|

Shives (papermaking)

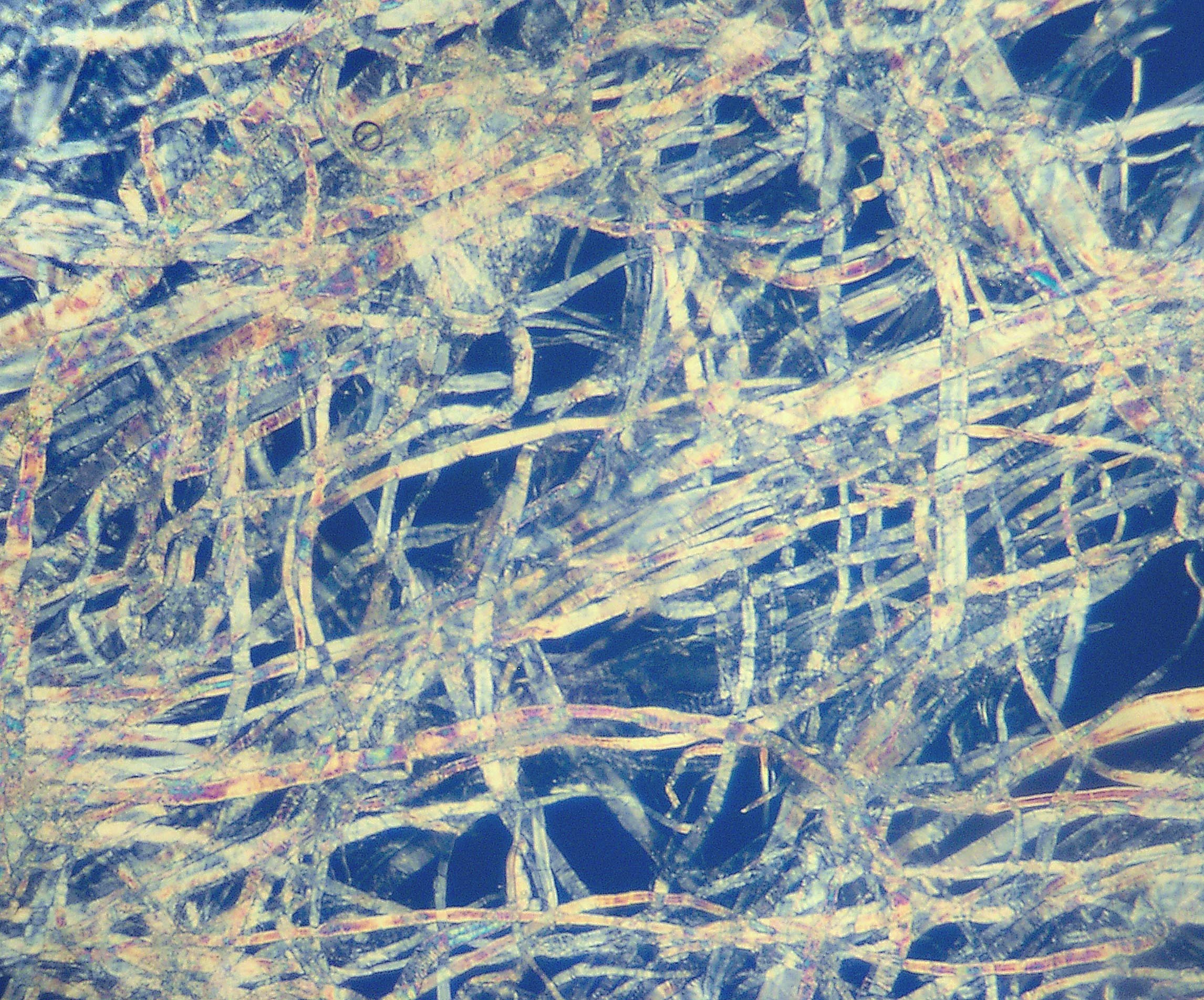

A shive is a small bundle of incompletely cooked wood fibres in the chemical pulp used in papermaking. They are smaller than knots and are more difficult to separate from the pulp. Typically the content of shives in kraft pulp is 0.1 to 1.0%. An excess of shives is a sign of poor impregnation of the wood chips. Shives are separated from the pulp in the screening and can be added back after refining. Even though shives are darker than rest of the pulp, they may pass unnoticed to the paper machine because they are easily bleached. Shives in the paper machine can cause web breakage or other operational problems. They might also end as spots in the finished paper. See also *Knot (papermaking) *Kraft process The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood ... References {{Paper Paperma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or it is defined more broadly to include the same type of tissue elsewhere such as in the roots of trees or shrubs. In a living tree it performs a support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients between the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, or woodchips or fiber. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper. More recently it emerged as a feedstock for the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulber ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Papermaking

Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a specialized craft and a medium for artistic expression. In papermaking, a dilute suspension consisting mostly of separate cellulose fibres in water is drained through a sieve-like screen, so that a mat of randomly interwoven fibres is laid down. Water is further removed from this sheet by pressing, sometimes aided by suction or vacuum, or heating. Once dry, a generally flat, uniform and strong sheet of paper is achieved. Before the invention and current widespread adoption of automated machinery, all paper was made by hand, formed or laid one sheet at a time by specialized laborers. Even today those who make paper by hand use tools and technologies quite similar to those existing hundreds of years ago, as originally developed in China and other r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knot (papermaking)

Knots are unwanted, large, dark aggregates of wood fibres when making chemical pulp. Knots are incompletely cooked wood chips coming out of the digester. Their origin is often dense parts of branches, such as compression wood or timber knots – hence the name. Knots can also stem from large/oversized wood chips due to insufficient impregnation with cooking liquors. The content of lignin is very high. In kraft pulping knots are typically 0.5–3.0 % of the digester throughput. The knots are screened from the pulp, because if left in the pulp they may damage washing equipment and consume large amounts of bleaching chemicals. They are normally sent back to the digester and re-cooked so that their fibres are not wasted. See also *Shives *Kraft process The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kraft Pulp

Kraft paper or kraft is paper or paperboard (cardboard) produced from chemical pulp produced in the kraft process. Sack kraft paper (or just sack paper) is a porous kraft paper with high elasticity and high tear resistance, designed for packaging products with high demands for strength and durability. Pulp produced by the kraft process is stronger than that made by other pulping processes; acidic sulfite processes degrade cellulose more, leading to weaker fibers, and mechanical pulping processes leave most of the lignin with the fibers, whereas kraft pulping removes most of the lignin present originally in the wood. Low lignin is important to the resulting strength of the paper, as the hydrophobic nature of lignin interferes with the formation of the hydrogen bonds between cellulose (and hemicellulose) in the fibers. Kraft pulp is darker than other wood pulps, but it can be bleached to make very white pulp. Fully bleached kraft pulp is used to make high quality paper where st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Chips

Woodchips are small- to medium-sized pieces of wood formed by cutting or chipping larger pieces of wood such as trees, branches, logging residues, stumps, roots, and wood waste. Woodchips may be used as a biomass solid fuel and are raw material for producing wood pulp. They may also be used as an organic mulch in gardening, landscaping, and ecosystem restoration; in bioreactors for denitrification; and as a substrate for mushroom cultivation. The process of making woodchips is called wood chipping and is done using a wood chipper. The types of woodchips formed following chipping is dependent on the type of wood chipper used and the material from which they are made. Woodchip varieties include: forest chips (from forested areas), wood residue chips (from untreated wood residues, recycled wood and off-cuts), sawing residue chips (from sawmill residues), and short rotation forestry chips (from energy crops). Raw materials The raw materials of woodchips can be pulpwood, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kraft Process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes. The process name is derived from German word ''Kraft'', meaning "strength" in this context, due to the strength of the kraft paper produced using this process. History A precursor of the Kraft process was used during the Napoleonic Wars in England. The kraft process (so called be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper Machine

A paper machine (or paper-making machine) is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web. The basic process is an industrialised version of the historical process of hand paper-making, which could not satisfy the demands of developing modern society for large quantities of a printing and writing substrate. The first modern paper machine was invented by Louis-Nicolas Robert in France in 1799, and an improved version patented in Britain by Henry and Sealy Fourdrinier in 1806. The same process is used to produce paperboard on a paperboard machine. Process sections Paper machines usually have at le ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, Textile, rags, poaceae, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distributed on the surface, followed by pressing and drying. Although paper was originally made in single sheets by hand, almost all is now made on large machines—some making reels 10 metres wide, running at 2,000 metres per minute and up to 600,000 tonnes a year. It is a versatile material with many uses, including printing, painting, graphics, signage, design, packaging, decorating, writing, and Housekeeping, cleaning. It may also be used as filter paper, wallpaper, book endpaper, conservation paper, laminated worktops, toilet tissue, or currency and security paper, or in a number of industrial and construction processes. The papermaking process developed in east Asia, probably China, at least as early as 105 Common Era, CE, by t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)