Metallurgical Facilities In Michigan on:

[Wikipedia]

[Google]

[Amazon]

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic

The earliest recorded metal employed by humans appears to be gold, which can be found

The earliest recorded metal employed by humans appears to be gold, which can be found  In the

In the

Extractive metallurgy is the practice of removing valuable metals from an ore and refining the extracted raw metals into a purer form. In order to convert a metal

Extractive metallurgy is the practice of removing valuable metals from an ore and refining the extracted raw metals into a purer form. In order to convert a metal

Much effort has been placed on understanding iron–carbon alloy system, which includes

Much effort has been placed on understanding iron–carbon alloy system, which includes

* Casting – molten metal is poured into a shaped mold. Variants of casting include sand casting, investment casting (also called the lost wax process), die casting, and continuous castings. Each of these forms has advantages for certain metals and applications considering factors like magnetism and corrosion.

*

* Casting – molten metal is poured into a shaped mold. Variants of casting include sand casting, investment casting (also called the lost wax process), die casting, and continuous castings. Each of these forms has advantages for certain metals and applications considering factors like magnetism and corrosion.

*

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing,

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing,

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope, and the image contrast provides details on the composition, mechanical properties, and processing history.

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope, and the image contrast provides details on the composition, mechanical properties, and processing history.

elements

Element or elements may refer to:

Science

* Chemical element, a pure substance of one type of atom

* Heating element, a device that generates heat by electrical resistance

* Orbital elements, parameters required to identify a specific orbit of ...

, their inter-metallic compounds, and their mixtures, which are known as alloys.

Metallurgy encompasses both the science and the technology of metals; that is, the way in which science is applied to the production of metals, and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist.

The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include mineral processing, the extraction of metals, thermodynamics, electrochemistry, and chemical degradation ( corrosion). In contrast, physical metallurgy focuses on the mechanical properties of metals, the physical properties of metals, and the physical performance of metals. Topics studied in physical metallurgy include crystallography

Crystallography is the experimental science of determining the arrangement of atoms in crystalline solids. Crystallography is a fundamental subject in the fields of materials science and solid-state physics (condensed matter physics). The wor ...

, material characterization

Characterization, when used in materials science, refers to the broad and general process by which a material's structure and properties are probed and measured. It is a fundamental process in the field of materials science, without which no scie ...

, mechanical metallurgy, phase transformations, and failure mechanisms.

Historically, metallurgy has predominately focused on the production of metals. Metal production begins with the processing of ores to extract the metal, and includes the mixture of metals to make alloys. Metal alloys are often a blend of at least two different metallic elements. However, non-metallic elements are often added to alloys in order to achieve properties suitable for an application. The study of metal production is subdivided into ferrous metallurgy (also known as ''black metallurgy'') and non-ferrous metallurgy (also known as ''colored metallurgy'').

Ferrous metallurgy involves processes and alloys based on iron, while non-ferrous metallurgy involves processes and alloys based on other metals. The production of ferrous metals accounts for 95% of world metal production.

Modern metallurgists work in both emerging and traditional areas as part of an interdisciplinary team alongside material scientists and other engineers. Some traditional areas include mineral processing, metal production, heat treatment, failure analysis Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability.

According to Bloch and Geitner, ”machinery failures reveal a reaction chain o ...

, and the joining of metals (including welding, brazing, and soldering). Emerging areas for metallurgists include nanotechnology

Nanotechnology, also shortened to nanotech, is the use of matter on an atomic, molecular, and supramolecular scale for industrial purposes. The earliest, widespread description of nanotechnology referred to the particular technological goal o ...

, superconductors, composites, biomedical materials

A biomaterial is a substance that has been engineered to interact with biological systems for a medical purpose, either a therapeutic (treat, augment, repair, or replace a tissue function of the body) or a diagnostic one. As a science, biomateria ...

, electronic materials

A semiconductor is a material which has an electrical conductivity value falling between that of a conductor, such as copper, and an insulator, such as glass. Its resistivity falls as its temperature rises; metals behave in the opposite way. ...

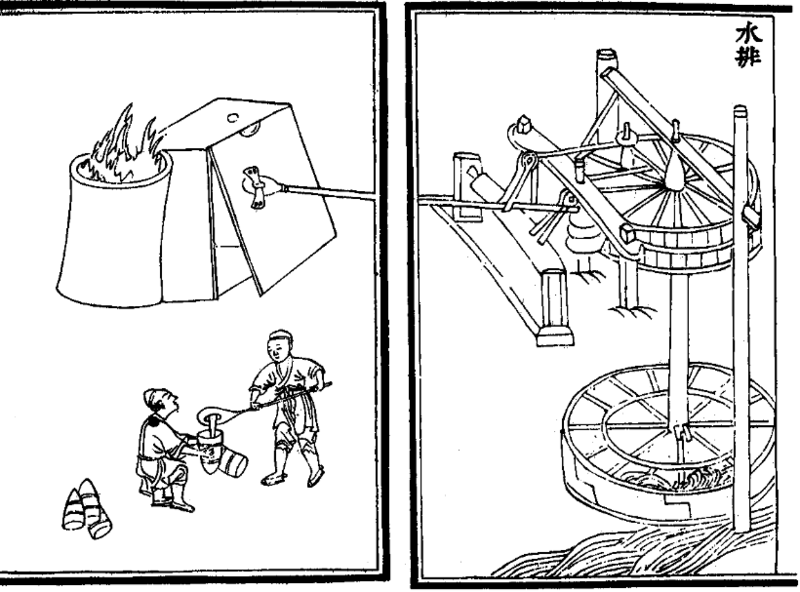

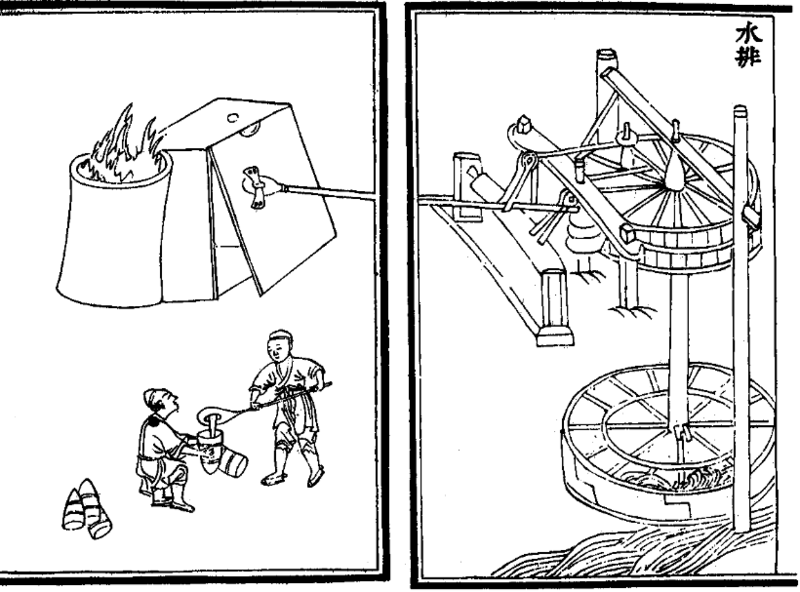

(semiconductors) and surface engineering. Many applications, practices, and devices associated or involved in metallurgy were established in ancient China, such as the innovation of the blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric ...

, cast iron, hydraulic-powered trip hammers, and double acting piston bellows.R. F. Tylecote (1992) ''A History of Metallurgy'' Robert K.G. Temple (2007). ''The Genius of China: 3,000 Years of Science, Discovery, and Invention'' (3rd ed.). London: André Deutsch. pp. 44–56. .

Etymology and pronunciation

''Metallurgy'' derives from the Ancient Greek , , "worker in metal", from , , "mine, metal" + , , "work" The word was originally analchemist

Alchemy (from Arabic: ''al-kīmiyā''; from Ancient Greek: χυμεία, ''khumeía'') is an ancient branch of natural philosophy, a philosophical and protoscience, protoscientific tradition that was historically practiced in Chinese alchemy, C ...

's term for the extraction of metals from minerals, the ending ''-urgy'' signifying a process, especially manufacturing: it was discussed in this sense in the 1797 '' Encyclopædia Britannica''. In the late 19th century, it was extended to the more general scientific study of metals, alloys, and related processes. In English, the pronunciation is the more common one in the UK and Commonwealth. The pronunciation is the more common one in the US and is the first-listed variant in various American dictionaries (e.g., ''Merriam-Webster Collegiate'', ''American Heritage'').

History of metallurgy

The earliest recorded metal employed by humans appears to be gold, which can be found

The earliest recorded metal employed by humans appears to be gold, which can be found free

Free may refer to:

Concept

* Freedom, having the ability to do something, without having to obey anyone/anything

* Freethought, a position that beliefs should be formed only on the basis of logic, reason, and empiricism

* Emancipate, to procur ...

or " native". Small amounts of natural gold have been found in Spanish caves dating to the late Paleolithic

The Paleolithic or Palaeolithic (), also called the Old Stone Age (from Greek: παλαιός ''palaios'', "old" and λίθος ''lithos'', "stone"), is a period in human prehistory that is distinguished by the original development of stone too ...

period, 40,000 BC. Silver, copper, tin and meteoric iron can also be found in native form, allowing a limited amount of metalworking in early cultures. Certain metals, notably tin, lead, and at a higher temperature, copper, can be recovered from their ores by simply heating the rocks in a fire or blast furnace, a process known as smelting. The first evidence of this extractive metallurgy, dating from the 5th and 6th millennia BC, has been found at archaeological sites in Majdanpek, Jarmovac and Pločnik, in present-day Serbia. To date, the earliest evidence of copper smelting is found at the Belovode site near Pločnik. This site produced a copper axe from 5,500 BC, belonging to the Vinča culture.

The earliest use of lead is documented from the late neolithic settlements of Yarim Tepe and Arpachiyah

Tell Arpachiyah (outside modern Mosul in Ninawa Governorate Iraq) is a prehistoric archaeological site in Nineveh Province (Iraq). It takes its name from a more recent village located about from Nineveh. The proper name of the mound on which the ...

in Iraq. The artifacts suggest that lead smelting predated copper smelting.

Copper smelting is also documented at this site at about the same time period (soon after 6,000 BC), although the use of lead seems to precede copper smelting. Early metallurgy is also documented at the nearby site of Tell Maghzaliyah, which seems to be dated even earlier, and completely lacks that pottery. The Balkans were the site of major Neolithic cultures, including Butmir, Vinča, Varna, Karanovo, and Hamangia.

The Varna Necropolis, Bulgaria, is a burial site in the western industrial zone of Varna (approximately 4 km from the city centre), internationally considered one of the key archaeological sites in world prehistory. The oldest gold treasure in the world, dating from 4,600 BC to 4,200 BC, was discovered at the site. The gold piece dating from 4,500 BC, recently founded in Durankulak

Durankulak ( bg, Дуранкулак ) is a village in northeastern Bulgaria, part of Shabla Municipality, Dobrich Province. Located in the historical region of Southern Dobruja, Durankulak is the north-easternmost inhabited place in Bulgaria an ...

, near Varna is another important example. Other signs of early metals are found from the third millennium BC in places like Palmela (Portugal), Los Millares (Spain), and Stonehenge

Stonehenge is a prehistoric monument on Salisbury Plain in Wiltshire, England, west of Amesbury. It consists of an outer ring of vertical sarsen standing stones, each around high, wide, and weighing around 25 tons, topped by connectin ...

(United Kingdom). However, the ultimate beginnings cannot be clearly ascertained and new discoveries are both continuous and ongoing.

Near East

The ''Near East''; he, המזרח הקרוב; arc, ܕܢܚܐ ܩܪܒ; fa, خاور نزدیک, Xāvar-e nazdik; tr, Yakın Doğu is a geographical term which roughly encompasses a transcontinental region in Western Asia, that was once the hist ...

, about 3,500 BC, it was discovered that by combining copper and tin, a superior metal could be made, an alloy called bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals, such as phosphorus, or metalloids such ...

. This represented a major technological shift known as the Bronze Age.

The extraction of iron from its ore into a workable metal is much more difficult than for copper or tin. The process appears to have been invented by the Hittites in about 1200 BC, beginning the Iron Age. The secret of extracting and working iron was a key factor in the success of the Philistines.W. Keller (1963) ''The Bible as History''. p. 156.

Historical developments in ferrous metallurgy can be found in a wide variety of past cultures and civilizations. This includes the ancient and medieval kingdoms and empires of the Middle East and Near East

The ''Near East''; he, המזרח הקרוב; arc, ܕܢܚܐ ܩܪܒ; fa, خاور نزدیک, Xāvar-e nazdik; tr, Yakın Doğu is a geographical term which roughly encompasses a transcontinental region in Western Asia, that was once the hist ...

, ancient Iran, ancient Egypt, ancient Nubia, and Anatolia ( Turkey), Ancient Nok, Carthage, the Greeks and Romans of ancient Europe, medieval Europe, ancient and medieval China

China, officially the People's Republic of China (PRC), is a country in East Asia. It is the world's most populous country, with a population exceeding 1.4 billion, slightly ahead of India. China spans the equivalent of five time zones and ...

, ancient and medieval India, ancient and medieval Japan

Japan ( ja, 日本, or , and formally , ''Nihonkoku'') is an island country in East Asia. It is situated in the northwest Pacific Ocean, and is bordered on the west by the Sea of Japan, while extending from the Sea of Okhotsk in the north ...

, amongst others. Many applications, practices, and devices associated or involved in metallurgy were established in ancient China, such as the innovation of the blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric ...

, cast iron, hydraulic-powered trip hammers, and double acting piston bellows.

A 16th century book by Georg Agricola called '' De re metallica'' describes the highly developed and complex processes of mining metal ores, metal extraction and metallurgy of the time. Agricola has been described as the "father of metallurgy".

Extraction

Extractive metallurgy is the practice of removing valuable metals from an ore and refining the extracted raw metals into a purer form. In order to convert a metal

Extractive metallurgy is the practice of removing valuable metals from an ore and refining the extracted raw metals into a purer form. In order to convert a metal oxide

An oxide () is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O2– (molecular) ion. with oxygen in the oxidation state of −2. Most of the E ...

or sulphide

Sulfide (British English also sulphide) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to chemical compounds la ...

to a purer metal, the ore must be reduced physically, chemically

A chemical reaction is a process that leads to the IUPAC nomenclature for organic transformations, chemical transformation of one set of chemical substances to another. Classically, chemical reactions encompass changes that only involve the pos ...

, or electrolytically. Extractive metallurgists are interested in three primary streams: feed, concentrate (metal oxide/sulphide) and tailings (waste).

After mining, large pieces of the ore feed are broken through crushing or grinding in order to obtain particles small enough, where each particle is either mostly valuable or mostly waste. Concentrating the particles of value in a form supporting separation enables the desired metal to be removed from waste products.

Mining may not be necessary, if the ore body and physical environment are conducive to leaching. Leaching dissolves minerals in an ore body and results in an enriched solution. The solution is collected and processed to extract valuable metals. Ore bodies often contain more than one valuable metal.

Tailings of a previous process may be used as a feed in another process to extract a secondary product from the original ore. Additionally, a concentrate may contain more than one valuable metal. That concentrate would then be processed to separate the valuable metals into individual constituents.

Metal and its alloys

Much effort has been placed on understanding iron–carbon alloy system, which includes

Much effort has been placed on understanding iron–carbon alloy system, which includes steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

s and cast irons. Plain carbon steels (those that contain essentially only carbon as an alloying element) are used in low-cost, high-strength applications, where neither weight nor corrosion are a major concern. Cast irons, including ductile iron, are also part of the iron-carbon system. Iron-Manganese-Chromium alloys (Hadfield-type steels) are also used in non-magnetic applications such as directional drilling.

Other common engineering metals include aluminium, chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

, copper, magnesium, nickel, titanium, zinc, and silicon. These metals are most often used as alloys with the noted exception of silicon, as it is not a metal.

* Stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corros ...

, particularly Austenitic stainless steel

Austenitic stainless steel is one of the five classes of stainless steel by crystalline structure (along with ''ferritic'', ''martensitic, duplex and precipitation hardened''). Its primary crystalline structure is austenite (face-centered cubic) ...

s, galvanized steel, nickel alloys, titanium alloys

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance a ...

, or occasionally copper alloys are used, where resistance to corrosion is important.

* Aluminium alloys and magnesium alloys are commonly used, when a lightweight strong part is required such as in automotive and aerospace applications.

* Copper-nickel alloys (such as Monel) are used in highly corrosive environments and for non-magnetic applications.

* Nickel-based superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, g ...

s like Inconel are used in high-temperature applications such as gas turbines, turbochargers, pressure vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size o ...

s, and heat exchangers.

* For extremely high temperatures, single crystal alloys are used to minimize creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

. In modern electronics, high purity single crystal silicon is essential for metal-oxide-silicon

The metal–oxide–semiconductor field-effect transistor (MOSFET, MOS-FET, or MOS FET) is a type of field-effect transistor (FET), most commonly fabricated by the thermal oxidation, controlled oxidation of silicon. It has an insulated gate, the ...

transistors (MOS) and integrated circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

s.

Production

In production engineering, metallurgy is concerned with the production of metallic components for use in consumer or engineering products. This involves production of alloys, shaping, heat treatment and surface treatment of product. The task of the metallurgist is to achieve balance between material properties, such as cost, weight, strength, toughness, hardness, corrosion,fatigue

Fatigue describes a state of tiredness that does not resolve with rest or sleep. In general usage, fatigue is synonymous with extreme tiredness or exhaustion that normally follows prolonged physical or mental activity. When it does not resolve ...

resistance and performance in temperature extremes. To achieve this goal, the operating environment must be carefully considered.

Determining the hardness of the metal using the Rockwell, Vickers, and Brinell hardness scales is a commonly used practice that helps better understand the metal's elasticity and plasticity for different applications and production processes. In a saltwater environment, most ferrous metals and some non-ferrous alloys corrode quickly. Metals exposed to cold or cryogenic

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

The 13th IIR International Congress of Refrigeration (held in Washington DC in 1971) endorsed a universal definition of “cryogenics” and “cr ...

conditions may undergo a ductile to brittle transition and lose their toughness, becoming more brittle and prone to cracking. Metals under continual cyclic loading can suffer from metal fatigue. Metals under constant stress at elevated temperatures can creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

.

Metalworking processes

* Casting – molten metal is poured into a shaped mold. Variants of casting include sand casting, investment casting (also called the lost wax process), die casting, and continuous castings. Each of these forms has advantages for certain metals and applications considering factors like magnetism and corrosion.

*

* Casting – molten metal is poured into a shaped mold. Variants of casting include sand casting, investment casting (also called the lost wax process), die casting, and continuous castings. Each of these forms has advantages for certain metals and applications considering factors like magnetism and corrosion.

* Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which i ...

– a red-hot billet is hammered into shape.

* Rolling – a billet is passed through successively narrower rollers to create a sheet.

* Extrusion – a hot and malleable metal is forced under pressure through a die

Die, as a verb, refers to death, the cessation of life.

Die may also refer to:

Games

* Die, singular of dice, small throwable objects used for producing random numbers

Manufacturing

* Die (integrated circuit), a rectangular piece of a semicondu ...

, which shapes it before it cools.

* Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

– lathes, milling machines and drill

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to ...

s cut the cold metal to shape.

* Sintering – a powdered metal

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and ...

is heated in a non-oxidizing environment after being compressed into a die.

* Fabrication

Fabrication may refer to:

* Manufacturing, specifically the crafting of individual parts as a solo product or as part of a larger combined product.

Processes in arts, crafts and manufacturing

*Semiconductor device fabrication, the process used t ...

– sheets of metal are cut with guillotines or gas cutters and bent and welded into structural shape.

* Laser cladding

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling s ...

– metallic powder is blown through a movable laser beam (e.g. mounted on a NC 5-axis machine). The resulting melted metal reaches a substrate to form a melt pool. By moving the laser head, it is possible to stack the tracks and build up a three-dimensional piece.

* 3D printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is ...

– Sintering or melting amorphous powder metal in a 3D space to make any object to shape.

Cold-working processes, in which the product's shape is altered by rolling, fabrication or other processes, while the product is cold, can increase the strength of the product by a process called work hardening. Work hardening creates microscopic defects in the metal, which resist further changes of shape.

Heat treatment

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing,

Metals can be heat-treated to alter the properties of strength, ductility, toughness, hardness and resistance to corrosion. Common heat treatment processes include annealing, precipitation strengthening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and so ...

, quenching, and tempering:

* Annealing process softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that, when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal.

* Quenching is the process of cooling metal very quickly after heating, thus "freezing" the metal's molecules in the very hard martensite form, which makes the metal harder.

* Tempering relieves stresses in the metal that were caused by the hardening process; tempering makes the metal less hard while making it better able to sustain impacts without breaking.

Often, mechanical and thermal treatments are combined in what are known as thermo-mechanical treatments for better properties and more efficient processing of materials. These processes are common to high-alloy special steels, superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, g ...

s and titanium alloys.

Plating

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be ...

is a chemical surface-treatment technique. It involves bonding a thin layer of another metal such as gold, silver, chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal.

Chromium metal is valued for its high corrosion resistance and hardne ...

or zinc to the surface of the product. This is done by selecting the coating material electrolyte solution, which is the material that is going to coat the workpiece (gold, silver, zinc). There needs to be two electrodes of different materials: one the same material as the coating material and one that is receiving the coating material. Two electrodes are electrically charged and the coating material is stuck to the work piece. It is used to reduce corrosion as well as to improve the product's aesthetic appearance. It is also used to make inexpensive metals look like the more expensive ones (gold, silver).

Shot peening

Shot peening is a cold working process used to finish metal parts. In the process of shot peening, small round shot is blasted against the surface of the part to be finished. This process is used to prolong the product life of the part, prevent stress corrosion failures, and also prevent fatigue. The shot leaves small dimples on the surface like a peen hammer does, which cause compression stress under the dimple. As the shot media strikes the material over and over, it forms many overlapping dimples throughout the piece being treated. The compression stress in the surface of the material strengthens the part and makes it more resistant to fatigue failure, stress failures, corrosion failure, and cracking.Thermal spraying

Thermal spraying techniques are another popular finishing option, and often have better high temperature properties than electroplated coatings. Thermal spraying, also known as a spray welding process, is an industrial coating process that consists of a heat source (flame or other) and a coating material that can be in a powder or wire form, which is melted then sprayed on the surface of the material being treated at a high velocity. The spray treating process is known by many different names such as HVOF (High Velocity Oxygen Fuel), plasma spray, flame spray, arc spray and metalizing.Characterization

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope, and the image contrast provides details on the composition, mechanical properties, and processing history.

Metallurgists study the microscopic and macroscopic structure of metals using metallography, a technique invented by Henry Clifton Sorby.

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope, and the image contrast provides details on the composition, mechanical properties, and processing history.

Crystallography

Crystallography is the experimental science of determining the arrangement of atoms in crystalline solids. Crystallography is a fundamental subject in the fields of materials science and solid-state physics (condensed matter physics). The wor ...

, often using diffraction

Diffraction is defined as the interference or bending of waves around the corners of an obstacle or through an aperture into the region of geometrical shadow of the obstacle/aperture. The diffracting object or aperture effectively becomes a s ...

of x-rays or electrons, is another valuable tool available to the modern metallurgist. Crystallography allows identification of unknown materials and reveals the crystal structure of the sample. Quantitative crystallography can be used to calculate the amount of phases present as well as the degree of strain to which a sample has been subjected.

See also

* Adrien Chenot * Archaeometallurgy * CALPHAD *Carbonyl metallurgy

Carbonyl metallurgy is used to manufacture products of iron, nickel, steel, and other metals. Coatings are produced by vapor plating using metal carbonyl vapors. These are metal-ligand complexes where carbon monoxide is bonded to individual atoms ...

* Cupellation

* Experimental archaeometallurgy

* Goldbeating

* Gold phosphine complex

* Metallurgical failure analysis

* Mineral industry

* Pyrometallurgy

References

External links

* * {{Use dmy dates, date=April 2017 Metals