biodigester on:

[Wikipedia]

[Google]

[Amazon]

Anaerobic digestion is a sequence of processes by which

Anaerobic digestion is a sequence of processes by which

* Hydrolysis

In most cases, biomass is made up of large organic polymers. For the bacteria in anaerobic digesters to access the energy potential of the material, these chains must first be broken down into their smaller constituent parts. These constituent parts, or monomers, such as sugars, are readily available to other bacteria. The process of breaking these chains and dissolving the smaller molecules into solution is called hydrolysis. Therefore, hydrolysis of these high-molecular-weight polymeric components is the necessary first step in anaerobic digestion. Through

* Hydrolysis

In most cases, biomass is made up of large organic polymers. For the bacteria in anaerobic digesters to access the energy potential of the material, these chains must first be broken down into their smaller constituent parts. These constituent parts, or monomers, such as sugars, are readily available to other bacteria. The process of breaking these chains and dissolving the smaller molecules into solution is called hydrolysis. Therefore, hydrolysis of these high-molecular-weight polymeric components is the necessary first step in anaerobic digestion. Through

Anaerobic digesters can be designed and engineered to operate using a number of different configurations and can be categorized into batch vs. continuous process mode,

Anaerobic digesters can be designed and engineered to operate using a number of different configurations and can be categorized into batch vs. continuous process mode,

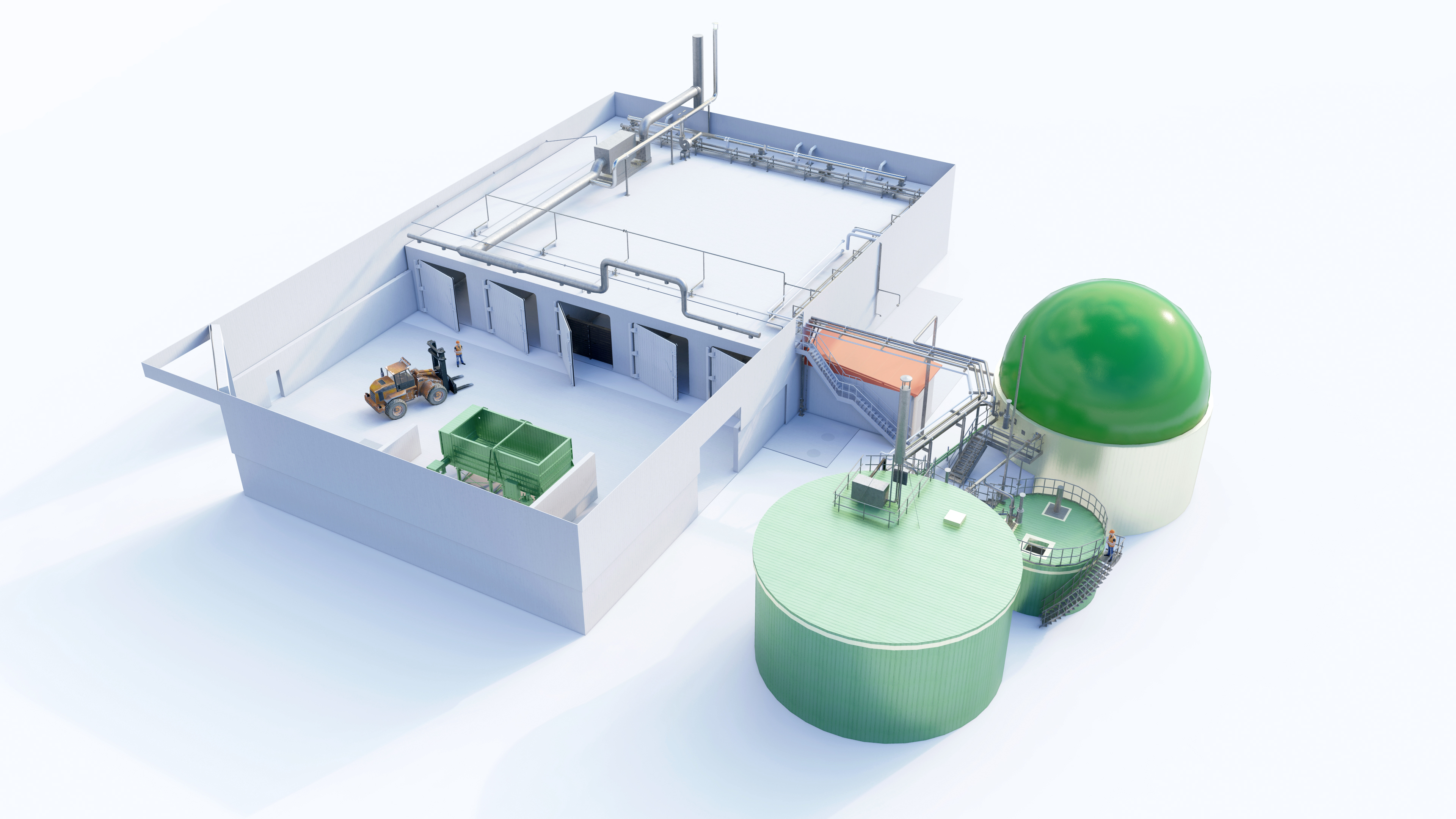

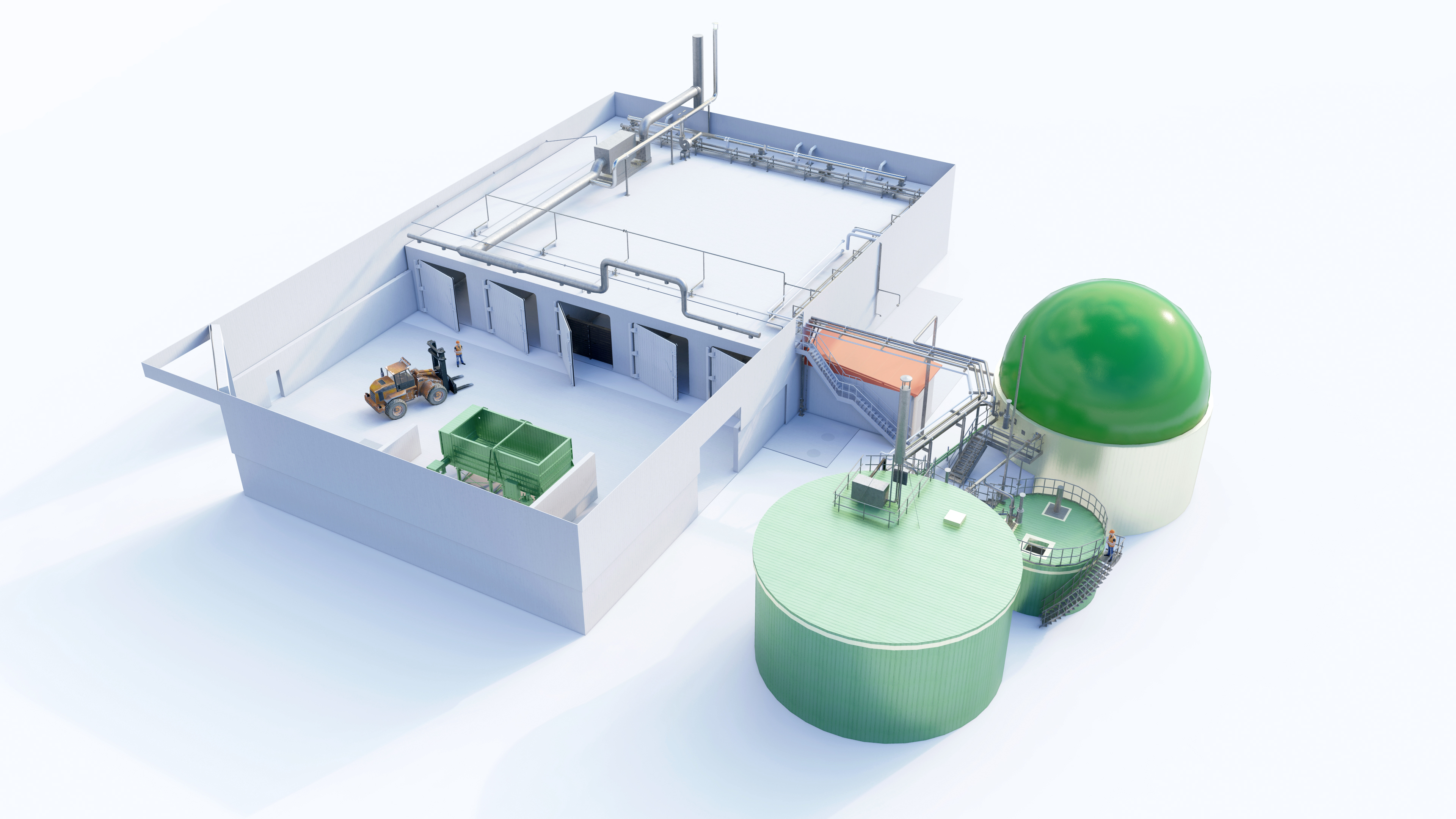

High solids (dry) digesters are designed to process materials with a solids content between 25 and 40%. Unlike wet digesters that process pumpable slurries, high solids (dry – stackable substrate) digesters are designed to process solid substrates without the addition of water. The primary styles of dry digesters are continuous vertical plug flow and batch tunnel horizontal digesters. Continuous vertical plug flow digesters are upright, cylindrical tanks where feedstock is continuously fed into the top of the digester, and flows downward by gravity during digestion. In batch tunnel digesters, the feedstock is deposited in tunnel-like chambers with a gas-tight door. Neither approach has mixing inside the digester. The amount of pretreatment, such as contaminant removal, depends both upon the nature of the waste streams being processed and the desired quality of the digestate. Size reduction (grinding) is beneficial in continuous vertical systems, as it accelerates digestion, while batch systems avoid grinding and instead require structure (e.g. yard waste) to reduce compaction of the stacked pile. Continuous vertical dry digesters have a smaller footprint due to the shorter effective retention time and vertical design. Wet digesters can be designed to operate in either a high-solids content, with a

High solids (dry) digesters are designed to process materials with a solids content between 25 and 40%. Unlike wet digesters that process pumpable slurries, high solids (dry – stackable substrate) digesters are designed to process solid substrates without the addition of water. The primary styles of dry digesters are continuous vertical plug flow and batch tunnel horizontal digesters. Continuous vertical plug flow digesters are upright, cylindrical tanks where feedstock is continuously fed into the top of the digester, and flows downward by gravity during digestion. In batch tunnel digesters, the feedstock is deposited in tunnel-like chambers with a gas-tight door. Neither approach has mixing inside the digester. The amount of pretreatment, such as contaminant removal, depends both upon the nature of the waste streams being processed and the desired quality of the digestate. Size reduction (grinding) is beneficial in continuous vertical systems, as it accelerates digestion, while batch systems avoid grinding and instead require structure (e.g. yard waste) to reduce compaction of the stacked pile. Continuous vertical dry digesters have a smaller footprint due to the shorter effective retention time and vertical design. Wet digesters can be designed to operate in either a high-solids content, with a

eunomia.co.uk, Retrieved 19.08.07. High solids (wet) digesters process a thick slurry that requires more energy input to move and process the feedstock. The thickness of the material may also lead to associated problems with abrasion. High solids digesters will typically have a lower land requirement due to the lower volumes associated with the moisture. High solids digesters also require correction of conventional performance calculations (e.g. gas production, retention time, kinetics, etc.) originally based on very dilute sewage digestion concepts, since larger fractions of the feedstock mass are potentially convertible to biogas. Low solids (wet) digesters can transport material through the system using standard pumps that require significantly lower energy input. Low solids digesters require a larger amount of land than high solids due to the increased volumes associated with the increased liquid-to-feedstock ratio of the digesters. There are benefits associated with operation in a liquid environment, as it enables more thorough circulation of materials and contact between the bacteria and their food. This enables the bacteria to more readily access the substances on which they are feeding, and increases the rate of gas production.

The most important initial issue when considering the application of anaerobic digestion systems is the feedstock to the process. Almost any organic material can be processed with anaerobic digestion; however, if biogas production is the aim, the level of putrescibility is the key factor in its successful application. The more putrescible (digestible) the material, the higher the gas yields possible from the system.

Feedstocks can include biodegradable waste materials, such as waste paper, grass clippings, leftover food, sewage, and animal waste.

The most important initial issue when considering the application of anaerobic digestion systems is the feedstock to the process. Almost any organic material can be processed with anaerobic digestion; however, if biogas production is the aim, the level of putrescibility is the key factor in its successful application. The more putrescible (digestible) the material, the higher the gas yields possible from the system.

Feedstocks can include biodegradable waste materials, such as waste paper, grass clippings, leftover food, sewage, and animal waste.

Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways:

* Replacement of fossil fuels

* Reducing or eliminating the energy footprint of waste treatment plants

* Reducing methane emission from landfills

* Displacing industrially produced chemical fertilizers

* Reducing

Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways:

* Replacement of fossil fuels

* Reducing or eliminating the energy footprint of waste treatment plants

* Reducing methane emission from landfills

* Displacing industrially produced chemical fertilizers

* Reducing

lrrd.org From 1975, China and India have both had large, government-backed schemes for adaptation of small biogas plants for use in the household for cooking and lighting. At present, projects for anaerobic digestion in the developing world can gain financial support through the

, waste.nl. Retrieved 19.08.07. The first known anaerobic digester was built in 1859 at a By the early 20th century, anaerobic digestion systems began to resemble the technology as it appears today. In 1906, Karl Imhoff created the Imhoff tank; an early form of anaerobic digester and model wastewater treatment system throughout the early 20th century. After 1920, closed tank systems began to replace the previously common use of anaerobic lagoons – covered earthen basins used to treat volatile solids. Research on anaerobic digestion began in earnest in the 1930s.

Around the time of

By the early 20th century, anaerobic digestion systems began to resemble the technology as it appears today. In 1906, Karl Imhoff created the Imhoff tank; an early form of anaerobic digester and model wastewater treatment system throughout the early 20th century. After 1920, closed tank systems began to replace the previously common use of anaerobic lagoons – covered earthen basins used to treat volatile solids. Research on anaerobic digestion began in earnest in the 1930s.

Around the time of

''www.biogasworld.com'', accessed 19 October 2022 (though few of them were 'serious' with direct consequences for the human population).Analysis of accidents in biogas production and upgrading

"More than 800 accidents occurred after 2005 among 13,171 European biogas stations (Kotek et al. 2015). Casson et al., (2016) created a database of 169 biogas accidents and the study showed..." October 2015 Renewable Energy 96 DOI:10.1016/j.renene.2015.10.017 via www.researchgate.net, accessed 19 October 2022 Fortunately, according to one source, 'less than a dozen of them had consequences on humans'- for example, the incident at Rhadereistedt, Germany (4 dead). Safety analyses have included a 2016 study compiled a database of 169 accidents involving ADs.Analysis of accidents in biogas production and upgrading

Renewable Energy Volume 96, Part B, October 2016, Pages 1127-1134 via ''www.sciencedirect.com'', accessed 19 October 2022

Anaerobic digestion is a sequence of processes by which

Anaerobic digestion is a sequence of processes by which microorganisms

A microorganism, or microbe,, ''mikros'', "small") and ''organism'' from the el, ὀργανισμός, ''organismós'', "organism"). It is usually written as a single word but is sometimes hyphenated (''micro-organism''), especially in olde ...

break down biodegradable

Biodegradation is the breakdown of organic matter by microorganisms, such as bacteria and fungi. It is generally assumed to be a natural process, which differentiates it from composting. Composting is a human-driven process in which biodegradati ...

material in the absence of oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as we ...

. The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses anaerobic digestion.

Anaerobic digestion occurs naturally in some soils and in lake and oceanic basin sediment

Sediment is a naturally occurring material that is broken down by processes of weathering and erosion, and is subsequently transported by the action of wind, water, or ice or by the force of gravity acting on the particles. For example, sa ...

s, where it is usually referred to as "anaerobic activity". This is the source of marsh gas methane as discovered by Alessandro Volta in 1776.

The digestion process begins with bacteria

Bacteria (; singular: bacterium) are ubiquitous, mostly free-living organisms often consisting of one biological cell. They constitute a large domain of prokaryotic microorganisms. Typically a few micrometres in length, bacteria were am ...

l hydrolysis

Hydrolysis (; ) is any chemical reaction in which a molecule of water breaks one or more chemical bonds. The term is used broadly for substitution, elimination, and solvation reactions in which water is the nucleophile.

Biological hydrolysis ...

of the input materials. Insoluble organic polymer

A polymer (; Greek ''poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and ...

s, such as carbohydrate

In organic chemistry, a carbohydrate () is a biomolecule consisting of carbon (C), hydrogen (H) and oxygen (O) atoms, usually with a hydrogen–oxygen atom ratio of 2:1 (as in water) and thus with the empirical formula (where ''m'' may or ...

s, are broken down to soluble derivatives that become available for other bacteria. Acidogenic bacteria then convert the sugars and amino acid

Amino acids are organic compounds that contain both amino and carboxylic acid functional groups. Although hundreds of amino acids exist in nature, by far the most important are the alpha-amino acids, which comprise proteins. Only 22 alpha ...

s into carbon dioxide, hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-toxic ...

, ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogeno ...

, and organic acid

An organic acid is an organic compound with acidic properties. The most common organic acids are the carboxylic acids, whose acidity is associated with their carboxyl group –COOH. Sulfonic acids, containing the group –SO2OH, are ...

s. In acetogenesis, bacteria convert these resulting organic acids into acetic acid

Acetic acid , systematically named ethanoic acid , is an acidic, colourless liquid and organic compound with the chemical formula (also written as , , or ). Vinegar is at least 4% acetic acid by volume, making acetic acid the main componen ...

, along with additional ammonia, hydrogen, and carbon dioxide amongst other compounds. Finally, methanogen

Methanogens are microorganisms that produce methane as a metabolic byproduct in hypoxic conditions. They are prokaryotic and belong to the domain Archaea. All known methanogens are members of the archaeal phylum Euryarchaeota. Methanogens ar ...

s convert these products to methane and carbon dioxide. The methanogenic archaea populations play an indispensable role in anaerobic wastewater treatments.

Anaerobic digestion is used as part of the process to treat biodegradable waste and sewage sludge

Sewage sludge is the residual, semi-solid material that is produced as a by-product during sewage treatment of industrial or municipal wastewater. The term " septage" also refers to sludge from simple wastewater treatment but is connected to si ...

. As part of an integrated waste management

Waste management or waste disposal includes the processes and actions required to manage waste from its inception to its final disposal.

This includes the collection, transport, treatment and disposal of waste, together with monitori ...

system, anaerobic digestion reduces the emission of landfill gas

Landfill gas is a mix of different gases created by the action of microorganisms within a landfill as they decompose organic waste, including for example, food waste and paper waste. Landfill gas is approximately forty to sixty percent methane ...

into the atmosphere. Anaerobic digesters can also be fed with purpose-grown energy crops, such as maize

Maize ( ; ''Zea mays'' subsp. ''mays'', from es, maíz after tnq, mahiz), also known as corn ( North American and Australian English), is a cereal grain first domesticated by indigenous peoples in southern Mexico about 10,000 years ago. ...

.

Anaerobic digestion is widely used as a source of renewable energy. The process produces a biogas

Biogas is a mixture of gases, primarily consisting of methane, carbon dioxide and hydrogen sulphide, produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste and food waste. I ...

, consisting of methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The relative abundance of methane on Ear ...

, carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

, and traces of other 'contaminant' gases. This biogas can be used directly as fuel, in combined heat and power gas engines or upgraded to natural gas-quality biomethane

Renewable natural gas (RNG), also known as sustainable natural gas (SNG) or biomethane, is a biogas which has been upgraded to a quality similar to fossil natural gas and having a methane concentration of 90% or greater. By increasing the concentr ...

. The nutrient-rich digestate also produced can be used as fertilizer

A fertilizer (American English) or fertiliser (British English; see spelling differences) is any material of natural or synthetic origin that is applied to soil or to plant tissues to supply plant nutrients. Fertilizers may be distinct from ...

.

With the re-use of waste as a resource and new technological approaches that have lowered capital costs, anaerobic digestion has in recent years received increased attention among governments in a number of countries, among these the United Kingdom (2011), Germany, Denmark (2011), and the United States.

Process

Many microorganisms affect anaerobic digestion, including acetic acid-formingbacteria

Bacteria (; singular: bacterium) are ubiquitous, mostly free-living organisms often consisting of one biological cell. They constitute a large domain of prokaryotic microorganisms. Typically a few micrometres in length, bacteria were am ...

( acetogens) and methane-forming archaea (methanogen

Methanogens are microorganisms that produce methane as a metabolic byproduct in hypoxic conditions. They are prokaryotic and belong to the domain Archaea. All known methanogens are members of the archaeal phylum Euryarchaeota. Methanogens ar ...

s). These organisms promote a number of chemical processes in converting the biomass to biogas

Biogas is a mixture of gases, primarily consisting of methane, carbon dioxide and hydrogen sulphide, produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste and food waste. I ...

.

Gaseous oxygen is excluded from the reactions by physical containment. Anaerobes utilize electron acceptors from sources other than oxygen gas. These acceptors can be the organic material itself or may be supplied by inorganic oxides from within the input material. When the oxygen source in an anaerobic system is derived from the organic material itself, the 'intermediate' end products are primarily alcohol

Alcohol most commonly refers to:

* Alcohol (chemistry), an organic compound in which a hydroxyl group is bound to a carbon atom

* Alcohol (drug), an intoxicant found in alcoholic drinks

Alcohol may also refer to:

Chemicals

* Ethanol, one of sev ...

s, aldehyde

In organic chemistry, an aldehyde () is an organic compound containing a functional group with the structure . The functional group itself (without the "R" side chain) can be referred to as an aldehyde but can also be classified as a formyl group ...

s, and organic acids, plus carbon dioxide. In the presence of specialised methanogens, the intermediates are converted to the 'final' end products of methane, carbon dioxide, and trace levels of hydrogen sulfide

Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hydride gas, and is poisonous, corrosive, and flammable, with trace amounts in ambient atmosphere having a characteristic foul odor of rotten eggs. The und ...

. In an anaerobic system, the majority of the chemical energy contained within the starting material is released by methanogenic archaea as methane.

Populations of anaerobic microorganisms typically take a significant period of time to establish themselves to be fully effective. Therefore, common practice is to introduce anaerobic microorganisms from materials with existing populations, a process known as "seeding" the digesters, typically accomplished with the addition of sewage sludge or cattle slurry.

Process stages

The four key stages of anaerobic digestion involvehydrolysis

Hydrolysis (; ) is any chemical reaction in which a molecule of water breaks one or more chemical bonds. The term is used broadly for substitution, elimination, and solvation reactions in which water is the nucleophile.

Biological hydrolysis ...

, acidogenesis, acetogenesis Acetogenesis is a process through which acetate is produced either by the reduction of CO2 or by the reduction of organic acids, rather than by the oxidative breakdown of carbohydrates or ethanol, as with acetic acid bacteria.

The different bact ...

and methanogenesis

Methanogenesis or biomethanation is the formation of methane coupled to energy conservation by microbes known as methanogens. Organisms capable of producing methane for energy conservation have been identified only from the domain Archaea, a gro ...

.

The overall process can be described by the chemical reaction, where organic material such as glucose is biochemically digested into carbon dioxide (CO2) and methane (CH4) by the anaerobic microorganisms.

C6H12O6 → 3CO2 + 3CH4

* Hydrolysis

In most cases, biomass is made up of large organic polymers. For the bacteria in anaerobic digesters to access the energy potential of the material, these chains must first be broken down into their smaller constituent parts. These constituent parts, or monomers, such as sugars, are readily available to other bacteria. The process of breaking these chains and dissolving the smaller molecules into solution is called hydrolysis. Therefore, hydrolysis of these high-molecular-weight polymeric components is the necessary first step in anaerobic digestion. Through

* Hydrolysis

In most cases, biomass is made up of large organic polymers. For the bacteria in anaerobic digesters to access the energy potential of the material, these chains must first be broken down into their smaller constituent parts. These constituent parts, or monomers, such as sugars, are readily available to other bacteria. The process of breaking these chains and dissolving the smaller molecules into solution is called hydrolysis. Therefore, hydrolysis of these high-molecular-weight polymeric components is the necessary first step in anaerobic digestion. Through hydrolysis

Hydrolysis (; ) is any chemical reaction in which a molecule of water breaks one or more chemical bonds. The term is used broadly for substitution, elimination, and solvation reactions in which water is the nucleophile.

Biological hydrolysis ...

the complex organic molecules are broken down into simple sugar

Monosaccharides (from Greek '' monos'': single, '' sacchar'': sugar), also called simple sugars, are the simplest forms of sugar and the most basic units ( monomers) from which all carbohydrates are built.

They are usually colorless, water-so ...

s, amino acids, and fatty acid

In chemistry, particularly in biochemistry, a fatty acid is a carboxylic acid with an aliphatic chain, which is either saturated or unsaturated. Most naturally occurring fatty acids have an unbranched chain of an even number of carbon atoms, ...

s.

Acetate and hydrogen produced in the first stages can be used directly by methanogens. Other molecules, such as volatile fatty acids (VFAs) with a chain length greater than that of acetate must first be catabolised into compounds that can be directly used by methanogens.

* Acidogenesis

The biological process of acidogenesis results in further breakdown of the remaining components by acidogenic (fermentative) bacteria. Here, VFAs are created, along with ammonia, carbon dioxide, and hydrogen sulfide

Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hydride gas, and is poisonous, corrosive, and flammable, with trace amounts in ambient atmosphere having a characteristic foul odor of rotten eggs. The und ...

, as well as other byproducts. The process of acidogenesis is similar to the way milk sours.

* Acetogenesis

The third stage of anaerobic digestion is acetogenesis Acetogenesis is a process through which acetate is produced either by the reduction of CO2 or by the reduction of organic acids, rather than by the oxidative breakdown of carbohydrates or ethanol, as with acetic acid bacteria.

The different bact ...

. Here, simple molecules created through the acidogenesis phase are further digested by acetogens to produce largely acetic acid, as well as carbon dioxide and hydrogen.

* Methanogenesis

The terminal stage of anaerobic digestion is the biological process of methanogenesis

Methanogenesis or biomethanation is the formation of methane coupled to energy conservation by microbes known as methanogens. Organisms capable of producing methane for energy conservation have been identified only from the domain Archaea, a gro ...

. Here, methanogens use the intermediate products of the preceding stages and convert them into methane, carbon dioxide, and water. These components make up the majority of the biogas emitted from the system. Methanogenesis is sensitive to both high and low pHs and occurs between pH 6.5 and pH 8. The remaining, indigestible material the microbes cannot use and any dead bacterial remains constitute the digestate.

Configuration

Anaerobic digesters can be designed and engineered to operate using a number of different configurations and can be categorized into batch vs. continuous process mode,

Anaerobic digesters can be designed and engineered to operate using a number of different configurations and can be categorized into batch vs. continuous process mode, mesophilic

A mesophile is an organism that grows best in moderate temperature, neither too hot nor too cold, with an optimum growth range from . The optimum growth temperature for these organisms is 37°C. The term is mainly applied to microorganisms. Org ...

vs. thermophilic

A thermophile is an organism—a type of extremophile—that thrives at relatively high temperatures, between . Many thermophiles are archaea, though they can be bacteria or fungi. Thermophilic eubacteria are suggested to have been among the ear ...

temperature conditions, high vs. low portion of solids, and single stage vs. multistage processes. Continuous process requires more complex design, but still, it may be more economical than batch process, because batch process requires more initial building money and a larger volume of the digesters (spread across several batches) to handle the same amount of waste as a continuous process digester. Higher heat energy is required in a thermophilic system compared to a mesophilic system, but the thermophilic system requires much less time and has a larger gas output capacity and higher methane gas content, so one has to consider that trade-off carefully. For solids content, low will handle up to 15% solid content. Above this level is considered high solids content and can also be known as dry digestion. In a single stage process, one reactor houses the four anaerobic digestion steps. A multistage process utilizes two or more reactors for digestion to separate the methanogenesis and hydrolysis phases.

Batch or continuous

Anaerobic digestion can be performed as a batch process or a continuous process. In a batch system, biomass is added to the reactor at the start of the process. The reactor is then sealed for the duration of the process. In its simplest form batch processing needs inoculation with already processed material to start the anaerobic digestion. In a typical scenario, biogas production will be formed with anormal distribution

In statistics, a normal distribution or Gaussian distribution is a type of continuous probability distribution for a real-valued random variable. The general form of its probability density function is

:

f(x) = \frac e^

The parameter \mu i ...

pattern over time. Operators can use this fact to determine when they believe the process of digestion of the organic matter has completed. There can be severe odour issues if a batch reactor is opened and emptied before the process is well completed. A more advanced type of batch approach has limited the odour issues by integrating anaerobic digestion with in-vessel composting. In this approach inoculation takes place through the use of recirculated degasified percolate. After anaerobic digestion has completed, the biomass is kept in the reactor which is then used for in-vessel composting before it is opened As the batch digestion is simple and requires less equipment and lower levels of design work, it is typically a cheaper form of digestion. Using more than one batch reactor at a plant can ensure constant production of biogas.

In continuous digestion processes, organic matter is constantly added (continuous complete mixed) or added in stages to the reactor (continuous plug flow; first in – first out). Here, the end products are constantly or periodically removed, resulting in constant production of biogas. A single or multiple digesters in sequence may be used. Examples of this form of anaerobic digestion include continuous stirred-tank reactor

The continuous stirred-tank reactor (CSTR), also known as vat- or backmix reactor, mixed flow reactor (MFR), or a continuous-''flow'' stirred-tank reactor (C''F''STR), is a common model for a chemical reactor in chemical engineering and environme ...

s, upflow anaerobic sludge blankets, expanded granular sludge beds, and internal circulation reactors.

Temperature

The two conventional operational temperature levels for anaerobic digesters determine the species of methanogens in the digesters: * ''Mesophilic'' digestion takes place optimally around 30 to 38 °C, or at ambient temperatures between 20 and 45 °C, where mesophiles are the primary microorganisms present. * ''Thermophilic'' digestion takes place optimally around 49 to 57 °C, or at elevated temperatures up to 70 °C, where thermophiles are the primary microorganisms present. A limit case has been reached inBolivia

, image_flag = Bandera de Bolivia (Estado).svg

, flag_alt = Horizontal tricolor (red, yellow, and green from top to bottom) with the coat of arms of Bolivia in the center

, flag_alt2 = 7 × 7 square p ...

, with anaerobic digestion in temperature working conditions of less than 10 °C. The anaerobic process is very slow, taking more than three times the normal mesophilic time process. In experimental work at University of Alaska Fairbanks

The University of Alaska Fairbanks (UAF or Alaska) is a public land-grant research university in College, Alaska, a suburb of Fairbanks. It is the flagship campus of the University of Alaska system. UAF was established in 1917 and opened for ...

, a 1,000-litre digester using psychrophiles harvested from "mud from a frozen lake in Alaska" has produced 200–300 litres of methane per day, about 20 to 30% of the output from digesters in warmer climates.

Mesophilic species outnumber thermophiles, and they are also more tolerant to changes in environmental conditions than thermophiles. Mesophilic systems are, therefore, considered to be more stable than thermophilic digestion systems. In contrast, while thermophilic digestion systems are considered less stable, their energy input is higher, with more biogas being removed from the organic matter in an equal amount of time. The increased temperatures facilitate faster reaction rates, and thus faster gas yields. Operation at higher temperatures facilitates greater pathogen reduction of the digestate. In countries where legislation, such as the Animal By-Products Regulations The European Union's Animal By-Products Regulations (Regulation No 1069/2009) allows for the treatment of some animal by-products in composting and biogas plants (anaerobic digesters). The following article describes procedures required to allow sol ...

in the European Union, requires digestate to meet certain levels of pathogen reduction there may be a benefit to using thermophilic temperatures instead of mesophilic.

Additional pre-treatment can be used to reduce the necessary retention time to produce biogas. For example, certain processes shred the substrates to increase the surface area or use a thermal pretreatment stage (such as pasteurisation) to significantly enhance the biogas output. The pasteurisation process can also be used to reduce the pathogenic concentration in the digestate, leaving the anaerobic digester. Pasteurisation may be achieved by heat treatment combined with maceration of the solids.

Solids content

In a typical scenario, three different operational parameters are associated with the solids content of the feedstock to the digesters: * High solids (dry—stackable substrate) * High solids (wet—pumpable substrate) * Low solids (wet—pumpable substrate) High solids (dry) digesters are designed to process materials with a solids content between 25 and 40%. Unlike wet digesters that process pumpable slurries, high solids (dry – stackable substrate) digesters are designed to process solid substrates without the addition of water. The primary styles of dry digesters are continuous vertical plug flow and batch tunnel horizontal digesters. Continuous vertical plug flow digesters are upright, cylindrical tanks where feedstock is continuously fed into the top of the digester, and flows downward by gravity during digestion. In batch tunnel digesters, the feedstock is deposited in tunnel-like chambers with a gas-tight door. Neither approach has mixing inside the digester. The amount of pretreatment, such as contaminant removal, depends both upon the nature of the waste streams being processed and the desired quality of the digestate. Size reduction (grinding) is beneficial in continuous vertical systems, as it accelerates digestion, while batch systems avoid grinding and instead require structure (e.g. yard waste) to reduce compaction of the stacked pile. Continuous vertical dry digesters have a smaller footprint due to the shorter effective retention time and vertical design. Wet digesters can be designed to operate in either a high-solids content, with a

High solids (dry) digesters are designed to process materials with a solids content between 25 and 40%. Unlike wet digesters that process pumpable slurries, high solids (dry – stackable substrate) digesters are designed to process solid substrates without the addition of water. The primary styles of dry digesters are continuous vertical plug flow and batch tunnel horizontal digesters. Continuous vertical plug flow digesters are upright, cylindrical tanks where feedstock is continuously fed into the top of the digester, and flows downward by gravity during digestion. In batch tunnel digesters, the feedstock is deposited in tunnel-like chambers with a gas-tight door. Neither approach has mixing inside the digester. The amount of pretreatment, such as contaminant removal, depends both upon the nature of the waste streams being processed and the desired quality of the digestate. Size reduction (grinding) is beneficial in continuous vertical systems, as it accelerates digestion, while batch systems avoid grinding and instead require structure (e.g. yard waste) to reduce compaction of the stacked pile. Continuous vertical dry digesters have a smaller footprint due to the shorter effective retention time and vertical design. Wet digesters can be designed to operate in either a high-solids content, with a total suspended solids

Total suspended solids (TSS) is the dry-weight of suspended particles, that are not dissolved, in a sample of water that can be trapped by a filter that is analyzed using a filtration apparatus known as sintered glass crucible. TSS is a water qu ...

(TSS) concentration greater than ~20%, or a low-solids concentration less than ~15%.Feasibility study concerning anaerobic digestion in Northern Irelandeunomia.co.uk, Retrieved 19.08.07. High solids (wet) digesters process a thick slurry that requires more energy input to move and process the feedstock. The thickness of the material may also lead to associated problems with abrasion. High solids digesters will typically have a lower land requirement due to the lower volumes associated with the moisture. High solids digesters also require correction of conventional performance calculations (e.g. gas production, retention time, kinetics, etc.) originally based on very dilute sewage digestion concepts, since larger fractions of the feedstock mass are potentially convertible to biogas. Low solids (wet) digesters can transport material through the system using standard pumps that require significantly lower energy input. Low solids digesters require a larger amount of land than high solids due to the increased volumes associated with the increased liquid-to-feedstock ratio of the digesters. There are benefits associated with operation in a liquid environment, as it enables more thorough circulation of materials and contact between the bacteria and their food. This enables the bacteria to more readily access the substances on which they are feeding, and increases the rate of gas production.

Complexity

Digestion systems can be configured with different levels of complexity. In a single-stage digestion system (one-stage), all of the biological reactions occur within a single, sealed reactor or holding tank. Using a single stage reduces construction costs, but results in less control of the reactions occurring within the system. Acidogenic bacteria, through the production of acids, reduce the pH of the tank. Methanogenic archaea, as outlined earlier, operate in a strictly defined pH range. Therefore, the biological reactions of the different species in a single-stage reactor can be in direct competition with each other. Another one-stage reaction system is ananaerobic lagoon An anaerobic lagoon or manure lagoon is a man-made outdoor earthen basin filled with animal waste that undergoes anaerobic respiration as part of a system designed to manage and treat refuse created by concentrated animal feeding operations (CAFOs) ...

. These lagoons are pond-like, earthen basins used for the treatment and long-term storage of manures. Here the anaerobic reactions are contained within the natural anaerobic sludge contained in the pool.

In a two-stage digestion system (multistage), different digestion vessels are optimised to bring maximum control over the bacterial communities living within the digesters. Acidogenic bacteria produce organic acids and more quickly grow and reproduce than methanogenic archaea. Methanogenic archaea require stable pH and temperature to optimise their performance.

Under typical circumstances, hydrolysis, acetogenesis, and acidogenesis occur within the first reaction vessel. The organic material is then heated to the required operational temperature (either mesophilic or thermophilic) prior to being pumped into a methanogenic reactor. The initial hydrolysis or acidogenesis tanks prior to the methanogenic reactor can provide a buffer to the rate at which feedstock is added. Some European countries require a degree of elevated heat treatment to kill harmful bacteria in the input waste. In this instance, there may be a pasteurisation or sterilisation stage prior to digestion or between the two digestion tanks. Notably, it is not possible to completely isolate the different reaction phases, and often some biogas is produced in the hydrolysis or acidogenesis tanks.

Residence time

The residence time in a digester varies with the amount and type of feed material, and with the configuration of the digestion system. In a typical two-stage mesophilic digestion, residence time varies between 15 and 40 days, while for a single-stage thermophilic digestion, residence times is normally faster and takes around 14 days. The plug-flow nature of some of these systems will mean the full degradation of the material may not have been realised in this timescale. In this event, digestate exiting the system will be darker in colour and will typically have more odour. In the case of anupflow anaerobic sludge blanket digestion

Upflow anaerobic sludge blanket (UASB) technology, normally referred to as UASB reactor, is a form of anaerobic digester that is used for wastewater treatment.

The UASB reactor is a methanogenic (methane-producing) digester that evolved from th ...

(UASB), hydraulic residence times can be as short as 1 hour to 1 day, and solid retention times can be up to 90 days. In this manner, a UASB system is able to separate solids and hydraulic retention times with the use of a sludge blanket. Continuous digesters have mechanical or hydraulic devices, depending on the level of solids in the material, to mix the contents, enabling the bacteria and the food to be in contact. They also allow excess material to be continuously extracted to maintain a reasonably constant volume within the digestion tanks.

Inhibition

The anaerobic digestion process can be inhibited by several compounds, affecting one or more of the bacterial groups responsible for the different organic matter degradation steps. The degree of the inhibition depends, among other factors, on the concentration of the inhibitor in the digester. Potential inhibitors are ammonia, sulfide, light metal ions (Na, K, Mg, Ca, Al), heavy metals, some organics (chlorophenols, halogenated aliphatics, N-substituted aromatics, long chain fatty acids), etc. Total ammonia nitrogen (TAN) has been shown to inhibit production of methane. Furthermore, it destabilises the microbial community, impacting the synthesis of acetic acid. Acetic acid is one of the driving forces in methane production. At an excess of 5000 mg/L TAN, pH adjustment is needed to keep the reaction stable.Yenigün, O., & Demirel, B. (2013). Ammonia inhibition in anaerobic digestion: a review. ''Process Biochemistry'', ''48''(5-6), 901-911. A TAN concentration above 1700- 1800 mg/L inhibits methane production and yield decreases at greater TAN concentrations. High TAN concentrations cause the reaction to turn acidic and lead to a domino effect of inhibition. Total ammonia nitrogen is the combination of free ammonia and ionized ammonia. TAN is produced through degrading material high in nitrogen, typically proteins and will naturally build in anaerobic digestion. This is depending on the organic feed stock fed to the system. In typical wastewater treatment practices, TAN reduction is done with vianitrification

''Nitrification'' is the biological oxidation of ammonia to nitrite followed by the oxidation of the nitrite to nitrate occurring through separate organisms or direct ammonia oxidation to nitrate in comammox bacteria. The transformation of amm ...

. Nitrification is an aerobic process where TAN is consumed by aerobic heterotrophic bacteria. These bacteria release nitrate and nitrite which are later converted to nitrogen gas through the denitrification process. Hydrolysis and acidogenesis can also be impacted by TAN concentration. In mesophilic conditions, inhibition for hydrolysis was found to occur at 5500 mg/L TAN, while acidogenesis inhibition occurs at 6500 mg/L TAN.

Feedstocks

The most important initial issue when considering the application of anaerobic digestion systems is the feedstock to the process. Almost any organic material can be processed with anaerobic digestion; however, if biogas production is the aim, the level of putrescibility is the key factor in its successful application. The more putrescible (digestible) the material, the higher the gas yields possible from the system.

Feedstocks can include biodegradable waste materials, such as waste paper, grass clippings, leftover food, sewage, and animal waste.

The most important initial issue when considering the application of anaerobic digestion systems is the feedstock to the process. Almost any organic material can be processed with anaerobic digestion; however, if biogas production is the aim, the level of putrescibility is the key factor in its successful application. The more putrescible (digestible) the material, the higher the gas yields possible from the system.

Feedstocks can include biodegradable waste materials, such as waste paper, grass clippings, leftover food, sewage, and animal waste. Wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of ligni ...

y wastes are the exception, because they are largely unaffected by digestion, as most anaerobes are unable to degrade lignin

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity ...

. Xylophagous anaerobes (lignin consumers) or high temperature pretreatment, such as pyrolysis, can be used to break lignin down. Anaerobic digesters can also be fed with specially grown energy crop

Energy crops are low-cost and low-maintenance crops grown solely for energy production by combustion (not for food). The crops are processed into solid, liquid or gaseous fuels, such as pellets, bioethanol or biogas. The fuels are burned to ...

s, such as silage

Silage () is a type of fodder made from green foliage crops which have been preserved by fermentation to the point of acidification. It can be fed to cattle, sheep and other such ruminants ( cud-chewing animals). The fermentation and storage ...

, for dedicated biogas production. In Germany and continental Europe, these facilities are referred to as "biogas" plants. A codigestion or cofermentation plant is typically an agricultural anaerobic digester that accepts two or more input materials for simultaneous digestion.

The length of time required for anaerobic digestion depends on the chemical complexity of the material. Material rich in easily digestible sugars breaks down quickly, whereas intact lignocellulosic material rich in cellulose and hemicellulose polymers can take much longer to break down. Anaerobic microorganisms are generally unable to break down lignin, the recalcitrant aromatic component of biomass.

Anaerobic digesters were originally designed for operation using sewage sludge and manures. Sewage and manure are not, however, the material with the most potential for anaerobic digestion, as the biodegradable material has already had much of the energy content taken out by the animals that produced it. Therefore, many digesters operate with codigestion of two or more types of feedstock. For example, in a farm-based digester that uses dairy manure as the primary feedstock, the gas production may be significantly increased by adding a second feedstock, e.g., grass and corn (typical on-farm feedstock), or various organic byproducts, such as slaughterhouse waste, fats, oils and grease from restaurants, organic household waste, etc. (typical off-site feedstock).

Digesters processing dedicated energy crops can achieve high levels of degradation and biogas production. Slurry-only systems are generally cheaper, but generate far less energy than those using crops, such as maize and grass silage; by using a modest amount of crop material (30%), an anaerobic digestion plant can increase energy output tenfold for only three times the capital cost, relative to a slurry-only system.

Moisture content

A second consideration related to the feedstock is moisture content. Drier, stackable substrates, such as food and yard waste, are suitable for digestion in tunnel-like chambers. Tunnel-style systems typically have near-zero wastewater discharge, as well, so this style of system has advantages where the discharge of digester liquids are a liability. The wetter the material, the more suitable it will be to handling with standard pumps instead of energy-intensive concrete pumps and physical means of movement. Also, the wetter the material, the more volume and area it takes up relative to the levels of gas produced. The moisture content of the target feedstock will also affect what type of system is applied to its treatment. To use a high-solids anaerobic digester for dilute feedstocks, bulking agents, such as compost, should be applied to increase the solids content of the input material. Another key consideration is the carbon:nitrogen ratio of the input material. This ratio is the balance of food a microbe requires to grow; the optimal C:N ratio is 20–30:1. Excess N can lead to ammonia inhibition of digestion.Contamination

The level of contamination of the feedstock material is a key consideration when using wet digestion or plug-flow digestion. If the feedstock to the digesters has significant levels of physical contaminants, such as plastic, glass, or metals, then processing to remove the contaminants will be required for the material to be used. If it is not removed, then the digesters can be blocked and will not function efficiently. This contamination issue does not occur with dry digestion or solid-state anaerobic digestion (SSAD) plants, since SSAD handles dry, stackable biomass with a high percentage of solids (40-60%) in gas-tight chambers called fermenter boxes. It is with this understanding that mechanical biological treatment plants are designed. The higher the level of pretreatment a feedstock requires, the more processing machinery will be required, and, hence, the project will have higher capital costs. National Non-Food Crops Centre. After sorting or screening to remove any physical contaminants from the feedstock, the material is often shredded, minced, and mechanically or hydraulically pulped to increase the surface area available to microbes in the digesters and, hence, increase the speed of digestion. The maceration of solids can be achieved by using a chopper pump to transfer the feedstock material into the airtight digester, where anaerobic treatment takes place.Substrate composition

Substrate composition is a major factor in determining the methane yield and methane production rates from the digestion of biomass. Techniques to determine the compositional characteristics of the feedstock are available, while parameters such as solids, elemental, and organic analyses are important for digester design and operation. Methane yield can be estimated from the elemental composition of substrate along with an estimate of its degradability (the fraction of the substrate that is converted to biogas in a reactor). In order to predict biogas composition (the relative fractions of methane and carbon dioxide) it is necessary to estimatecarbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

partitioning between the aqueous and gas phases, which requires additional information (reactor temperature, pH, and substrate composition) and a chemical speciation model. Direct measurements of biomethanation potential are also made using gas evolution or more recent gravimetric assays.

Applications

Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways:

* Replacement of fossil fuels

* Reducing or eliminating the energy footprint of waste treatment plants

* Reducing methane emission from landfills

* Displacing industrially produced chemical fertilizers

* Reducing

Using anaerobic digestion technologies can help to reduce the emission of greenhouse gases in a number of key ways:

* Replacement of fossil fuels

* Reducing or eliminating the energy footprint of waste treatment plants

* Reducing methane emission from landfills

* Displacing industrially produced chemical fertilizers

* Reducing vehicle

A vehicle (from la, vehiculum) is a machine that transports people or cargo. Vehicles include wagons, bicycles, motor vehicles ( motorcycles, cars, trucks, buses, mobility scooters for disabled people), railed vehicles ( trains, trams ...

movements

* Reducing electrical grid

An electrical grid is an interconnected network for electricity delivery from producers to consumers. Electrical grids vary in size and can cover whole countries or continents. It consists of:Kaplan, S. M. (2009). Smart Grid. Electrical Power ...

transportation losses

* Reducing usage of LP Gas for cooking

Cooking, cookery, or culinary arts is the art, science and craft of using heat to prepare food for consumption. Cooking techniques and ingredients vary widely, from grilling food over an open fire to using electric stoves, to baking in vari ...

*An important component of the Zero Waste

Zero waste is a set of principles focused on waste prevention that encourages redesigning resource life cycles so that all products are reused. The goal of this movement is to avoid sending trash to landfills, incinerators, or the ocean. Cur ...

initiatives.

Waste and wastewater treatment

Anaerobic digestion is particularly suited to organic material, and is commonly used for industrial effluent,wastewater

Wastewater is water generated after the use of freshwater, raw water, drinking water or saline water in a variety of deliberate applications or processes. Another definition of wastewater is "Used water from any combination of domestic, industri ...

and sewage sludge treatment. Anaerobic digestion, a simple process, can greatly reduce the amount of organic matter which might otherwise be destined to be dumped at sea, dumped in landfills, or burnt in incinerator

Incineration is a waste treatment process that involves the combustion of substances contained in waste materials. Industrial plants for waste incineration are commonly referred to as waste-to-energy facilities. Incineration and other high ...

s.

Pressure from environmentally related legislation

Legislation is the process or result of enrolling, enacting, or promulgating laws by a legislature, parliament, or analogous governing body. Before an item of legislation becomes law it may be known as a bill, and may be broadly referred to ...

on solid waste

Waste (or wastes) are unwanted or unusable materials. Waste is any substance discarded after primary use, or is worthless, defective and of no use. A by-product, by contrast is a joint product of relatively minor economic value. A waste pr ...

disposal methods in developed countries

A developed country (or industrialized country, high-income country, more economically developed country (MEDC), advanced country) is a sovereign state that has a high quality of life, developed economy and advanced technological infrastr ...

has increased the application of anaerobic digestion as a process for reducing waste volumes and generating useful byproducts. It may either be used to process the source-separated fraction of municipal waste or alternatively combined with mechanical sorting systems, to process residual mixed municipal waste. These facilities are called mechanical biological treatment plants.

If the putrescible waste processed in anaerobic digesters were disposed of in a landfill, it would break down naturally and often anaerobically. In this case, the gas will eventually escape into the atmosphere. As methane is about 20 times more potent as a greenhouse gas

A greenhouse gas (GHG or GhG) is a gas that absorbs and emits radiant energy within the thermal infrared range, causing the greenhouse effect. The primary greenhouse gases in Earth's atmosphere are water vapor (), carbon dioxide (), met ...

than carbon dioxide, this has significant negative environmental effects.

In countries that collect household waste, the use of local anaerobic digestion facilities can help to reduce the amount of waste that requires transportation to centralized landfill sites or incineration facilities. This reduced burden on transportation reduces carbon emissions from the collection vehicles. If localized anaerobic digestion facilities are embedded within an electrical distribution network, they can help reduce the electrical losses associated with transporting electricity over a national grid.

Power generation

In developing countries, simple home and farm-based anaerobic digestion systems offer the potential for low-cost energy for cooking and lighting.Transfer of low-cost plastic biodigester technology at household level in Bolivialrrd.org From 1975, China and India have both had large, government-backed schemes for adaptation of small biogas plants for use in the household for cooking and lighting. At present, projects for anaerobic digestion in the developing world can gain financial support through the

United Nations

The United Nations (UN) is an intergovernmental organization whose stated purposes are to maintain international peace and security, develop friendly relations among nations, achieve international cooperation, and be a centre for harmonizi ...

Clean Development Mechanism

The Clean Development Mechanism (CDM) is a United Nations-run carbon offset scheme allowing countries to fund greenhouse gas emissions-reducing projects in other countries and claim the saved emissions as part of their own efforts to meet internat ...

if they are able to show they provide reduced carbon emissions.

Methane and power produced in anaerobic digestion facilities can be used to replace energy derived from fossil fuels, and hence reduce emissions of greenhouse gases, because the carbon in biodegradable material is part of a carbon cycle

The carbon cycle is the biogeochemical cycle by which carbon is exchanged among the biosphere, pedosphere, geosphere, hydrosphere, and atmosphere of the Earth. Carbon is the main component of biological compounds as well as a major componen ...

. The carbon released into the atmosphere from the combustion of biogas has been removed by plants for them to grow in the recent past, usually within the last decade, but more typically within the last growing season. If the plants are regrown, taking the carbon out of the atmosphere once more, the system will be carbon neutral. In contrast, carbon in fossil fuels has been sequestered in the earth for many millions of years, the combustion of which increases the overall levels of carbon dioxide in the atmosphere. Power generation through anaerobic digestors is best suited to large-scale operations, rather than small farms, as large operations have the volume of manure that is able to make the systems financially viable.

Biogas from sewage sludge treatment is sometimes used to run a gas engine to produce electrical power, some or all of which can be used to run the sewage works. Some waste heat from the engine is then used to heat the digester. The waste heat is, in general, enough to heat the digester to the required temperatures. The power potential from sewage works is limited – in the UK, there are about 80 MW total of such generation, with the potential to increase to 150 MW, which is insignificant compared to the average power demand in the UK of about 35,000 MW. The scope for biogas generation from nonsewage waste biological matter – energy crops, food waste, abattoir waste, etc. - is much higher, estimated to be capable of about 3,000 MW. Farm biogas plants using animal waste and energy crops are expected to contribute to reducing CO2 emissions and strengthen the grid, while providing UK farmers with additional revenues.

Some countries offer incentives in the form of, for example, feed-in tariff

A feed-in tariff (FIT, FiT, standard offer contract,Couture, T., Cory, K., Kreycik, C., Williams, E., (2010)Policymaker's Guide to Feed-in Tariff Policy Design National Renewable Energy Laboratory, U.S. Dept. of Energy advanced renewable tariff, ...

s for feeding electricity onto the power grid to subsidize green energy production.

In Oakland, California at the East Bay Municipal Utility District's main wastewater treatment plant (EBMUD), food waste

Food loss and waste is food that is not eaten. The causes of food waste or loss are numerous and occur throughout the food system, during production, processing, distribution, retail and food service sales, and consumption. Overall, abou ...

is currently codigested with primary and secondary municipal wastewater solids and other high-strength wastes. Compared to municipal wastewater solids digestion alone, food waste codigestion has many benefits. Anaerobic digestion of food waste pulp from the EBMUD food waste process provides a higher normalized energy benefit, compared to municipal wastewater solids: 730 to 1,300 kWh per dry ton of food waste applied compared to 560 to 940 kWh per dry ton of municipal wastewater solids applied.

Grid injection

Biogas grid-injection is the injection of biogas into the natural gas grid. The raw biogas has to be previously upgraded to biomethane. This upgrading implies the removal of contaminants such as hydrogen sulphide or siloxanes, as well as the carbon dioxide. Several technologies are available for this purpose, the most widely implemented being pressure swing adsorption (PSA), water or amine scrubbing (absorption processes) and, in recent years, membrane separation. As an alternative, the electricity and the heat can be used for on-site generation, resulting in a reduction of losses in the transportation of energy. Typical energy losses in natural gas transmission systems range from 1–2%, whereas the current energy losses on a large electrical system range from 5–8%. In October 2010, Didcot Sewage Works became the first in the UK to producebiomethane

Renewable natural gas (RNG), also known as sustainable natural gas (SNG) or biomethane, is a biogas which has been upgraded to a quality similar to fossil natural gas and having a methane concentration of 90% or greater. By increasing the concentr ...

gas supplied to the national grid, for use in up to 200 homes in Oxfordshire. By 2017, UK electricity firm Ecotricity plan to have digester fed by locally sourced grass fueling 6000 homes

Vehicle fuel

After upgrading with the above-mentioned technologies, the biogas (transformed into biomethane) can be used as vehicle fuel in adapted vehicles. This use is very extensive in Sweden, where over 38,600 gas vehicles exist, and 60% of the vehicle gas is biomethane generated in anaerobic digestion plants.Fertiliser and soil conditioner

The solid, fibrous component of the digested material can be used as a soil conditioner to increase the organic content of soils. Digester liquor can be used as a fertiliser to supply vital nutrients to soils instead of chemical fertilisers that require large amounts of energy to produce and transport. The use of manufactured fertilisers is, therefore, more carbon-intensive than the use of anaerobic digester liquor fertiliser. In countries such asSpain

, image_flag = Bandera de España.svg

, image_coat = Escudo de España (mazonado).svg

, national_motto = '' Plus ultra'' ( Latin)(English: "Further Beyond")

, national_anthem = (English: "Royal March")

, ...

, where many soils are organically depleted, the markets for the digested solids can be equally as important as the biogas.

Cooking gas

By using a bio-digester, which produces the bacteria required for decomposing, cooking gas is generated. The organic waste like fallen leaves, kitchen waste, food waste etc. are fed into a crusher unit, where it is mixed with a small amount of water. The mixture is then fed into the bio-digester, where the archaea decomposes it to produce cooking gas. This gas is piped to kitchen stove. A 2 cubic meter bio-digester can produce 2 cubic meters of cooking gas. This is equivalent to 1 kg of LPG. The notable advantage of using a bio-digester is the sludge which is a rich organic manure.Products

The three principal products of anaerobic digestion are biogas, digestate, and water.Biogas

Biogas holder with lightning protection rods and backup gas flare upright=0.6, Biogas carrying pipes Biogas is the ultimate waste product of the bacteria feeding off the input biodegradable feedstock (themethanogenesis

Methanogenesis or biomethanation is the formation of methane coupled to energy conservation by microbes known as methanogens. Organisms capable of producing methane for energy conservation have been identified only from the domain Archaea, a gro ...

stage of anaerobic digestion is performed by archaea, a micro-organism on a distinctly different branch of the phylogenetic

In biology, phylogenetics (; from Greek φυλή/ φῦλον [] "tribe, clan, race", and wikt:γενετικός, γενετικός [] "origin, source, birth") is the study of the evolutionary history and relationships among or within groups o ...

tree of life to bacteria), and is mostly methane and carbon dioxide, with a small amount hydrogen and trace hydrogen sulfide. (As-produced, biogas also contains water vapor, with the fractional water vapor volume a function of biogas temperature). Most of the biogas is produced during the middle of the digestion, after the bacterial population has grown, and tapers off as the putrescible material is exhausted. The gas is normally stored on top of the digester in an inflatable gas bubble or extracted and stored next to the facility in a gas holder.

The methane in biogas can be burned to produce both heat and electricity, usually with a reciprocating engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common fea ...

or microturbine often in a cogeneration

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

Cogeneration is a more efficient use of fuel or heat, because otherwise- wasted heat from elec ...

arrangement where the electricity and waste heat generated are used to warm the digesters or to heat buildings. Excess electricity can be sold to suppliers or put into the local grid. Electricity produced by anaerobic digesters is considered to be renewable energy and may attract subsidies. Biogas does not contribute to increasing atmospheric carbon dioxide concentrations because the gas is not released directly into the atmosphere and the carbon dioxide comes from an organic source with a short carbon cycle.

Biogas may require treatment or 'scrubbing' to refine it for use as a fuel. Hydrogen sulfide

Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hydride gas, and is poisonous, corrosive, and flammable, with trace amounts in ambient atmosphere having a characteristic foul odor of rotten eggs. The und ...

, a toxic product formed from sulfates in the feedstock, is released as a trace component of the biogas. National environmental enforcement agencies, such as the U.S. Environmental Protection Agency or the English and Welsh Environment Agency

The Environment Agency (EA) is a non-departmental public body, established in 1996 and sponsored by the United Kingdom government's Department for Environment, Food and Rural Affairs, with responsibilities relating to the protection and en ...

, put strict limits on the levels of gases containing hydrogen sulfide, and, if the levels of hydrogen sulfide in the gas are high, gas scrubbing and cleaning equipment (such as amine gas treating) will be needed to process the biogas to within regionally accepted levels. Alternatively, the addition of ferrous chloride FeCl2 to the digestion tanks inhibits hydrogen sulfide production.

Volatile siloxane

A siloxane is a functional group in organosilicon chemistry with the Si−O−Si linkage. The parent siloxanes include the oligomeric and polymeric hydrides with the formulae H(OSiH2)''n''OH and (OSiH2)n. Siloxanes also include branched compound ...

s can also contaminate the biogas; such compounds are frequently found in household waste and wastewater. In digestion facilities accepting these materials as a component of the feedstock, low-molecular-weight siloxanes volatilise into biogas. When this gas is combusted in a gas engine, turbine, or boiler, siloxanes are converted into silicon dioxide (SiO2), which deposits internally in the machine, increasing wear and tear. Practical and cost-effective technologies to remove siloxanes and other biogas contaminants are available at the present time., appliedfiltertechnology.com In certain applications, ''in situ'' treatment can be used to increase the methane purity by reducing the offgas carbon dioxide content, purging the majority of it in a secondary reactor.

In countries such as Switzerland, Germany, and Sweden, the methane in the biogas may be compressed for it to be used as a vehicle transportation fuel or input directly into the gas mains. In countries where the driver for the use of anaerobic digestion are renewable electricity subsidies, this route of treatment is less likely, as energy is required in this processing stage and reduces the overall levels available to sell.

Digestate

Digestate is the solid remnants of the original input material to the digesters that the microbes cannot use. It also consists of the mineralised remains of the dead bacteria from within the digesters. Digestate can come in three forms: fibrous, liquor, or a sludge-based combination of the two fractions. In two-stage systems, different forms of digestate come from different digestion tanks. In single-stage digestion systems, the two fractions will be combined and, if desired, separated by further processing. The second byproduct (acidogenic digestate) is a stable, organic material consisting largely of lignin and cellulose, but also of a variety of mineral components in a matrix of dead bacterial cells; some plastic may be present. The material resembles domestic compost and can be used as such or to make low-grade building products, such as fibreboard. The solid digestate can also be used as feedstock for ethanol production. The third byproduct is a liquid (methanogenic digestate) rich in nutrients, which can be used as a fertiliser, depending on the quality of the material being digested. Levels of potentially toxic elements (PTEs) should be chemically assessed. This will depend upon the quality of the original feedstock. In the case of most clean and source-separated biodegradable waste streams, the levels of PTEs will be low. In the case of wastes originating from industry, the levels of PTEs may be higher and will need to be taken into consideration when determining a suitable end use for the material. Digestate typically contains elements, such as lignin, that cannot be broken down by the anaerobic microorganisms. Also, the digestate may contain ammonia that is phytotoxic, and may hamper the growth of plants if it is used as a soil-improving material. For these two reasons, a maturation or composting stage may be employed after digestion. Lignin and other materials are available for degradation by aerobic microorganisms, such as fungi, helping reduce the overall volume of the material for transport. During this maturation, the ammonia will be oxidized into nitrates, improving the fertility of the material and making it more suitable as a soil improver. Large composting stages are typically used by dry anaerobic digestion technologies.Wastewater

The final output from anaerobic digestion systems is water, which originates both from the moisture content of the original waste that was treated and water produced during the microbial reactions in the digestion systems. This water may be released from the dewatering of the digestate or may be implicitly separate from the digestate. The wastewater exiting the anaerobic digestion facility will typically have elevated levels ofbiochemical oxygen demand

Biochemical oxygen demand (BOD) is the amount of dissolved oxygen (DO) needed (i.e. demanded) by aerobic biological organisms to break down organic material present in a given water sample at a certain temperature over a specific time period. ...

(BOD) and chemical oxygen demand

In environmental chemistry, the chemical oxygen demand (COD) is an indicative measure of the amount of oxygen that can be consumed by reactions in a measured solution. It is commonly expressed in mass of oxygen consumed over volume of solution w ...

(COD). These measures of the reactivity of the effluent indicate an ability to pollute. Some of this material is termed 'hard COD', meaning it cannot be accessed by the anaerobic bacteria for conversion into biogas. If this effluent were put directly into watercourses, it would negatively affect them by causing eutrophication

Eutrophication is the process by which an entire body of water, or parts of it, becomes progressively enriched with minerals and nutrients, particularly nitrogen and phosphorus. It has also been defined as "nutrient-induced increase in phytopla ...

. As such, further treatment of the wastewater is often required. This treatment will typically be an oxidation stage wherein air is passed through the water in a sequencing batch reactors or reverse osmosis

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic ...

unit.

History

The history of anaerobic digestion is a long one, beginning as early as tenth century BCE inAssyria

Assyria (Neo-Assyrian cuneiform: , romanized: ''māt Aššur''; syc, ܐܬܘܪ, ʾāthor) was a major ancient Mesopotamian civilization which existed as a city-state at times controlling regional territories in the indigenous lands of the As ...

where biogas

Biogas is a mixture of gases, primarily consisting of methane, carbon dioxide and hydrogen sulphide, produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste and food waste. I ...

was used to heat bath water. Reported scientific interest in the manufacturing of gas produced by the natural decomposition of organic matter dates from the 17th century, when Robert Boyle

Robert Boyle (; 25 January 1627 – 31 December 1691) was an Anglo-Irish natural philosopher, chemist, physicist, alchemist and inventor. Boyle is largely regarded today as the first modern chemist, and therefore one of the founders of ...

(1627-1691) and Stephen Hales

Stephen Hales (17 September 16774 January 1761) was an English clergyman who made major contributions to a range of scientific fields including botany, pneumatic chemistry and physiology. He was the first person to measure blood pressure. He a ...

(1677-1761) noted that disturbing the sediment

Sediment is a naturally occurring material that is broken down by processes of weathering and erosion, and is subsequently transported by the action of wind, water, or ice or by the force of gravity acting on the particles. For example, sa ...

of streams and lakes released flammable gas.Fergusen, T. & Mah, R. (2006) Methanogenic bacteria in Anaerobic digestion of biomass, p49 In 1778, the Italian physicist Alessandro Volta (1745-1827), the father of electrochemistry

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference, as a measurable and quantitative phenomenon, and identifiable chemical change, with the potential difference as an outc ...

, scientifically identified that gas as methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The relative abundance of methane on Ear ...

.

In 1808 Sir Humphry Davy

Sir Humphry Davy, 1st Baronet, (17 December 177829 May 1829) was a British chemist and inventor who invented the Davy lamp and a very early form of arc lamp. He is also remembered for isolating, by using electricity, several elements for the ...

proved the presence of methane in the gases produced by cattle

Cattle (''Bos taurus'') are large, domesticated, cloven-hooved, herbivores. They are a prominent modern member of the subfamily Bovinae and the most widespread species of the genus '' Bos''. Adult females are referred to as cows and adult ...

manure

Manure is organic matter that is used as organic fertilizer in agriculture. Most manure consists of animal feces; other sources include compost and green manure. Manures contribute to the fertility of soil by adding organic matter and nut ...

.Anaerobic digestion, waste.nl. Retrieved 19.08.07. The first known anaerobic digester was built in 1859 at a

leper colony

A leper colony, also known by many other names, is an isolated community for the quarantining and treatment of lepers, people suffering from leprosy. ''M. leprae'', the bacterium responsible for leprosy, is believed to have spread from East Af ...

in Bombay

Mumbai (, ; also known as Bombay — the official name until 1995) is the capital city of the Indian state of Maharashtra and the '' de facto'' financial centre of India. According to the United Nations, as of 2018, Mumbai is the sec ...

in India

India, officially the Republic of India ( Hindi: ), is a country in South Asia. It is the seventh-largest country by area, the second-most populous country, and the most populous democracy in the world. Bounded by the Indian Ocean on the ...

. In 1895, the technology was developed in Exeter

Exeter () is a city in Devon, South West England. It is situated on the River Exe, approximately northeast of Plymouth and southwest of Bristol.