|

Scania-Vabis 314

The Scania-Vabis 314/324/325 was a series of trucks produced by Swedish automaker Scania-Vabis between 1925 and 1936. History Until 1927 Scania-Vabis had produced their trucks at two sites: at Scania in Malmö and at Vabis in Södertälje. The trucks were built entirely to customer order. This procedure was really not cost effective and although Scania-Vabis trucks were very expensive the company went bankrupt in 1921. After reconstruction Scania-Vabis emphasized their efforts on a "standard truck" which was first produced in Södertälje in 1925. With this new truck the company started its standardization of components and minimizing the number of variants that has made Scania one of the world's most profitable truck manufacturer.Scania Group - history Scania-Vabis 314 Scania-Vabis’ new ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scania-Vabis

Scania AB is a major Swedish manufacturer headquartered in Södertälje, focusing on commercial vehicles—specifically heavy lorries, trucks and buses. It also manufactures diesel engines for heavy vehicles as well as marine and general industrial applications. Scania was formed in 1911 through the merger of Södertälje-based Vabis and Malmö-based Maskinfabriks-aktiebolaget Scania. Since 1912, the company has been re-located again to Södertälje after the merger. Today, Scania has production facilities in Sweden, France, the Netherlands, Thailand, China, India, Argentina, Brazil, Poland, Russia and Finland. In addition, there are assembly plants in ten countries in Africa, Asia and Europe. Scania's sales and service organisation and finance companies are worldwide. In 2012, the company employed approximately 42,100 people around the world. Scania was listed on the NASDAQ OMX Stockholm stock exchange from 1996 to 2014. The company is a subsidiary of Traton, part of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Box

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term ''transmission'' properly refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive vehicles), differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted. Often, a transmission has multiple gear ratios (or simply "gears") with the ability to switch between them as the speed varies. This switching may be done manually (by the operator) or automatically (by a control unit). Directional (forward and reverse) control may also be provided. Single-ratio transmissions also exist, which simply ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-six Engine

The straight-six engine (also referred to as an inline-six engine; abbreviated I6 or L6) is a piston engine with six cylinders arranged in a straight line along the crankshaft. A straight-six engine has perfect primary and secondary engine balance, resulting in fewer vibrations than other designs of six or less cylinders. Until the mid-20th century, the straight-six layout was the most common design for engines with six cylinders. However, V6 engines became more common from the 1960s and by the 2000s most straight-six engines had been replaced by V6 engines. An exception to this trend is BMW which has produced automotive straight-six engines from 1933 to the present day. Characteristics In terms of packaging, straight-six engines are almost always narrower than a V6 engine or V8 engine, but longer than straight-four engines, V6s, and most V8s. Straight-six engines are typically produced in displacements ranging from , however engines ranging in size from the Benelli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petrol Engine

A petrol engine (gasoline engine in American English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends (such as ''E10'' and ''E85''). Most petrol engines use spark ignition, unlike diesel engines which typically use compression ignition. Another key difference to diesel engines is that petrol engines typically have a lower compression ratio. Design Thermodynamic cycle Most petrol engines use either the four-stroke Otto cycle or the two-stroke cycle. Petrol engines have also been produced using the Miller cycle and Atkinson cycle. Layout Most petrol-powered piston engines are straight engines or V engines. However, flat engines, W engines and other layouts are sometimes used. Wankel engines are classified by the number of rotors used. Compression ratio Cooling Petrol engines are either air-cooled or water-cooled. Ignitio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inline-four Engine

A straight-four engine (also called an inline-four) is a four-cylinder Reciprocating engine, piston engine where cylinders are arranged in a line along a common crankshaft. The vast majority of automotive four-cylinder engines use a straight-four layout (with the exceptions of the flat-four engines produced by Subaru and Porsche) and the layout is also very common in motorcycles and other machinery. Therefore the term "four-cylinder engine" is usually synonymous with straight-four engines. When a straight-four engine is installed at an inclined angle (instead of with the cylinders oriented vertically), it is sometimes called a Slant-4 engine, slant-four. Between 2005 and 2008, the proportion of new vehicles sold in the United States with four-cylinder engines rose from 30% to 47%. By the 2020 model year, the share for light-duty vehicles had risen to 59%. Design A four-stroke straight-four engine always has a cylinder on its power stroke, unlike engines with fewer cylinders ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scania-Vabis Truck 1933

Scania AB is a major Swedish manufacturer headquartered in Södertälje, focusing on commercial vehicles—specifically heavy lorries, trucks and buses. It also manufactures diesel engines for heavy vehicles as well as marine and general industrial applications. Scania was formed in 1911 through the merger of Södertälje-based Vabis and Malmö-based Maskinfabriks-aktiebolaget Scania. Since 1912, the company has been re-located again to Södertälje after the merger. Today, Scania has production facilities in Sweden, France, the Netherlands, Thailand, China, India, Argentina, Brazil, Poland, Russia and Finland. In addition, there are assembly plants in ten countries in Africa, Asia and Europe. Scania's sales and service organisation and finance companies are worldwide. In 2012, the company employed approximately 42,100 people around the world. Scania was listed on the NASDAQ OMX Stockholm stock exchange from 1996 to 2014. The company is a subsidiary of Traton, part of the V ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tonne

The tonne ( or ; symbol: t) is a unit of mass equal to 1000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton to distinguish it from the non-metric units of the short ton ( United States customary units), and the long ton ( British imperial units). It is equivalent to approximately 2204.6 pounds, 1.102 short tons, and 0.984 long tons. The official SI unit is the megagram (symbol: Mg), a less common way to express the same mass. Symbol and abbreviations The BIPM symbol for the tonne is t, adopted at the same time as the unit in 1879.Table 6 . BIPM. Retrieved on 2011-07-10. Its use is also official for the metric ton in the United States, having been adopted by the United States |

Tire

A tire (American English) or tyre (British English) is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively. The materials of modern pneumatic tires are synthetic rubber, natural rubber, fabric, and wire, along with carbon black and other chemical compounds. They consist of a tread and a body. The tread provides traction while the body provides containment for a quantity of compressed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic

Pneumatics (from Greek ‘wind, breath’) is a branch of engineering that makes use of gas or pressurized air. Pneumatic systems used in industry are commonly powered by compressed air or compressed inert gases. A centrally located and electrically-powered compressor powers cylinders, air motors, pneumatic actuators, and other pneumatic devices. A pneumatic system controlled through manual or automatic solenoid valves is selected when it provides a lower cost, more flexible, or safer alternative to electric motors, and hydraulic actuators. Pneumatics also has applications in dentistry, construction, mining, and other areas. Gases used in pneumatic systems Pneumatic systems in fixed installations, such as factories, use compressed air because a sustainable supply can be made by compressing atmospheric air. The air usually has moisture removed, and a small quantity of oil is added at the compressor to prevent corrosion and lubricate mechanical components. Factory-plumbed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drive Shaft

A drive shaft, driveshaft, driving shaft, tailshaft ( Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a component for transmitting mechanical power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them. As torque carriers, drive shafts are subject to torsion and shear stress, equivalent to the difference between the input torque and the load. They must therefore be strong enough to bear the stress, while avoiding too much additional weight as that would in turn increase their inertia. To allow for variations in the alignment and distance between the driving and driven components, drive shafts frequently incorporate one or more universal joints, jaw couplings, or rag joints, and sometimes a splined joint or prismatic joint. History The term ''driveshaft'' first appeared during the mid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

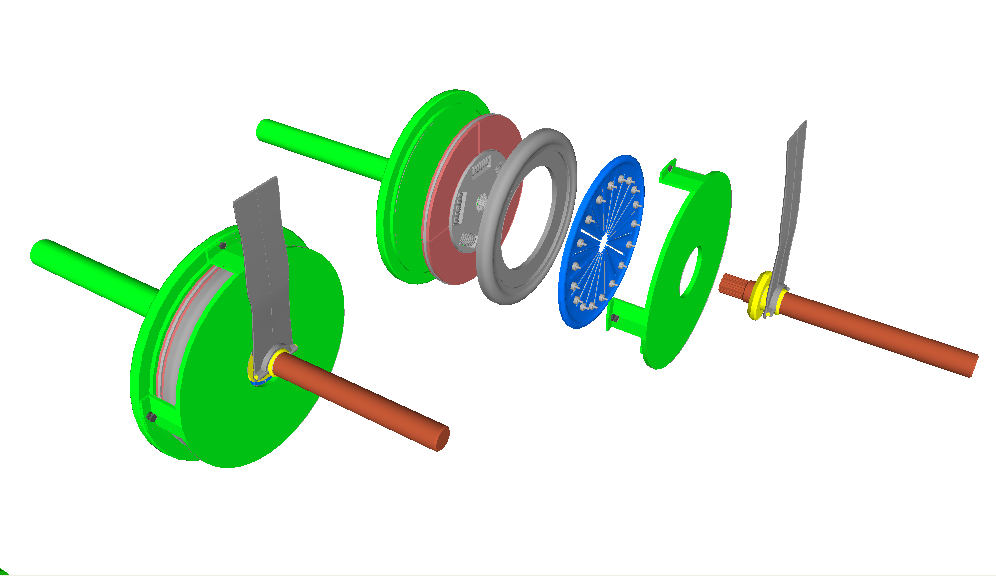

Clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine or other power unit (the driving member), while the other shaft (the driven member) provides output power for work. Typically the motions involved are rotary, but linear clutches also exist. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission, and briefly disconnects, or separates the engine from the transmission system. This disconnects the drive wheels whenever the clutch pedal is depressed, allowing the driver to smoothly change gears. In a torque-controlled drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so they may be locked together and spin at th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Valve Engine

An overhead valve (OHV) engine, sometimes called a ''pushrod engine'', is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with earlier flathead engines, where the valves were located below the combustion chamber in the engine block. Although an overhead camshaft (OHC) engine also has overhead valves, the common usage of the term "overhead valve engine" is limited to engines where the camshaft is located in the engine block. In these traditional OHV engines, the motion of the camshaft is transferred using pushrods (hence the term "pushrod engine") and rocker arms to operate the valves at the top of the engine. Some early intake-over-exhaust engines used a hybrid design combining elements of both side-valves and overhead valves. History Predecessors The first internal combustion engines were based on steam engines and therefore used slide valves. This was the case for the first Otto engine, which was first s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |