|

Tape Casting

Tape casting (also called doctor blading, knife coating, and shank shifting) is a casting process used in the manufacture of thin ceramic tapes and sheets from ceramic slurry. The ceramic slurry is cast in a thin layer onto a flat surface and then dried and sintered. It's a part of powder metallurgy. History Tape casting was first described as a method to mass-produce capacitors. In this first published description from 1947 the process was described as: In 1960 a patent was filed for multilayered tape casting and in 1996 the first tapes under 5 μm were cast. Production process The tape casting process converts ceramic powder to a thin film by making a liquid form of it, casting it on a flat plane and drying it. Ingredients The starting point for the tape casting process is the powder that the 'tape' is to be consisting of. This is the active component of the final product and the other contents, such as binder material and solvents have to be compatible with the powder. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass

Glass is a non-Crystallinity, crystalline, often transparency and translucency, transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of the Melting, molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured glass are "silicate glasses" based on the chemical compound silicon dioxide, silica (silicon dioxide, or quartz), the primary constituent of sand. Soda–lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. The term ''glass'', in popular usage, is often used to refer only to this type of material, although silica-free glasses often have desirable properties for applications in modern communications technology. Some objects, such as drinking glasses and glasses, eyeglasses, are so commonly made of silicate- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molten Carbonate Fuel Cell

Molten-carbonate fuel cells (MCFCs) are high-temperature fuel cells that operate at temperatures of 600 °C and above. Molten carbonate fuel cells (MCFCs) were developed for natural gas, biogas (produced as a result of anaerobic digestion or biomass gasification), and coal- based power plants for electrical utility, industrial, and military applications. MCFCs are high-temperature fuel cells that use an electrolyte composed of a molten carbonate salt mixture suspended in a porous, chemically inert ceramic matrix of beta-alumina solid electrolyte (BASE). Since they operate at extremely high temperatures of 650 °C (roughly 1,200 °F) and above, non-precious metals can be used as catalysts at the anode and cathode, reducing costs. Improved efficiency is another reason MCFCs offer significant cost reductions over phosphoric acid fuel cells (PAFCs). Molten carbonate fuel cells can reach efficiencies approaching 60%, considerably higher than the 37–42% efficienci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photovoltaics

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials that exhibit the photovoltaic effect, a phenomenon studied in physics, photochemistry, and electrochemistry. The photovoltaic effect is commercially used for electricity generation and as photosensors. A photovoltaic system employs solar modules, each comprising a number of solar cells, which generate electrical power. PV installations may be ground-mounted, rooftop-mounted, wall-mounted or floating. The mount may be fixed or use a solar tracker to follow the sun across the sky. Photovoltaic technology helps to mitigate climate change because it emits much less carbon dioxide than fossil fuels. Solar PV has specific advantages as an energy source: once installed, its operation generates no pollution and no greenhouse gas emissions, it shows scalability in respect of power needs and silicon has large availability in the Earth's crust, although other materials required in PV s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Electrolytes

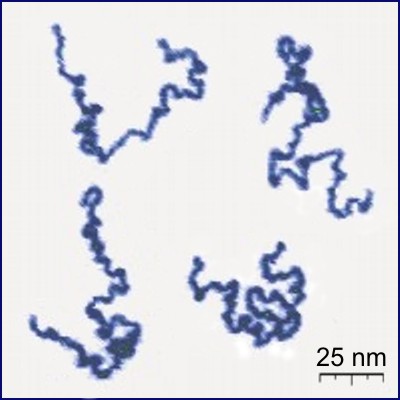

A polymer electrolyte is a polymer matrix capable of ion conduction. Much like other types of electrolyte—liquid and solid-state—polymer electrolytes aid in movement of charge between the anode and cathode of a cell. The use of polymers as an electrolyte was first demonstrated using dye-sensitized solar cells. The field has expanded since and is now primarily focused on the development of polymer electrolytes with applications in batteries, fuel cells, and membranes. Molecular Design of Polymer Electrolytes for Cation Transport Overview Generally, polymer electrolytes comprise a polymer which incorporates a highly polar motif capable of electron donation. Performance parameters impact selection of homo- or heterogenous electrolyte. There exist four major types of polymer electrolyte: (1) gel polymer electrolyte, (2) solid-state polymer electrolyte, (3) plasticized polymer electrolyte, and (4) composite polymer electrolyte. The degree of crystallinity of a polymer elect ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic Capacitor

A ceramic capacitor is a fixed-value capacitor where the ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material defines the electrical behavior and therefore applications. Ceramic capacitors are divided into two application classes: * Class 1 ceramic capacitors offer high stability and low losses for resonant circuit applications. * Class 2 ceramic capacitors offer high volumetric efficiency for buffer, by-pass, and coupling applications. Ceramic capacitors, especially multilayer ceramic capacitors (MLCCs), are the most produced and used capacitors in electronic equipment that incorporate approximately one trillion (1012) pieces per year.Download Ceramic capacitors of special shapes and styles are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymers

A polymer (; Greek ''poly-'', "many" + '' -mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'', ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coated Paper

Coated paper (also known as enamel paper, gloss paper, and thin paper) is paper that has been coated by a mixture of materials or a polymer to impart certain qualities to the paper, including weight, surface gloss, smoothness, or reduced ink absorbency. Various materials, including kaolinite, calcium carbonate, bentonite, and talc, can be used to coat paper for high-quality printing used in the packaging industry and in magazines. The chalk or china clay is bound to the paper with synthetic s, such as styrene-butadiene latexes and natural organic binders such as starch. The coating formulation may also contain chemical additives as dispersants, resins, or polyethylene to give water resistance and wet strength to the paper, or to protect against ultraviolet radiation. Varieties Machine-finished coated paper ''Machine-finished coated paper'' (MFC) has a basis weight of 48–80 g/m2. They have good surface properties, high print gloss and adequate sheet stiffness. M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were pottery objects (''pots,'' ''vessels or vases'') or figurines made from clay, either by itself or mixed with other materials like silica, hardened and sintered in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as in semiconductors. The word "'' ceramic''" comes from the Greek word (), "of pottery" or "for pottery", from (), "potter's clay, tile, pottery". The earliest k ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tape Casting

Tape casting (also called doctor blading, knife coating, and shank shifting) is a casting process used in the manufacture of thin ceramic tapes and sheets from ceramic slurry. The ceramic slurry is cast in a thin layer onto a flat surface and then dried and sintered. It's a part of powder metallurgy. History Tape casting was first described as a method to mass-produce capacitors. In this first published description from 1947 the process was described as: In 1960 a patent was filed for multilayered tape casting and in 1996 the first tapes under 5 μm were cast. Production process The tape casting process converts ceramic powder to a thin film by making a liquid form of it, casting it on a flat plane and drying it. Ingredients The starting point for the tape casting process is the powder that the 'tape' is to be consisting of. This is the active component of the final product and the other contents, such as binder material and solvents have to be compatible with the powder. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |