Boiler (power Generation) on:

[Wikipedia]

[Google]

[Amazon]

An industrial boiler, originally used for supplying steam to a stationary steam engine

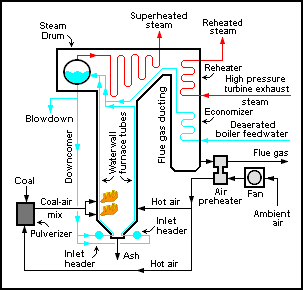

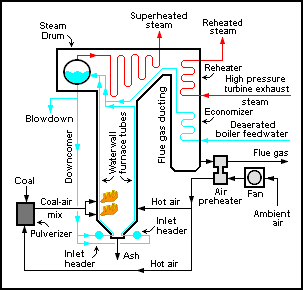

A boiler or steam generator is a device used to create steam by applying

The steam generator or steam boiler is an integral component of a steam engine when considered as a

The steam generator or steam boiler is an integral component of a steam engine when considered as a

heat energy

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is al ...

to water

Water (chemical formula ) is an Inorganic compound, inorganic, transparent, tasteless, odorless, and Color of water, nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living ...

. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed ''boilers'' and worked at low to medium pressure () but, at pressures above this, it is more usual to speak of a ''steam generator''.

A boiler or steam generator is used wherever a source of steam is required. The form and size depends on the application: mobile steam engines such as steam locomotives, portable engines and steam-powered road vehicles typically use a smaller boiler that forms an integral part of the vehicle; stationary steam engines, industrial installations and power stations will usually have a larger separate steam generating facility connected to the point-of-use by piping. A notable exception is the steam-powered fireless locomotive

A fireless locomotive is a type of locomotive which uses reciprocating engines powered from a reservoir of compressed air or steam, which is filled at intervals from an external source. They offer advantages over conventional steam locomotives of ...

, where separately-generated steam is transferred to a receiver (tank) on the locomotive.

As a component of a prime mover

The steam generator or steam boiler is an integral component of a steam engine when considered as a

The steam generator or steam boiler is an integral component of a steam engine when considered as a prime mover

Prime mover may refer to:

Philosophy

*Unmoved mover, a concept in Aristotle's writings

Engineering

* Prime mover (engine), motor, a machine that converts various other forms of energy (chemical, electrical, fluid pressure/flow, etc) into energy ...

. However it needs to be treated separately, as to some extent a variety of generator types can be combined with a variety of engine units. A boiler incorporates a firebox

Firebox may refer to:

*Firebox (steam engine), the area where the fuel is burned in a steam engine

*Firebox (architecture), the part of a fireplace where fuel is combusted

*Firebox Records

Firebox Records was a Finnish record label based in S ...

or furnace

A furnace is a structure in which heat is produced with the help of combustion.

Furnace may also refer to:

Appliances Buildings

* Furnace (central heating): a furnace , or a heater or boiler , used to generate heat for buildings

* Boiler, used t ...

in order to burn the fuel and generate heat

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is ...

. The generated heat is transferred to water to make steam, the process of boiling. This produces saturated steam

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization ...

at a rate which can vary according to the pressure above the boiling water. The higher the furnace temperature, the faster the steam production. The saturated steam thus produced can then either be used immediately to produce power via a turbine and alternator, or else may be further superheated

A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. Superheated steam is used in steam turbines for electricity generation, steam engines, and in processes such as steam reforming. There are ...

to a higher temperature; this notably reduces suspended water content making a given volume of steam produce more work and creates a greater temperature gradient, which helps reduce the potential to form condensation. Any remaining heat in the combustion gas

Combustion, or burning, is a high-temperature exothermic redox chemical reaction between a fuel (the reductant) and an oxidant, usually atmospheric oxygen, that produces oxidized, often gaseous products, in a mixture termed as smoke. Combustion ...

es can then either be evacuated or made to pass through an economiser

Economizers (US and Oxford spelling), or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, po ...

, the role of which is to warm the feed water before it reaches the boiler.

Types

Haycock and wagon top boilers

For the firstNewcomen engine

The atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to as the Newcomen fire engine (see below) or simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creati ...

of 1712, the boiler was little more than large brewer's kettle

A kettle, sometimes called a tea kettle or teakettle, is a type of pot specialized for boiling water, commonly with a ''lid'', ''spout'', and ''handle'', or a small electric kitchen appliance of similar shape that functions in a self-contained ...

installed beneath the power cylinder. Because the engine's power was derived from the vacuum

A vacuum is a space devoid of matter. The word is derived from the Latin adjective ''vacuus'' for "vacant" or " void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressure. Physicists often di ...

produced by condensation of the steam, the requirement was for large volumes of steam at very low pressure hardly more than The whole boiler was set into brickwork

Brickwork is masonry produced by a bricklayer, using bricks and mortar. Typically, rows of bricks called ''courses'' are laid on top of one another to build up a structure such as a brick wall.

Bricks may be differentiated from blocks by si ...

which retained some heat. A voluminous coal fire was lit on a grate beneath the slightly dished pan which gave a very small heating surface; there was therefore a great deal of heat wasted up the chimney. In later models, notably by John Smeaton

John Smeaton (8 June 1724 – 28 October 1792) was a British civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist. Smeaton was the fi ...

, heating surface was considerably increased by making the gases heat the boiler sides, passing through a flue

A flue is a duct, pipe, or opening in a chimney for conveying exhaust gases from a fireplace, furnace, water heater, boiler, or generator to the outdoors. Historically the term flue meant the chimney itself. In the United States, they are ...

. Smeaton further lengthened the path of the gases by means of a spiral labyrinth flue beneath the boiler. These under-fired boilers were used in various forms throughout the 18th Century. Some were of round section (haycock). A longer version on a rectangular plan was developed around 1775 by Boulton and Watt (wagon top boiler). This is what is today known as a three-pass boiler, the fire heating the underside, the gases then passing through a central square-section tubular flue and finally around the boiler sides.

Cylindrical fire-tube boilers

An early proponent of the cylindrical form was the British engineer John Blakey, who proposed his design in 1774. Another early proponent was the American engineer,Oliver Evans

Oliver Evans (September 13, 1755 – April 15, 1819) was an American inventor, engineer and businessman born in rural Delaware and later rooted commercially in Philadelphia. He was one of the first Americans building steam engines and an advoca ...

, who rightly recognised that the cylindrical form was the best from the point of view of mechanical resistance and towards the end of the 18th century began to incorporate it into his projects. Probably inspired by the writings on Leupold's "high-pressure" engine scheme that appeared in encyclopaedic works from 1725, Evans favoured "strong steam" i.e. non condensing engines in which the steam pressure alone drove the piston and was then exhausted to atmosphere. The advantage of strong steam as he saw it was that more work could be done by smaller volumes of steam; this enabled all the components to be reduced in size and engines could be adapted to transport and small installations. To this end he developed a long cylindrical wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

horizontal boiler into which was incorporated a single fire tube, at one end of which was placed the fire grate

A fireplace or hearth is a structure made of brick, stone or metal designed to contain a fire. Fireplaces are used for the relaxing ambiance they create and for heating a room. Modern fireplaces vary in heat efficiency, depending on the design ...

. The gas flow was then reversed into a passage or flue beneath the boiler barrel, then divided to return through side flues to join again at the chimney (Columbian engine boiler). Evans incorporated his cylindrical boiler into several engines, both stationary and mobile. Due to space and weight considerations the latter were one-pass exhausting directly from fire tube to chimney. Another proponent of "strong steam" at that time was the Cornishman, Richard Trevithick

Richard Trevithick (13 April 1771 – 22 April 1833) was a British inventor and mining engineer. The son of a mining captain, and born in the mining heartland of Cornwall, Trevithick was immersed in mining and engineering from an early age. He w ...

. His boilers worked at and were at first of hemispherical then cylindrical form. From 1804 onwards Trevithick produced a small two-pass or return flue boiler for semi-portable and locomotive engines. The Cornish boiler

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and ...

developed around 1812 by Richard Trevithick was both stronger and more efficient than the simple boilers which preceded it. It consisted of a cylindrical water tank around long and in diameter, and had a coal fire grate placed at one end of a single cylindrical tube about three feet wide which passed longitudinally inside the tank. The fire was tended from one end and the hot gases from it travelled along the tube and out of the other end, to be circulated back along flues running along the outside then a third time beneath the boiler barrel before being expelled into a chimney. This was later improved upon by another 3-pass boiler, the Lancashire boiler

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and t ...

which had a pair of furnaces in separate tubes side-by-side. This was an important improvement since each furnace could be stoked at different times, allowing one to be cleaned while the other was operating.

Railway locomotive boilers were usually of the 1-pass type, although in early days, 2-pass "return flue" boilers were common, especially with locomotives built by Timothy Hackworth

Timothy Hackworth (22 December 1786 – 7 July 1850) was an English steam locomotive engineer who lived in Shildon, County Durham, England and was the first locomotive superintendent of the Stockton and Darlington Railway.

Youth and early wor ...

.

Multi-tube boilers

A significant step forward came in France in 1828 whenMarc Seguin

Marc Seguin (20 April 1786 – 24 February 1875) was a French engineer, inventor of the wire- cable suspension bridge and the multi-tubular steam-engine boiler.

Early life

Seguin was born in Annonay, Ardèche to Marc François Seguin, th ...

devised a two-pass boiler of which the second pass was formed by a bundle of multiple tubes. A similar design with natural induction used for marine purposes was the popular Scotch marine boiler

A "Scotch" marine boiler (or simply Scotch boiler) is a design of steam boiler best known for its use on ships.

The general layout is that of a squat horizontal cylinder. One or more large cylindrical furnaces are in the lower part of the boiler ...

.

Prior to the Rainhill trials of 1829 Henry Booth

Henry Booth (4 April 1788 – 28 March 1869) was a British corn merchant, businessman and engineer particularly known as one of the key people behind the construction and management of the pioneering Liverpool and Manchester Railway (L&M), the ...

, treasurer of the Liverpool and Manchester Railway

The Liverpool and Manchester Railway (L&MR) was the first inter-city railway in the world. It opened on 15 September 1830 between the Lancashire towns of Liverpool and Manchester in England. It was also the first railway to rely exclusively ...

suggested to George Stephenson

George Stephenson (9 June 1781 – 12 August 1848) was a British civil engineer and mechanical engineer. Renowned as the "Father of Railways", Stephenson was considered by the Victorians

In the history of the United Kingdom and the ...

, a scheme for a multi-tube one-pass horizontal boiler made up of two units: a firebox

Firebox may refer to:

*Firebox (steam engine), the area where the fuel is burned in a steam engine

*Firebox (architecture), the part of a fireplace where fuel is combusted

*Firebox Records

Firebox Records was a Finnish record label based in S ...

surrounded by water spaces and a boiler barrel consisting of two telescopic rings inside which were mounted 25 copper tubes; the tube bundle occupied much of the water space in the barrel and vastly improved heat transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, ...

. Old George immediately communicated the scheme to his son Robert and this was the boiler used on Stephenson's Rocket, outright winner of the trial. The design formed the basis for all subsequent Stephensonian-built locomotives, being immediately taken up by other constructors; this pattern of fire-tube boiler has been built ever since.

Structural resistance

The 1712 boiler was assembled from riveted copper plates with a domed top made of lead in the first examples. Later boilers were made of small wrought iron plates riveted together. The problem was producing big enough plates, so that even pressures of around were not absolutely safe, nor was the cast iron hemispherical boiler initially used by Richard Trevithick. This construction with small plates persisted until the 1820s, when larger plates became feasible and could be rolled into a cylindrical form with just one butt-jointed seam reinforced by agusset

In sewing, a gusset is a triangular or rhomboidal piece of fabric inserted into a seam to add breadth or reduce stress from tight-fitting clothing. Gussets were used at the shoulders, underarms, and hems of traditional shirts and chemises made ...

; Timothy Hackworth's ''Sans Pareil 11'' of 1849 had a longitudinal welded seam. Welded construction for locomotive boilers was extremely slow to take hold.

Once-through monotubular water tube boilers as used by Doble, Lamont and Pritchard are capable of withstanding considerable pressure and of releasing it without danger of explosion.

Combustion

The source of heat for a boiler is combustion of any of several fuels, such aswood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin ...

, coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

, oil

An oil is any nonpolar chemical substance that is composed primarily of hydrocarbons and is hydrophobic (does not mix with water) & lipophilic (mixes with other oils). Oils are usually flammable and surface active. Most oils are unsaturated ...

, or natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

. Nuclear fission

Nuclear fission is a reaction in which the nucleus of an atom splits into two or more smaller nuclei. The fission process often produces gamma photons, and releases a very large amount of energy even by the energetic standards of radio ...

is also used as a heat source for generating steam. Heat recovery steam generator

A heat recovery steam generator (''HRSG'') is an energy recovery heat exchanger that recovers heat from a hot gas stream, such as a combustion turbine or other waste gas stream. It produces steam that can be used in a process (cogeneration) or us ...

s (HRSGs) use the heat rejected from other processes such as gas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directi ...

s.

Solid fuel firing

In order to create optimum burning characteristics of thefire

Fire is the rapid oxidation of a material (the fuel) in the exothermic chemical process of combustion, releasing heat, light, and various reaction Product (chemistry), products.

At a certain point in the combustion reaction, called the ignition ...

, air needs to be supplied both through the grate, and above the fire. Most boilers now depend on mechanical draft equipment rather than natural draught. This is because natural draught is subject to outside air conditions and temperature of flue gases

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced ...

leaving the furnace, as well as chimney height. All these factors make effective draught hard to attain and therefore make mechanical draught equipment much more economical. There are three types of mechanical draught:

# Induced draught: This is obtained one of three ways, the first being the "stack effect" of a heated chimney, in which the flue gas

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produc ...

is less dense than the ambient air surrounding the boiler. The denser column of ambient air forces combustion air into and through the boiler. The second method is through use of a steam jet. The steam jet or ejector oriented in the direction of flue gas flow induces flue gases into the stack and allows for a greater flue gas velocity increasing the overall draught in the furnace. This method was common on steam driven locomotives which could not have tall chimneys. The third method is by simply using an induced draught fan (ID fan) which sucks flue gases out of the furnace and up the stack. Almost all induced draught furnaces have a negative pressure.

# Forced draught: draught is obtained by forcing air into the furnace by means of a fan (FD fan) and duct-work. Air is often passed through an air heater; which, as the name suggests, heats the air going into the furnace in order to increase the overall efficiency of the boiler. Dampers are used to control the quantity of air admitted to the furnace. Forced draught furnaces usually have a positive pressure.

# Balanced draught: Balanced draught is obtained through use of both induced and forced draft. This is more common with larger boilers where the flue gases have to travel a long distance through many boiler passes. The induced draft fan works in conjunction with the forced draft fan allowing the furnace pressure to be maintained slightly below atmospheric.

Firetube boilers

The next stage in the process is to boil water and make steam. The goal is to make the heat flow as completely as possible from the heat source to the water. The water is confined in a restricted space heated by the fire. The steam produced has lower density than the water and therefore will accumulate at the highest level in the vessel; its temperature will remain at boiling point and will only increase as pressure increases. Steam in this state (in equilibrium with the liquid water which is being evaporated within the boiler) is named "saturated steam

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization ...

". For example, saturated steam at atmospheric pressure boils at . Saturated steam taken from the boiler may contain entrained water droplets, however a well designed boiler will supply virtually "dry" saturated steam, with very little entrained water. Continued heating of the saturated steam will bring the steam to a "superheated" state, where the steam is heated to a temperature above the saturation temperature, and no liquid water can exist under this condition. Most reciprocating steam engines of the 19th century used saturated steam, however modern steam power plants universally use superheated steam

Superheated steam is steam at a temperature higher than its vaporization point at the absolute pressure where the temperature is measured.

Superheated steam can therefore cool (lose internal energy) by some amount, resulting in a lowering of its ...

which allows higher steam cycle efficiency.

Superheaters

L.D. Porta gives the following equation determining the efficiency of asteam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomot ...

, applicable to steam engines of all kinds: power (kW) = steam Production (kg h−1)/Specific steam consumption (kg/kW h).

A greater quantity of steam can be generated from a given quantity of water by superheating it. As the fire is burning at a much higher temperature than the saturated steam it produces, far more heat can be transferred to the once-formed steam by superheating it and turning the water droplets suspended therein into more steam and greatly reducing water consumption.

The superheater works like coils on an air conditioning

Air conditioning, often abbreviated as A/C or AC, is the process of removing heat from an enclosed space to achieve a more comfortable interior environment (sometimes referred to as 'comfort cooling') and in some cases also strictly controlling ...

unit, however to a different end. The steam piping (with steam flowing through it) is directed through the flue gas path in the boiler furnace. This area typically is between . Some superheaters are radiant type (absorb heat by thermal radiation

Thermal radiation is electromagnetic radiation generated by the thermal motion of particles in matter. Thermal radiation is generated when heat from the movement of charges in the material (electrons and protons in common forms of matter) is ...

), others are convection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the convec ...

type (absorb heat via a fluid i.e. gas) and some are a combination of the two. So whether by convection or radiation the extreme heat in the boiler furnace/flue gas path will also heat the superheater steam piping and the steam within as well. While the temperature of the steam in the superheater is raised, the pressure of the steam is not: the turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating e ...

or moving pistons offer a "continuously expanding space" and the pressure remains the same as that of the boiler. The process of superheating steam is most importantly designed to remove all droplets entrained in the steam to prevent damage to the turbine blading and/or associated piping. Superheating the steam expands the volume of steam, which allows a given quantity (by weight) of steam to generate more power.

When the totality of the droplets is eliminated, the steam is said to be in a superheated state.

In a Stephensonian firetube locomotive boiler, this entails routing the saturated steam through small diameter pipes suspended inside large diameter firetubes putting them in contact with the hot gases exiting the firebox; the saturated steam flows backwards from the wet header towards the firebox, then forwards again to the dry header. Superheating only began to be generally adopted for locomotives around the year 1900 due to problems of overheating of and lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

Lubrication mechanisms such as fluid-lubric ...

of the moving parts in the cylinders and steam chests.

Many firetube boilers heat water until it boils, and then the steam is used at saturation temperature in other words the temperature of the boiling point of water at a given pressure (saturated steam); this still contains a large proportion of water in suspension. Saturated steam can and has been directly used by an engine, but as the suspended water cannot expand and do work and work implies temperature drop, much of the working fluid is wasted along with the fuel expended to produce it.

Water tube boilers

Another way to rapidly produce steam is to feed the water under pressure into a tube or tubes surrounded by the combustion gases. The earliest example of this was developed byGoldsworthy Gurney

Sir Goldsworthy Gurney (14 February 1793 – 28 February 1875) was an English surgeon, chemist, architect, builder, lecturer and consultant. He was a prototypical British gentleman scientist and inventor of the Victorian era.

Amongst many acc ...

in the late 1820s for use in steam road carriages. This boiler was ultra-compact and light in weight and this arrangement has since become the norm for marine and stationary applications. The tubes frequently have a large number of bends and sometimes fins to maximize the surface area. This type of boiler is generally preferred in high pressure applications since the high pressure water/steam is contained within narrow pipes which can contain the pressure with a thinner wall. It can however be susceptible to damage by vibration in surface transport appliances. In a cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

sectional boiler, sometimes called a "pork chop boiler" the water is contained inside cast iron sections. These sections are mechanically assembled on site to create the finished boiler.

Supercritical steam generators

Supercritical steam generators are frequently used for the production ofelectric power

Electric power is the rate at which electrical energy is transferred by an electric circuit. The SI unit of power is the watt, one joule per second. Standard prefixes apply to watts as with other SI units: thousands, millions and billions o ...

. They operate at supercritical pressure. In contrast to a "subcritical boiler", a supercritical steam generator operates at such a high pressure (over ) that actual boiling ceases to occur, the boiler has no liquid water - steam separation. There is no generation of steam bubbles within the water, because the pressure is above the critical pressure

In thermodynamics, a critical point (or critical state) is the end point of a phase equilibrium curve. The most prominent example is the liquid–vapor critical point, the end point of the pressure–temperature curve that designates conditions ...

at which steam bubbles can form. It passes below the critical point as it does work in a high-pressure turbine and enters the generator's condenser. This results in slightly less fuel use and therefore less greenhouse gas

A greenhouse gas (GHG or GhG) is a gas that Absorption (electromagnetic radiation), absorbs and Emission (electromagnetic radiation), emits radiant energy within the thermal infrared range, causing the greenhouse effect. The primary greenhouse ...

production. The term "boiler" should not be used for a supercritical pressure steam generator, as no "boiling" actually occurs in this device.

Water treatment

Large cation/anion ion exchangers used in demineralization of boiler feedwater Feed water for boilers needs to be as pure as possible with a minimum of suspended solids and dissolved impurities which causecorrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

, foaming

Foams are materials formed by trapping pockets of gas in a liquid or solid.

A bath sponge and the head on a glass of beer are examples of foams. In most foams, the volume of gas is large, with thin films of liquid or solid separating the r ...

and water carryover Carryover may refer to:

* Carryover effect, in automated analyzer

* Carryover basis, in taxation

* Carryover cooking

* Carryover with steam Carryover with steam, in steam technology, refers to transport of moisture and impurities with steam.

The ...

. The most common options for demineralization of boiler feedwater are reverse osmosis

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pre ...

(RO) and ion exchange

Ion exchange is a reversible interchange of one kind of ion present in an insoluble solid with another of like charge present in a solution surrounding the solid with the reaction being used especially for softening or making water demineralised, ...

(IX).

Safety

When water is converted to steam it expands in volume 1,600 times and travels down steam pipes at over 25 m/s. Because of this, steam is a good way of moving energy and heat around a site from a central boiler house to where it is needed, but without the right boiler feed water treatment, a steam-raising plant will suffer from scale formation and corrosion. At best, this increases energy costs and can lead to poor quality steam, reduced efficiency, shorter plant life and an operation which is unreliable. At worst, it can lead to catastrophic failure and loss of life. While variations in standards may exist in different countries, stringent legal, testing, training and certification is applied to try to minimize or prevent such occurrences. Failure modes include: * Overpressurization of the boiler * Insufficient water in the boiler causing overheating and vessel failure * Pressure vessel failure of the boiler due to inadequate construction or maintenance.Doble boiler

TheDoble steam car

The Doble steam car was an American steam car maker from 1909 to 1931. Its latter models of steam car, with fast-firing boiler and electric start,

were considered the pinnacle of steam car development. The term "Doble steam car" comprises any o ...

uses a once-through type contra-flow generator, consisting of a continuous tube. The fire here is on top of the coil instead of underneath. Water is pumped into the tube at the bottom and the steam is drawn off at the top. This means that every particle of water and steam must necessarily pass through every part of the generator causing an intense circulation which prevents any sediment

Sediment is a naturally occurring material that is broken down by processes of weathering and erosion, and is subsequently transported by the action of wind, water, or ice or by the force of gravity acting on the particles. For example, sand an ...

or scale from forming on the inside of the tube. Water enters the bottom of this tube at the flow rate of a second with less than two quarts of water in the tube at any one time.

As the hot gases pass down between the coils, they gradually cool, as the heat is being absorbed by the water. The last portion of the generator with which the gases come into contact remains the cold incoming water.

The fire is positively cut off when the pressure reaches a pre-determined point, usually set at , cold water pressure; a safety valve

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds ...

set at provides added protection. The fire is automatically cut off by temperature as well as pressure, so in case the boiler were completely dry it would be impossible to damage the coil as the fire would be automatically cut off by the temperature.

Similar forced circulation generators, such as the Pritchard and Lamont and Velox boilers present the same advantages.

Applications

Steam boilers are used where steam and hot steam is needed. Hence, steam boilers are used as generators to produce electricity in the energy business. It is also used in rice mills for parboiling and drying. Besides many different application areas in the industry for example in heating systems or forcement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mix ...

production, steam boilers are used in agriculture

Agriculture or farming is the practice of cultivating plants and livestock. Agriculture was the key development in the rise of sedentary human civilization, whereby farming of domesticated species created food surpluses that enabled people to ...

as well for soil steaming.

Testing

The preeminent code for testing fired steam generators in the USA is theAmerican Society of Mechanical Engineers

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

(ASME) performance test code, PTC 4. A related component is the regenerative air heater. A major revision to the performance test code for air heaters will be published in 2013. Copies of the draft are available for review. The European standards for acceptance test of steam boilers are EN 12952-15 and EN 12953-11. The British standards BS 845-1 and BS 845-2 remain also in use in the UK.BS 845-2: "Methods for assessing thermal performance of boilers for steam, hot water and high temperature heat transfer fluids. Comprehensive procedure. (1987)

See also

*Glossary of boiler terminology

Boilers for generating steam or hot water have been designed in countless shapes, sizes and configurations. An extensive terminology has evolved to describe their common features. This glossary provides definitions for these terms.

Terms which r ...

References

External links

* {{commonscat-inline, Steam boilers Steam engines