|

Powder Metallurgy

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product. Powder metallurgy is also used to make unique materials impossible to get from melting or forming in other ways. A very important product of this type is tungsten carbide (WC). WC is used to cut and form other metals and is made from WC particles bonded with cobalt. It is very widely used in industry for tools of many types and globally ~50,000 tonnes/year (t/y) is made by PM. Other products include sintered filters, porous oil-impregnated bearings, electrical contacts and diamond tools. Since the advent of industrial production–scale metal powder–based additive manufacturing (AM) in the 2010s, selective laser sintering and other metal AM processes are a new category of commercially important p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron Powder

Iron powder has several uses; for example production of magnetic alloys and certain types of steels. Iron powder is formed as a whole from several other iron particles. The particle sizes vary anywhere from 20-200 μm. The iron properties differ depending on the production method and history of a specific iron powder. There are three types of iron powder classifications: reduced iron powder, Atomizer nozzle, atomized powder, and electrolytic iron powder. Each type is used in various applications depending on their properties. There is very little difference in the visual appearances of reduced iron powder and atomized iron powder. Applications Automobiles Most iron powders are used for automobile parts. Engine parts *Cam shaft pulley *Cam shaft sprocket *Crank shaft pulley *Crank shaft sprocket *Cap crank bearing *Valve guide *Valve seat *Rocker arm chip *Oil pump inner rotor *Oil pump outer rotor Steering parts, suspension, and brake parts *Power steering rotor cam ring *Pres ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Pressing

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure. Hot pressing is mainly used to fabricate hard and brittle materials. One large use is in the consolidation of diamond-metal composite cutting tools and technical ceramics. The densification works through particle rearrangement and plastic flow at the particle contacts. The loose powder or the pre-compacted part is in most of the cases filled to a graphite mould that allows induction or resistance heating up to temperatures of typically . Pressures of up to can be applied. Other great use is in the pressing of different types of polymers. Within hot pressing technology, three distinctly different types of heating can be found in use: induction heating, indirect resistance heating and field assisted sintering technique (FAST) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

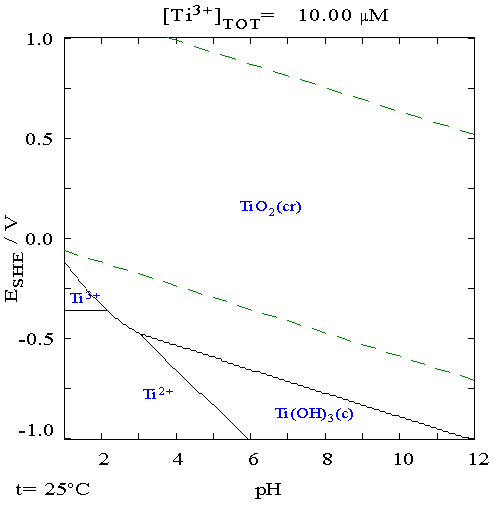

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide, is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and catalysts; and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phase (matter)

In the physical sciences, a phase is a region of space (a thermodynamic system), throughout which all physical properties of a material are essentially uniform. Examples of physical properties include density, index of refraction, magnetization and chemical composition. A simple description is that a phase is a region of material that is chemically uniform, physically distinct, and (often) mechanically separable. In a system consisting of ice and water in a glass jar, the ice cubes are one phase, the water is a second phase, and the humid air is a third phase over the ice and water. The glass of the jar is another separate phase. (See ) The term ''phase'' is sometimes used as a synonym for state of matter, but there can be several immiscible phases of the same state of matter. Also, the term ''phase'' is sometimes used to refer to a set of equilibrium states demarcated in terms of state variables such as pressure and temperature by a phase boundary on a phase diagram. Bec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gibbs' Phase Rule

In thermodynamics, the phase rule is a general principle governing "pVT" systems, whose thermodynamic states are completely described by the variables pressure (), volume () and temperature (), in thermodynamic equilibrium. If is the number of degrees of freedom, is the number of components and is the number of phases, then :F = C - P + 2 It was derived by American physicist Josiah Willard Gibbs in his landmark paper titled ''On the Equilibrium of Heterogeneous Substances'', published in parts between 1875 and 1878. The rule assumes the components do not react with each other. The number of degrees of freedom is the number of independent intensive variables, i.e. the largest number of thermodynamic parameters such as temperature or pressure that can be varied simultaneously and arbitrarily without determining one another. An example of one-component system is a system involving one pure chemical, while two-component systems, such as mixtures of water and ethanol, have two ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity (optics), opacity, and lustre (mineralogy), luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in Atomic ratio, atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were pottery objects (''pots,'' ''vessels or vases'') or figurines made from clay, either by itself or mixed with other materials like silica, hardened and sintered in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as in semiconductors. The word "'' ceramic''" comes from the Greek word (), "of pottery" or "for pottery", from (), "potter's clay, tile, pottery". The earliest kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron Beam Melting

Electron-beam additive manufacturing, or electron-beam melting (EBM) is a type of additive manufacturing, or 3D printing, for metal parts. The raw material (metal powder or wire) is placed under a vacuum and fused together from heating by an electron beam. This technique is distinct from selective laser sintering as the raw material fuses having completely melted. Metal powder-based systems Metal powders can be consolidated into a solid mass using an electron beam as the heat source. Parts are manufactured by melting metal powder, layer by layer, with an electron beam in a high vacuum. This powder bed method produces fully dense metal parts directly from metal powder with characteristics of the target material. The EBM machine reads data from a 3D CAD model and lays down successive layers of powdered material. These layers are melted together utilizing a computer-controlled electron beam. In this way it builds up the parts. The process takes place under vacuum, which makes it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Selective Laser Melting

Selective laser melting (SLM) is one of many proprietary names for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together. History Selective laser melting is one of many proprietary powder bed fusion technologies, started in 1995 at the Fraunhofer Institute ILT in Aachen, Germany, with a German research project, resulting in the so-called basic ILT SLM patent. Already during its pioneering phase Dr. Dieter Schwarze and Dr. Matthias Fockele from F&S Stereolithographietechnik GmbH located in Paderborn collaborated with the ILT researchers Dr. Wilhelm Meiners and Dr. Konrad Wissenbach. In the early 2000s F&S entered into a commercial partnership with MCP HEK ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under Computer Numerical Control, computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |