Metallurgist on:

[Wikipedia]

[Google]

[Amazon]

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of

The earliest recorded metal employed by humans appears to be

The earliest recorded metal employed by humans appears to be  In the Near East, about 3,500 BC, it was discovered that by combining copper and tin, a superior metal could be made, an

In the Near East, about 3,500 BC, it was discovered that by combining copper and tin, a superior metal could be made, an

Much effort has been placed on understanding

Much effort has been placed on understanding

*

*

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing, precipitation strengthening, quenching, and tempering:

* Annealing process softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that, when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal.

*

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing, precipitation strengthening, quenching, and tempering:

* Annealing process softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that, when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal.

*

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or

metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typi ...

lic elements

Element or elements may refer to:

Science

* Chemical element, a pure substance of one type of atom

* Heating element, a device that generates heat by electrical resistance

* Orbital elements, parameters required to identify a specific orbit of ...

, their inter-metallic compounds, and their mixtures, which are known as alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

s.

Metallurgy encompasses both the science

Science is a systematic endeavor that Scientific method, builds and organizes knowledge in the form of Testability, testable explanations and predictions about the universe.

Science may be as old as the human species, and some of the earli ...

and the technology

Technology is the application of knowledge to reach practical goals in a specifiable and reproducible way. The word ''technology'' may also mean the product of such an endeavor. The use of technology is widely prevalent in medicine, scie ...

of metals; that is, the way in which science is applied to the production of metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typi ...

s, and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft

A craft or trade is a pastime or an occupation that requires particular skills and knowledge of skilled work. In a historical sense, particularly the Middle Ages and earlier, the term is usually applied to people occupied in small scale pr ...

of metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale ...

. Metalworking relies on metallurgy in a similar manner to how medicine

Medicine is the science and Praxis (process), practice of caring for a patient, managing the diagnosis, prognosis, Preventive medicine, prevention, therapy, treatment, Palliative care, palliation of their injury or disease, and Health promotion ...

relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist.

The science of metallurgy is further subdivided into two broad categories: chemical metallurgy Chemical metallurgy is the science of obtaining metals from their concentrates, semi products, recycled bodies and solutions, and of considering reactions of metals with an approach of disciplines belonging to chemistry. As such, it involves react ...

and physical metallurgy {{unreferenced, date=April 2017

Physical metallurgy is one of the two main branches of the scientific approach to metallurgy, which considers in a systematic way the physical properties of metals and alloys. It is basically the fundamentals and ap ...

. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include mineral processing

In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores.

History

Before the advent of heavy machinery the raw ore was broken up using ...

, the extraction of metals, thermodynamics

Thermodynamics is a branch of physics that deals with heat, work, and temperature, and their relation to energy, entropy, and the physical properties of matter and radiation. The behavior of these quantities is governed by the four laws o ...

, electrochemistry

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference, as a measurable and quantitative phenomenon, and identifiable chemical change, with the potential difference as an outc ...

, and chemical degradation (corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

). In contrast, physical metallurgy {{unreferenced, date=April 2017

Physical metallurgy is one of the two main branches of the scientific approach to metallurgy, which considers in a systematic way the physical properties of metals and alloys. It is basically the fundamentals and ap ...

focuses on the mechanical properties of metals, the physical properties of metals, and the physical performance of metals. Topics studied in physical metallurgy include crystallography

Crystallography is the experimental science of determining the arrangement of atoms in crystalline solids. Crystallography is a fundamental subject in the fields of materials science and solid-state physics (condensed matter physics). The wo ...

, material characterization

Characterization, when used in materials science, refers to the broad and general process by which a material's structure and properties are probed and measured. It is a fundamental process in the field of materials science, without which no scie ...

, mechanical metallurgy, phase transformations, and failure mechanisms.

Historically, metallurgy has predominately focused on the production of metals. Metal production begins with the processing of ores to extract the metal, and includes the mixture of metals to make alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

s. Metal alloys are often a blend of at least two different metallic elements. However, non-metallic elements are often added to alloys in order to achieve properties suitable for an application. The study of metal production is subdivided into ferrous metallurgy

Ferrous metallurgy is the metallurgy of iron and its alloys. The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, were made from meteoritic iron-nickel. It is not known when or where the smelting of iron from ...

(also known as ''black metallurgy'') and non-ferrous metallurgy

In metallurgy, non-ferrous metals are metals or alloys that do not contain iron (allotropes of iron, ferrite, and so on) in appreciable amounts.

Generally more costly than ferrous metals, non-ferrous metals are used because of desirable proper ...

(also known as ''colored metallurgy'').

Ferrous metallurgy involves processes and alloys based on iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in ...

, while non-ferrous metallurgy involves processes and alloys based on other metals. The production of ferrous metals accounts for 95% of world metal production.

Modern metallurgists work in both emerging and traditional areas as part of an interdisciplinary team alongside material scientists and other engineers. Some traditional areas include mineral processing, metal production, heat treatment, failure analysis Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability.

According to Bloch and Geitner, ”machinery failures reveal a reaction chain o ...

, and the joining of metals (including welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as br ...

, brazing, and soldering

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal ( solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not in ...

). Emerging areas for metallurgists include nanotechnology

Nanotechnology, also shortened to nanotech, is the use of matter on an atomic, molecular, and supramolecular scale for industrial purposes. The earliest, widespread description of nanotechnology referred to the particular technological goal o ...

, superconductors

Superconductivity is a set of physical properties observed in certain materials where electrical resistance vanishes and magnetic flux fields are expelled from the material. Any material exhibiting these properties is a superconductor. Unlike ...

, composites, biomedical materials, electronic materials

A semiconductor is a material which has an electrical conductivity value falling between that of a conductor, such as copper, and an insulator, such as glass. Its resistivity falls as its temperature rises; metals behave in the opposite way. ...

(semiconductors) and surface engineering

Surface engineering is the sub-discipline of materials science which deals with the surface of solid matter. It has applications to chemistry, mechanical engineering, and electrical engineering (particularly in relation to semiconductor manufac ...

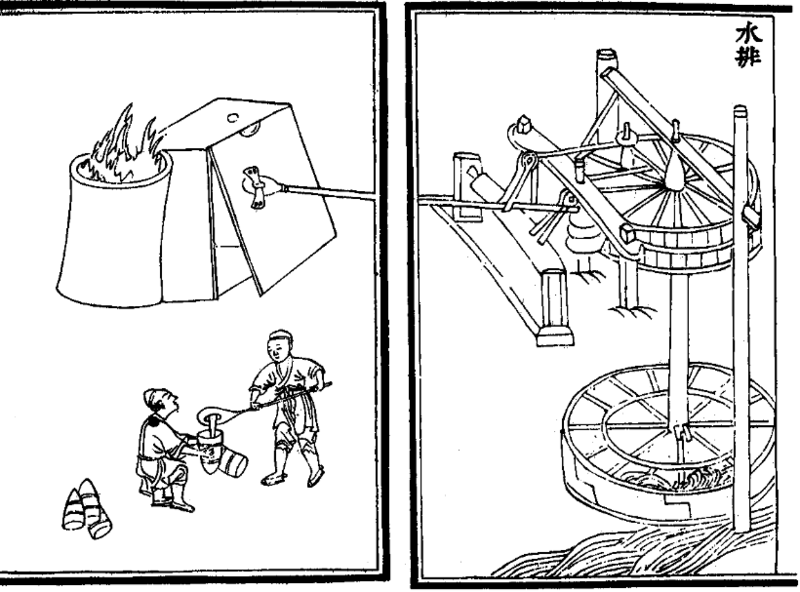

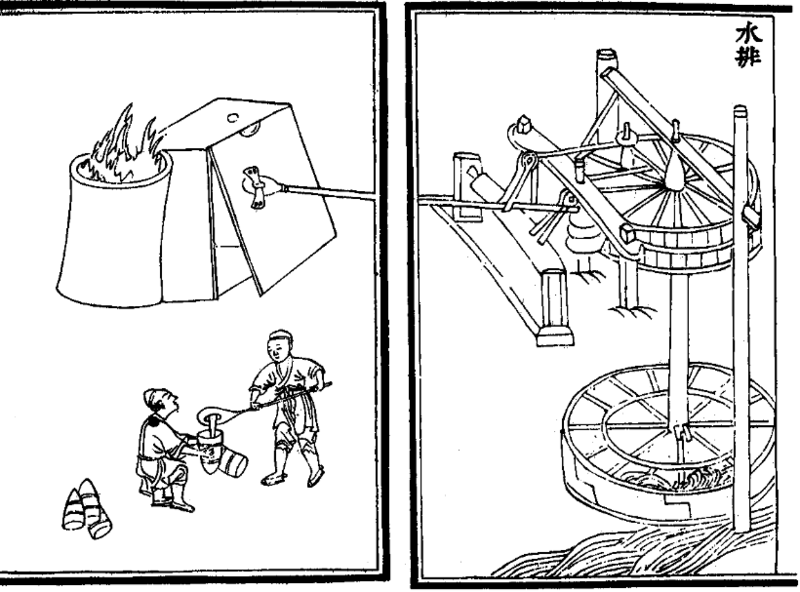

. Many applications, practices, and devices associated or involved in metallurgy were established in ancient China, such as the innovation of the blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric p ...

, cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impu ...

, hydraulic

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counter ...

-powered trip hammer

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, decorticating and polishing of grain in agriculture. In mining, trip hammers were used for crushing metal ...

s, and double acting piston bellows

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtig ...

.R. F. Tylecote (1992) ''A History of Metallurgy'' Robert K.G. Temple (2007). ''The Genius of China: 3,000 Years of Science, Discovery, and Invention'' (3rd ed.). London: André Deutsch. pp. 44–56. .

Etymology and pronunciation

''Metallurgy'' derives from theAncient Greek

Ancient Greek includes the forms of the Greek language used in ancient Greece and the ancient world from around 1500 BC to 300 BC. It is often roughly divided into the following periods: Mycenaean Greek (), Dark Ages (), the Archaic p ...

, , "worker in metal", from , , "mine, metal" + , , "work" The word was originally an alchemist

Alchemy (from Arabic: ''al-kīmiyā''; from Ancient Greek: χυμεία, ''khumeía'') is an ancient branch of natural philosophy, a philosophical and protoscientific tradition that was historically practiced in China, India, the Muslim world, ...

's term for the extraction of metals from minerals, the ending ''-urgy'' signifying a process, especially manufacturing: it was discussed in this sense in the 1797 ''Encyclopædia Britannica

The ( Latin for "British Encyclopædia") is a general knowledge English-language encyclopaedia. It is published by Encyclopædia Britannica, Inc.; the company has existed since the 18th century, although it has changed ownership various ...

''. In the late 19th century, it was extended to the more general scientific study of metals, alloys, and related processes. In English, the pronunciation is the more common one in the UK and Commonwealth. The pronunciation is the more common one in the US and is the first-listed variant in various American dictionaries (e.g., ''Merriam-Webster Collegiate'', ''American Heritage'').

History of metallurgy

The earliest recorded metal employed by humans appears to be

The earliest recorded metal employed by humans appears to be gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile ...

, which can be found free

Free may refer to:

Concept

* Freedom, having the ability to do something, without having to obey anyone/anything

* Freethought, a position that beliefs should be formed only on the basis of logic, reason, and empiricism

* Emancipate, to procur ...

or " native". Small amounts of natural gold have been found in Spanish caves dating to the late Paleolithic

The Paleolithic or Palaeolithic (), also called the Old Stone Age (from Greek: παλαιός '' palaios'', "old" and λίθος ''lithos'', "stone"), is a period in human prehistory that is distinguished by the original development of stone to ...

period, 40,000 BC. Silver

Silver is a chemical element with the Symbol (chemistry), symbol Ag (from the Latin ', derived from the Proto-Indo-European wikt:Reconstruction:Proto-Indo-European/h₂erǵ-, ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, whi ...

, copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish ...

, tin and meteoric iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in ...

can also be found in native form, allowing a limited amount of metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale ...

in early cultures. Certain metals, notably tin, lead

Lead is a chemical element with the Symbol (chemistry), symbol Pb (from the Latin ) and atomic number 82. It is a heavy metals, heavy metal that is density, denser than most common materials. Lead is Mohs scale of mineral hardness#Intermediate ...

, and at a higher temperature, copper, can be recovered from their ores by simply heating the rocks in a fire or blast furnace, a process known as smelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a ...

. The first evidence of this extractive metallurgy, dating from the 5th and 6th millennia BC, has been found at archaeological sites in Majdanpek, Jarmovac and Pločnik, in present-day Serbia

Serbia (, ; Serbian: , , ), officially the Republic of Serbia (Serbian: , , ), is a landlocked country in Southeastern and Central Europe, situated at the crossroads of the Pannonian Basin and the Balkans. It shares land borders with Hung ...

. To date, the earliest evidence of copper smelting is found at the Belovode site near Pločnik. This site produced a copper axe from 5,500 BC, belonging to the Vinča culture

The Vinča culture (), also known as Turdaș culture or Turdaș–Vinča culture, is a Neolithic archaeological culture of Southeast Europe, dated to the period 5700–4500 BC or 5300–4700/4500 BC.. Named for its type site, Vinča-Belo Brdo ...

.

The earliest use of lead is documented from the late neolithic

The Neolithic period, or New Stone Age, is an Old World archaeological period and the final division of the Stone Age. It saw the Neolithic Revolution, a wide-ranging set of developments that appear to have arisen independently in several part ...

settlements of Yarim Tepe

Yarim Tepe is an archaeological site of an early farming settlement that goes back to about 6000 BC. It is located in the Sinjar valley some 7km southwest from the town of Tal Afar in northern Iraq. The site consists of several hills reflecting ...

and Arpachiyah

Tell Arpachiyah (outside modern Mosul in Ninawa Governorate Iraq) is a prehistoric archaeological site in Nineveh Province (Iraq). It takes its name from a more recent village located about from Nineveh. The proper name of the mound on which the ...

in Iraq. The artifacts suggest that lead smelting predated copper smelting.

Copper smelting is also documented at this site at about the same time period (soon after 6,000 BC), although the use of lead seems to precede copper smelting. Early metallurgy is also documented at the nearby site of Tell Maghzaliyah, which seems to be dated even earlier, and completely lacks that pottery. The Balkans were the site of major Neolithic cultures, including Butmir, Vinča, Varna, Karanovo, and Hamangia.

The Varna Necropolis

The Varna Necropolis ( bg, Варненски некропол), or Varna Cemetery, is a burial site in the western industrial zone of Varna (approximately half a kilometre from Lake Varna and 4 km from the city centre), internationally c ...

, Bulgaria

Bulgaria (; bg, България, Bǎlgariya), officially the Republic of Bulgaria,, ) is a country in Southeast Europe. It is situated on the eastern flank of the Balkans, and is bordered by Romania to the north, Serbia and North Mac ...

, is a burial site in the western industrial zone of Varna (approximately 4 km from the city centre), internationally considered one of the key archaeological sites in world prehistory. The oldest gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile ...

treasure in the world, dating from 4,600 BC to 4,200 BC, was discovered at the site. The gold piece dating from 4,500 BC, recently founded in Durankulak

Durankulak ( bg, Дуранкулак ) is a village in northeastern Bulgaria, part of Shabla Municipality, Dobrich Province. Located in the historical region of Southern Dobruja, Durankulak is the north-easternmost inhabited place in Bulgaria an ...

, near Varna is another important example. Other signs of early metals are found from the third millennium BC in places like Palmela (Portugal), Los Millares (Spain), and Stonehenge

Stonehenge is a prehistoric monument on Salisbury Plain in Wiltshire, England, west of Amesbury. It consists of an outer ring of vertical sarsen standing stones, each around high, wide, and weighing around 25 tons, topped by connecting ...

(United Kingdom). However, the ultimate beginnings cannot be clearly ascertained and new discoveries are both continuous and ongoing.

alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

called bronze. This represented a major technological shift known as the Bronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second pri ...

.

The extraction of iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in ...

from its ore into a workable metal is much more difficult than for copper or tin. The process appears to have been invented by the Hittites

The Hittites () were an Anatolian people who played an important role in establishing first a kingdom in Kussara (before 1750 BC), then the Kanesh or Nesha kingdom (c. 1750–1650 BC), and next an empire centered on Hattusa in north-cent ...

in about 1200 BC, beginning the Iron Age

The Iron Age is the final epoch of the three-age division of the prehistory and protohistory of humanity. It was preceded by the Stone Age (Paleolithic, Mesolithic, Neolithic) and the Bronze Age (Chalcolithic). The concept has been mostly appl ...

. The secret of extracting and working iron was a key factor in the success of the Philistines

The Philistines ( he, פְּלִשְׁתִּים, Pəlīštīm; Koine Greek (Septuagint, LXX): Φυλιστιείμ, romanized: ''Phulistieím'') were an ancient people who lived on the south coast of Canaan from the 12th century BC until 6 ...

.W. Keller (1963) ''The Bible as History''. p. 156.

Historical developments in ferrous metallurgy can be found in a wide variety of past cultures and civilizations. This includes the ancient and medieval kingdoms and empires of the Middle East

The Middle East ( ar, الشرق الأوسط, ISO 233: ) is a geopolitical region commonly encompassing Arabia (including the Arabian Peninsula and Bahrain), Asia Minor (Asian part of Turkey except Hatay Province), East Thrace (Europ ...

and Near East, ancient Iran

Iran, officially the Islamic Republic of Iran, and also called Persia, is a country located in Western Asia. It is bordered by Iraq and Turkey to the west, by Azerbaijan and Armenia to the northwest, by the Caspian Sea and Turkm ...

, ancient Egypt

Egypt ( ar, مصر , ), officially the Arab Republic of Egypt, is a transcontinental country spanning the northeast corner of Africa and southwest corner of Asia via a land bridge formed by the Sinai Peninsula. It is bordered by the Med ...

, ancient Nubia

Nubia () (Nobiin language, Nobiin: Nobīn, ) is a region along the Nile river encompassing the area between the Cataracts of the Nile, first cataract of the Nile (just south of Aswan in southern Egypt) and the confluence of the Blue Nile, Blue ...

, and Anatolia

Anatolia, tr, Anadolu Yarımadası), and the Anatolian plateau, also known as Asia Minor, is a large peninsula in Western Asia and the westernmost protrusion of the Asian continent. It constitutes the major part of modern-day Turkey. The r ...

(Turkey

Turkey ( tr, Türkiye ), officially the Republic of Türkiye ( tr, Türkiye Cumhuriyeti, links=no ), is a list of transcontinental countries, transcontinental country located mainly on the Anatolia, Anatolian Peninsula in Western Asia, with ...

), Ancient Nok, Carthage

Carthage was the capital city of Ancient Carthage, on the eastern side of the Lake of Tunis in what is now Tunisia. Carthage was one of the most important trading hubs of the Ancient Mediterranean and one of the most affluent cities of the clas ...

, the Greeks

The Greeks or Hellenes (; el, Έλληνες, ''Éllines'' ) are an ethnic group and nation indigenous to the Eastern Mediterranean and the Black Sea regions, namely Greece, Greek Cypriots, Cyprus, Greeks in Albania, Albania, Greeks in Italy, ...

and Romans of ancient Europe

Europe is a large peninsula conventionally considered a continent in its own right because of its great physical size and the weight of its history and traditions. Europe is also considered a subcontinent of Eurasia and it is located enti ...

, medieval Europe, ancient and medieval China, ancient and medieval India

India, officially the Republic of India ( Hindi: ), is a country in South Asia. It is the seventh-largest country by area, the second-most populous country, and the most populous democracy in the world. Bounded by the Indian Ocean on the ...

, ancient and medieval Japan, amongst others. Many applications, practices, and devices associated or involved in metallurgy were established in ancient China, such as the innovation of the blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric p ...

, cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impu ...

, hydraulic

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counter ...

-powered trip hammer

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, decorticating and polishing of grain in agriculture. In mining, trip hammers were used for crushing metal ...

s, and double acting piston bellows

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtig ...

.

A 16th century book by Georg Agricola called '' De re metallica'' describes the highly developed and complex processes of mining metal ores, metal extraction and metallurgy of the time. Agricola has been described as the "father of metallurgy".

Extraction

Extractive metallurgy

Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a materials science, covering all aspects of the types of ore, wa ...

is the practice of removing valuable metals from an ore and refining the extracted raw metals into a purer form. In order to convert a metal oxide or sulphide to a purer metal, the ore must be reduced physically, chemically

A chemical reaction is a process that leads to the IUPAC nomenclature for organic transformations, chemical transformation of one set of chemical substances to another. Classically, chemical reactions encompass changes that only involve the pos ...

, or electrolytically. Extractive metallurgists are interested in three primary streams: feed, concentrate (metal oxide/sulphide) and tailings

In mining, tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction ( gangue) of an ore. Tailings are different to overburden, which is the waste rock or other material that overl ...

(waste).

After mining, large pieces of the ore feed are broken through crushing or grinding in order to obtain particles small enough, where each particle is either mostly valuable or mostly waste. Concentrating the particles of value in a form supporting separation enables the desired metal to be removed from waste products.

Mining may not be necessary, if the ore body and physical environment are conducive to leaching. Leaching dissolves minerals in an ore body and results in an enriched solution. The solution is collected and processed to extract valuable metals. Ore bodies often contain more than one valuable metal.

Tailings of a previous process may be used as a feed in another process to extract a secondary product from the original ore. Additionally, a concentrate may contain more than one valuable metal. That concentrate would then be processed to separate the valuable metals into individual constituents.

Metal and its alloys

Much effort has been placed on understanding

Much effort has been placed on understanding iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in ...

–carbon alloy system, which includes steels and cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impu ...

s. Plain carbon steels (those that contain essentially only carbon as an alloying element) are used in low-cost, high-strength applications, where neither weight nor corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

are a major concern. Cast irons, including ductile iron

Ductile iron, also known as ductile cast iron, nodular cast iron, spheroidal graphite iron, spheroidal graphite cast iron and SG iron, is a type of graphite-rich cast iron discovered in 1943 by Keith Millis. While most varieties of cast iron ar ...

, are also part of the iron-carbon system. Iron-Manganese-Chromium alloys (Hadfield-type steels) are also used in non-magnetic applications such as directional drilling.

Other common engineering metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typi ...

s include aluminium

Aluminium (aluminum in AmE, American and CanE, Canadian English) is a chemical element with the Symbol (chemistry), symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately o ...

, chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and h ...

, copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish ...

, magnesium

Magnesium is a chemical element with the symbol Mg and atomic number 12. It is a shiny gray metal having a low density, low melting point and high chemical reactivity. Like the other alkaline earth metals (group 2 of the periodic ...

, nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

, titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

, zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic t ...

, and silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ...

. These metals are most often used as alloys with the noted exception of silicon, as it is not a metal.

* Stainless steel, particularly Austenitic stainless steel

Austenitic stainless steel is one of the five classes of stainless steel by crystalline structure (along with ''ferritic'', '' martensitic, duplex and precipitation hardened''). Its primary crystalline structure is austenite (face-centered cub ...

s, galvanized steel

Galvanization or galvanizing ( also spelled galvanisation or galvanising) is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are submer ...

, nickel alloys, titanium alloys

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance a ...

, or occasionally copper alloys are used, where resistance to corrosion is important.

* Aluminium alloys and magnesium alloys are commonly used, when a lightweight strong part is required such as in automotive and aerospace applications.

* Copper-nickel alloys (such as Monel) are used in highly corrosive environments and for non-magnetic applications.

* Nickel-based superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, ...

s like Inconel

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys.

Inconel alloys are oxidation- corrosion-resistant materials well suited for service in extreme environments subjected ...

are used in high-temperature applications such as gas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

s, turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to pr ...

s, pressure vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size o ...

s, and heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct conta ...

s.

* For extremely high temperatures, single crystal

In materials science, a single crystal (or single-crystal solid or monocrystalline solid) is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries.RIWD. "R ...

alloys are used to minimize creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

. In modern electronics, high purity single crystal silicon is essential for metal-oxide-silicon transistors (MOS) and integrated circuits.

Production

Inproduction engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

, metallurgy is concerned with the production of metallic components for use in consumer or engineering

Engineering is the use of scientific method, scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad rang ...

products. This involves production of alloys, shaping, heat treatment and surface treatment of product. The task of the metallurgist is to achieve balance between material properties, such as cost, weight

In science and engineering, the weight of an object is the force acting on the object due to gravity.

Some standard textbooks define weight as a vector quantity, the gravitational force acting on the object. Others define weight as a scalar q ...

, strength, toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion (mechanical), abrasion. In general, different materials differ in their hardn ...

, corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

, fatigue

Fatigue describes a state of tiredness that does not resolve with rest or sleep. In general usage, fatigue is synonymous with extreme tiredness or exhaustion that normally follows prolonged physical or mental activity. When it does not resolve ...

resistance and performance in temperature

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measured with a thermometer.

Thermometers are calibrated in various temperature scales that historically have relied on ...

extremes. To achieve this goal, the operating environment must be carefully considered.

Determining the hardness of the metal using the Rockwell, Vickers, and Brinell hardness scales is a commonly used practice that helps better understand the metal's elasticity and plasticity for different applications and production processes. In a saltwater environment, most ferrous metals and some non-ferrous alloys corrode quickly. Metals exposed to cold or cryogenic

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

The 13th IIR International Congress of Refrigeration (held in Washington DC in 1971) endorsed a universal definition of “cryogenics” and “cr ...

conditions may undergo a ductile to brittle transition and lose their toughness, becoming more brittle and prone to cracking. Metals under continual cyclic loading can suffer from metal fatigue

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts o ...

. Metals under constant stress at elevated temperatures can creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

.

Metalworking processes

*

* Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected ...

– molten metal is poured into a shaped mold

A mold () or mould () is one of the structures certain fungi can form. The dust-like, colored appearance of molds is due to the formation of spores containing fungal secondary metabolites. The spores are the dispersal units of the fungi. Not ...

. Variants of casting include sand casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced ...

, investment casting (also called the lost wax process), die casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly ...

, and continuous castings. Each of these forms has advantages for certain metals and applications considering factors like magnetism and corrosion.

* Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at whi ...

– a red-hot billet

A billet is a living-quarters to which a soldier is assigned to sleep. Historically, a billet was a private dwelling that was required to accept the soldier.

Soldiers are generally billeted in barracks or garrisons when not on combat duty, alt ...

is hammered into shape.

* Rolling

Rolling is a type of motion that combines rotation (commonly, of an axially symmetric object) and translation of that object with respect to a surface (either one or the other moves), such that, if ideal conditions exist, the two are in contact ...

– a billet is passed through successively narrower rollers to create a sheet.

* Extrusion – a hot and malleable metal is forced under pressure through a die, which shapes it before it cools.

* Machining – lathes

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to ...

, milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

s and drills cut the cold metal to shape.

* Sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

– a powdered metal is heated in a non-oxidizing environment after being compressed into a die.

* Fabrication

Fabrication may refer to:

* Manufacturing, specifically the crafting of individual parts as a solo product or as part of a larger combined product.

Processes in arts, crafts and manufacturing

*Semiconductor device fabrication, the process used t ...

– sheets of metal are cut with guillotine

A guillotine is an apparatus designed for efficiently carrying out executions by beheading. The device consists of a tall, upright frame with a weighted and angled blade suspended at the top. The condemned person is secured with stocks at t ...

s or gas cutters and bent and welded into structural shape.

* Laser cladding

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling s ...

– metallic powder is blown through a movable laser beam (e.g. mounted on a NC 5-axis machine). The resulting melted metal reaches a substrate to form a melt pool. By moving the laser head, it is possible to stack the tracks and build up a three-dimensional piece.

* 3D printing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

– Sintering or melting amorphous powder metal in a 3D space to make any object to shape.

Cold-working processes, in which the product's shape is altered by rolling, fabrication or other processes, while the product is cold, can increase the strength of the product by a process called work hardening

In materials science, work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. Work hardening may be desirable, undesirable, or inconsequential, depending on the context.

This strength ...

. Work hardening creates microscopic defects in the metal, which resist further changes of shape.

Heat treatment

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing, precipitation strengthening, quenching, and tempering:

* Annealing process softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that, when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal.

*

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing, precipitation strengthening, quenching, and tempering:

* Annealing process softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that, when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal.

* Quenching

In materials science, quenching is the rapid cooling of a workpiece in water, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as ...

is the process of cooling metal very quickly after heating, thus "freezing" the metal's molecules in the very hard martensite form, which makes the metal harder.

* Tempering relieves stresses in the metal that were caused by the hardening process; tempering makes the metal less hard while making it better able to sustain impacts without breaking.

Often, mechanical and thermal treatments are combined in what are known as thermo-mechanical treatments for better properties and more efficient processing of materials. These processes are common to high-alloy special steels, superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, ...

s and titanium alloys.

Plating

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the redox, reduction of cations of that metal by means of a direct current, direct electric cur ...

is a chemical surface-treatment technique. It involves bonding a thin layer of another metal such as gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile ...

, silver

Silver is a chemical element with the Symbol (chemistry), symbol Ag (from the Latin ', derived from the Proto-Indo-European wikt:Reconstruction:Proto-Indo-European/h₂erǵ-, ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, whi ...

, chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and h ...

or zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic t ...

to the surface of the product. This is done by selecting the coating material electrolyte solution, which is the material that is going to coat the workpiece (gold, silver, zinc). There needs to be two electrodes of different materials: one the same material as the coating material and one that is receiving the coating material. Two electrodes are electrically charged and the coating material is stuck to the work piece. It is used to reduce corrosion as well as to improve the product's aesthetic appearance. It is also used to make inexpensive metals look like the more expensive ones (gold, silver).

Shot peening

Shot peening is a cold working process used to finish metal parts. In the process of shot peening, small round shot is blasted against the surface of the part to be finished. This process is used to prolong the product life of the part, prevent stress corrosion failures, and also prevent fatigue. The shot leaves small dimples on the surface like a peen hammer does, which cause compression stress under the dimple. As the shot media strikes the material over and over, it forms many overlapping dimples throughout the piece being treated. The compression stress in the surface of the material strengthens the part and makes it more resistant to fatigue failure, stress failures, corrosion failure, and cracking.Thermal spraying

Thermal spraying techniques are another popular finishing option, and often have better high temperature properties than electroplated coatings. Thermal spraying, also known as a spray welding process, is an industrial coating process that consists of a heat source (flame or other) and a coating material that can be in a powder or wire form, which is melted then sprayed on the surface of the material being treated at a high velocity. The spray treating process is known by many different names such as HVOF (High Velocity Oxygen Fuel), plasma spray, flame spray, arc spray and metalizing.Characterization

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope

An electron microscope is a microscope that uses a beam of accelerated electrons as a source of illumination. As the wavelength of an electron can be up to 100,000 times shorter than that of visible light photons, electron microscopes have a ...

, and the image contrast provides details on the composition, mechanical properties, and processing history.

Crystallography

Crystallography is the experimental science of determining the arrangement of atoms in crystalline solids. Crystallography is a fundamental subject in the fields of materials science and solid-state physics (condensed matter physics). The wo ...

, often using diffraction of x-ray

X-rays (or rarely, ''X-radiation'') are a form of high-energy electromagnetic radiation. In many languages, it is referred to as Röntgen radiation, after the German scientist Wilhelm Conrad Röntgen, who discovered it in 1895 and named it ' ...

s or electron

The electron (, or in nuclear reactions) is a subatomic particle with a negative one elementary electric charge. Electrons belong to the first generation of the lepton particle family,

and are generally thought to be elementary partic ...

s, is another valuable tool available to the modern metallurgist. Crystallography allows identification of unknown materials and reveals the crystal structure of the sample. Quantitative crystallography can be used to calculate the amount of phases present as well as the degree of strain to which a sample has been subjected.

See also

* Adrien Chenot * Archaeometallurgy * CALPHAD *Carbonyl metallurgy

Carbonyl metallurgy is used to manufacture products of iron, nickel, steel, and other metals. Coatings are produced by vapor plating using metal carbonyl vapors. These are metal-ligand complexes where carbon monoxide is bonded to individual atoms ...

* Cupellation

* Experimental archaeometallurgy Experimental archaeometallurgy is a subset of experimental archaeology that specifically involves past metallurgical processes most commonly involving the replication of copper and iron objects as well as testing the methodology behind the producti ...

* Goldbeating

* Gold phosphine complex

* Metallurgical failure analysis

Metallurgical failure analysis is the process to determine the mechanism that has caused a metal component to fail. It can identify the cause of failure, providing insight into the root cause and potential solutions to prevent similar failures in ...

* Mineral industry

Mining is the extraction of valuable minerals or other geological materials from the Earth, usually from an ore body, lode, vein, seam, reef, or placer deposit. The exploitation of these deposits for raw material is based on the economic viabi ...

* Pyrometallurgy

References

External links

* * {{Use dmy dates, date=April 2017 Metals