Metalworking Tools on:

[Wikipedia]

[Google]

[Amazon]

Metalworking is the process of shaping and reshaping

Metalworking is the process of shaping and reshaping

By the historical periods of the Pharaohs in

By the historical periods of the Pharaohs in

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools. Each of these categories contains various processes.

Prior to most operations, the metal must be marked out and/or measured, depending on the desired finished product.

'' Marking out'' (also known as layout) is the process of transferring a

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools. Each of these categories contains various processes.

Prior to most operations, the metal must be marked out and/or measured, depending on the desired finished product.

'' Marking out'' (also known as layout) is the process of transferring a

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

* Centrifugal casting

* Die casting

* Sand casting

* Shell casting

* Spin casting

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

* Centrifugal casting

* Die casting

* Sand casting

* Shell casting

* Spin casting

* Planishing

* Raising

* Roll forming

* Roll bending

* Repoussé and chasing

* Rubber pad forming

* Shearing

* Stamping

* Superplastic forming (SPF)

* Wheeling using an English wheel (wheeling machine)

* Planishing

* Raising

* Roll forming

* Roll bending

* Repoussé and chasing

* Rubber pad forming

* Shearing

* Stamping

* Superplastic forming (SPF)

* Wheeling using an English wheel (wheeling machine)

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or swarf and excess metal.

Cutting processes fall into one of three major categories:

* Chip producing processes most commonly known as

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or swarf and excess metal.

Cutting processes fall into one of three major categories:

* Chip producing processes most commonly known as

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a drill), and a worktable that can move in multiple directions (usually two dimensions and y axisrelative to the workpiece). The spindle usually moves in the z axis. It is possible to raise the table (where the workpiece rests). Milling machines may be operated manually or under

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a drill), and a worktable that can move in multiple directions (usually two dimensions and y axisrelative to the workpiece). The spindle usually moves in the z axis. It is possible to raise the table (where the workpiece rests). Milling machines may be operated manually or under

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, George

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, George

Chapter 4: Turning Tools and Operations

American Machinist, January 2010 A ''lathe'' is a machine tool which spins a block or cylinder of material so that when abrasive, cutting, or deformation tools are applied to the workpiece, it can be shaped to produce an object which has

Parting: The tool is fed radially into the workpiece to cut off the end of a part.

Threading: A tool is fed along and across the outside or inside surface of rotating parts to produce external or internal threads.

Boring: A single-point tool is fed linearly and parallel to the axis of rotation to create a round hole.

Knurling: Uses a tool to produce a rough surface texture on the work piece. Frequently used to allow grip by hand on a metal part. Modern computer numerical control (CNC) lathes and (CNC) machining centres can do secondary operations like milling by using driven tools. When driven tools are used the work piece stops rotating and the driven tool executes the machining operation with a rotating cutting tool. The CNC machines use x, y, and z coordinates in order to control the turning tools and produce the product. Most modern day CNC lathes are able to produce most turned objects in 3D. Nearly all types of metal can be turned, although more time & specialist cutting tools are needed for harder workpieces.

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an abrasive wheel as the cutting device. This wheel can be made up of various sizes and types of stones,

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an abrasive wheel as the cutting device. This wheel can be made up of various sizes and types of stones,

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a machinist to work to fine tolerances and was the hallmark of the craft. Today filing is rarely used as a production technique in industry, though it remains as a common method of deburring.

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a machinist to work to fine tolerances and was the hallmark of the craft. Today filing is rarely used as a production technique in industry, though it remains as a common method of deburring.

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

What's the Best Way to Cut Thick Steel?

Schneider, George. "Chapter 1: Cutting Tool Materials", ''American Machinist'', October, 2009

Schneider, George. "Cutting Tool Applications: Chapter 2 Metal Removal Methods", ''American Machinist'', November, 2009

Videos about metalworking

published by Institut für den Wissenschaftlichen Film. Available in the AV-Portal of the German National Library of Science and Technology.

Evidences of Metalworking History Reference

* {{Authority control Metal industry M M 9th-millennium BC establishments Articles containing video clips

Metalworking is the process of shaping and reshaping

Metalworking is the process of shaping and reshaping metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

s in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ship

A ship is a large watercraft, vessel that travels the world's oceans and other Waterway, navigable waterways, carrying cargo or passengers, or in support of specialized missions, such as defense, research and fishing. Ships are generally disti ...

s, buildings, and bridge

A bridge is a structure built to Span (engineering), span a physical obstacle (such as a body of water, valley, road, or railway) without blocking the path underneath. It is constructed for the purpose of providing passage over the obstacle, whi ...

s, down to precise engine

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power ge ...

parts and delicate jewellery

Jewellery (or jewelry in American English) consists of decorative items worn for personal adornment such as brooches, ring (jewellery), rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the ...

.

The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metal

A native metal is any metal that is found pure in its metallic form in nature. Metals that can be found as native element mineral, native deposits singly or in alloys include antimony, arsenic, bismuth, cadmium, chromium, cobalt, indium, iron, ma ...

s like gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

with simple hand tools, through the smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

of ores and hot forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classif ...

of harder metals like iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

, up to and including highly technical modern processes such as machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

and welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Co ...

. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft.

Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Modern metalworking workshops, typically known as machine shops, hold a wide variety of specialized or general-use machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, Boring (manufacturing), boring, grinding (abrasive cutting), grinding, shearing, or other forms of deformations. Machine tools employ some s ...

s capable of creating highly precise, useful products. Many simpler metalworking techniques, such as blacksmithing, are no longer economically competitive on a large scale in developed countries; some of them are still in use in less developed countries, for artisanal or hobby work, or for historical reenactment.

Prehistory

The oldest archaeological evidence ofcopper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

mining

Mining is the Resource extraction, extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agriculture, agricultural processes, or feasib ...

and working was the discovery of a copper pendant in northern Iraq

Iraq, officially the Republic of Iraq, is a country in West Asia. It is bordered by Saudi Arabia to Iraq–Saudi Arabia border, the south, Turkey to Iraq–Turkey border, the north, Iran to Iran–Iraq border, the east, the Persian Gulf and ...

from 8,700 BCE. The earliest substantiated and dated evidence of metalworking in the Americas

The Americas, sometimes collectively called America, are a landmass comprising the totality of North America and South America.''Webster's New World College Dictionary'', 2010 by Wiley Publishing, Inc., Cleveland, Ohio. When viewed as a sing ...

was the processing of copper in Wisconsin

Wisconsin ( ) is a U.S. state, state in the Great Lakes region, Great Lakes region of the Upper Midwest of the United States. It borders Minnesota to the west, Iowa to the southwest, Illinois to the south, Lake Michigan to the east, Michig ...

, near Lake Michigan

Lake Michigan ( ) is one of the five Great Lakes of North America. It is the second-largest of the Great Lakes by volume () and depth () after Lake Superior and the third-largest by surface area (), after Lake Superior and Lake Huron. To the ...

. Copper was hammered until it became brittle, then heated so it could be worked further. In America, this technology is dated to about 4000–5000 BCE. The oldest gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

artifacts in the world come from the Bulgarian Varna Necropolis

The Varna Necropolis (), or Varna Cemetery, is a burial site in the western industrial zone of Varna, Bulgaria, Varna (approximately half a kilometre from Lake Varna and 4 km from the city centre), internationally considered one of the key a ...

and date from 4450 BCE.

Not all metal required fire to obtain it or work it. Isaac Asimov

Isaac Asimov ( ; – April 6, 1992) was an Russian-born American writer and professor of biochemistry at Boston University. During his lifetime, Asimov was considered one of the "Big Three" science fiction writers, along with Robert A. H ...

speculated that gold was the "first metal". His reasoning being, that, by its chemistry

Chemistry is the scientific study of the properties and behavior of matter. It is a physical science within the natural sciences that studies the chemical elements that make up matter and chemical compound, compounds made of atoms, molecules a ...

, it is found in nature as nuggets of pure gold. In other words, gold, as rare as it is, is sometimes found in nature as a native metal

A native metal is any metal that is found pure in its metallic form in nature. Metals that can be found as native element mineral, native deposits singly or in alloys include antimony, arsenic, bismuth, cadmium, chromium, cobalt, indium, iron, ma ...

. Some metals can also be found in meteor

A meteor, known colloquially as a shooting star, is a glowing streak of a small body (usually meteoroid) going through Earth's atmosphere, after being heated to incandescence by collisions with air molecules in the upper atmosphere,

creating a ...

s. Almost all other metals are found in ores, a mineral-bearing rock, that require heat or some other process to liberate the metal. Another feature of gold is that it is workable as it is found, meaning that no technology beyond a stone hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nail (fastener), nails into wood, to sh ...

and anvil

An anvil is a metalworking tool consisting of a large block of metal (usually Forging, forged or Steel casting, cast steel), with a flattened top surface, upon which another object is struck (or "worked").

Anvils are massive because the hi ...

is needed to work the metal. This is a result of gold's properties of malleability

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

and ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

. The earliest tool

A tool is an Physical object, object that can extend an individual's ability to modify features of the surrounding environment or help them accomplish a particular task. Although many Tool use by animals, animals use simple tools, only human bei ...

s were stone, bone

A bone is a rigid organ that constitutes part of the skeleton in most vertebrate animals. Bones protect the various other organs of the body, produce red and white blood cells, store minerals, provide structure and support for the body, ...

, wood, and sinew, all of which sufficed to work gold.

At some unknown time, the process of liberating metals from rock by heat became known, and rocks rich in copper, tin, and lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

came into demand. These ores were mined wherever they were recognized. Remnants of such ancient mines have been found all over Southwestern Asia. Metalworking was being carried out by the South Asia

South Asia is the southern Subregion#Asia, subregion of Asia that is defined in both geographical and Ethnicity, ethnic-Culture, cultural terms. South Asia, with a population of 2.04 billion, contains a quarter (25%) of the world's populatio ...

n inhabitants of Mehrgarh between 7000 and 3300 BCE.Possehl, Gregory L. (1996). ''Mehrgarh'' in ''Oxford Companion to Archaeology'', Brian Fagan (Ed.). Oxford University Press. The end of the beginning of metalworking occurs sometime around 6000 BCE when copper smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

became common in Southwestern Asia.

Ancient civilisations knew of seven metals. Here they are arranged in order of their oxidation potential (in volt

The volt (symbol: V) is the unit of electric potential, Voltage#Galvani potential vs. electrochemical potential, electric potential difference (voltage), and electromotive force in the International System of Units, International System of Uni ...

s):

*Iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

+0.44 V,

* Tin +0.14 V

*Lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

+0.13 V

*Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

−0.34 V

* Mercury −0.79 V

*Silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

−0.80 V

*Gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

−1.50 V.

The oxidation potential is important because it is one indicator of how tightly bound to the ore the metal is likely to be. As can be seen, iron is significantly higher than the other six metals while gold is dramatically lower than the six above it. Gold's low oxidation is one of the main reasons that gold is found in nuggets. These nuggets are relatively pure gold and are workable as they are found.

Copper ore, being relatively abundant, and tin ore became the next important substances in the story of metalworking. Using heat to smelt copper from ore, a great deal of copper was produced. It was used for both jewelry

Jewellery (or jewelry in American English) consists of decorative items worn for personal adornment such as brooches, ring (jewellery), rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the ...

and simple tools. However, copper by itself was too soft for tools requiring edges and stiffness. At some point tin was added into the molten copper and bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloid ...

was developed thereby. Bronze is an alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

of copper and tin. Bronze was an important advance because it had the edge-durability and stiffness that pure copper lacked. Until the advent of iron, bronze was the most advanced metal for tools and weapon

A weapon, arm, or armament is any implement or device that is used to deter, threaten, inflict physical damage, harm, or kill. Weapons are used to increase the efficacy and efficiency of activities such as hunting, crime (e.g., murder), law ...

s in common use (see Bronze Age

The Bronze Age () was a historical period characterised principally by the use of bronze tools and the development of complex urban societies, as well as the adoption of writing in some areas. The Bronze Age is the middle principal period of ...

for more detail).

Outside Southwestern Asia, these same advances and materials were being discovered and used around the world. People in China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

and Great Britain

Great Britain is an island in the North Atlantic Ocean off the north-west coast of continental Europe, consisting of the countries England, Scotland, and Wales. With an area of , it is the largest of the British Isles, the List of European ...

began using bronze with little time being devoted to copper. Japan

Japan is an island country in East Asia. Located in the Pacific Ocean off the northeast coast of the Asia, Asian mainland, it is bordered on the west by the Sea of Japan and extends from the Sea of Okhotsk in the north to the East China Sea ...

ese began the use of bronze and iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

almost simultaneously. In the Americas it was different. Although the peoples of the Americas knew of metals, it was not until the European colonisation that metalworking for tools and weapons became common. Jewelry and art were the principal uses of metals in the Americas prior to European influence.

About 2700 BCE, production of bronze was common in locales where the necessary materials could be assembled for smelting, heating, and working the metal. Iron was beginning to be smelted and began its emergence as an important metal for tools and weapons. The period that followed became known as the Iron Age

The Iron Age () is the final epoch of the three historical Metal Ages, after the Chalcolithic and Bronze Age. It has also been considered as the final age of the three-age division starting with prehistory (before recorded history) and progre ...

.

History

By the historical periods of the Pharaohs in

By the historical periods of the Pharaohs in Egypt

Egypt ( , ), officially the Arab Republic of Egypt, is a country spanning the Northeast Africa, northeast corner of Africa and Western Asia, southwest corner of Asia via the Sinai Peninsula. It is bordered by the Mediterranean Sea to northe ...

, the Vedic King

King is a royal title given to a male monarch. A king is an Absolute monarchy, absolute monarch if he holds unrestricted Government, governmental power or exercises full sovereignty over a nation. Conversely, he is a Constitutional monarchy, ...

s in India

India, officially the Republic of India, is a country in South Asia. It is the List of countries and dependencies by area, seventh-largest country by area; the List of countries by population (United Nations), most populous country since ...

, the Tribes of Israel, and the Maya civilization

The Maya civilization () was a Mesoamerican civilization that existed from antiquity to the early modern period. It is known by its ancient temples and glyphs (script). The Maya script is the most sophisticated and highly developed writin ...

in North America

North America is a continent in the Northern Hemisphere, Northern and Western Hemisphere, Western hemispheres. North America is bordered to the north by the Arctic Ocean, to the east by the Atlantic Ocean, to the southeast by South Ameri ...

, among other ancient populations, precious metal

Precious metals are rare, naturally occurring metallic chemical elements of high Value (economics), economic value. Precious metals, particularly the noble metals, are more corrosion resistant and less reactivity (chemistry), chemically reac ...

s began to have value attached to them. In some cases rules for ownership, distribution, and trade

Trade involves the transfer of goods and services from one person or entity to another, often in exchange for money. Economists refer to a system or network that allows trade as a market.

Traders generally negotiate through a medium of cr ...

were created, enforced, and agreed upon by the respective peoples. By the above periods metalworkers were very skilled at creating objects of adornment, religious artifacts, and trade instruments of precious metals

Precious metals are rare, naturally occurring metallic chemical elements of high economic value. Precious metals, particularly the noble metals, are more corrosion resistant and less chemically reactive than most elements. They are usual ...

(non-ferrous), as well as weaponry usually of ferrous metals and/or alloys. These skills were well executed. The techniques were practiced by artisans, blacksmith

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from #Other metals, other metals, by forging the metal, using tools to hammer, bend, and cut (cf. tinsmith). Blacksmiths produce objects such ...

s, atharvavedic practitioners, alchemists, and other categories of metalworkers around the globe. For example, the granulation technique was employed by numerous ancient cultures before the historic record shows people traveled to far regions to share this process. Metalsmith

A metalsmith or simply smith is a craftsperson fashioning useful items (for example, tools, kitchenware, tableware, jewelry, armor and weapons) out of various metals. Smithing is one of the oldest list of metalworking occupations, metalworking o ...

s today still use this and many other ancient techniques.

As time progressed, metal objects became more common, and ever more complex. The need to further acquire and work metals grew in importance. Skills related to extracting metal ores from the earth began to evolve, and metalsmiths became more knowledgeable. Metalsmiths became important members of society. Fates and economies of entire civilizations were greatly affected by the availability of metals and metalsmiths. The metalworker depends on the extraction of precious metals to make jewelry

Jewellery (or jewelry in American English) consists of decorative items worn for personal adornment such as brooches, ring (jewellery), rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the ...

, build more efficient electronics

Electronics is a scientific and engineering discipline that studies and applies the principles of physics to design, create, and operate devices that manipulate electrons and other Electric charge, electrically charged particles. It is a subfield ...

, and for industrial and technological applications from construction

Construction are processes involved in delivering buildings, infrastructure, industrial facilities, and associated activities through to the end of their life. It typically starts with planning, financing, and design that continues until the a ...

to shipping containers to rail, and air transport. Without metals, goods and services would cease to move around the globe on the scale we know today.

General processes

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools. Each of these categories contains various processes.

Prior to most operations, the metal must be marked out and/or measured, depending on the desired finished product.

'' Marking out'' (also known as layout) is the process of transferring a

Metalworking generally is divided into three categories: ''forming'', ''cutting'', and ''joining''. Most metal cutting is done by high speed steel tools or carbide tools. Each of these categories contains various processes.

Prior to most operations, the metal must be marked out and/or measured, depending on the desired finished product.

'' Marking out'' (also known as layout) is the process of transferring a design

A design is the concept or proposal for an object, process, or system. The word ''design'' refers to something that is or has been intentionally created by a thinking agent, and is sometimes used to refer to the inherent nature of something ...

or pattern to a workpiece and is the first step in the handcraft of metalworking. It is performed in many industries or hobbies, although in industry, the repetition eliminates the need to mark out every individual piece. In the metal trades area, marking out consists of transferring the engineer's plan

A plan is typically any diagram or list of steps with details of timing and resources, used to achieve an Goal, objective to do something. It is commonly understood as a modal logic, temporal set (mathematics), set of intended actions through wh ...

to the workpiece in preparation for the next step, machining or manufacture.

'' Calipers'' are hand tools designed to precisely measure the distance between two points. Most calipers have two sets of flat, parallel edges used for inner or outer diameter measurements. These calipers can be accurate to within one-thousandth of an inch (25.4 μm). Different types of calipers have different mechanisms for displaying the distance measured. Where larger objects need to be measured with less precision, a tape measure

A tape measure or measuring tape is a long, flexible ruler used to measure length or distance. It usually consists of a ribbon of cloth, plastic, fibreglass, or metal (usually - hard steel alloy) strip with linear measurement markings.

Types

Ta ...

is often used.

Casting

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

* Centrifugal casting

* Die casting

* Sand casting

* Shell casting

* Spin casting

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:

* Investment casting (called lost wax casting in art)

* Centrifugal casting

* Die casting

* Sand casting

* Shell casting

* Spin casting

Forming processes

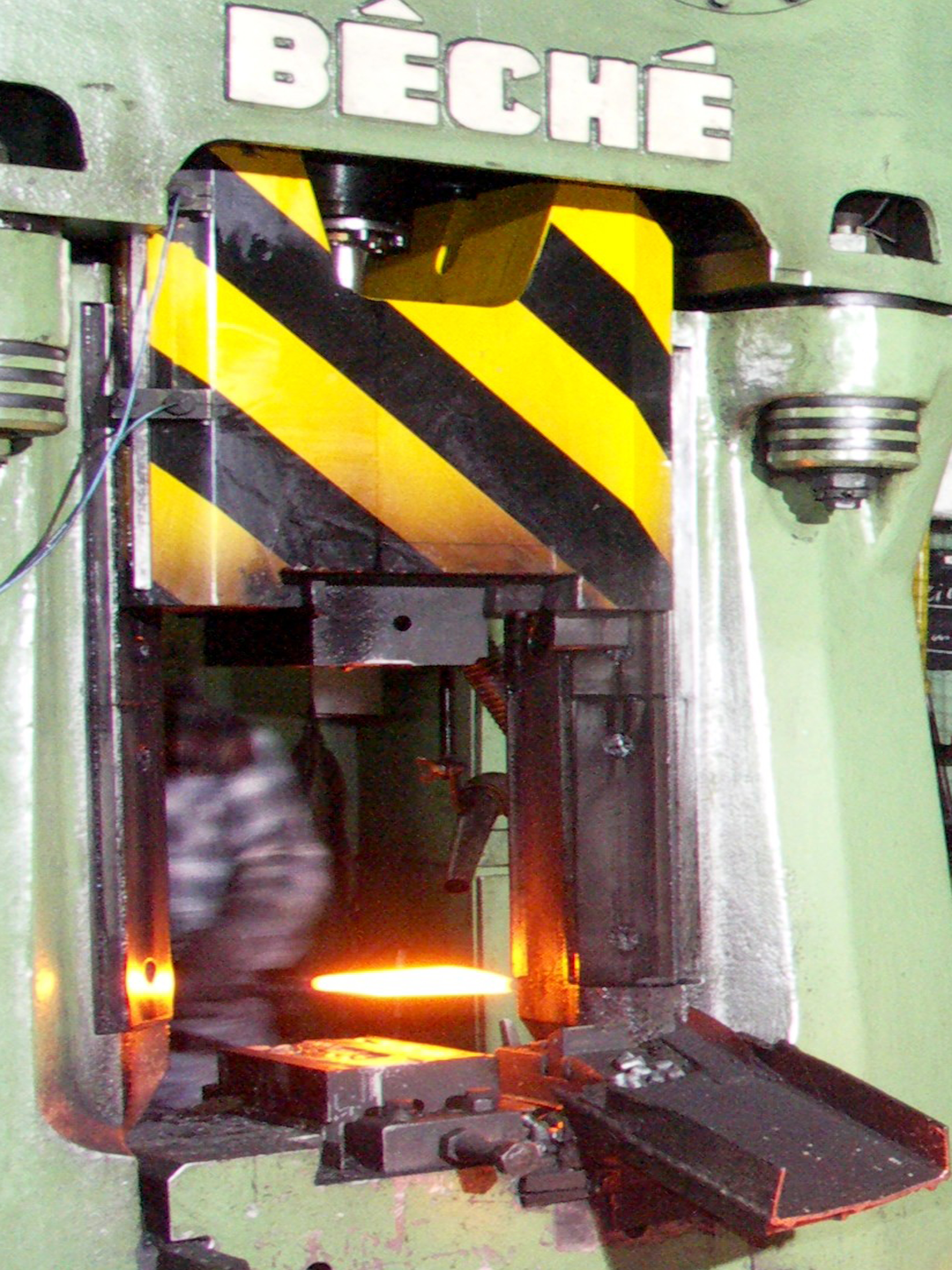

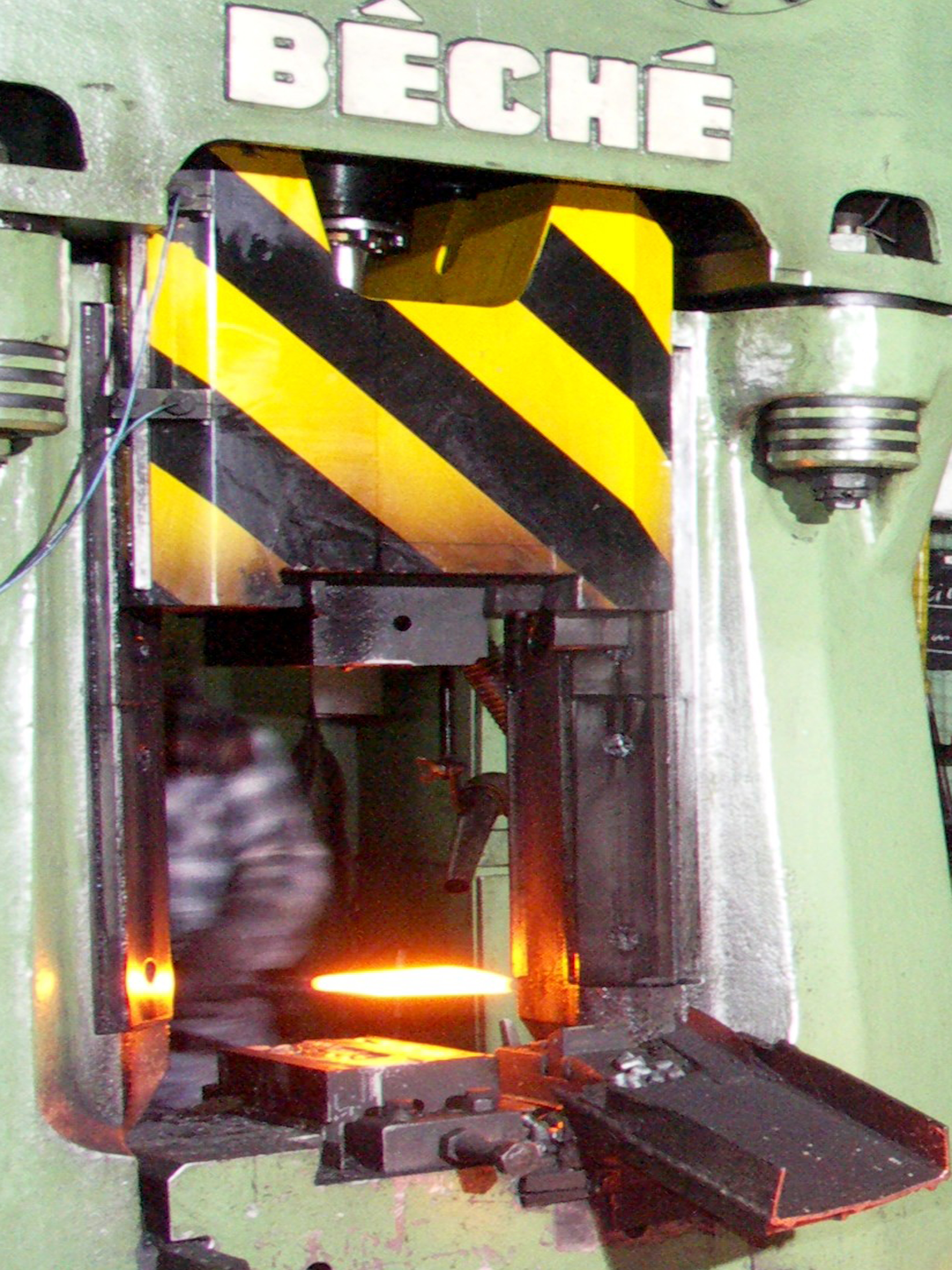

These ''forming'' processes modify metal or workpiece by deforming the object, that is, without removing any material. Forming is done with a system of mechanical forces and, especially for bulk metal forming, with heat.Bulk forming processes

Plastic

Plastics are a wide range of synthetic polymers, synthetic or Semisynthesis, semisynthetic materials composed primarily of Polymer, polymers. Their defining characteristic, Plasticity (physics), plasticity, allows them to be Injection moulding ...

deformation involves using heat or pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and eve ...

to make a workpiece more conductive to mechanical force. Historically, this and casting were done by blacksmiths, though today the process has been industrialized. In bulk metal forming, the workpiece is generally heated up.

* Cold sizing

* Extrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing pro ...

* Drawing

Drawing is a Visual arts, visual art that uses an instrument to mark paper or another two-dimensional surface, or a digital representation of such. Traditionally, the instruments used to make a drawing include pencils, crayons, and ink pens, some ...

* Forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classif ...

* Powder metallurgy

* Friction drilling

* Rolling

Rolling is a Motion (physics)#Types of motion, type of motion that combines rotation (commonly, of an Axial symmetry, axially symmetric object) and Translation (geometry), translation of that object with respect to a surface (either one or the ot ...

* Burnishing

Sheet (and tube) forming processes

These types of forming process involve the application of mechanical force at room temperature. However, some recent developments involve the heating of dies and/or parts. Advancements in automated metalworking technology have made progressive die stamping possible which is a method that can encompass punching, coining, bending and several other ways below that modify metal at less cost while resulting in less scrap. * Bending * Coining * Decambering * Deep drawing (DD) * Foldforming * Hydroforming (HF) * Hot metal gas forming * Hot press hardening * Incremental forming (IF) * Spinning, Shear forming or Flowforming * Planishing

* Raising

* Roll forming

* Roll bending

* Repoussé and chasing

* Rubber pad forming

* Shearing

* Stamping

* Superplastic forming (SPF)

* Wheeling using an English wheel (wheeling machine)

* Planishing

* Raising

* Roll forming

* Roll bending

* Repoussé and chasing

* Rubber pad forming

* Shearing

* Stamping

* Superplastic forming (SPF)

* Wheeling using an English wheel (wheeling machine)

Cutting processes

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or swarf and excess metal.

Cutting processes fall into one of three major categories:

* Chip producing processes most commonly known as

''Cutting'' is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. In woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or swarf and excess metal.

Cutting processes fall into one of three major categories:

* Chip producing processes most commonly known as machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

* Burning, a set of processes wherein the metal is cut by oxidizing a kerf to separate pieces of metal

* Miscellaneous specialty process, not falling easily into either of the above categories

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross section (geometry), cross-section in solid materials. The drill bit is usually a rotary Cutting tool (machining), cutting tool, often multi-point. The bit i ...

a hole in a metal part is the most common example of a chip producing process. Using an oxy-fuel cutting torch to separate a plate of steel into smaller pieces is an example of burning. Chemical milling is an example of a specialty process that removes excess material by the use of etching chemicals and masking chemicals.

There are many technologies available to cut metal, including:

*Manual technologies: saw, chisel, shear or snips

*Machine technologies: turning, milling, drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross section (geometry), cross-section in solid materials. The drill bit is usually a rotary Cutting tool (machining), cutting tool, often multi-point. The bit i ...

, grinding, sawing

*Welding/burning technologies: burning by laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radi ...

, oxy-fuel burning, and plasma

*Erosion technologies: by water jet, electric discharge, or abrasive flow machining.

*Chemical technologies: Photochemical machining

Cutting fluid or coolant is used where there is significant friction and heat at the cutting interface between a cutter such as a drill or an end mill and the workpiece. Coolant is generally introduced by a spray across the face of the tool and workpiece to decrease friction and temperature at the cutting tool/workpiece interface to prevent excessive tool wear. In practice there are many methods of delivering coolant.

Health effects

The use of an angle grinder in cutting is not preferred as large amounts of harmful sparks and fumes (and particulates) are generated when compared with using reciprocating saw orband saw

A bandsaw (also written band saw) is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumb ...

. Angle grinders produce sparks when cutting ferrous metals. They also produce shards cutting other materials.

Milling

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a drill), and a worktable that can move in multiple directions (usually two dimensions and y axisrelative to the workpiece). The spindle usually moves in the z axis. It is possible to raise the table (where the workpiece rests). Milling machines may be operated manually or under

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a drill), and a worktable that can move in multiple directions (usually two dimensions and y axisrelative to the workpiece). The spindle usually moves in the z axis. It is possible to raise the table (where the workpiece rests). Milling machines may be operated manually or under computer numerical control

Computer numerical control (CNC) or CNC machining is the Automation, automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched ...

(CNC), and can perform a vast number of complex operations, such as slot cutting, planing, drilling and threading, rabbeting, routing

Routing is the process of selecting a path for traffic in a Network theory, network or between or across multiple networks. Broadly, routing is performed in many types of networks, including circuit-switched networks, such as the public switched ...

, etc. Two common types of mills are the horizontal mill and vertical mill.

The pieces produced are usually complex 3D objects that are converted into x, y, and z coordinates that are then fed into the CNC machine and allow it to complete the tasks required. The milling machine can produce most parts in 3D, but some require the objects to be rotated around the x, y, or z coordinate axis (depending on the need). Tolerances come in a variety of standards, depending on the locale. In countries still using the imperial system, this is usually in the thousandths of an inch (unit known as ''thou''), depending on the specific machine. In many other European countries, standards following the ISO are used instead.

In order to keep both the bit and material cool, a high temperature coolant is used. In most cases the coolant is sprayed from a hose directly onto the bit and material. This coolant can either be machine or user controlled, depending on the machine.

Materials that can be milled range from aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

to stainless steel and almost everything in between. Each material requires a different speed on the milling tool and varies in the amount of material that can be removed in one pass of the tool. Harder materials are usually milled at slower speeds with small amounts of material removed. Softer materials vary, but usually are milled with a high bit speed.

The use of a milling machine adds costs that are factored into the manufacturing process. Each time the machine is used coolant is also used, which must be periodically added in order to prevent breaking bits. A milling bit must also be changed as needed in order to prevent damage to the material. Time is the biggest factor for costs. Complex parts can require hours to complete, while very simple parts take only minutes. This in turn varies the production time as well, as each part will require different amounts of time.

Safety is key with these machines. The bits are traveling at high speeds and removing pieces of usually scalding hot metal. The advantage of having a CNC milling machine is that it protects the machine operator.

Turning

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, George

Turning is a metal cutting process for producing a cylindrical surface with a single point tool. The workpiece is rotated on a spindle and the cutting tool is fed into it radially, axially or both. Producing surfaces perpendicular to the workpiece axis is called facing. Producing surfaces using both radial and axial feeds is called profiling.Schneider, GeorgeChapter 4: Turning Tools and Operations

American Machinist, January 2010 A ''lathe'' is a machine tool which spins a block or cylinder of material so that when abrasive, cutting, or deformation tools are applied to the workpiece, it can be shaped to produce an object which has

rotational symmetry

Rotational symmetry, also known as radial symmetry in geometry, is the property a shape (geometry), shape has when it looks the same after some rotation (mathematics), rotation by a partial turn (angle), turn. An object's degree of rotational s ...

about an axis of rotation. Examples of objects that can be produced on a lathe include candlestick holders, crankshafts, camshafts, and bearing mounts.

Lathes have four main components: the bed, the headstock, the carriage, and the tailstock. The bed is a precise & very strong base which all of the other components rest upon for alignment. The headstock's spindle secures the workpiece with a chuck, whose jaws (usually three or four) are tightened around the piece. The spindle rotates at high speed, providing the energy to cut the material. While historically lathes were powered by belts from a line shaft, modern examples uses electric motors. The workpiece extends out of the spindle along the axis of rotation above the flat bed. The carriage is a platform that can be moved, precisely and independently parallel and perpendicular to the axis of rotation. A hardened cutting tool

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force.

Implements commonly used for cutting are the knife and saw, or in medicine and science the scalpel an ...

is held at the desired height (usually the middle of the workpiece) by the toolpost. The carriage is then moved around the rotating workpiece, and the cutting tool gradually removes material from the workpiece. The tailstock can be slid along the axis of rotation and then locked in place as necessary. It may hold centers to further secure the workpiece, or cutting tools driven into the end of the workpiece.

Other operations that can be performed with a single point tool on a lathe are:

Chamfering: Cutting an angle on the corner of a cylinder.Parting: The tool is fed radially into the workpiece to cut off the end of a part.

Threading: A tool is fed along and across the outside or inside surface of rotating parts to produce external or internal threads.

Boring: A single-point tool is fed linearly and parallel to the axis of rotation to create a round hole.

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross section (geometry), cross-section in solid materials. The drill bit is usually a rotary Cutting tool (machining), cutting tool, often multi-point. The bit i ...

: Feeding the drill into the workpiece axially.Knurling: Uses a tool to produce a rough surface texture on the work piece. Frequently used to allow grip by hand on a metal part. Modern computer numerical control (CNC) lathes and (CNC) machining centres can do secondary operations like milling by using driven tools. When driven tools are used the work piece stops rotating and the driven tool executes the machining operation with a rotating cutting tool. The CNC machines use x, y, and z coordinates in order to control the turning tools and produce the product. Most modern day CNC lathes are able to produce most turned objects in 3D. Nearly all types of metal can be turned, although more time & specialist cutting tools are needed for harder workpieces.

Threading

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

There are many threading processes including: cutting threads with a tap or die, thread milling, single-point thread cutting, thread rolling, cold root rolling and forming, and thread grinding. A ''tap'' is used to cut a female thread on the inside surface of a pre-drilled hole, while a ''die'' cuts a male thread on a preformed cylindrical rod.

Grinding

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an abrasive wheel as the cutting device. This wheel can be made up of various sizes and types of stones,

''Grinding'' uses an abrasive process to remove material from the workpiece. A grinding machine is a machine tool used for producing very fine finishes, making very light cuts, or high precision forms using an abrasive wheel as the cutting device. This wheel can be made up of various sizes and types of stones, diamond

Diamond is a Allotropes of carbon, solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Diamond is tasteless, odourless, strong, brittle solid, colourless in pure form, a poor conductor of e ...

s or inorganic

An inorganic compound is typically a chemical compound that lacks carbon–hydrogen bondsthat is, a compound that is not an organic compound. The study of inorganic compounds is a subfield of chemistry known as '' inorganic chemistry''.

Inor ...

materials.

The simplest grinder is a bench grinder or a hand-held angle grinder, for deburring parts or cutting metal with a zip-disc.

Grinders have increased in size and complexity with advances in time and technology. From the old days of a manual toolroom grinder sharpening endmills for a production shop, to today's 30000 RPM CNC auto-loading manufacturing cell producing jet turbines, grinding processes vary greatly.

Grinders need to be very rigid machines to produce the required finish. Some grinders are even used to produce glass scales for positioning CNC machine axis. The common rule is the machines used to produce scales be 10 times more accurate than the machines the parts are produced for.

In the past grinders were used for finishing operations only because of limitations of tooling. Modern grinding wheel materials and the use of industrial diamonds or other man-made coatings (cubic boron nitride) on wheel forms have allowed grinders to achieve excellent results in production environments instead of being relegated to the back of the shop.

Modern technology has advanced grinding operations to include CNC controls, high material removal rates with high precision, lending itself well to aerospace applications and high volume production runs of precision components.

Filing

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a machinist to work to fine tolerances and was the hallmark of the craft. Today filing is rarely used as a production technique in industry, though it remains as a common method of deburring.

''Filing'' is combination of grinding and saw tooth cutting using a file. Prior to the development of modern machining equipment it provided a relatively accurate means for the production of small parts, especially those with flat surfaces. The skilled use of a file allowed a machinist to work to fine tolerances and was the hallmark of the craft. Today filing is rarely used as a production technique in industry, though it remains as a common method of deburring.

Other

Broaching is a machining operation used to cut keyways into shafts. Electron beam machining (EBM) is a machining process where high-velocity electrons are directed toward a work piece, creating heat and vaporizing the material. Ultrasonic machining uses ultrasonic vibrations to machine very hard or brittle materials.Joining processes

Welding

''Welding'' is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, but sometimes pressure is used in conjunction with heat, or by itself, to produce the weld. Many different energy sources can be used for welding, including a gas flame, anelectric arc

An electric arc (or arc discharge) is an electrical breakdown of a gas that produces a prolonged electrical discharge. The electric current, current through a normally Electrical conductance, nonconductive medium such as air produces a plasma ( ...

, a laser, an electron

The electron (, or in nuclear reactions) is a subatomic particle with a negative one elementary charge, elementary electric charge. It is a fundamental particle that comprises the ordinary matter that makes up the universe, along with up qua ...

beam, friction, and ultrasound

Ultrasound is sound with frequency, frequencies greater than 20 Hertz, kilohertz. This frequency is the approximate upper audible hearing range, limit of human hearing in healthy young adults. The physical principles of acoustic waves apply ...

. While often an industrial process, welding can be done in many different environments, including open air, underwater and in space

Space is a three-dimensional continuum containing positions and directions. In classical physics, physical space is often conceived in three linear dimensions. Modern physicists usually consider it, with time, to be part of a boundless ...

. Regardless of location, however, welding remains dangerous, and precautions must be taken to avoid burns, electric shock

An electrical injury (electric injury) or electrical shock (electric shock) is damage sustained to the skin or internal organs on direct contact with an electric current.

The injury depends on the Current density, density of the current, tissu ...

, poisonous fumes, and overexposure to ultraviolet light.

Brazing

''Brazing'' is a joining process in which a filler metal is melted and drawn into acapillary

A capillary is a small blood vessel, from 5 to 10 micrometres in diameter, and is part of the microcirculation system. Capillaries are microvessels and the smallest blood vessels in the body. They are composed of only the tunica intima (the inn ...

formed by the assembly of two or more work pieces. The filler metal reacts metallurgically with the workpieces and solidifies in the capillary, forming a strong joint. Unlike welding, the work piece is not melted. Brazing is similar to soldering, but occurs at temperatures in excess of . Brazing has the advantage of producing less thermal stresses than welding, and brazed assemblies tend to be more ductile than weldments because alloying elements can not segregate and precipitate.

Brazing techniques include, flame brazing, resistance brazing, furnace brazing, diffusion brazing, inductive brazing and vacuum brazing.

Soldering

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

''Soldering'' is a joining process that occurs at temperatures below . It is similar to brazing in the way that a filler is melted and drawn into a capillary to form a joint, although at a lower temperature. Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint.

Riveting

''Riveting'' is one of the most ancient metalwork joining processes. Its use declined markedly during the second half of the 20th century, but it still retains important uses in industry and construction, and in artisan crafts such asjewellery

Jewellery (or jewelry in American English) consists of decorative items worn for personal adornment such as brooches, ring (jewellery), rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the ...

, medieval armouring and metal couture in the early 21st century. The earlier use of rivets is being superseded by improvements in welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Co ...

and component fabrication techniques.

A rivet is essentially a two-headed and unthreaded bolt which holds two other pieces of metal together. Holes are drilled or punched through the two pieces of metal to be joined. The holes being aligned, a rivet is passed through the holes and permanent heads are formed onto the ends of the rivet utilizing hammers and forming dies (by either cold working or hot working

In metallurgy, hot working refers to processes where metals are plastically deformed above their recrystallization temperature. Being above the recrystallization temperature allows the material to recrystallize during deformation. This is impo ...

).

Rivets are commonly purchased with one head already formed.

When it is necessary to remove rivets, one of the rivet's heads is sheared off with a cold chisel. The rivet is then driven out with a hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nail (fastener), nails into wood, to sh ...

and punch.

Mechanical fixings

This includes screws, as well as bolts. This is often used as it requires relatively little specialist equipment, and are therefore often used in flat-pack furniture. It can also be used when a metal is joined to another material (such as wood) or a particular metal does not weld well (such asaluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

). This can be done to directly join metals, or with an intermediate material such as nylon. While often weaker than other methods such as welding or brazing, the metal can easily be removed and therefore reused or recycled. It can also be done in conjunction with an epoxy or glue, reverting its ecological benefits.

Associated processes

While these processes are not primary metalworking processes, they are often performed before or after metalworking processes.Heat treatment

Metals can be heat treated to alter the properties of strength, ductility, toughness, hardness or resistance to corrosion. Common heat treatment processes include annealing, precipitation hardening, quenching, and tempering: * annealing softens the metal by allowing recovery of cold work and grain growth. * quenching can be used to harden alloy steels, or in precipitation hardenable alloys, to trap dissolved solute atoms in solution. * tempering will cause the dissolved alloying elements to precipitate, or in the case of quenched steels, improve impact strength and ductile properties. Often, mechanical and thermal treatments are combined in what is known as thermo-mechanical treatments for better properties and more efficient processing of materials. These processes are common to high alloy special steels, super alloys and titanium alloys.Plating

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the redox, reduction of cations of that metal by means of a direct current, direct electric cur ...

is a common surface-treatment technique. It involves bonding a thin layer of another metal such as gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

, silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

, chromium or zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

to the surface of the product by hydrolysis. It is used to reduce corrosion, create abrasion resistance and improve the product's aesthetic appearance. Plating can even change the properties of the original part including conductivity, heat dissipation or structural integrity. There are four main electroplating methods to ensure proper coating and cost effectiveness per product: mass plating, rack plating, continuous plating and line plating.

Thermal spraying

Thermal spraying techniques are another popular finishing option, and often have better high temperature properties than electroplated coatings due to the thicker coating. The four main thermal spray processes include electric wire arc spray, flame (oxy acetylene combustion) spray, plasma spray and high velocity oxy fuel (HVOF) spray.See also

* Bronze and brass ornamental work * Chip formation * Heavy metals *Lead poisoning

Lead poisoning, also known as plumbism and saturnism, is a type of metal poisoning caused by lead in the body. Symptoms may include abdominal pain, constipation, headaches, irritability, memory problems, infertility, numbness and paresthesia, t ...

* List of metalworking occupations

* Metal swarf

*Metal testing

Metal testing is a process or procedure used to check composition of an unknown metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity ...

* Metalworking hand tool

* Occupational dust exposure

* Particulates

*Power tool

A power tool is a tool that is actuator, actuated by an additional engine, power source and mechanism (engineering), mechanism other than the solely manual labour, manual labor used with hand tools. The most common types of power tools use electric ...

* Stone mould

General:

* List of manufacturing processes

* Timeline of materials technology

References

External links

What's the Best Way to Cut Thick Steel?

Schneider, George. "Chapter 1: Cutting Tool Materials", ''American Machinist'', October, 2009

Schneider, George. "Cutting Tool Applications: Chapter 2 Metal Removal Methods", ''American Machinist'', November, 2009

Videos about metalworking

published by Institut für den Wissenschaftlichen Film. Available in the AV-Portal of the German National Library of Science and Technology.

Evidences of Metalworking History Reference

* {{Authority control Metal industry M M 9th-millennium BC establishments Articles containing video clips