|

Spray Forming

Spray forming, also known as spray casting, spray deposition and in-situ compaction,. is a method of casting near net shape metal components with homogeneous microstructures via the deposition of semi-solid sprayed droplets onto a shaped substrate. In spray forming an alloy is melted, normally in an induction furnace, then the molten metal is slowly poured through a conical tundish into a small-bore ceramic nozzle. The molten metal exits the furnace as a thin free-falling stream and is broken up into droplets by an annular array of gas jets, and these droplets then proceed downwards, accelerated by the gas jets to impact onto a substrate. The process is arranged such that the droplets strike the substrate whilst in the semi-solid condition, this provides sufficient liquid fraction to 'stick' the solid fraction together. Deposition continues, gradually building up a spray formed billet of metal on the substrate. The ''gas atomised spray forming'' (''GASF'') process typically has a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting (metalworking)

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part (the ''casting'') is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years, and have been widely used for sculpture (especially in bronze), jewelry in precious metals, and weapons and tools. Highly engineered castings are found in 90 percent of durable goods, including cars, trucks, aerospace, trains, mining and construction equipment, oil wells, appliances, pipes, hydrants, wind turbines, nuclear plants, medical devices, defense products, toys, and more. Traditional techniques include ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

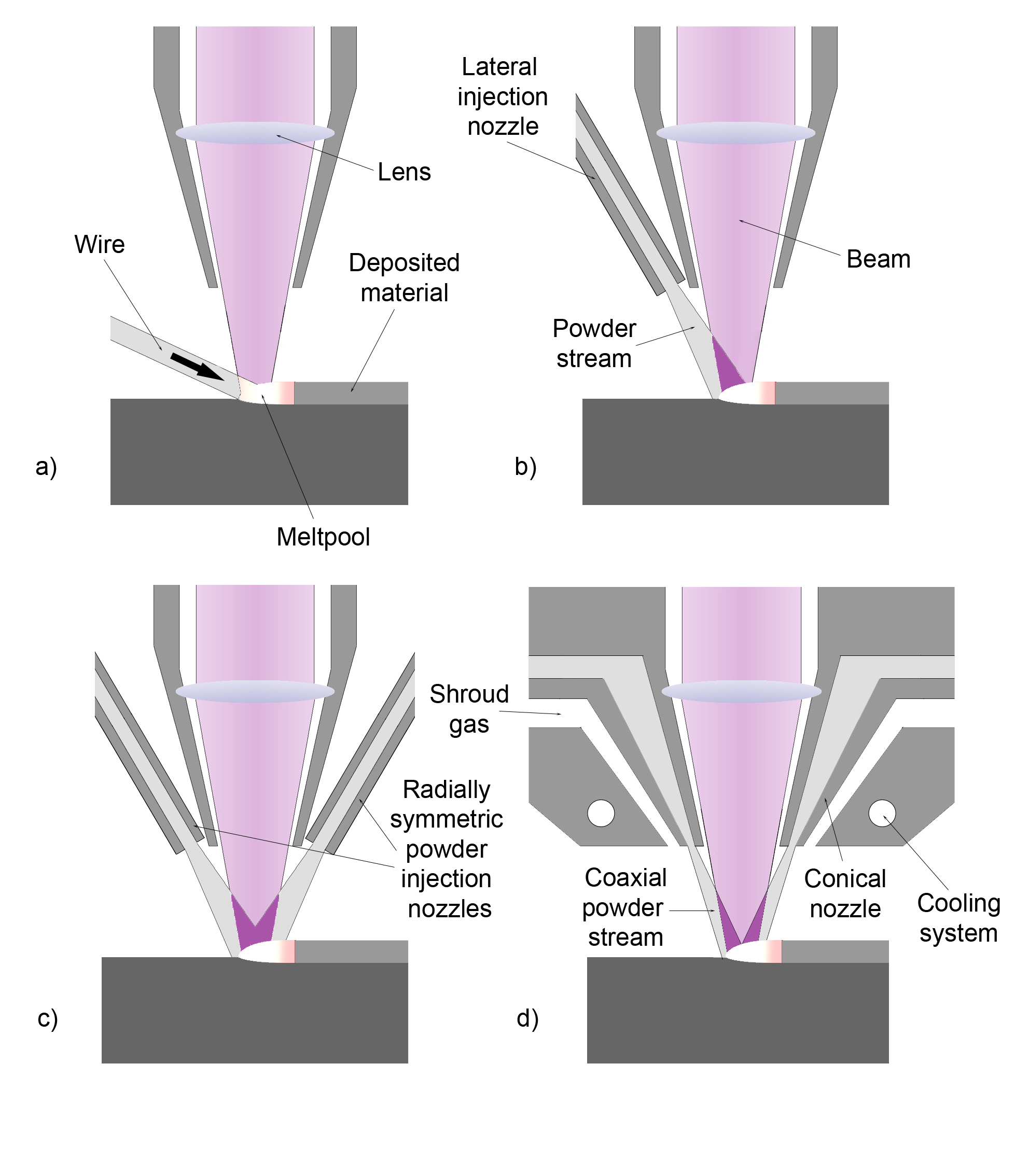

Cladding (metalworking)

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure. The United States Mint uses cladding to manufacture coins from different metals. This allows a cheaper metal to be used as a filler. For example, dimes and quarters struck since 1965 have cores made from pure copper, with a clad layer consisting of 75% copper and 25% nickel added during production. Laser cladding is an additive manufacturing approach for metal coatings or precise piece restorations by using high power multi-mode optical fiber laser. Roll bonding In roll bonding, two or more layers of different metals are thoroughly cleaned and passed through a pair of rollers under sufficient pressure to bond the layers. The pressure is high enough to deform the metals and reduce the combined thick ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ingot

An ingot is a piece of relatively pure material, usually metal, that is cast into a shape suitable for further processing. In steelmaking, it is the first step among semi-finished casting products. Ingots usually require a second procedure of shaping, such as cold/hot working, cutting, or milling to produce a useful final product. Non-metallic and semiconductor materials prepared in bulk form may also be referred to as ingots, particularly when cast by mold based methods. Precious metal ingots can be used as currency (with or without being processed into other shapes), or as a currency reserve, as with gold bars. Types Ingots are generally made of metal, either pure or alloy, heated past its melting point and cast into a bar or block using a mold chill method. A special case are polycrystalline or single crystal ingots made by pulling from a molten melt. Single crystal Single crystal ingots (called boules) of materials are grown (crystal growth) using methods such as the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

History Of Spray Forming

Spray forming, also known as spray casting, spray deposition and in-situ compaction,. is a method of casting near net shape metal components with homogeneous microstructures via the deposition of semi-solid sprayed droplets onto a shaped substrate. In spray forming an alloy is melted, normally in an induction furnace, then the molten metal is slowly poured through a conical tundish into a small-bore ceramic nozzle. The molten metal exits the furnace as a thin free-falling stream and is broken up into droplets by an annular array of gas jets, and these droplets then proceed downwards, accelerated by the gas jets to impact onto a substrate. The process is arranged such that the droplets strike the substrate whilst in the semi-solid condition, this provides sufficient liquid fraction to 'stick' the solid fraction together. Deposition continues, gradually building up a spray formed billet of metal on the substrate. The ''gas atomised spray forming'' (''GASF'') process typically has a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Speed Steel

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material. It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name ''high-speed steel''. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above Rockwell hardness 60) and abrasion resistance (generally linked to tungsten and vanadium content often used in HSS) compared with common carbon and tool steels. History In 1868 English metallurgist Robert Forester Mushet developed Mushet steel, considered the forerunner of modern high-speed steels. It consisted of 2% carbon, 2.5% manganese, and 7% tungsten. The major advantage of this steel was that it hardened when air cooled from a temperatur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Liner

In a reciprocating engine, the cylinder is the space in which a piston travels. The inner surface of the cylinder is formed from either a thin metallic liner (also called "sleeve") or a surface coating applied to the engine block. A piston is seated inside each cylinder by several metal piston rings, which also provide seals for compression and the lubricating oil. The piston rings do not actually touch the cylinder walls, instead they ride on a thin layer of lubricating oil. Steam engines The cylinder in a steam engine is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in cast iron and later in steel. The cylinder casting can include other features such as valve ports and mounting feet. Internal combustion engines The cylinder is the space through which the piston travels, propelled to the energy generated from the combustion of the air/fuel mixture in the combustion chamber. In an ai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic table: carbon is above it; and germanium, tin, lead, and flerovium are below it. It is relatively unreactive. Because of its high chemical affinity for oxygen, it was not until 1823 that Jöns Jakob Berzelius was first able to prepare it and characterize it in pure form. Its oxides form a family of anions known as silicates. Its melting and boiling points of 1414 °C and 3265 °C, respectively, are the second highest among all the metalloids and nonmetals, being surpassed only by boron. Silicon is the eighth most common element in the universe by mass, but very rarely occurs as the pure element in the Earth's crust. It is widely distributed in space in cosmic dusts, planetoids, and planets as various forms of silicon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silver

Silver is a chemical element with the Symbol (chemistry), symbol Ag (from the Latin ', derived from the Proto-Indo-European wikt:Reconstruction:Proto-Indo-European/h₂erǵ-, ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. The metal is found in the Earth's crust in the pure, free elemental form ("native silver"), as an alloy with gold and other metals, and in minerals such as argentite and chlorargyrite. Most silver is produced as a byproduct of copper, gold, lead, and zinc Refining (metallurgy), refining. Silver has long been valued as a precious metal. Silver metal is used in many bullion coins, sometimes bimetallism, alongside gold: while it is more abundant than gold, it is much less abundant as a native metal. Its purity is typically measured on a per-mille basis; a 94%-pure alloy is described as "0.940 fine". As one of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Neodymium

Neodymium is a chemical element with the symbol Nd and atomic number 60. It is the fourth member of the lanthanide series and is considered to be one of the rare-earth metals. It is a hard, slightly malleable, silvery metal that quickly tarnishes in air and moisture. When oxidized, neodymium reacts quickly producing pink, purple/blue and yellow compounds in the +2, +3 and +4 oxidation states. It is generally regarded as having one of the most complex spectra of the elements. Neodymium was discovered in 1885 by the Austrian chemist Carl Auer von Welsbach, who also discovered praseodymium. It is present in significant quantities in the minerals monazite and bastnäsite. Neodymium is not found naturally in metallic form or unmixed with other lanthanides, and it is usually refined for general use. Neodymium is fairly common—about as common as cobalt, nickel, or copper—and is widely distributed in the Earth's crust. Most of the world's commercial neodymium is mined in China, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

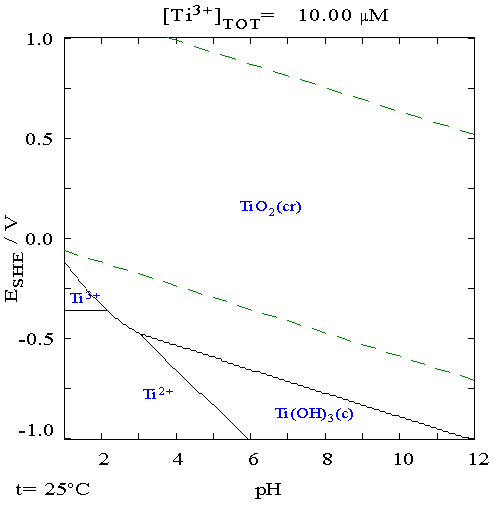

Titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Kingdom of Great Britain, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titan (mythology), Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll process, Kroll and Hunter process, Hunter processes. The most common compound, titanium dioxide, is a popular photocatalysis, photocatalyst and is used in the manufacture of white pigments ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium

Aluminium (aluminum in AmE, American and CanE, Canadian English) is a chemical element with the Symbol (chemistry), symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It has a great affinity towards oxygen, and Passivation (chemistry), forms a protective layer of Aluminium oxide, oxide on the surface when exposed to air. Aluminium visually resembles silver, both in its color and in its great ability to reflect light. It is soft, Magnetism, non-magnetic and ductility, ductile. It has one stable isotope, 27Al; this isotope is very common, making aluminium the twelfth most common element in the Universe. The radioactivity of Aluminum-26, 26Al is used in Radiometric dating, radiodating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ is small and h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power generation), heat energy (e.g. geothermal), chemical energy, electric potential and nuclear energy (from nuclear fission or nuclear fusion). Many of these processes generate heat as an intermediate energy form, so heat engines have special importance. Some natural processes, such as atmospheric convection cells convert environmental heat into motion (e.g. in the form of rising air currents). Mechanical energy is of particular importance in transportation, but also plays a role in many industrial processes such as cutting, grinding, crushing, and mixing. Mechanical heat engines convert heat into work via various thermodynamic processes. The internal combustion engine is perhaps the most common example of a mechanical heat engine, in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)