|

Tooling (other)

Tooling may refer to: * Machine tools and the tooling, such as cutting tools, fixtures, and accessories, that is used on them ** Cutting tool (machining), any of hundreds of kinds of cutters ** Fixture (tool), a fixed workholding or support device ** Jig (tool), a movable workholding or support device ** Tool management, keeping track of, and maximizing efficient use of, all the tooling * Tooling University, a training program of SME (society) that teaches machinists about machine tools and tooling * Agile tooling, the process of using modular means to design tooling that is produced by additive manufacturing or 3D printing methods to enable quick prototyping and responses to tooling and fixture needs * Programming tools, a set of apps that supports software development See also * Re-tooling (other) * Tool (other) A tool is a device that is required or helpful for the performance of an operation. Tool may also refer to: * Magical tools in Wicca, a set of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting Tool (machining)

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majority of these tools are designed exclusively for metals. There are several different types of single edge cutting tools that are made from a variety of hardened metal alloys that are ground to a specific shape in order to perform a specific part of the turning process resulting in a finished machined part. Single edge cutting tools are used mainly in the turning operations performed by a lathe in which they vary in size as well as alloy composition depending on the size and the type of material being turned. These cutting tools are held stationary by what is known as a tool post which is what manipulates the tools to cut the material into the desired shape. Single edge cutting tools are also the means of cutting material performed by metal sh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fixture (tool)

A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run. A fixture differs from a jig in that when a fixture is used, the tool must move relative to the workpiece; a jig moves the piece while the tool remains stationary. Purpose A fixture's primary purpose is to create a secure mounting point for a workpiece, allowing for support during operation and increased accuracy, precision, reliability, and interchangeability in the finished parts. It also serves to reduce working time by allowing quick set-up ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jig (tool)

A jig is a type of custom-made tool used to control the location and/or motion of parts or other tools. Description A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products.. An example of a jig is when a key is duplicated; the original is used as a jig so the new key can have the same path as the old one. Since the advent of automation and computer numerical controlled (CNC) machines, jigs are often not required because the tool path is digitally programmed and stored in memory. Jigs may be made for reforming plastics. Jigs or templates have been known long before the industrial age. There are many types of jigs, and each one is custom-tailored to do a specific job. Drill jig A ''drill jig'' is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole center ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Management

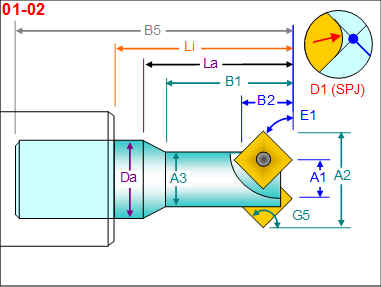

Tool management is needed in metalworking so that the information regarding the tools on hand can be uniformly organized and integrated. The information is stored in a database and is registered and applied using tool management. Tool data management consists of specific data fields, graphics and parameters that are essential in production, as opposed to managing general production equipment. Unlike hand tools, a tool in numerically (digitally) controlled machines is composed of several parts, such as the cutting tool (which may be one piece or comprise a body plus indexable inserts), a collet, and a toolholder with a machine taper. Putting the parts together accurately into an assembly is required to achieve error-free production. Processing a part with a CNC (computer numerically controlled) machining operation requires several tool assemblies that are documented in a list. Each component, each assembly and each list has an identifier under which the specifications are found. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SME (society)

SME (previously the Society of Manufacturing Engineers) is a non-profit student and professional association for educating and advancing the manufacturing industry in North America. History SME was founded in January 1932 at the height of the Great Depression. Originally named the Society of Tool Engineers, and renamed the American Society of Tool Engineers one year later, it was formed by a group of 33 engineers and mechanics gathered at the Detroit College of Applied Science. By April of that year, just four months after its beginning, membership increased from the original 33 members to 200 members and continued to grow rapidly with new chapters popping up across the country. As the economic troubles of the 1930s pushed the world ever-closer to war, Society members responded by helping to convert America's industries into the primary military supplier for the Allied war effort, or what President Roosevelt referred to as the "arsenal of democracy." The organization also tailo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Agile Tooling

Agile tooling is the design and fabrication of manufacturing related-tools such as dies, molds, patterns, jigs and fixtures in a configuration that aims to maximise the tools' performance, minimise manufacturing time and cost, and avoid delay in prototyping. A fully functional agile tooling laboratory consists of CNC milling, turning and routing equipment. It can also include additive manufacturing platforms (such as fused filament fabrication, selective laser sintering, Stereolithography, and direct metal laser sintering), hydroforming, vacuum forming, die casting, stamping, injection molding and welding equipment. Agile tooling is similar to rapid tooling, which uses additive manufacturing to make tools or tooling quickly, either directly by making parts that serve as the actual tools or tooling components, such as mold inserts; or indirectly by producing patterns that are in turn used in a secondary process to produce the actual tools. Another similar technique is prototyp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Programming Tool

A programming tool or software development tool is a computer program that software developers use to create, debug, maintain, or otherwise support other programs and applications. The term usually refers to relatively simple programs, that can be combined to accomplish a task, much as one might use multiple hands to fix a physical object. The most basic tools are a source code editor and a compiler or interpreter, which are used ubiquitously and continuously. Other tools are used more or less depending on the language, development methodology, and individual engineer, often used for a discrete task, like a debugger or profiler. Tools may be discrete programs, executed separately – often from the command line – or may be parts of a single large program, called an integrated development environment (IDE). In many cases, particularly for simpler use, simple ad hoc techniques are used instead of a tool, such as print debugging instead of using a debugger, manual timing (of overal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Software Development

Software development is the process of conceiving, specifying, designing, programming, documenting, testing, and bug fixing involved in creating and maintaining applications, frameworks, or other software components. Software development involves writing and maintaining the source code, but in a broader sense, it includes all processes from the conception of the desired software through to the final manifestation of the software, typically in a planned and structured process. Software development also includes research, new development, prototyping, modification, reuse, re-engineering, maintenance, or any other activities that result in software products. Methodologies One system development methodology is not necessarily suitable for use by all projects. Each of the available methodologies are best suited to specific kinds of projects, based on various technical, organizational, project, and team considerations. Software development activities Identification of need The sou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Re-tooling (other)

Re-tooling or retooling may refer to: * Changing tools * Tool management change * Soft retooling * Reboot (fiction) In serial fiction, the term "reboot" signifies a new start to an established fictional universe, work, or series. A reboot discards continuity to re-create its characters, plotlines and backstory from the beginning. It has been described as a ... See also * Tooling (other) {{Dab ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |