|

Raising (metalworking)

Raising is a metalworking technique whereby sheet metal is formed over a solid object by repeated "courses" of hammering and Annealing (metallurgy), annealing. A sheet metal worker is often required to raise, or bump, the work into form from the flat metal by means of a raising hammer and raising block. The raising block is made from substance giving resistance to the blows. A modern term is ''synclastic raising'', the dominant curves of the object being forged are at right angles and move in the same direction; as in a bowl. This results in a surface possessing elliptic geometry. ''Anticlastic raising'', on the other hand, refers to shaping an object where the dominant axes move in opposite directions; a familiar example of this is a potato crisp. This results in a surface possessing hyperbolic geometry. See also * Planishing * Sinking (metalworking) References Bibliography *Finegold, Rupert and William Seitz. ''Silversmithing''. Krause; 1983. Metal forming {{met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper Vase

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable metallic form ( native metals). This led to very early human use in several regions, from circa 8000 BC. Thousands of years later, it was the first metal to be smelted from sulfide ores, circa 5000 BC; the first metal to be cast into a shape in a mold, c. 4000 BC; and the first metal to be purposely alloyed with another metal, tin, to create bronze, c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bracelet Modern Anticlastic

A bracelet is an article of jewellery that is worn around the wrist. Bracelets may serve different uses, such as being worn as an ornament. When worn as ornaments, bracelets may have a supportive function to hold other items of decoration, such as charms. Medical and identity information are marked on some bracelets, such as allergy bracelets, hospital patient-identification tags, and bracelet tags for newborn babies. Bracelets may be worn to signify a certain phenomenon, such as breast cancer awareness, or for religious/cultural purposes. If a bracelet is a single, inflexible loop, it is often called a '' bangle''. When it is worn around the ankle it is called an ''ankle bracelet'' or '' anklet''. A ''boot bracelet'' is used to decorate boots. Bracelets can be manufactured from metal, leather, cloth, plastic, bead or other materials, and jewelry bracelets sometimes contain jewels, rocks, wood, shells, crystals, metal, or plastic hoops, pearls and many more materials. Orig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Cop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annealing (metallurgy)

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooling. In annealing, atoms migrate in the crystal lattice and the number of dislocations decreases, leading to a change in ductility and hardness. As the material cools it recrystallizes. For many alloys, including carbon steel, the crystal grain size and phase composition, which ultimately determine the material properties, are dependent on the heating rate and cooling rate. Hot working or cold working after the annealing process alters the metal structure, so further heat treatments may be used to achieve the properties required. With knowledge of the composition and phase diagram, heat treatment can be used to ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elliptic Geometry

Elliptic geometry is an example of a geometry in which Euclid's parallel postulate does not hold. Instead, as in spherical geometry, there are no parallel lines since any two lines must intersect. However, unlike in spherical geometry, two lines are usually assumed to intersect at a single point (rather than two). Because of this, the elliptic geometry described in this article is sometimes referred to as ''single elliptic geometry'' whereas spherical geometry is sometimes referred to as ''double elliptic geometry''. The appearance of this geometry in the nineteenth century stimulated the development of non-Euclidean geometry generally, including hyperbolic geometry. Elliptic geometry has a variety of properties that differ from those of classical Euclidean plane geometry. For example, the sum of the interior angles of any triangle is always greater than 180°. Definitions In elliptic geometry, two lines perpendicular to a given line must intersect. In fact, the perpendiculars o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Potato Crisp

A potato chip (North American English; often just chip) or crisp (British and Irish English) is a thin slice of potato that has been either deep fried, baked, or air fried until crunchy. They are commonly served as a snack, side dish, or appetizer. The basic chips are cooked and salted; additional varieties are manufactured using various flavorings and ingredients including herbs, spices, cheeses, other natural flavors, artificial flavors, and additives. Potato chips form a large part of the snack food and convenience food market in Western countries. The global potato chip market generated total revenue of US$16.49 billion in 2005. This accounted for 35.5% of the total savory snacks market in that year ($46.1 billion). History The earliest known recipe for something similar to today's potato chips is in William Kitchiner's book '' The Cook's Oracle'' published in 1817, which was a bestseller in the United Kingdom and the United States. The 1822 edition's recipe for "Pota ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hyperbolic Geometry

In mathematics, hyperbolic geometry (also called Lobachevskian geometry or Bolyai– Lobachevskian geometry) is a non-Euclidean geometry. The parallel postulate of Euclidean geometry is replaced with: :For any given line ''R'' and point ''P'' not on ''R'', in the plane containing both line ''R'' and point ''P'' there are at least two distinct lines through ''P'' that do not intersect ''R''. (Compare the above with Playfair's axiom, the modern version of Euclid's parallel postulate.) Hyperbolic plane geometry is also the geometry of pseudospherical surfaces, surfaces with a constant negative Gaussian curvature. Saddle surfaces have negative Gaussian curvature in at least some regions, where they locally resemble the hyperbolic plane. A modern use of hyperbolic geometry is in the theory of special relativity, particularly the Minkowski model. When geometers first realised they were working with something other than the standard Euclidean geometry, they described their geomet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Planishing

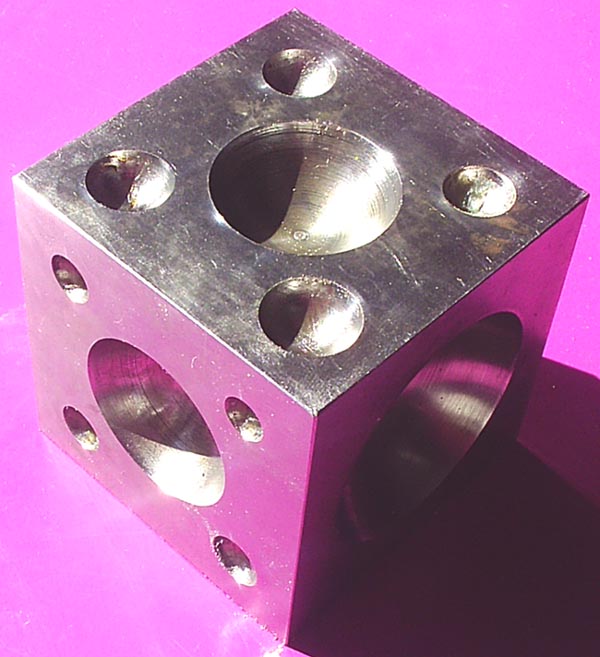

Planishing (from the Latin ''planus'', "flat") is a metalworking technique that involves finishing the surface by finely shaping and smoothing sheet metal. Process This is done by hammering with a planishing panel hammer or slapper file against a shaped surface called a ''planishing stake'' that is held in a vise or a mounting hole in a blacksmith's beak anvil, or against hand-held, shaped, metal tools that are known as ''dollies'' or ''anvils''. The shape of the stake or dolly has to match the desired work piece contour, and so they come in a variety of complex shapes. Alternatively, planishing may be done by the use of an English wheel. After approximately forming a metal object, by stretching with techniques such as sinking and raising, and then shaping and smoothing an object, metal workers use planishing for surface finishing. Planishing is a hand-driven process used in auto body repair and sheet metal craft work such as medieval armour production. Tools Common tools used fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sinking (metalworking)

Sinking, also known as doming, dishing or dapping, is a metalworking technique whereby flat sheet metal is formed into a non-flat object by hammering it into a concave indentation. While sinking is a relatively fast method, it results in stretching and therefore thinning the metal, risking failure of the metal if it is "sunk" too far. Sinking is used in the manufacture of many items, from jewellery to plate armour. See also * Planishing Planishing (from the Latin ''planus'', "flat") is a metalworking technique that involves finishing the surface by finely shaping and smoothing sheet metal. Process This is done by hammering with a planishing panel hammer or slapper file against a ... References * Rupert Finegold and William Seitz. ''Silversmithing''. Krause; 1983. * Price, Brian R. ''Techniques of Medieval Armour Reproduction''. Boulder, CO: Paladin Press, 2000. {{Metalworking navbox, formopen Metal forming Jewellery making ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |