|

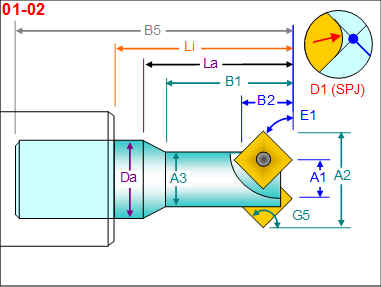

Tool Management

Tool management is needed in metalworking so that the information regarding the tools on hand can be uniformly organized and integrated. The information is stored in a database and is registered and applied using tool management. Tool data management consists of specific data fields, graphics and parameters that are essential in production, as opposed to managing general production equipment. Unlike hand tools, a tool in numerically (digitally) controlled machines is composed of several parts, such as the cutting tool (which may be one piece or comprise a body plus indexable inserts), a collet, and a toolholder with a machine taper. Putting the parts together accurately into an assembly is required to achieve error-free production. Processing a part with a CNC (computer numerically controlled) machining operation requires several tool assemblies that are documented in a list. Each component, each assembly and each list has an identifier under which the specifications are found. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tipped Tool

A tipped tool is any cutting tool in which the cutting edge consists of a separate piece of material that is brazed, welded, or clamped onto a body made of another material. In the types in which the cutter portion is an indexable part clamped by a screw, the cutters are called inserts (because they are inserted into the tool body). Tipped tools allow each part of the tool, the shank and the cutter(s), to be made of the material with the best properties for its job. Common materials for the cutters (brazed tips or clamped inserts) include cemented carbide, polycrystalline diamond, and cubic boron nitride. Tools that are commonly tipped include milling cutters (such as end mills, face mills, and fly cutters), tool bits, router bits, and saw blades (especially the metal-cutting ones). Advantages and disadvantages The advantage of tipped tools is only a small insert of the cutting material is needed to provide the cutting ability. The small size makes manufacturing of the inser ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to ''additive manufacturing'' (3D printing), which uses controlled addition of material. Machining is a part of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material. A person who specializes in machining is called a machinist. A room, building, or company where machining is done is called a machine shop. Much of modern-day machining is carried out by computer numerical control (CNC), in which computers are used to control the movement and operation of the mills, lathes, and other cutting machines. This increases efficiency, as the CNC machine runs unmanned therefore reducing labour costs for machine shops. History and ter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Default (computer Science)

A default, in computer science, refers to the preexisting value of a user-configurable setting that is assigned to a software application, computer program or device. Such settings are also called presets or factory presets, especially for electronic devices. Default values are standards values that are universal to all instances of the device or model and intended to make the device as accessible as possible "out of the box" without necessitating a lengthy configuration process prior to use. The user only has to modify the default settings according to their personal preferences. In many devices, the user has the option to restore these default settings for one or all options. Such an assignment makes the choice of that setting or value more likely, this is called the default effect. Examples Application software preferences One use of default parameters is for initial settings for application software. For example, the first time a user runs an application it may suggest that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bill Of Material

A bill of materials or product structure (sometimes bill of material, BOM or associated list) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. A BOM may be used for communication between manufacturing partners or confined to a single manufacturing plant. A bill of materials is often tied to a production order whose issuance may generate reservations for components in the bill of materials that are in stock and requisitions for components that are not in stock. There are two types of bill materials. A BOM can define products as they are designed (engineering bill of materials), as they are ordered (sales bill of materials), as they are built ( manufacturing bill of materials), or as they are maintained (service bill of materials). The different types depend on the business need and use for which they are intended. In process industries, the BOM is also known as the for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer Aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for miniature applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earliest perforated artifacts, such as bone, ivory, shells, and antler ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting Speed

The phrase speeds and feeds or feeds and speeds refers to two separate velocities in machine tool practice, cutting speed and feed rate. They are often considered as a pair because of their combined effect on the cutting process. Each, however, can also be considered and analyzed in its own right. ''Cutting speed'' (also called ''surface speed'' or simply ''speed'') is the speed difference ( relative velocity) between the cutting tool and the surface of the workpiece it is operating on. It is expressed in units of distance across the workpiece surface per unit of time, typically surface feet per minute (sfm) or meters per minute (m/min). ''Feed rate'' (also often styled as a solid compound, ''feedrate'', or called simply ''feed'') is the relative velocity at which the cutter is advanced along the workpiece; its vector is perpendicular to the vector of cutting speed. Feed rate units depend on the motion of the tool and workpiece; when the workpiece rotates (''e.g.'', in tu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

STL (file Format)

STL is a file format native to the stereolithography CAD software created by 3D Systems. STL has several backronyms such as "Standard Triangle Language" and "Standard Tessellation Language". This file format is supported by many other software packages; it is widely used for rapid prototyping, 3D printing and computer-aided manufacturing. STL files describe only the surface geometry of a three-dimensional object without any representation of color, texture or other common CAD model attributes. The STL format specifies both ASCII and binary representations. Binary files are more common, since they are more compact. An STL file describes a raw, unstructured triangulated surface by the unit normal and vertices (ordered by the right-hand rule) of the triangles using a three-dimensional Cartesian coordinate system. In the original specification, all STL coordinates were required to be positive numbers, but this restriction is no longer enforced and negative coordinates are commonly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ISO 10303

ISO 10303 is an ISO standard for the computer-interpretable representation and exchange of product manufacturing information. It is an ASCII-based format. Its official title is: ''Automation systems and integration — Product data representation and exchange''. It is known informally as "STEP", which stands for "Standard for the Exchange of Product model data". ISO 10303 can represent 3D objects in Computer-aided design (CAD) and related information. Overview The objective of the international standard is to provide a mechanism that is capable of describing product data throughout the life cycle of a product, independent from any particular system. The nature of this description makes it suitable not only for neutral file exchange, but also as a basis for implementing and sharing product databases and archiving. STEP can be typically used to exchange data between CAD, computer-aided manufacturing, computer-aided engineering, product data management/enterprise data modelin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

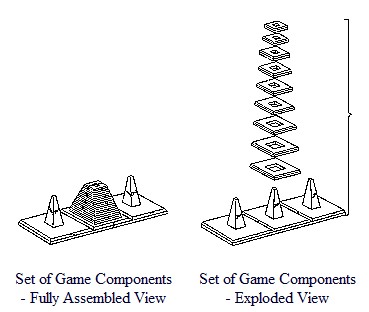

Exploded View

An exploded-view drawing is a diagram, picture, schematic or technical drawing of an object, that shows the relationship or order of assembly of various parts. It shows the components of an object slightly separated by distance, or suspended in surrounding space in the case of a three-dimensional exploded diagram. An object is represented as if there had been a small controlled explosion emanating from the middle of the object, causing the object's parts to be separated an equal distance away from their original locations. The exploded-view drawing is used in parts catalogs, assembly and maintenance manuals and other instructional material. The projection of an exploded view is usually shown from above and slightly in diagonal from the left or right side of the drawing. (See exploded-view drawing of a gear pump to the right: it is slightly from above and shown from the left side of the drawing in diagonal.) Overview An exploded-view drawing is a type of drawing, that shows ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |