Textile is an

umbrella term that includes various

fiber-based materials, including fibers,

yarns,

filaments,

threads

Thread may refer to:

Objects

* Thread (yarn), a kind of thin yarn used for sewing

** Thread (unit of measurement), a cotton yarn measure

* Screw thread, a helical ridge on a cylindrical fastener

Arts and entertainment

* ''Thread'' (film), 2016 ...

, different

fabric types, etc. At first, the word "textiles" only referred to

woven fabrics. However,

weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use.

Knitting

Knitting is a method by which yarn is manipulated to create a textile, or fabric. It is used to create many types of garments. Knitting may be done by hand or by machine.

Knitting creates stitches: loops of yarn in a row, either flat or i ...

and

non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the

material needs for versatile applications, from simple daily

clothing to

bulletproof jackets,

spacesuit

A space suit or spacesuit is a garment worn to keep a human alive in the harsh environment of outer space, vacuum and temperature extremes. Space suits are often worn inside spacecraft as a safety precaution in case of loss of cabin pressure, ...

s, and

doctor's gowns.

Textiles are divided into two groups: Domestic purposes

onsumer textilesand

technical textiles. In consumer textiles,

aesthetics and

comfort are the most important factors, but in technical textiles,

functional properties are the priority.

s,

industrial textiles,

medical textiles

Medical textiles are various fiber-based materials intended for medical purposes. Medical textile is a sector of technical textiles that focuses on fiber-based products used in health care applications such as prevention, care, and hygiene. The s ...

, and many other areas are examples of technical textiles, whereas

clothing and furnishings are examples of consumer textiles. Each component of a textile product, including fiber, yarn, fabric, processing, and

finishing, affects the final product. Components may vary among various textile products as they are selected based on their

fitness for purpose.

Fiber is the smallest component of a fabric; fibers are typically spun into yarn, and yarns are used to manufacture fabrics.

Fiber has a hair-like appearance and a higher length-to-width ratio. The sources of fibers may be

natural,

synthetic Synthetic things are composed of multiple parts, often with the implication that they are artificial. In particular, 'synthetic' may refer to:

Science

* Synthetic chemical or compound, produced by the process of chemical synthesis

* Synthetic o ...

, or both. The techniques of

felting and

bonding directly transform fibers into fabric. In other cases, yarns are manipulated with different fabric manufacturing systems to produce various fabric constructions. The fibers are twisted or laid out to make a long, continuous strand of yarn.

Yarns are then used to make different kinds of fabric by weaving, knitting,

crochet

Crochet (; ) is a process of creating textiles by using a crochet hook to interlock loops of yarn, thread (yarn), thread, or strands of other materials. The name is derived from the French term ''crochet'', meaning 'hook'. Hooks can be made from ...

ing,

knotting,

tatting, or

braid

A braid (also referred to as a plait) is a complex structure or pattern formed by interlacing two or more strands of flexible material such as textile yarns, wire, or hair.

The simplest and most common version is a flat, solid, three-strande ...

ing.

After manufacturing, textile materials are processed and finished to add value, such as aesthetics, physical characteristics, and increased usefulness.

The manufacturing of textiles is the oldest industrial

art.

Dyeing,

printing, and

embroidery are all different decorative arts applied to textile materials.

Etymology

Textile

The word 'textile' comes from the

Latin adjective , meaning 'woven', which itself stems from , the past participle of the verb , 'to weave'.

Originally applied to

woven fabrics, the term "textiles" is now used to encompass a diverse range of materials, including fibers,

yarns, and

fabrics, as well as other related items.

Fabric

A "fabric" is defined as any thin, flexible material made from yarn, directly from fibers, polymeric film, foam, or any combination of these techniques. Fabric has a broader application than cloth.

Fabric is synonymous with cloth, material, goods, or

piece goods.

The word 'fabric' also derives from Latin, with roots in the

Proto-Indo-European language. Stemming most recently from the

Middle French , or "building," and earlier from the Latin ('workshop; an art, trade; a skillful production, structure, fabric'), the noun stems from the Latin " artisan who works in hard materials', which itself is derived from the Proto-Indo-European ''dhabh-'', meaning 'to fit together'.

Cloth

Cloth is a kind of fabric that consists of a fine, flexible network of yarns. While the term "cloth" is synonymous with fabric, not all fabrics can be defined as cloth.

The word 'cloth' derives from the

Old English

Old English (, ), or Anglo-Saxon, is the earliest recorded form of the English language, spoken in England and southern and eastern Scotland in the early Middle Ages. It was brought to Great Britain by Anglo-Saxon settlement of Britain, Anglo ...

, meaning "a cloth, woven, or felted material to wrap around one's body', from the

Proto-Germanic , similar to the

Old Frisian , the

Middle Dutch , the

Middle High German and the

German , all meaning 'garment'.

History

Textiles themselves are too fragile to survive across millennia; the tools used for

spinning

Spin or spinning most often refers to:

* Spinning (textiles), the creation of yarn or thread by twisting fibers together, traditionally by hand spinning

* Spin, the rotation of an object around a central axis

* Spin (propaganda), an intentionally b ...

and

weaving make up most prehistoric evidence for textile work. The earliest tool for spinning was the

spindle to which a

whorl

A whorl ( or ) is an individual circle, oval, volution or equivalent in a whorled pattern, which consists of a spiral or multiple concentric objects (including circles, ovals and arcs).

Whorls in nature

File:Photograph and axial plane flo ...

was eventually added. The weight of the whorl improved the thickness and twist of spun thread. Later the

spinning wheel was invented. Historians are unsure where; some say China and others India.

The precursor of today's textiles includes leaves, barks, fur pelts, and felted cloths.

The Banton Burial Cloth, the oldest existing example of

warp

Warp, warped or warping may refer to:

Arts and entertainment Books and comics

* WaRP Graphics, an alternative comics publisher

* ''Warp'' (First Comics), comic book series published by First Comics based on the play ''Warp!''

* Warp (comics), a ...

ikat in Southeast

Asia, is displayed at the

National Museum of the Philippines. The cloth was most likely made by the native Asian people of the northwest

Romblon.

The first clothes, worn at least 70,000 years ago and perhaps much earlier, were probably made of animal skins and helped protect early humans from the elements. At some point, people learned to weave plant fibers into textiles.

The discovery of

dyed flax fibers in a cave in the

Republic of Georgia dated to 34,000

BCE suggests that textile-like materials were made as early as the Paleolithic era.

[Supporting Online Material]

The speed and scale of textile production have been altered almost beyond recognition by industrialization and the introduction of modern

manufacturing techniques.

Textile industry

The

textile industry grew out of art and craft and was kept going by

guilds. In the 18th and 19th centuries, during the

industrial revolution, it became increasingly mechanized. In 1765, when a machine for spinning wool or cotton called the

spinning jenny was invented in the United Kingdom, textile production became the first economic activity to be industrialised. In the 20th century,

science and

technology were driving forces.

Naming

Most textiles were called by their generic names, their place of origin, or were put into groups based loosely on manufacturing techniques, characteristics, and on their designs.

,

Olefin

In organic chemistry, an alkene is a hydrocarbon containing a carbon–carbon double bond.

Alkene is often used as synonym of olefin, that is, any hydrocarbon containing one or more double bonds.H. Stephen Stoker (2015): General, Organic, an ...

,

Acrylic are all generic names for some synthetic fibers.

Related terms

The related words "fabric"

and "cloth"

and "material" are often used in textile assembly trades (such as

tailoring and

dressmaking) as synonyms for ''textile''. However, there are subtle differences in these terms in specialized usage. A textile is any material made of interlacing fibers, including

carpeting and

geotextiles, which may not necessarily be used in the production of further goods, such as

clothing and

upholstery. A ''fabric'' is a material made through

weaving,

knitting

Knitting is a method by which yarn is manipulated to create a textile, or fabric. It is used to create many types of garments. Knitting may be done by hand or by machine.

Knitting creates stitches: loops of yarn in a row, either flat or i ...

, spreading, felting, stitching, crocheting or bonding that may be used in the production of further products, such as clothing and upholstery, thus requiring a further step of the production. ''Cloth'' may also be used synonymously with ''fabric'', but often specifically refers to a piece of fabric that has been processed or cut.

* Greige goods: Textiles that are raw and unfinished are referred to as

greige goods

Greige goods (Gray goods, Grey goods, Corah or ) are loom state woven fabrics, or unprocessed knitted fabrics. Greige goods undergo many subsequent processes, for instance, dyeing, printing, and finishing, prior to further converting to finished ...

. After manufacturing, the materials are processed and finished.

* Piece goods:

Piece goods were textile materials sold in cut pieces as specified by the buyer. Piece goods were either cut from a fabric roll or made to a specific length, also known as yard goods.

Types

Textiles are various materials made from fibers and yarns. The term "textile" was originally only used to refer to woven fabrics, but today it covers a broad range of subjects.

Textiles are classified at various levels, such as according to fiber origin (natural or synthetic), structure (woven, knitted, nonwoven), finish, etc.

However, there are primarily two types of textiles:

Consumer textiles

Textiles have an assortment of uses, the most common of which are for

clothing and for

containers such as bags and

baskets. In the household, textiles are used in

carpeting, upholstered

furnishings,

window shade

A window blind is a type of window covering. There are many different kinds of window blinds which use a variety of control systems. A typical window blind is made up of several long horizontal or vertical slats of various types of hard mater ...

s,

towels, coverings for tables, beds, and other flat surfaces, and in

art. Textiles are used in many traditional hand

crafts such as

sewing,

quilting, and

embroidery.

Technical textiles

Textiles produced for industrial purposes, and designed and chosen for technical characteristics beyond their appearance, are commonly referred to as ''

technical textiles.'' Technical textiles include textile structures for automotive applications, medical textiles (such as implants),

geotextile (reinforcement of embankments), agrotextiles (textiles for

crop protection), protective clothing (such as clothing resistant to heat and radiation for fire fighter clothing, against molten metals for welders, stab protection, and

bullet

A bullet is a kinetic projectile, a component of firearm ammunition that is shot from a gun barrel. Bullets are made of a variety of materials, such as copper, lead, steel, polymer, rubber and even wax. Bullets are made in various shapes and co ...

proof vests).

In the workplace, textiles can be used in industrial and scientific processes such as filtering. Miscellaneous uses include

flag

A flag is a piece of fabric (most often rectangular or quadrilateral) with a distinctive design and colours. It is used as a symbol, a signalling device, or for decoration. The term ''flag'' is also used to refer to the graphic design empl ...

s,

backpacks,

tent

A tent () is a shelter consisting of sheets of fabric or other material draped over, attached to a frame of poles or a supporting rope. While smaller tents may be free-standing or attached to the ground, large tents are usually anchored using gu ...

s,

nets, cleaning

rags,

transportation devices such as

balloons,

kites,

sail

A sail is a tensile structure—which is made from fabric or other membrane materials—that uses wind power to propel sailing craft, including sailing ships, sailboats, windsurfers, ice boats, and even sail-powered land vehicles. Sails may ...

s, and

parachute

A parachute is a device used to slow the motion of an object through an atmosphere by creating drag or, in a ram-air parachute, aerodynamic lift. A major application is to support people, for recreation or as a safety device for aviators, who ...

s; textiles are also used to provide strengthening in

composite materials such as

fibreglass and industrial

geotextiles.

Due to the often highly technical and legal requirements of these products, these textiles are typically tested in order to ensure they meet stringent performance requirements. Other forms of technical textiles may be produced to experiment with their scientific qualities and to explore the possible benefits they may have in the future. Threads coated with

zinc oxide nanowires, when woven into fabric, have been shown capable of "self-powering nanosystems", using vibrations created by everyday actions like wind or body movements to generate energy.

Significance

Textiles are all around us. The textile is a component of basic needs like food and shelter. Textiles are everywhere in our lives, from bath towels to space suits. Textiles help humans by comforting, protecting, and extending their lives. Textiles meet our clothing needs, keeping us warm in the winter and cool in the summer. There are several applications for textiles, such as medical textiles, intelligent textiles, and automotive textiles. All of them contribute to the well-being of humans.

Serviceability in textiles

The term "serviceability" refers to a textile product's ability to meet the needs of consumers. The emphasis is on knowing the target market and matching the needs of the target market to the product's serviceability. Serviceability in textiles or Performance is the ability of textile materials to withstand various conditions, environments, and hazards. Aesthetics, durability, comfort and safety, appearance retention, care, environmental impact, and cost are the serviceability concepts employed in structuring the material.

Components

Fibers, yarns, fabric construction, and finishes and designing

f garments

F, or f, is the sixth letter in the Latin alphabet, used in the modern English alphabet, the alphabets of other western European languages and others worldwide. Its name in English is ''ef'' (pronounced ), and the plural is ''efs''.

Hist ...

are the various components of a textile product. The selection of components varies with the intended use. Henceforth, the fibers, yarns, and fabric manufacturing systems are selected with consideration of the required performance.

Use and applications

Other uses

Textiles, textile production, and clothing were necessities of life in prehistory, intertwined with the social, economic, and religious systems. Other than clothing, textile crafts produced utilitarian, symbolic, and opulent items. Archaeological artifacts from the Stone Age and the Iron Age in Central Europe are used to examine prehistoric clothing and its role in forming individual and group identities.

Source of knowledge

Artifacts unearthed in various

archaeological excavation

In archaeology, excavation is the exposure, processing and recording of archaeological remains. An excavation site or "dig" is the area being studied. These locations range from one to several areas at a time during a project and can be condu ...

s informs us about the remains of past human life and their activities. Dyed flax fibers discovered in the Republic of Georgia indicate that textile-like materials were developed during the

Paleolithic period.

Radiocarbon dates

Radiocarbon dating (also referred to as carbon dating or carbon-14 dating) is a method for determining the age of an object containing organic material by using the properties of radiocarbon, a radioactive isotope of carbon.

The method was dev ...

the microscopic fibers to 36,000 years ago, when modern humans migrated from Africa.

Several textile remnants, such as the Inca Empire's textile arts remnants, which embody the Incas' aesthetics and social ideals, serve as a means for disseminating information about numerous civilizations, customs, and cultures.

There are

textile museums that display history related to many aspects of textiles. The Textile Museum raises public awareness and appreciation of the artistic merits and cultural significance of the world's textiles on a local, national, and international scale.

Textile Museum in

Washington, D.C., was established in 1925.

Narrative art

The

Bayeux Tapestry is a rare example of secular

Romanesque art

Romanesque art is the art of Europe from approximately 1000 AD to the rise of the Gothic Art, Gothic style in the 12th century, or later depending on region. The preceding period is known as the Pre-Romanesque period. The term was invented by 1 ...

. The art work depicts the

Norman Conquest of England in 1066.

Decorative art

Textiles are also used for

decorative art

]

The decorative arts are arts or crafts whose object is the design and manufacture of objects that are both beautiful and functional. It includes most of the arts making objects for the interiors of buildings, and interior design, but not usual ...

.

Pipili appliqué work, Appliqué work of pipili is decorative art of

Odisha, a state in

eastern India

East India is a region of India consisting of the Indian states of Bihar, Jharkhand, Odisha

and West Bengal and also the union territory of the Andaman and Nicobar Islands. The region roughly corresponds to the historical region of Magadha fr ...

, used for

umbrellas, wall hangings, lamp sheds, and bags. To make a range of decorative products, colored clothes are sewn in the shapes of animals, birds, flowers, and magnificent walls on a base cloth.

Architextiles

Architextiles

Architextiles refers to a broad range of projects and approaches that combine architecture, textiles, and materials science. Architextiles explore textile-based approaches and inspirations for creating structures, spaces, surfaces, and textures ...

, a combination of the words architecture and textile, are textile-based assemblages. Awnings are a basic type of architectural textile.

Mughal Shahi Lal Dera Tent, which was a movable palace, is an example of the architextiles of the

Mughal period.

Currency

Textiles had been used as currency as well. In Africa, textiles were used as currency in addition to being used for clothing, headwear, swaddling, tents, sails, bags, sacks, carpets, rugs, curtains, etc.Along the east–west axis in sub-Saharan Africa, cloth strip, which was typically produced in the savannah, was used as a form of currency.

Votive offering

Textiles were among the

objects offered to the gods

otive offering in ancient Greece for

religious purposes.

Fiber

The smallest component of a fabric is fiber; fibers are typically spun into yarn, and yarns are used to make fabrics. Fibers are very thin and hair-like structures. The sources of fibers may be

natural,

synthetic Synthetic things are composed of multiple parts, often with the implication that they are artificial. In particular, 'synthetic' may refer to:

Science

* Synthetic chemical or compound, produced by the process of chemical synthesis

* Synthetic o ...

, or both.

Global consumption

Global fiber production per person has increased from 8.4 kilograms in 1975 to 14.3 kilograms in 2021. After a modest drop due to

COVID-19 pandemic in 2020, global fiber output rebounded to 113 million tons in 2021. Global fiber output roughly doubled from 58 million tons in 2000 to 113 million tons in 2021 and is anticipated to reach 149 million tons in 2030.

The demand for synthetic fibers is increasing rapidly. This has numerous causes. Reasons include its low price, the demand-supply imbalance of cotton, and its

ynthetic fibers'versatility in design and application. Synthetic fibers accounts for 70% of global fiber use, mainly polyester. By 2030, the synthetic fiber market will reach 98.21 billion US dollars. From 2022 to 2030, the market is anticipated to increase by 5.1% per year.

Fiber Sources

* Natural fibers are obtained from plants, animals and minerals.

Since prehistoric times, textiles have been made from natural fibers. Natural fibers are further categorized as cellulosic, protein, and mineral.

* Synthetic or manmade fibers are manufactured with

chemical synthesis.

* Semi-synthetic: A subset of synthetic or manmade fibers is semi-synthetic fiber. Rayon is a classified as a semi-synthetic fiber, made with natural polymers.

Monomers are the building blocks of polymers. Polymers in fibers are of two types: additive or condensation. Natural fibers, such as cotton and wool, have a condensation polymer type, whereas synthetic fibers can have either an additive or a condensation polymer type. For example,

acrylic fiber and

olefin fibers have additive polymers, and

nylon and

polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natural ...

are condensation polymers.

Types

Fiber properties

Fiber properties influence textile characteristics such as aesthetics, durability, comfort, and cost.

Fineness is one of the important characteristics of the fibers. They have a greater length-to-width ratio

00 times the diameter Fibers need to be strong, cohesive, and flexible. The usefulness of fibers are characterized on the basis of certain parameters such as strength, flexibility, and length to diameter ratio, and spinnability. Natural fibers are relatively short

staple

Staple may refer to:

*Staple food, a foodstuff that forms the basic constituent of a diet

*Staple (fastener), a small formed metal fastener

**Surgical staple

Arts, entertainment, and media

* Staple (band), a Christian post-hardcore band

** ''Stap ...

] in length. Synthetic fibers are produced in longer lengths called filaments. Silk is the only natural fiber that is a filament. The classification of fibers is based on their origin, derivation, and generic types.

Certain properties of synthetic fibers, such as their diameter,

cross section, and color, can be altered during production.

Cotton: Cotton has a long history of use in the clothing due to its favorable properties. This fiber is soft, moisture-absorbent, breathable, and is renowned for its long durability.

Blends (blended textiles)

Fabric or

yarn produced with a

combination of two or more types of different

fibers

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate ...

, or yarns to obtain desired traits. Blending is possible at various stages of

textile manufacturing. Final composition is liable for the properties of the resultant product.

Natural and

synthetic fiber

Synthetic fibers or synthetic fibres (in British English; see spelling differences) are fibers made by humans through chemical synthesis, as opposed to natural fibers that are directly derived from living organisms, such as plants (like cotton) ...

s are blended to overcome disadvantage of single fiber properties and to achieve better performance characteristics and aesthetic effects such as

devoré,

heather effect, cross dyeing and stripes pattern etc.

Clothing woven from a blend of

cotton and

polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natural ...

can be more durable and easier to maintain than material woven solely from cotton. Other than sharing functional properties, blending makes the products more economical.

Union or Union fabrics is the 19th century term for blended fabrics. While it is no longer in use. ''Mixture'' or ''mixed cloth'' is another term used for blended cloths when different types of yarns are used in warp and weft sides.

Blended textiles are not new.

*

Mashru

Mashru (also historically spelled mashroo, misru, mushroo or mushru) is a woven cloth that is a blend of silk and cotton. It was historically a hand-woven satin silk fabric variety found in the Indian subcontinent, and its proper use is described ...

was a 16th-century fabric, is one of the earliest forms of "mixed cloth", a material composed of silk and cotton.

*

Siamoise was a 17th-century cotton and linen material.

Composition

Fiber composition the fiber blend composition of mixtures of the fibers, is an important criterion to analyze the behavior, properties such as functional aspects, and commercial classification of the merchandise.

The most common blend is cotton and polyester. Regular blended fabric is 65% polyester and 35% cotton. It is called a ''reverse blend'' if the ratio of cotton predominates—the percentage of the fibers changes with the price and required properties.

Blending adds value to the textiles; it helps in reducing the cost (artificial fibers are less expensive than natural fibers) and adding advantage in properties of the final product. For instance, a small amount of spandex adds stretch to the fabrics. Wool can add warmth.

Uses of different fibers

Natural fibers

Plant

*

Grass,

rush

Rush(es) may refer to:

Places

United States

* Rush, Colorado

* Rush, Kentucky

* Rush, New York

* Rush City, Minnesota

* Rush Creek (Kishwaukee River tributary), Illinois

* Rush Creek (Marin County, California), a stream

* Rush Creek (Mono Cou ...

,

hemp

Hemp, or industrial hemp, is a botanical class of ''Cannabis sativa'' cultivars grown specifically for industrial or medicinal use. It can be used to make a wide range of products. Along with bamboo, hemp is among the fastest growing plants o ...

, and

sisal are all used in making

rope. In the first two, the entire plant is used for this purpose, while in the last two, only fibers from the plant are used.

Coir (

coconut

The coconut tree (''Cocos nucifera'') is a member of the palm tree family ( Arecaceae) and the only living species of the genus ''Cocos''. The term "coconut" (or the archaic "cocoanut") can refer to the whole coconut palm, the seed, or the ...

fiber) is used in making

twine, and also in floormats,

doormats,

brush

A brush is a common tool with bristles, wire or other filaments. It generally consists of a handle or block to which filaments are affixed in either a parallel or perpendicular orientation, depending on the way the brush is to be gripped durin ...

es,

mattress

A mattress is a large, usually rectangular pad for supporting a lying person. It is designed to be used as a bed, or on a bed frame as part of a bed. Mattresses may consist of a quilted or similarly fastened case, usually of heavy cloth, conta ...

es, floor tiles, and

sacking.

*

Straw

Straw is an agricultural byproduct consisting of the dry stalks of cereal plants after the grain and chaff have been removed. It makes up about half of the yield of cereal crops such as barley, oats, rice, rye and wheat. It has a number ...

and

bamboo are both used to make hats. Straw, a dried form of grass, is also used for stuffing, as is

kapok.

*Fibers from

pulpwood

Pulpwood is timber with the principal use of making wood pulp for paper production.

Applications

* Trees raised specifically for pulp production account for 15% of world pulp production, old growth forests 9% and second- and third- and more gener ...

trees, cotton,

rice, hemp, and

nettle are used in making

paper.

*

Cotton,

flax

Flax, also known as common flax or linseed, is a flowering plant, ''Linum usitatissimum'', in the family Linaceae. It is cultivated as a food and fiber crop in regions of the world with temperate climates. Textiles made from flax are known in ...

,

jute

Jute is a long, soft, shiny bast fiber that can be spun into coarse, strong threads. It is produced from flowering plants in the genus ''Corchorus'', which is in the mallow family Malvaceae. The primary source of the fiber is ''Corchorus olit ...

,

hemp

Hemp, or industrial hemp, is a botanical class of ''Cannabis sativa'' cultivars grown specifically for industrial or medicinal use. It can be used to make a wide range of products. Along with bamboo, hemp is among the fastest growing plants o ...

,

modal,

banana

A banana is an elongated, edible fruit – botanically a berry – produced by several kinds of large herbaceous flowering plants in the genus ''Musa''. In some countries, bananas used for cooking may be called "plantains", distinguis ...

,

bamboo,

lotus

Lotus may refer to:

Plants

*Lotus (plant), various botanical taxa commonly known as lotus, particularly:

** ''Lotus'' (genus), a genus of terrestrial plants in the family Fabaceae

**Lotus flower, a symbolically important aquatic Asian plant also ...

,

eucalyptus,

mulberry

''Morus'', a genus of flowering plants in the family Moraceae, consists of diverse species of deciduous trees commonly known as mulberries, growing wild and under cultivation in many temperate world regions. Generally, the genus has 64 identif ...

, and

sugarcane

Sugarcane or sugar cane is a species of (often hybrid) tall, Perennial plant, perennial grass (in the genus ''Saccharum'', tribe Andropogoneae) that is used for sugar Sugar industry, production. The plants are 2–6 m (6–20 ft) tall with ...

are all used in clothing.

Piña (

pineapple fiber) and

ramie are also fibers used in clothing, generally with a blend of other fibers such as cotton. Nettles have also been used to make a fiber and fabric very similar to hemp or flax. The use of milkweed stalk fiber has also been reported, but it tends to be somewhat weaker than other fibers like hemp or flax.

*The inner bark of the

lacebark tree is a fine netting that has been used to make clothing and accessories as well as utilitarian articles such as rope.

*

Acetate

An acetate is a salt (chemistry), salt formed by the combination of acetic acid with a base (e.g. Alkali metal, alkaline, Alkaline earth metal, earthy, Transition metal, metallic, nonmetallic or radical Radical (chemistry), base). "Acetate" als ...

is used to increase the shininess of certain fabrics such as

silks,

velvets, and

taffetas.

*

Seaweed

Seaweed, or macroalgae, refers to thousands of species of macroscopic, multicellular, marine algae. The term includes some types of '' Rhodophyta'' (red), ''Phaeophyta'' (brown) and ''Chlorophyta'' (green) macroalgae. Seaweed species such as ...

is used in the production of textiles: a water-soluble fiber known as

alginate is produced and is used as a holding fiber; when the cloth is finished, the alginate is dissolved, leaving an open area.

*

Rayon

Rayon is a semi-synthetic fiber, made from natural sources of regenerated cellulose, such as wood and related agricultural products. It has the same molecular structure as cellulose. It is also called viscose. Many types and grades of viscose f ...

is a manufactured fabric derived from plant pulp. Different types of rayon can imitate

feel and texture of silk, cotton, wool, or linen.

Fibers from the stalks of plants, such as hemp, flax, and nettles, are also known as 'bast' fibers. Hemp Fiber is yellowish-brown fiber made from the hemp plant. The fiber characteristics are coarser, harsher, strong and lightweight. Hemp fiber is used primary to make twine, rope and cordage.

Animal

Animal textiles are commonly made from

hair

Hair is a protein filament that grows from follicles found in the dermis. Hair is one of the defining characteristics of mammals.

The human body, apart from areas of glabrous skin, is covered in follicles which produce thick terminal and f ...

,

fur,

skin or

silk (in the case of silkworms).

* Wool refers to the hair of the domestic

sheep or

goat, which is distinguished from other types of animal hair in that the individual strands are coated with scales and tightly crimped, and the wool as a whole is coated with a

wax mixture known as

lanolin (sometimes called wool grease), which is waterproof and dirtproof. The lanolin and other contaminants are removed from the raw wool before further processing.

Woolen refers to a yarn produced from carded, non-parallel fibre, while

worsted refers to a finer yarn spun from longer fibers which have been combed to be parallel.

**Other animal textiles which are made from hair or fur are ''alpaca wool'', ''

vicuña wool'', ''llama wool'', and ''camel hair'', generally used in the production of

coats,

jacket

A jacket is a garment for the upper body, usually extending below the hips. A jacket typically has sleeves, and fastens in the front or slightly on the side. A jacket is generally lighter, tighter-fitting, and less insulating than a coat, which ...

s,

ponchos,

blankets, and other warm coverings.

** ''

Cashmere'', the hair of the Indian

cashmere goat, and

mohair, the hair of the North African

angora goat, are types of wool known for their softness. Used in the production of sweaters and scarfs.

** ''

Angora'' refers to the long, thick, soft hair of the

angora rabbit.

Qiviut is the fine inner wool of the

muskox.

* Silk is an animal textile made from the fibres of the

cocoon of the Chinese

silkworm

The domestic silk moth (''Bombyx mori''), is an insect from the moth family Bombycidae. It is the closest relative of ''Bombyx mandarina'', the wild silk moth. The silkworm is the larva or caterpillar of a silk moth. It is an economically imp ...

which is spun into a smooth fabric prized for its softness. There are two main types of the silk: 'mulberry silk' produced by the

Bombyx Mori, and 'wild silk' such as

Tussah silk (wild silk). Silkworm larvae produce the first type if cultivated in habitats with fresh mulberry leaves for consumption, while Tussah silk is produced by silkworms feeding purely on oak leaves. Around four-fifths of the world's silk production consists of cultivated silk. Silk production consists of pillow covers, dresses, tops, skirts, bed sheets, curtains.

Microbes

Bacterial cellulose

Bacterial cellulose is an organic compound with the formula produced by certain types of bacteria. While cellulose is a basic structural material of most plants, it is also produced by bacteria, principally of the genera ''Acetobacter'', Sarcina ( ...

can be made from industrial organic and agricultural waste, and used as material for textiles and clothing.

Mineral

* Asbestos and

basalt fibre

Basalt fibers are produced from basalt rocks by melting them and converting the melt into fibers.

Basalts are rocks of igneous origin. The main energy consumption for the preparation of basalt raw materials to produce of fibers is made in natural ...

are used for vinyl tiles, sheeting and adhesives, "transite" panels and siding, acoustical ceilings, stage curtains, and fire blankets.

*

Glass fibre

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass.

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the inventio ...

is used in the production of ironing board and mattress covers, ropes and cables, reinforcement fibre for composite materials, insect netting, flame-retardant and protective fabric, soundproof, fireproof, and insulating fibres. Glass fibres are woven and coated with

Teflon to produce

beta cloth, a virtually fireproof fabric which replaced nylon in the outer layer of United States

space suits since 1968.

* Metal fibre, metal foil, and metal wire have a variety of uses, including the production of

cloth-of-gold and

jewellery.

Hardware cloth

A mesh is a barrier made of connected strands of metal, fiber, or other flexible or ductile materials. A mesh is similar to a web or a net in that it has many attached or woven strands.

Types

* A plastic mesh may be extruded, oriented, ex ...

(US term only) is a coarse woven

mesh of steel wire, used in construction. It is much like standard

window screening, but heavier and with a more open weave.

Minerals and natural and synthetic fabrics may be combined, as in

emery cloth, a layer of

emery abrasive glued to a cloth backing. Also, "sand cloth" is a U.S. term for fine wire mesh with abrasive glued to it, employed like emery cloth or coarse

sandpaper.

Synthetic

In the 20th century, they were supplemented by artificial fibers made from

petroleum. Textiles are made in various strengths and degrees of durability, from the finest

microfibre made of strands thinner than one

denier to the sturdiest

canvas

Canvas is an extremely durable plain-woven fabric used for making sails, tents, marquees, backpacks, shelters, as a support for oil painting and for other items for which sturdiness is required, as well as in such fashion objects as handbags ...

.

Synthetic textiles are used primarily in the production of clothing, as well as the manufacture of

geotextiles. Synthetic fibers are those that are chemically constructed, therefore are unsustainable.

*

Polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natural ...

fibre is used in all types of clothing, either alone or blended with fibres such as cotton.

*

Aramid fibre (e.g.

Twaron) is used for flame-retardant clothing, cut-protection, and armour.

*

Acrylic is a fibre used to imitate wools, including cashmere, and is often used in replacement of them.

*

Nylon is a fibre used to imitate silk; it is used in the production of

pantyhose. Thicker nylon fibres are used in

rope and outdoor clothing.

*

Spandex (trade name ''Lycra'') is a

polyurethane product that can be made tight-fitting without impeding movement. It is used to make

activewear,

bras, and

swimsuit

A swimsuit is an item of clothing designed to be worn by people engaging in a water-based activity or List of water sports, water sports, such as swimming, Diving (sport), diving and surfing, or sun-orientated activities, such as sun bathing. Di ...

s.

*

Olefin fibre

Olefin fiber is a synthetic fiber made from a polyolefin, such as polypropylene or polyethylene. It is used in wallpaper, carpeting, ropes, and vehicle interiors.

Olefin's advantages are its strength, colorfastness and comfort, its resistance ...

is a fibre used in activewear, linings, and warm clothing. Olefins are hydrophobic, allowing them to dry quickly. A sintered felt of olefin fibres is sold under the trade name

Tyvek.

*

Ingeo is a

polylactide fibre blended with other fibres such as cotton and used in clothing. It is more hydrophilic than most other synthetics, allowing it to wick away perspiration.

*

Lurex is a metallic fibre used in clothing embellishment.

*

Milk proteins have also been used to create synthetic fabric. Milk or

casein fibre cloth was developed during

World War I in Germany, and further developed in Italy and America during the 1930s. Milk fibre fabric is not very durable and wrinkles easily, but has a pH similar to human skin and possesses anti-bacterial properties. It is marketed as a

biodegradable

Biodegradation is the breakdown of organic matter by microorganisms, such as bacteria and fungi. It is generally assumed to be a natural process, which differentiates it from composting. Composting is a human-driven process in which biodegradati ...

,

renewable synthetic fibre.

*

Carbon fibre is mostly used in composite materials, together with resin, such as

carbon fibre reinforced plastic. The fibres are made from polymer fibres through carbonization.

Production methods

Textile manufacturing has progressed from prehistoric crafts to a fully automated industry.

Over the years, there have been continuous improvements in fabric structure and design.

Important parameters in fabric selection:

The primary consideration in fabric selection is the end use. The fabric needs vary greatly depending on the application. Similar types of fabric may not be suitable for all applications.

Fabric weight

Textile fibers, Thread (yarn), threads, yarns and fabrics are measured in a multiplicity of units.

* A fiber, a single filament of natural material, such as cotton, linen or wool, or artificial material such as nylon, polyester, metal or mineral f ...

is an important criteria while producing different fabrics. A carpet requires a fabric with 1300 GSM, but a robe may be made with 160 GSM. Certainly, fabrics for clothes and carpets have distinct weights.

Stretchable fabrics have greater movability and are thus more comfortable than fabrics with no stretch or less stretch.

Textile exports

According to the United Nations Commodity Trade Statistics Database, the global textiles and apparel export market reached $772 billion in 2013.

Changing dynamics of the market

China is the largest exporter of textile goods. The majority of China's exports consist of apparel, apparel accessories, textile yarns, and textile products. The competitive advantages of the China are low prices and abundant labor, lowered commercial obstacles, and a ready supply of raw materials. China, along with the United States and India, is a major producer of cotton.

China's apparel market share has declined in recent years due to various reasons and a shift toward high-end, sophisticated products. Additionally, the investors from China made stakes in Myanmar, Vietnam, and Cambodia. Last year, its market share was 36.7%, or $161 billion, a decline of 8% year-over-year. In other words, China lost $14 billion in garment work orders to other countries in a single year. In 2016, Bangladesh's apparel market share was valued at $28 billion, increasing 7.69 percent from the previous year.

In 2016 the leading exporters of apparel were; China ($161 billion), Bangladesh ($28 billion), Vietnam ($25 billion), India ($18 billion), Hong Kong ($16 billion), Turkey ($15 billion), and Indonesia ($7 billion).

Finishing

The fabric, when it leaves a loom or knitting machine, is not readily usable. It may be rough, uneven, or have flaws like skewing. Hence, it is necessary to finish the fabric. Finishing techniques enhance the value of the treated fabrics.

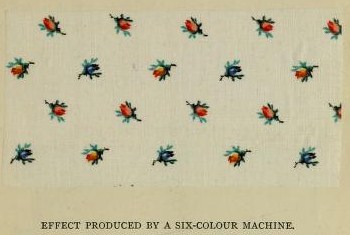

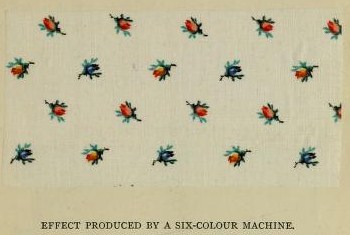

After manufacturing, textiles undergo a range of finishing procedures, including bleaching, dyeing, printing, as well as mechanical and chemical finishing.

Coloration

Textiles are often

dyed, with fabrics available in almost every

colour. The dyeing process often requires several dozen gallons of water for each pound of clothing. Coloured designs in textiles can be created by weaving together fibres of different colours (

tartan or Uzbek Ikat), adding coloured stitches to finished fabric (

embroidery), creating patterns by

resist dyeing methods, tying off areas of cloth and dyeing the rest (

tie-dyeing), drawing wax designs on cloth and dyeing in between them (

batik), or using various printing processes on finished fabric.

Woodblock printing, still used in India and elsewhere today, is the oldest of these dating back to at least 220 CE in

China

China, officially the People's Republic of China (PRC), is a country in East Asia. It is the world's most populous country, with a population exceeding 1.4 billion, slightly ahead of India. China spans the equivalent of five time zones and ...

. Textiles are also sometimes

bleach

Bleach is the generic name for any chemical product that is used industrially or domestically to remove color (whitening) from a fabric or fiber or to clean or to remove stains in a process called bleaching. It often refers specifically, to ...

ed, making the textile pale or white.

Finishes

Textile finishing is the process of converting the loomstate or raw goods into a useful product, which can be done mechanically or chemically. Finishing is a broad term that refers to a variety of physical and chemical techniques and treatments that finish one stage of textile production while also preparing for the next. Textile finishing can include aspects like improving surface feel, aesthetical enhancement, and adding advanced chemical finishes.

A finish is any process that transforms

unfinished products into finished products. This includes mechanical finishing and chemical applications which alter the composition of treated textiles (fiber, yarn or fabric.)

Since the 1990s, with advances in technologies such as

permanent press process,

finishing agents have been used to strengthen fabrics and make them wrinkle free. More recently, nanomaterials research has led to additional advancements, with companies such as Nano-Tex and NanoHorizons developing permanent treatments based on metallic

nanoparticles for making textiles more resistant to things such as water, stains, wrinkles, and pathogens such as bacteria and fungi.

Textiles receive a range of treatments before they reach the end-user. From

formaldehyde finishes (to improve crease-resistance) to biocidic finishes and from flame retardants to dyeing of many types of fabric, the possibilities are almost endless. However, many of these finishes may also have detrimental effects on the end user. A number of disperse, acid and reactive dyes, for example, have been shown to be allergenic to sensitive individuals. Further to this, specific dyes within this group have also been shown to induce purpuric contact dermatitis.

, meaning "iron yarn" in English, is a light-reflecting, strong material invented in

Germany in the 19th century. It is made by soaking cotton threads in a starch and paraffin wax solution. The threads are then stretched and polished by steel rollers and brushes. The result of the process is a lustrous, tear-resistant yarn which is extremely hardwearing.

[''Industriegeschichte aus dem Bergischen land''](_blank)

(in German). (Accessed: 27 November 2016)[WDR digit project. ''Eisengarnfabrikation in Barmen''.](_blank)

(Video (16 min) in German). (Accessed: 27 November 2016).

Environmental and health impacts

The textile sector is accountable for a substantial number of environmental impacts. However, the discharge of untreated effluents into water bodies is responsible for the majority of environmental harm produced by the textile sector. The textile sector is believed to utilise 79 trillion litres of water per year and to discharge around 20% of all industrial effluent into the environment. Reportedly,

aromatic and

heterocyclic compound

A heterocyclic compound or ring structure is a cyclic compound that has atoms of at least two different elements as members of its ring(s). Heterocyclic chemistry is the branch of organic chemistry dealing with the synthesis, properties, and ...

s with color-display and polar groups make up most of the dyes used in textile coloration processes. The structure is more complex and stable, making it more difficult to degrade printing and dyeing wastewater.

Many kinds of respiratory diseases, skin problems, and allergies may be caused by dyes and pigments discharged into the water.

Although formaldehyde levels in clothing are unlikely to be at levels high enough to cause an allergic reaction, due to the presence of such a chemical, quality control and testing are of utmost importance. Flame retardants (mainly in the brominated form) are also of concern where the environment, and their potential toxicity, are concerned.

Testing

Testing for these additives is possible at a number of commercial laboratories. It is also possible to have textiles tested according to the

Oeko-tex certification standard, which contains limits levels for the use of certain chemicals in textiles products.

Laws and regulations

Different countries have certain laws and regulations to protect consumers' interests. The

Textile Fiber Products Identification Act is a law that protects consumers in the United States. The act protects producer and consumer interests by implementing labelling (required content disclosure) and advertising requirements on textile products. The Textile Fiber Products Identification Act applies to all textile fiber products besides wool, which is governed by the Wool Product Label Number. The law prohibits misinformation about the fiber content, misbranding, and any unfair advertising practice, as well as requires businesses to operate in a particular manner.

Testing of textiles

Testing occurs at various stages of the textile manufacturing process, from raw material to finished product. The purpose of testing is to evaluate and analyze the regulatory compliance, the product's quality and performance, as well as to measure its specifications. Textile testing encompasses a wide range of methodologies, procedures, equipment, and sophisticated

laboratories. Local governments and authorized organization's such as

ASTM International,

International Organization for Standardization, and

American Association of Textile Chemists and Colorists establish standards for testing of textiles.

Some examples of tests at different stages:

For fiber: Fiber identification is a necessary test for determining fiber content and classifying products. The labelling of items with their fiber content percentage is a regulatory requirement. Using

microscopy

Microscopy is the technical field of using microscopes to view objects and areas of objects that cannot be seen with the naked eye (objects that are not within the resolution range of the normal eye). There are three well-known branches of micr ...

, solubility, and burn tests, fibers are distinguished from one another. More fiber relating tests include fiber length, diameter,

Micronaire

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

* A fiber, a single filament of natural material, such as cotton, linen or wool, or artificial material such as nylon, polyester, metal or mineral fiber, or man-m ...

.

For yarn:

Yarn count

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

* A fiber, a single filament of natural material, such as cotton, linen or wool, or artificial material such as nylon, polyester, metal or mineral fiber, ...

,

Denier, Strength, evenness.

For fabric:

Dimensional stability

In physics and mathematics, the dimension of a mathematical space (or object) is informally defined as the minimum number of coordinates needed to specify any point within it. Thus, a line has a dimension of one (1D) because only one coordina ...

,

color fastness,

thread count,

G.S.M,

pilling,

flammability.

Picture gallery

File:Karachi - Pakistan-market.jpg, Textile market on the sidewalks of Karachi, Pakistan

File:Simple-textile-magnified.jpg, Magnified view of a plain or tabby weave textile

File:P1080828.JPG, Fabric shop in canal town Mukalla, Yemen

File:DumbartonOaksTextileEuropa.jpg, Late antique textile, Egyptian, now in the Dumbarton Oaks collection

File:Conde nast fortuny.jpg, Mrs. Condé Nast wearing a silk Fortuny tea gown

File:Tablecloth romanian 1full view.jpg, Traditional tablecloth, Maramureș, Romania

File:Otavalo Artisan Market - Andes Mountains - South America - photograph 001.JPG, Textiles made from Alpaca wool at the Otavalo Artisan Market in the Andes Mountains, Ecuador

File:Banton Burial Cloth.JPG, The Banton Burial Cloth, the oldest existing example of warp ikat in Southeast Asia, displayed at the National Museum of the Philippines. The cloth was most likely made by the native Asia people of northwest Romblon.

File:Double ikat weaving from Sulu, Philippines, East-West Center.JPG, A double ikat weaving made by the Tausug people from Sulu

Sulu (), officially the Province of Sulu (Tausug language, Tausūg: ''Wilāya sin Lupa' Sūg''; tl, Lalawigan ng Sulu), is a Provinces of the Philippines, province of the Philippines in the Sulu Archipelago and part of the Bangsamoro, Bangsamor ...

, made of banana leaf stalk fiber ( Abacá)

File:1963 Zepel advertisement.jpg, Advertisement for Zepel, the trade name used to market Teflon as a fabric treatment

File:Plevna-sali 1932.jpg, A weaving shed

A weaving shed is a distinctive type of mill developed in the early 1800s in Lancashire, :Derbyshire and Yorkshire to accommodate the new power looms weaving cotton, silk, woollen and worsted. A weaving shed can be a stand-alone mill, or a com ...

of the Finlayson & Co

Finlayson Oy is a Finnish textile manufacturer. The company was founded in 1820 when James Finlayson, a Scottish engineer, established a cotton mill in Tampere. The company manufactures various interior textiles and bedding under the brand name ...

factory in Tampere, Finland, in 1932

File:Textile machinery at Cambrian Factory, Llanwrtyd (1293828).jpg, Textile machinery at the Cambrian Factory, Llanwrtyd, Wales, in the 1940s

File:BALLS OF COTTON (ANDHRA -SOUTH INDIA) READY FOR HARVEST.jpg, Cotton fiber

File:Nylon6 and Nylon 66.png, Nylon

File:Cloth 800.jpg, A variety of contemporary fabrics. From the left: evenweave cotton, velvet, printed cotton, calico, felt, satin, silk, hessian

A Hessian is an inhabitant of the German state of Hesse.

Hessian may also refer to:

Named from the toponym

*Hessian (soldier), eighteenth-century German regiments in service with the British Empire

**Hessian (boot), a style of boot

**Hessian f ...

, polycotton.

File:Dan Hadani collection (990044401360205171).jpg, A textile factory in Israel, 1969

This year is notable for Apollo 11's first landing on the moon.

Events January

* January 4 – The Government of Spain hands over Ifni to Morocco.

* January 5

**Ariana Afghan Airlines Flight 701 crashes into a house on its approach to ...

File:Tartan Clan Campbell.png, Woven tartan of Clan Campbell, Scotland

File:Embroidery-flowers-Alfaro-Nunez.jpg, Embroidered skirts by the Alfaro-Nùñez family of Cochas, Peru, using traditional Peruvian embroidery methodsArt-Gourds.com

Traditional Peruvian embroidery production methods

File:M0354 000727-005 1.jpg, alt=, A modern umbrella fabric has specific requirements for colour fastness to light, water and wet rubbing, and permeability.

File:Borduurtechnieken-applique kruis-gelegde draad.jpg, Appliqué cross. The edges are covered and stitches are hidden. It is overlaid with decorative gold thread.

File:Chiang Mai, Thailand, Colorful clothing.jpg, Clothing made of textiles, Thailand

File:Barong Up Close.jpg, Close-up view of a Barong Tagalog made with piña fiber in the Philippines

File:Scene with Fabric Tunnel - Srimangal - Sylhet Division - Bangladesh (12904860703).jpg, A fabric tunnel in Moulvibazar District, Bangladesh

File:49-QWSTION-BANANATEX-FABRIC.jpg, A modern Manila hemp made on industrial weaving machines

See also

*

Clothing in the ancient world

*

International Down and Feather Testing Laboratory

IDFL Laboratory and Institute, (originally known as the International Down and Feather Testing Laboratory) is the largest down and feather testing laboratory in the world with over 8,000 clients in 80 countries. IDFL provides testing services for ...

*

List of textile fibres Textile fibres or textile fibers (see spelling differences) can be created from many natural sources (animal hair or fur, cocoons as with silk worm cocoons), as well as semisynthetic methods that use naturally occurring polymers, and synthetic metho ...

*

Technical textile

*

Textile arts

*

Textile manufacturing (

terminology)

*

Textile printing

*

Timeline of clothing and textiles technology

References

Further reading

* Boucher, François.

20,000 Years of Fashion

''20,000 Years of Fashion: The History of Costume and Personal Adornment'' is a dictionary of western fashion from ancient times up to the 1960s, edited by Francois Boucher and his longtime assistant Yvonne Deslandres.

The book is widely cited a ...

: The history of costume and personal adornment. New York: Harry N. Abrams, 1987

* Conrad, James L. "'Drive That Branch': Samuel Slater, the Power Loom, and the Writing of America's Textile History." ''Technology and culture ''36.1 (1995): 1-28

online* Jenkins, David, ed.: ''The Cambridge History of Western Textiles'', Cambridge, UK: Cambridge University Press, 2003,

* Payne, Blanche; Winakor, Geitel; Farrell-Beck Jane (1992) ''The History of Costume, from the Ancient Mesopotamia to the Twentieth Century'', 2nd Edn, HarperCollins

* Piponnier, Françoise, and Perrine Mane; ''Dress in the Middle Ages''; Yale UP; 1997;

*

* Introduction by Teresa Archuleta-Sagel. 196 pages with 125 black and white as well as colour plates. Fisher is Curator Emirta, Textiles & Costumes of the

Museum of International Folk Art.

*

* Arai, Masanao (Textile Industry Research Institute of Gunma).

From Kitsch to Art Moderne: Popular Textiles for Women in the First Half of Twentieth-Century JapanArchive. ''Textile Society of America Symposium Proceedings''.

Textile Society of America, January 1, 1998.

{{Authority control

Clothing industry

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments,

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments,

Most textiles were called by their generic names, their place of origin, or were put into groups based loosely on manufacturing techniques, characteristics, and on their designs. Nylon,

Most textiles were called by their generic names, their place of origin, or were put into groups based loosely on manufacturing techniques, characteristics, and on their designs. Nylon,  Textiles are various materials made from fibers and yarns. The term "textile" was originally only used to refer to woven fabrics, but today it covers a broad range of subjects. Textiles are classified at various levels, such as according to fiber origin (natural or synthetic), structure (woven, knitted, nonwoven), finish, etc. However, there are primarily two types of textiles:

Textiles are various materials made from fibers and yarns. The term "textile" was originally only used to refer to woven fabrics, but today it covers a broad range of subjects. Textiles are classified at various levels, such as according to fiber origin (natural or synthetic), structure (woven, knitted, nonwoven), finish, etc. However, there are primarily two types of textiles:

Textiles produced for industrial purposes, and designed and chosen for technical characteristics beyond their appearance, are commonly referred to as '' technical textiles.'' Technical textiles include textile structures for automotive applications, medical textiles (such as implants), geotextile (reinforcement of embankments), agrotextiles (textiles for crop protection), protective clothing (such as clothing resistant to heat and radiation for fire fighter clothing, against molten metals for welders, stab protection, and

Textiles produced for industrial purposes, and designed and chosen for technical characteristics beyond their appearance, are commonly referred to as '' technical textiles.'' Technical textiles include textile structures for automotive applications, medical textiles (such as implants), geotextile (reinforcement of embankments), agrotextiles (textiles for crop protection), protective clothing (such as clothing resistant to heat and radiation for fire fighter clothing, against molten metals for welders, stab protection, and