Overhead valve engine on:

[Wikipedia]

[Google]

[Amazon]

An overhead valve (OHV) engine, sometimes called a ''pushrod engine'', is a

An overhead valve (OHV) engine, sometimes called a ''pushrod engine'', is a

OHV engines have several advantages compared with OHC engines:

* ''Smaller overall packaging'': The cam-in-block design of an OHV engine results in a smaller overall size, compared with an equivalent OHC engine.

* ''Using the same cylinder head casting for both cylinder banks:'' A V-type engine design allows both cylinder heads can be mirror images of each other at the front of each cylinder bank. In a V-type OHV engine design it is possible to use same cylinder head casting for both banks, by simply flipping it around for the second bank. General Motors LS-based small-block engine family is a popular example of these kind of OHV V-engines.

* ''Simpler camshaft drive system'': OHV engines have a less complex drive system for the camshaft when compared with OHC engines. Most OHC engines drive the

OHV engines have several advantages compared with OHC engines:

* ''Smaller overall packaging'': The cam-in-block design of an OHV engine results in a smaller overall size, compared with an equivalent OHC engine.

* ''Using the same cylinder head casting for both cylinder banks:'' A V-type engine design allows both cylinder heads can be mirror images of each other at the front of each cylinder bank. In a V-type OHV engine design it is possible to use same cylinder head casting for both banks, by simply flipping it around for the second bank. General Motors LS-based small-block engine family is a popular example of these kind of OHV V-engines.

* ''Simpler camshaft drive system'': OHV engines have a less complex drive system for the camshaft when compared with OHC engines. Most OHC engines drive the

piston engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common fea ...

whose valves are located in the cylinder head above the combustion chamber. This contrasts with earlier flathead engines, where the valves were located below the combustion chamber in the engine block.

Although an overhead camshaft

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion ...

(OHC) engine also has overhead valves, the common usage of the term "overhead valve engine" is limited to engines where the camshaft is located in the engine block. In these traditional OHV engines, the motion of the camshaft is transferred using pushrod

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) ...

s (hence the term "pushrod engine") and rocker arms to operate the valves at the top of the engine.

Some early intake-over-exhaust engines used a hybrid design combining elements of both side-valves and overhead valves.

History

Predecessors

The first internal combustion engines were based on steam engines and therefore used slide valves. This was the case for the first Otto engine, which was first successfully run in 1876. As internal combustion engines began to develop separately to steam engines,poppet valve

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine.

It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usual ...

s became increasingly common.

Beginning with the 1885 Daimler Reitwagen, several cars and motorcycles used inlet valve(s) located in the cylinder head, however these valves were vacuum-actuated ("atmospheric") rather than driven by a camshaft as with typical OHV engines. The exhaust valve(s) were driven by a camshaft, but were located in the engine block as with side-valve engines.

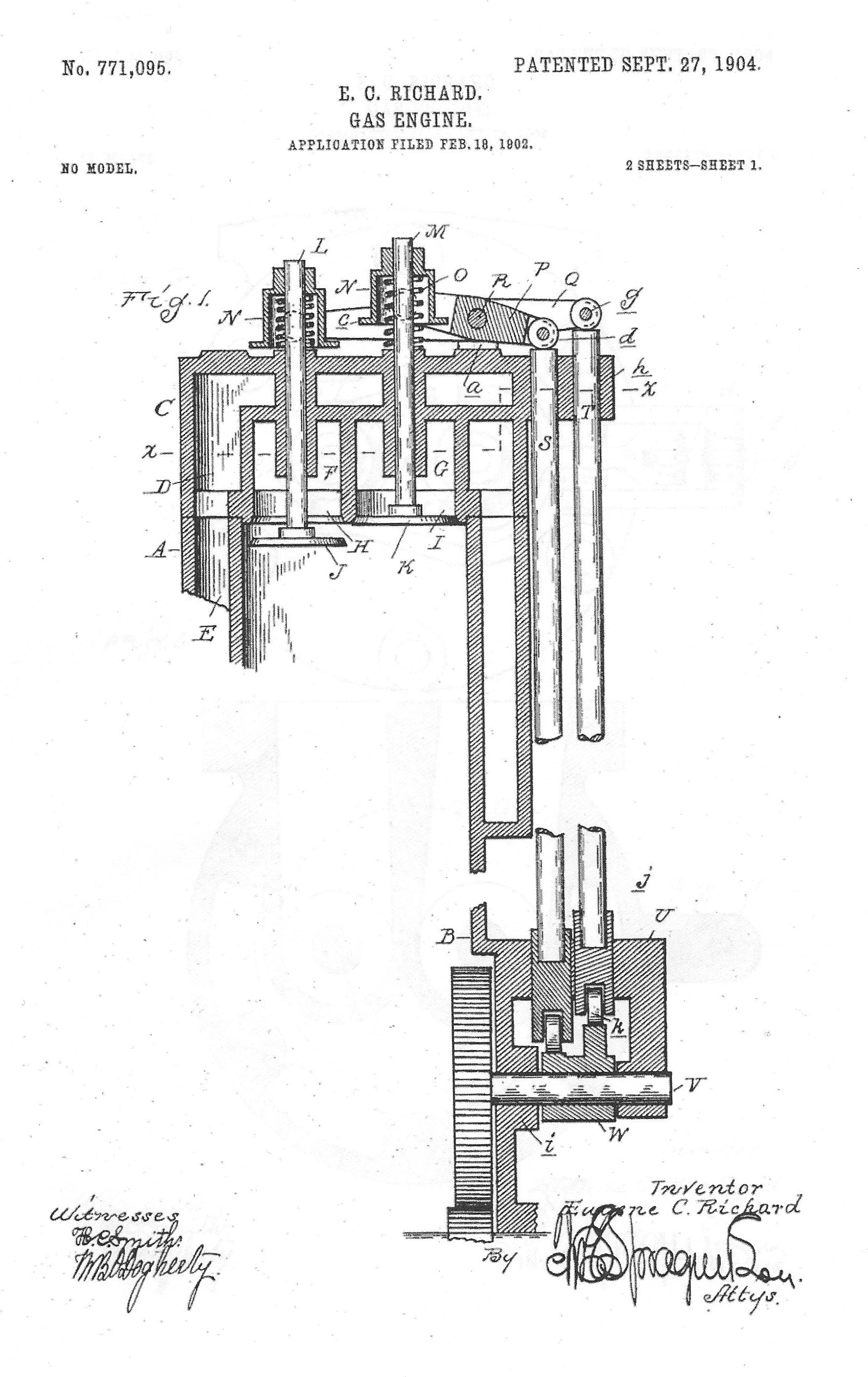

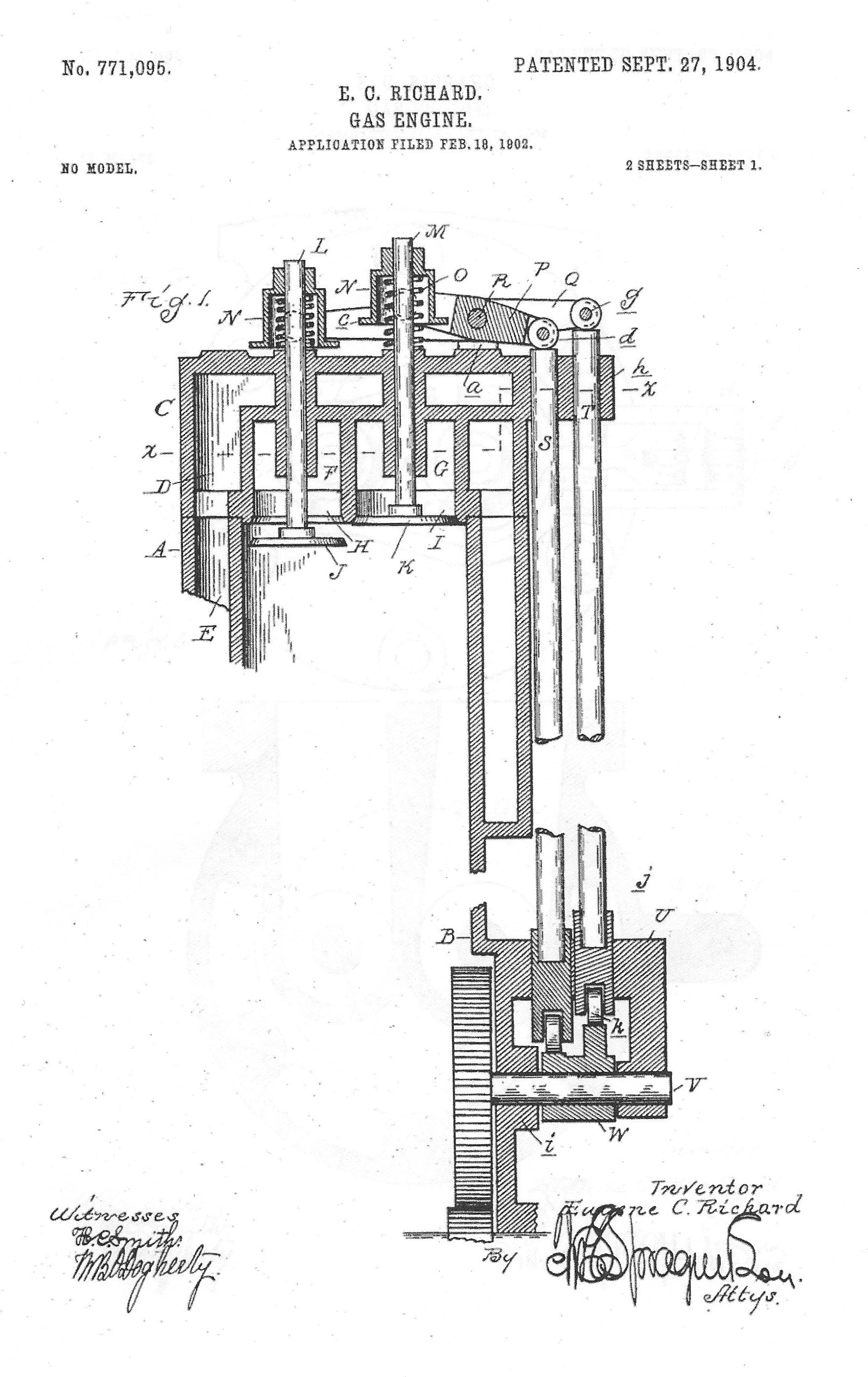

The 1894 Diesel prototype engine used overhead poppet valves actuated by a camshaft, pushrods and rocker arms, therefore becoming one of the first OHV engines. In 1896, U.S. patent 563,140 was taken out by William F. Davis for an OHV engine with liquid coolant used to cool the cylinder head, but no working model was built.

Production OHV engines

In 1898, bicycle manufacturer Walter Lorenzo Marr in the United States built a motorised tricycle powered by a single-cylinder OHV engine. Marr was hired byBuick

Buick () is a division of the American automobile manufacturer General Motors (GM). Started by automotive pioneer David Dunbar Buick in 1899, it was among the first American marques of automobiles, and was the company that established General ...

(then named ''Buick Auto-Vim and Power Company'') from 1899–1902, where the overhead valve engine design was further refined. This engine employed pushrod-actuated rocker arms, which in turn opened poppet valves parallel to the pistons. Marr returned to Buick in 1904 (having built a small quantity of the Marr Auto-Car, with the first known engine to use an overhead camshaft design), the same year that Buick received a patent for an overhead valve engine design. In 1904, the world's first production OHV engine was released in the Buick Model B. The engine was a flat-twin design with two valves per cylinder. The engine was very successful for Buick, with the company selling 750 such cars in 1905.

Several other manufacturers began to produce OHV engines, such as the 1906–1912 Wright Brothers ''Vertical 4-Cylinder Engine''. In 1911, Chevrolet joined Buick in almost exclusive use of OHV engines. However, side-valve engines remained commonplace until the late 1940s, when they began to be phased out for OHV engines.

Overhead camshaft engines

The first overhead camshaft (OHC) engine dates back to 1902, however use of this design was mostly limited to high performance cars for many decades. OHC engines slowly became more common from the 1950s to the 1990s, and by the start of the 21st century, the majority of automotive engines (except for some North American V8 engines) used an OHC design. At the 1994 Indianapolis 500 motor race, Team Penske entered a car powered by the custom-built Mercedes-Benz 500I pushrod engine. Due to a loophole in the rules, the pushrod engine was allowed to use a larger displacement and higher boost pressure, significantly increasing its power output compared to the OHC engines used by other teams. Team Penske qualified in pole position and won the race by a large margin. In the early 21st century, several pushrod V8 engines from General Motors and Chrysler usedvariable displacement Variable displacement is an automobile engine technology that allows the engine displacement to change, usually by deactivating cylinders, for improved fuel economy. The technology is primarily used in large, multi-cylinder engines. Many automobile ...

to reduce fuel consumption and exhaust emissions. In 2008, the first production pushrod engine to use variable valve timing was introduced in the Dodge Viper (fourth generation).

Design

OHV engines have several advantages compared with OHC engines:

* ''Smaller overall packaging'': The cam-in-block design of an OHV engine results in a smaller overall size, compared with an equivalent OHC engine.

* ''Using the same cylinder head casting for both cylinder banks:'' A V-type engine design allows both cylinder heads can be mirror images of each other at the front of each cylinder bank. In a V-type OHV engine design it is possible to use same cylinder head casting for both banks, by simply flipping it around for the second bank. General Motors LS-based small-block engine family is a popular example of these kind of OHV V-engines.

* ''Simpler camshaft drive system'': OHV engines have a less complex drive system for the camshaft when compared with OHC engines. Most OHC engines drive the

OHV engines have several advantages compared with OHC engines:

* ''Smaller overall packaging'': The cam-in-block design of an OHV engine results in a smaller overall size, compared with an equivalent OHC engine.

* ''Using the same cylinder head casting for both cylinder banks:'' A V-type engine design allows both cylinder heads can be mirror images of each other at the front of each cylinder bank. In a V-type OHV engine design it is possible to use same cylinder head casting for both banks, by simply flipping it around for the second bank. General Motors LS-based small-block engine family is a popular example of these kind of OHV V-engines.

* ''Simpler camshaft drive system'': OHV engines have a less complex drive system for the camshaft when compared with OHC engines. Most OHC engines drive the camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems ...

or camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems ...

s using a timing belt, a chain

A chain is a wikt:series#Noun, serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression (physics), compression but line (g ...

, or multiple chains. These systems require the use of tensioners, which add complexity. In contrast, an OHV engine has the camshaft positioned close to the crankshaft, which may be driven by a much shorter chain or even direct gear connection. However, this is somewhat negated by a more complex valvetrain requiring pushrods.

* ''Simpler lubrication system'': The lubrication requirements for OHV cylinder heads are much less, due to the lack of a camshaft and related bearings to lubricate. OHV heads only need lubrication for the rocker arms at the pushrod end, trunnion, and rocker tip. This lubrication to is typically provided through the pushrods themselves rather than a dedicated lubrication system in the head. The reduced lubrication requirements can also mean that a smaller, lower-capacity oil pump is used.

Compared with OHC engines, OHV engines have the following disadvantages:

* ''Limited engine speeds'': Although OHV engines have simpler drive systems for the camshaft, there are a greater number of moving parts in the valvetrain (i.e. the lifters, pushrods and rockers). Inertia from these valvetrain parts makes OHV engines more susceptible to valve float at high engine speeds (RPM).

* ''Constraints on valve quantity and location'': OHC engines often have four valves per cylinder, whereas it is rare for an OHV engine to have more than two valves per cylinder. In OHV engines, the size and shape of the intake ports as well as the position of the valves are limited by the pushrods and the need to accommodate them in the head casting.

References

{{Internal combustion engine Cam-in-block valvetrain configurations Engine valvetrain configurations Motorcycle engines Scottish inventions