|

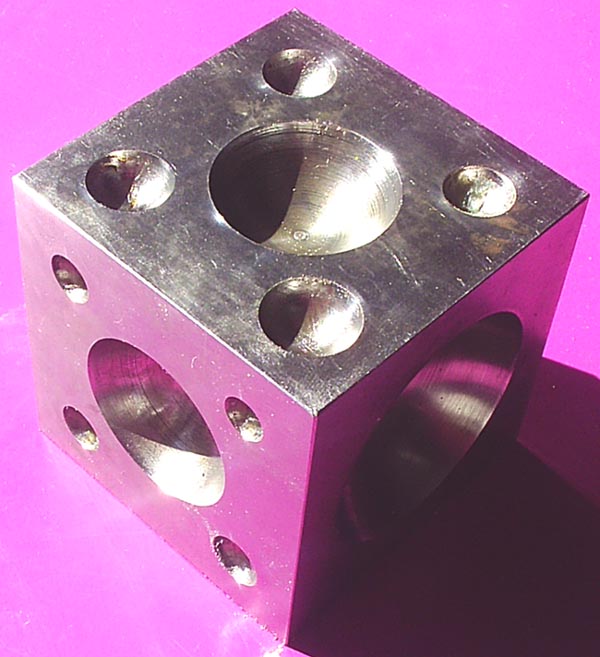

Sinking (metalworking)

Sinking, also known as doming, dishing or dapping, is a metalworking technique whereby flat sheet metal is formed into a non-flat object by hammering it into a concave indentation. While sinking is a relatively fast method, it results in stretching and therefore thinning the metal, risking failure of the metal if it is "sunk" too far. Sinking is used in the manufacture of many items, from jewellery to plate armour Plate armour is a historical type of personal body armour made from bronze, iron, or steel plates, culminating in the iconic suit of armour entirely encasing the wearer. Full plate steel armour developed in Europe during the Late Middle Ages, .... See also * Planishing References * Rupert Finegold and William Seitz. ''Silversmithing''. Krause; 1983. * Price, Brian R. ''Techniques of Medieval Armour Reproduction''. Boulder, CO: Paladin Press, 2000. {{Metalworking navbox, formopen Metal forming Jewellery making ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel Doming Block

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flat Steel Doming Block

Flat or flats may refer to: Architecture * Flat (housing), an apartment in the United Kingdom, Ireland, Australia and other Commonwealth countries Arts and entertainment * Flat (music), a symbol () which denotes a lower pitch * Flat (soldier), a two-dimensional toy soldier made of tin or plastic * Flat (theatre), a flat piece of theatrical scenery * Flat, a leading type of wordplay, as identified by the National Puzzlers' League * ''Flat!'' (2010), an Indian film * Flats (band), an English band * Flats (comics), the first stage in the comic coloring process Footwear * Flats, footwear which is not high-heeled * Ballet flats, derived from ballet shoes, for casual wear as well as dancing * Ballet shoes (also known as ballet slippers), often referred to as "flats" or "flat shoes" * Racing flats, lightweight shoes used primarily for running a race Geography Landforms * Flat (landform), a relatively level area within a region of greater relief Bodies of water * Flat, a shallow wat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as with a forge), or to crush rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship (as with a gong). Hammering is use of a hammer in its strike capacity, as opposed to prying with a secondary claw or grappling with a secondary hook. Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward planar arc—downward to add kinetic energy to the impact—pivoting mainly around the shoulder and elbow, with a small but brisk wrist rotation shortly before impact; for extreme i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

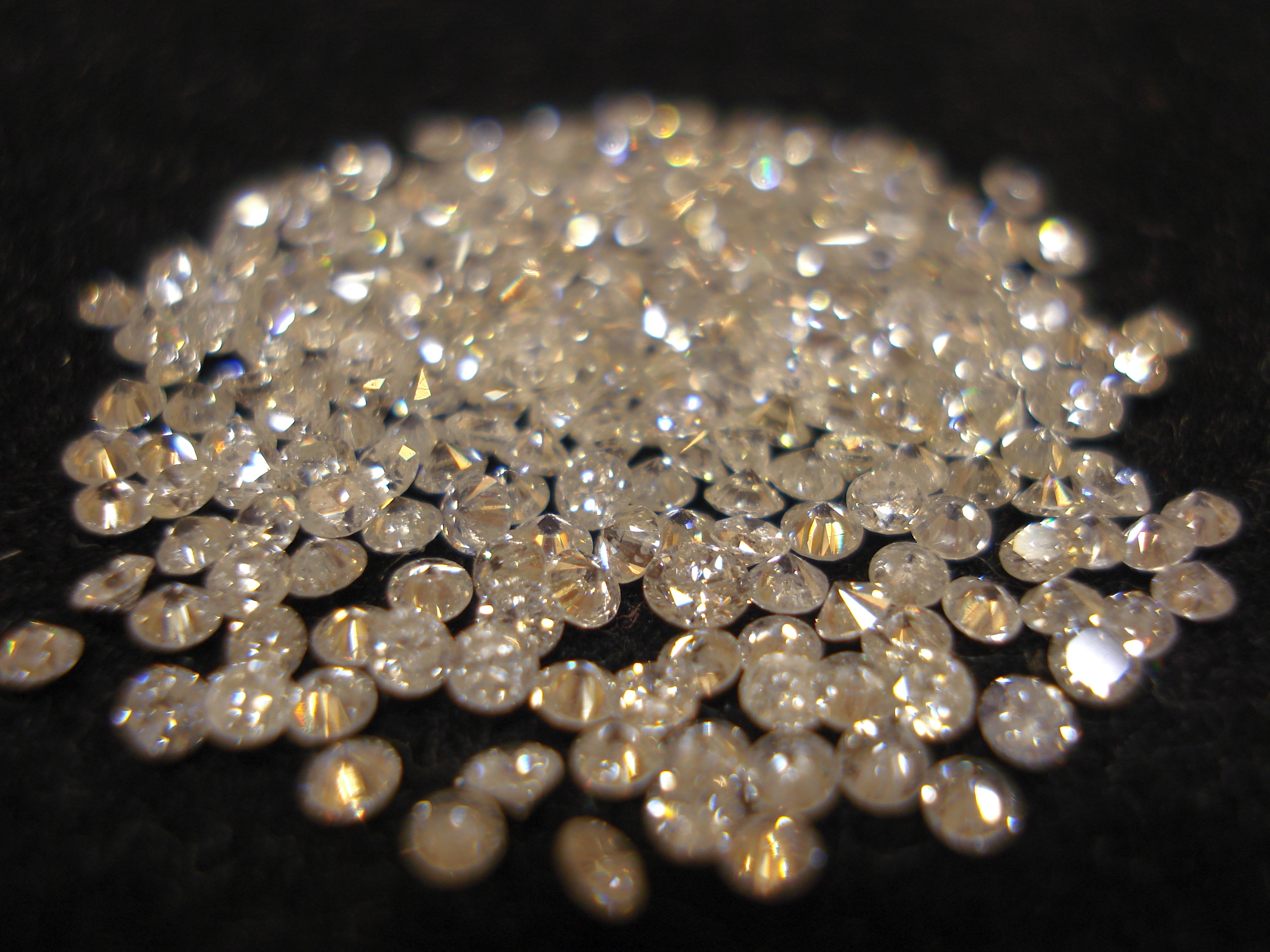

Jewellery

Jewellery ( UK) or jewelry ( U.S.) consists of decorative items worn for personal adornment, such as brooches, rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the clothes. From a western perspective, the term is restricted to durable ornaments, excluding flowers for example. For many centuries metal such as gold often combined with gemstones, has been the normal material for jewellery, but other materials such as glass, shells and other plant materials may be used. Jewellery is one of the oldest types of archaeological artefact – with 100,000-year-old beads made from '' Nassarius'' shells thought to be the oldest known jewellery.Study reveals 'oldest jewellery' , '' |

Plate Armour

Plate armour is a historical type of personal body armour made from bronze, iron, or steel plates, culminating in the iconic suit of armour entirely encasing the wearer. Full plate steel armour developed in Europe during the Late Middle Ages, especially in the context of the Hundred Years' War, from the coat of plates worn over mail suits during the 14th century. In Europe, plate armour reached its peak in the late 15th and early 16th centuries. The full suit of armour, also referred to as a panoply, is thus a feature of the very end of the Middle Ages and the Renaissance period. Its popular association with the " medieval knight” is due to the specialised jousting armour which developed in the 16th century. Full suits of Gothic plate armour were worn on the battlefields of the Burgundian and Italian Wars. The most heavily armoured troops of the period were heavy cavalry, such as the gendarmes and early cuirassiers, but the infantry troops of the Swiss mercenaries a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Planishing

Planishing (from the Latin ''planus'', "flat") is a metalworking technique that involves finishing the surface by finely shaping and smoothing sheet metal. Process This is done by hammering with a planishing panel hammer or slapper file against a shaped surface called a ''planishing stake'' that is held in a vise or a mounting hole in a blacksmith's beak anvil, or against hand-held, shaped, metal tools that are known as ''dollies'' or ''anvils''. The shape of the stake or dolly has to match the desired work piece contour, and so they come in a variety of complex shapes. Alternatively, planishing may be done by the use of an English wheel. After approximately forming a metal object, by stretching with techniques such as sinking and raising, and then shaping and smoothing an object, metal workers use planishing for surface finishing. Planishing is a hand-driven process used in auto body repair and sheet metal Sheet metal is metal formed into thin, flat pieces, usually by an indu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brian R

Brian (sometimes spelled Bryan in English) is a male given name of Irish and Breton origin, as well as a surname of Occitan origin. It is common in the English-speaking world. It is possible that the name is derived from an Old Celtic word meaning "high" or "noble". For example, the element ''bre'' means "hill"; which could be transferred to mean "eminence" or "exalted one". The name is quite popular in Ireland, on account of Brian Boru, a 10th-century High King of Ireland. The name was also quite popular in East Anglia during the Middle Ages. This is because the name was introduced to England by Bretons following the Norman Conquest. Bretons also settled in Ireland along with the Normans in the 12th century, and 'their' name was mingled with the 'Irish' version. Also, in the north-west of England, the 'Irish' name was introduced by Scandinavian settlers from Ireland. Within the Gaelic speaking areas of Scotland, the name was at first only used by professional families of Iri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Forming

Forming, metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed. Characteristics Metal forming tends to have more uniform characteristics across its subprocesses than its contemporary processes, cutting and joining. On the industrial scale, forming is characterized by: * Very high loads and stresses required, between 50 and () * Large, heavy, and expensive machinery in order to accommodate such high stresses and loads * Production runs with many parts, to maximize the economy of production and compensate for the expense of the machine tools Forming processes Forming processes tend to be categorised by differences in effective stresses. These categories and descriptions are highly simplifi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |