is at least one such pair of contact points; usually more than one, even a whole line or surface of contact.

Actual gears deviate from this model in many ways: they are not perfectly rigid, their mounting does not ensure that the rotation axis will be perfectly fixed in space, the teeth may have slightly different shapes and spacing, the tooth faces are not perfectly smooth, and so on. Yet, these deviations from the ideal model can be ignored for a basic analysis of the operation of a gear set.

Relative axis position

One criterion for classifying gears is the relative position and direction of the axes or rotation of the gears that are to be meshed together.Parallel

In the most common configuration, the axes of rotation of the two gears are parallel, and usually their sizes are such that they contact near a point between the two axes. In this configuration, the two gears turn in opposite senses. Occasionally the axes are parallel but one gear is nested inside the other. In this configuration, both gears turn in the same sense. If the two gears are cut by an imaginary plane perpendicular to the axes, each section of one gear will interact only with the corresponding section of the other gear. Thus the three-dimensional gear train can be understood as a stack of gears that are flat and infinitesimally thin — that is, essentially two-dimensional.Crossed

In a ''crossed'' arrangement, the axes of rotation of the two gears are not parallel but cross at an arbitrary angle except zero or 180 degrees. For best operation, each wheel then must be a bevel gear, whose overall shape is like a slice ( frustum) of acone

In geometry, a cone is a three-dimensional figure that tapers smoothly from a flat base (typically a circle) to a point not contained in the base, called the '' apex'' or '' vertex''.

A cone is formed by a set of line segments, half-lines ...

whose apex is the meeting point of the two axes.

Bevel gears with equal numbers of teeth and shaft axes at 90 degrees are called ''miter'' (US) or ''mitre'' (UK) gears.

Independently of the angle between the axes, the larger of two unequal matching bevel gears may be internal or external, depending the desired relative sense of rotation.

If the two gears are sliced by an imaginary sphere whose center is the point where the two axes cross, each section will remain on the surface of that sphere as the gear rotates, and the section of one gear will interact only with the corresponding section of the other gear. In this way, a pair of meshed 3D gears can be understood as a stack of nested infinitely thin cup-like gears.

Skew

The gears in a matching pair are said to be ''skew'' if their axes of rotation are skew lines -- neither parallel nor intersecting.

In this case, the best shape for each pitch surface is neither cylindrical nor conical but a portion of a

The gears in a matching pair are said to be ''skew'' if their axes of rotation are skew lines -- neither parallel nor intersecting.

In this case, the best shape for each pitch surface is neither cylindrical nor conical but a portion of a hyperboloid

In geometry, a hyperboloid of revolution, sometimes called a circular hyperboloid, is the surface generated by rotating a hyperbola around one of its principal axes. A hyperboloid is the surface obtained from a hyperboloid of revolution by def ...

of revolution. Such gears are called '' hypoid'' for short. Hypoid gears are most commonly found with shafts at 90 degrees.

Contact between hypoid gear teeth may be even smoother and more gradual than with spiral bevel gear teeth, but also have a sliding action along the meshing teeth as it rotates and therefore usually require some of the most viscous types of gear oil to avoid it being extruded from the mating tooth faces, the oil is normally designated HP (for hypoid) followed by a number denoting the viscosity. Also, the pinion can be designed with fewer teeth than a spiral bevel pinion, with the result that gear ratios of 60:1 and higher are feasible using a single set of hypoid gears.. This style of gear is most common in motor vehicle drive trains, in concert with a differential. Whereas a regular (nonhypoid) ring-and-pinion gear set is suitable for many applications, it is not ideal for vehicle drive trains because it generates more noise and vibration than a hypoid does. Bringing hypoid gears to market for mass-production applications was an engineering improvement of the 1920s.

Tooth orientation

Internal and external

A gear is said to be ''external'' if its teeth are directed generally away from the rotation axis, and ''internal'' otherwise. In a pair of matching wheels, only one of them (the larger one) may be internal.

A gear is said to be ''external'' if its teeth are directed generally away from the rotation axis, and ''internal'' otherwise. In a pair of matching wheels, only one of them (the larger one) may be internal.Crown

A '' crown gear'' or ''contrate gear'' is one whose teeth project at right angles to the plane. A crown gear is also sometimes meshed with anescapement

An escapement is a mechanical linkage in mechanical watches and clocks that gives impulses to the timekeeping element and periodically releases the gear train to move forward, advancing the clock's hands. The impulse action transfers energy to t ...

such as found in mechanical clocks.

Tooth cut direction

Gear teeth typically extend across the whole thickness of the gear. Another criterion for classifying gears is the general direction of the teeth across that dimension. This attribute is affected by the relative position and direction of the axes or rotation of the gears that are to be meshed together.Straight

In a cylindrical '' spur gear'' or ''straight-cut gear'', the tooth faces are straight along the direction parallel to the axis of rotation. Any imaginary cylinder with the same axis will cut the teeth along parallel straight lines. The teeth can be either internal or external. Two spur gears mesh together correctly only if fitted to parallel shafts. No axial thrust is created by the tooth loads. Spur gears are excellent at moderate speeds but tend to be noisy at high speeds. For arrangements with crossed non-parallel axes, the faces in a straight-cut gear are parts of a general conical surface whose generating lines (''generatrices'') go through the meeting point of the two axes, resulting in a bevel gear. Such gears are generally used only at speeds below , or, for small gears, 1000rpm

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or r⋅min−1) is a unit of rotational speed (or rotational frequency) for rotating machines.

One revolution per minute is equivalent to hertz.

Standards

ISO 80000-3:2019 def ...

..

Helical

In a ''helical'' or ''dry fixed'' gear the tooth walls are not parallel to the axis of rotation, but are set at an angle. An imaginary pitch surface (cylinder, cone, or hyperboloid, depending on the relative axis positions) intersects each tooth face along an arc of a

In a ''helical'' or ''dry fixed'' gear the tooth walls are not parallel to the axis of rotation, but are set at an angle. An imaginary pitch surface (cylinder, cone, or hyperboloid, depending on the relative axis positions) intersects each tooth face along an arc of a helix

A helix (; ) is a shape like a cylindrical coil spring or the thread of a machine screw. It is a type of smooth space curve with tangent lines at a constant angle to a fixed axis. Helices are important in biology, as the DNA molecule is for ...

. Helical gears can be meshed in either ''parallel'' or ''crossed'' orientations. The former refers to when the shafts are parallel to each other; this is the most common orientation. In the latter, the shafts are non-parallel, and in this configuration the gears are sometimes known as "skew gears".

The angled teeth engage more gradually than do spur gear teeth, causing them to run more smoothly and quietly. With parallel helical gears, each pair of teeth first make contact at a single point at one side of the gear wheel; a moving curve of contact then grows gradually across the tooth face to a maximum, then recedes until the teeth break contact at a single point on the opposite side. In spur gears, teeth suddenly meet at a line contact across their entire width, causing stress and noise. Spur gears make a characteristic whine at high speeds. For this reason spur gears are used in low-speed applications and in situations where noise control is not a problem, and helical gears are used in high-speed applications, large power transmission, or where noise abatement is important. The speed is considered high when the pitch line velocity exceeds 25 m/s.

A disadvantage of helical gears is a resultant

The angled teeth engage more gradually than do spur gear teeth, causing them to run more smoothly and quietly. With parallel helical gears, each pair of teeth first make contact at a single point at one side of the gear wheel; a moving curve of contact then grows gradually across the tooth face to a maximum, then recedes until the teeth break contact at a single point on the opposite side. In spur gears, teeth suddenly meet at a line contact across their entire width, causing stress and noise. Spur gears make a characteristic whine at high speeds. For this reason spur gears are used in low-speed applications and in situations where noise control is not a problem, and helical gears are used in high-speed applications, large power transmission, or where noise abatement is important. The speed is considered high when the pitch line velocity exceeds 25 m/s.

A disadvantage of helical gears is a resultant thrust

Thrust is a reaction force described quantitatively by Newton's third law. When a system expels or accelerates mass in one direction, the accelerated mass will cause a force of equal magnitude but opposite direction to be applied to that ...

along the axis of the gear, which must be accommodated by appropriate thrust bearing

A thrust bearing is a particular type of rotary bearing. Like other bearings they permanently rotate between parts, but they are designed to support a predominantly axial load.

Thrust bearings come in several varieties.

*''Thrust ball bearing ...

s. However, this issue can be circumvented by using a herringbone gear or ''double helical gear'', which has no axial thrust - and also provides self-aligning of the gears. This results in less axial thrust than a comparable spur gear.

A second disadvantage of helical gears is a greater degree of sliding friction between the meshing teeth, often addressed with additives in the lubricant.

For a "crossed" or "skew" configuration, the gears must have the same pressure angle and normal pitch; however, the helix angle and handedness can be different. The relationship between the two shafts is actually defined by the helix angle(s) of the two shafts and the handedness, as defined:

: for gears of the same handedness,

: for gears of opposite handedness,

where is the helix angle for the gear. The crossed configuration is less mechanically sound because there is only a point contact between the gears, whereas in the parallel configuration there is a line contact.

Quite commonly, helical gears are used with the helix angle of one having the negative of the helix angle of the other; such a pair might also be referred to as having a right-handed helix and a left-handed helix of equal angles. The two equal but opposite angles add to zero: the angle between shafts is zero—that is, the shafts are ''parallel''. Where the sum or the difference (as described in the equations above) is not zero, the shafts are ''crossed''. For shafts ''crossed'' at right angles, the helix angles are of the same hand because they must add to 90 degrees. (This is the case with the gears in the illustration above: they mesh correctly in the crossed configuration: for the parallel configuration, one of the helix angles should be reversed. The gears illustrated cannot mesh with the shafts parallel.)

3D animation of helical gears (parallel axis)

3D animation of helical gears (crossed axis)

Double helical

Double helical gears overcome the problem of axial thrust presented by single helical gears by using a double set of teeth, slanted in opposite directions. A double helical gear can be thought of as two mirrored helical gears mounted closely together on a common axle. This arrangement cancels out the net axial thrust, since each half of the gear thrusts in the opposite direction, resulting in a net axial force of zero. This arrangement can also remove the need for thrust bearings. However, double helical gears are more difficult to manufacture due to their more complicated shape. Herringbone gears are a special type of helical gears. They do not have a groove in the middle like some other double helical gears do; the two mirrored helical gears are joined so that their teeth form a V shape. This can also be applied to bevel gears, as in the final drive of the Citroën Type A. Another type of double helical gear is a Wüst gear. For both possible rotational directions, there exist two possible arrangements for the oppositely-oriented helical gears or gear faces. One arrangement is called stable, and the other unstable. In a stable arrangement, the helical gear faces are oriented so that each axial force is directed toward the center of the gear. In an unstable arrangement, both axial forces are directed away from the center of the gear. In either arrangement, the total (or ''net'') axial force on each gear is zero when the gears are aligned correctly. If the gears become misaligned in the axial direction, the unstable arrangement generates a net force that may lead to disassembly of the gear train, while the stable arrangement generates a net corrective force. If the direction of rotation is reversed, the direction of the axial thrusts is also reversed, so a stable configuration becomes unstable, and vice versa. Stable double helical gears can be directly interchanged with spur gears without any need for different bearings.Worm

''Worms'' resemble

''Worms'' resemble screw

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the screw head, head. The most common uses of screws are to hold objects together and there are many forms for a variety ...

s. A worm is meshed with a ''worm wheel'', which looks similar to a spur gear.

Worm-and-gear sets are a simple and compact way to achieve a high torque, low speed gear ratio. For example, helical gears are normally limited to gear ratios of less than 10:1 while worm-and-gear sets vary from 10:1 to 500:1.. A disadvantage is the potential for considerable sliding action, leading to low efficiency.

A worm gear is a species of helical gear, but its helix angle is usually somewhat large (close to 90 degrees) and its body is usually fairly long in the axial direction. These attributes give it screw like qualities. The distinction between a worm and a helical gear is that at least one tooth persists for a full rotation around the helix. If this occurs, it is a 'worm'; if not, it is a 'helical gear'. A worm may have as few as one tooth. If that tooth persists for several turns around the helix, the worm appears, superficially, to have more than one tooth, but what one in fact sees is the same tooth reappearing at intervals along the length of the worm. The usual screw nomenclature applies: a one-toothed worm is called ''single thread'' or ''single start''; a worm with more than one tooth is called ''multiple thread'' or ''multiple start''. The helix angle of a worm is not usually specified. Instead, the lead angle, which is equal to 90 degrees minus the helix angle, is given.

In a worm-and-gear set, the worm can always drive the gear. However, if the gear attempts to drive the worm, it may or may not succeed. Particularly if the lead angle is small, the gear's teeth may simply lock against the worm's teeth, because the force component circumferential to the worm is not sufficient to overcome friction. In traditional music box

A music box (American English) or musical box (British English) is an automatic musical instrument in a box that produces Musical note, musical notes by using a set of pins placed on a revolving cylinder (geometry), cylinder or disc to pluck ...

es, however, the gear drives the worm, which has a large helix angle. This mesh drives the speed-limiter vanes which are mounted on the worm shaft.

Worm-and-gear sets that do lock are called self locking, which can be used to advantage, as when it is desired to set the position of a mechanism by turning the worm and then have the mechanism hold that position. An example is the machine head found on some types of stringed instrument

In musical instrument classification, string instruments, or chordophones, are musical instruments that produce sound from vibrating strings when a performer strums, plucks, strikes or sounds the strings in varying manners.

Musicians play so ...

s.

If the gear in a worm-and-gear set is an ordinary helical gear only a single point of contact is achieved.. If medium to high power transmission is desired, the tooth shape of the gear is modified to achieve more intimate contact by making both gears partially envelop each other. This is done by making both concave and joining them at a saddle point

In mathematics, a saddle point or minimax point is a Point (geometry), point on the surface (mathematics), surface of the graph of a function where the slopes (derivatives) in orthogonal directions are all zero (a Critical point (mathematics), ...

; this is called a cone-drive or "Double enveloping".

Worm gears can be right or left-handed, following the long-established practice for screw threads.

Tooth profile

Another criterion to classify gears is the ''tooth profile'', the shape of the cross-section of a tooth face by an imaginary cut perpendicular to the pitch surface, such as the transverse, normal, or axial plane.

The tooth profile is crucial for the smoothness and uniformity of the movement of matching gears, as well as for the

Another criterion to classify gears is the ''tooth profile'', the shape of the cross-section of a tooth face by an imaginary cut perpendicular to the pitch surface, such as the transverse, normal, or axial plane.

The tooth profile is crucial for the smoothness and uniformity of the movement of matching gears, as well as for the friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of t ...

and wear.

Artisanal

The teeth of antique or artisanal gears that were cut by hand from sheet material, like those in the Antikhytera mechanism, generally had simple profiles, such as triangles.

The teeth of larger gears — such as used in windmills — were usually pegs with simple shapes like cylinders,

The teeth of antique or artisanal gears that were cut by hand from sheet material, like those in the Antikhytera mechanism, generally had simple profiles, such as triangles.

The teeth of larger gears — such as used in windmills — were usually pegs with simple shapes like cylinders, parallelepiped

In geometry, a parallelepiped is a three-dimensional figure formed by six parallelograms (the term ''rhomboid'' is also sometimes used with this meaning). By analogy, it relates to a parallelogram just as a cube relates to a square.

Three equiva ...

s, or triangular prisms inserted into a smooth wooden or metal wheel; or were holes with equally simple shapes cut into such a wheel.

Because of their sub-optimal profile, the effective gear ratio of such artisanal matching gears was not constant, but fluctuated over each tooth cycle, resulting in vibrations, noise, and accelerated wear.

Cage

A ''cage gear'', also called a ''lantern gear'' or ''lantern pinion'', is one of those artisanal gears having cylindrical rods for teeth, parallel to the axle and arranged in a circle around it, much as the bars on a round bird cage or lantern. The assembly is held together by disks at each end, into which the tooth rods and axle are set. Cage gears are more efficient than solid pinions, and dirt can fall through the rods rather than becoming trapped and increasing wear. They can be constructed with very simple tools as the teeth are not formed by cutting or milling, but rather by drilling holes and inserting rods.

Sometimes used in clocks, a cage gear should always be driven by a gearwheel, not used as the driver. The cage gear was not initially favoured by conservative clock makers. It became popular in turret clocks where dirty working conditions were most commonplace. Domestic American clock movements often used them.

A ''cage gear'', also called a ''lantern gear'' or ''lantern pinion'', is one of those artisanal gears having cylindrical rods for teeth, parallel to the axle and arranged in a circle around it, much as the bars on a round bird cage or lantern. The assembly is held together by disks at each end, into which the tooth rods and axle are set. Cage gears are more efficient than solid pinions, and dirt can fall through the rods rather than becoming trapped and increasing wear. They can be constructed with very simple tools as the teeth are not formed by cutting or milling, but rather by drilling holes and inserting rods.