|

Knot (papermaking)

Knots are unwanted, large, dark aggregates of wood fibres when making chemical pulp. Knots are incompletely cooked wood chips coming out of the digester. Their origin is often dense parts of branches, such as compression wood or timber knots – hence the name. Knots can also stem from large/oversized wood chips due to insufficient impregnation with cooking liquors. The content of lignin is very high. In kraft pulping knots are typically 0.5–3.0 % of the digester throughput. The knots are screened from the pulp, because if left in the pulp they may damage washing equipment and consume large amounts of bleaching chemicals. They are normally sent back to the digester and re-cooked so that their fibres are not wasted. See also *Shives *Kraft process The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves tr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

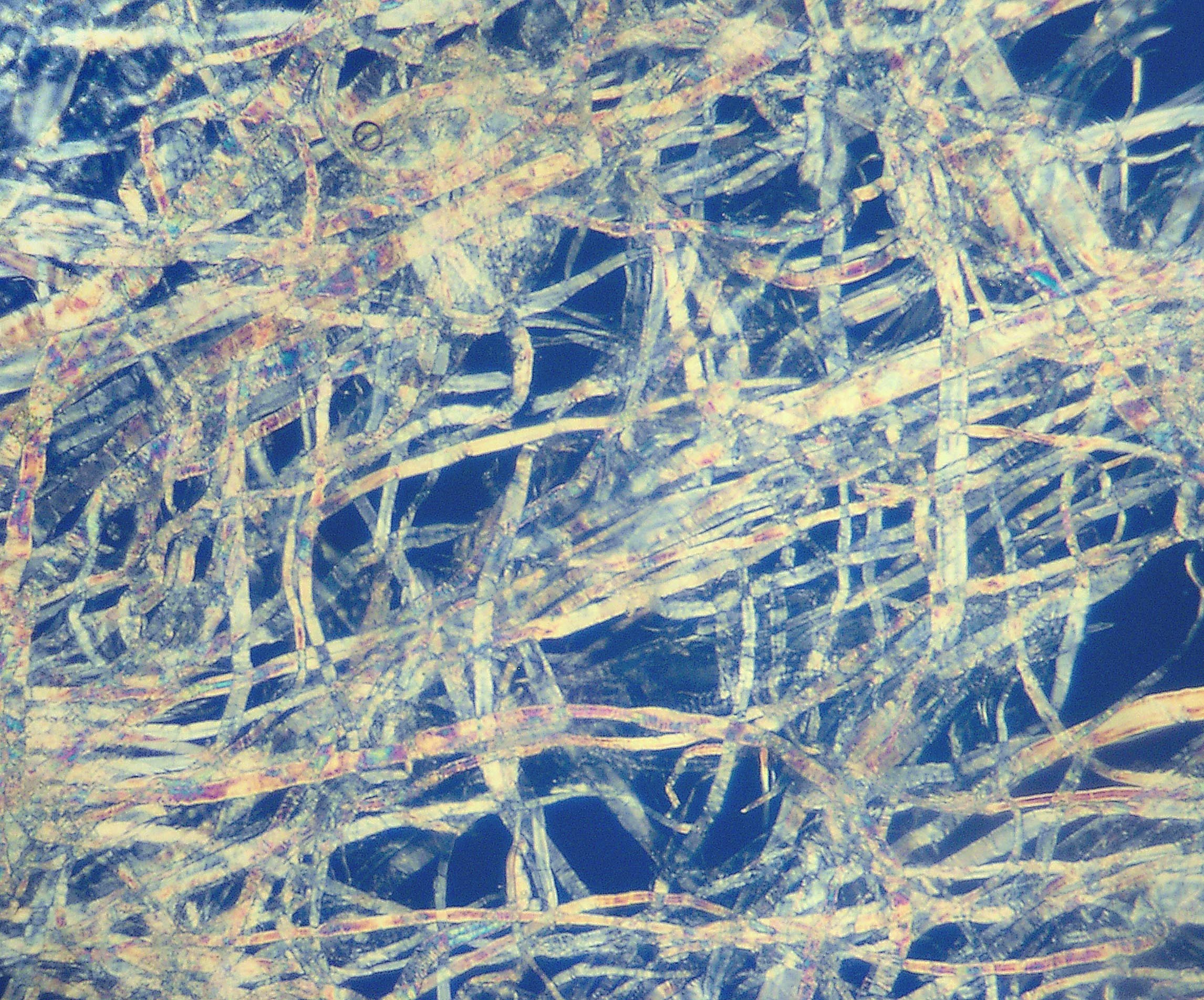

Wood Fibre

Wood fibres (also spelled wood fibers, see spelling differences) are usually cellulosic elements that are extracted from trees and used to make materials including paper. The end paper product (paper, paperboard, tissue, cardboard, etc.) dictates the species, or species blend, that is best suited to provide the desirable sheet characteristics, and also dictates the required fibre processing (chemical treatment, heat treatment, mechanical "brushing" or refining, etc.). In North America, virgin (non-recycled) wood fibre is primarily extracted from hardwood (deciduous) trees and softwood (coniferous) trees. The wood fibre can be extracted as a primary product, or collected during the milling of lumber. Wood fibres can also be recycled from used paper materials. Paper Wood fibres are treated by combining them with other additives which break down the fibres into a spongy mass called pulp. The pulp is then processed, and the network of tiny fibres is pressed flat, becoming paper. C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulberry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Chips

Woodchips are small- to medium-sized pieces of wood formed by cutting or chipping larger pieces of wood such as trees, branches, logging residues, stumps, roots, and wood waste. Woodchips may be used as a biomass solid fuel and are raw material for producing wood pulp. They may also be used as an organic mulch in gardening, landscaping, and ecosystem restoration; in bioreactors for denitrification; and as a substrate for mushroom cultivation. The process of making woodchips is called wood chipping and is done using a wood chipper. The types of woodchips formed following chipping is dependent on the type of wood chipper used and the material from which they are made. Woodchip varieties include: forest chips (from forested areas), wood residue chips (from untreated wood residues, recycled wood and off-cuts), sawing residue chips (from sawmill residues), and short rotation forestry chips (from energy crops). Raw materials The raw materials of woodchips can be pulpwood, waste wood, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knot (wood)

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or it is defined more broadly to include the same type of tissue elsewhere such as in the roots of trees or shrubs. In a living tree it performs a support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients between the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, or woodchips or fiber. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper. More recently it emerged as a feedstock for the production ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lignin

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity and do not rot easily. Chemically, lignins are polymers made by cross-linking phenolic precursors. History Lignin was first mentioned in 1813 by the Swiss botanist A. P. de Candolle, who described it as a fibrous, tasteless material, insoluble in water and alcohol but soluble in weak alkaline solutions, and which can be precipitated from solution using acid. He named the substance “lignine”, which is derived from the Latin word '' lignum'', meaning wood. It is one of the most abundant organic polymers on Earth, exceeded only by cellulose. Lignin constitutes 30% of non-fossil organic carbon on Earth, and 20 to 35% of the dry mass of wood. Lignin is present in red algae, which suggest that the common ancestor of plants and red algae ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kraft Process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes. The process name is derived from German word ''Kraft'', meaning "strength" in this context, due to the strength of the kraft paper produced using this process. History A precursor of the Kraft process was used during the Napoleonic Wars in England. The kraft process (so called because o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shives (papermaking)

A shive is a small bundle of incompletely cooked wood fibres in the chemical pulp used in papermaking. They are smaller than knots and are more difficult to separate from the pulp. Typically the content of shives in kraft pulp is 0.1 to 1.0%. An excess of shives is a sign of poor impregnation of the wood chips. Shives are separated from the pulp in the screening and can be added back after refining. Even though shives are darker than rest of the pulp, they may pass unnoticed to the paper machine because they are easily bleached. Shives in the paper machine can cause web breakage or other operational problems. They might also end as spots in the finished paper. See also *Knot (papermaking) *Kraft process The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chip ... References {{Paper Paperma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |