|

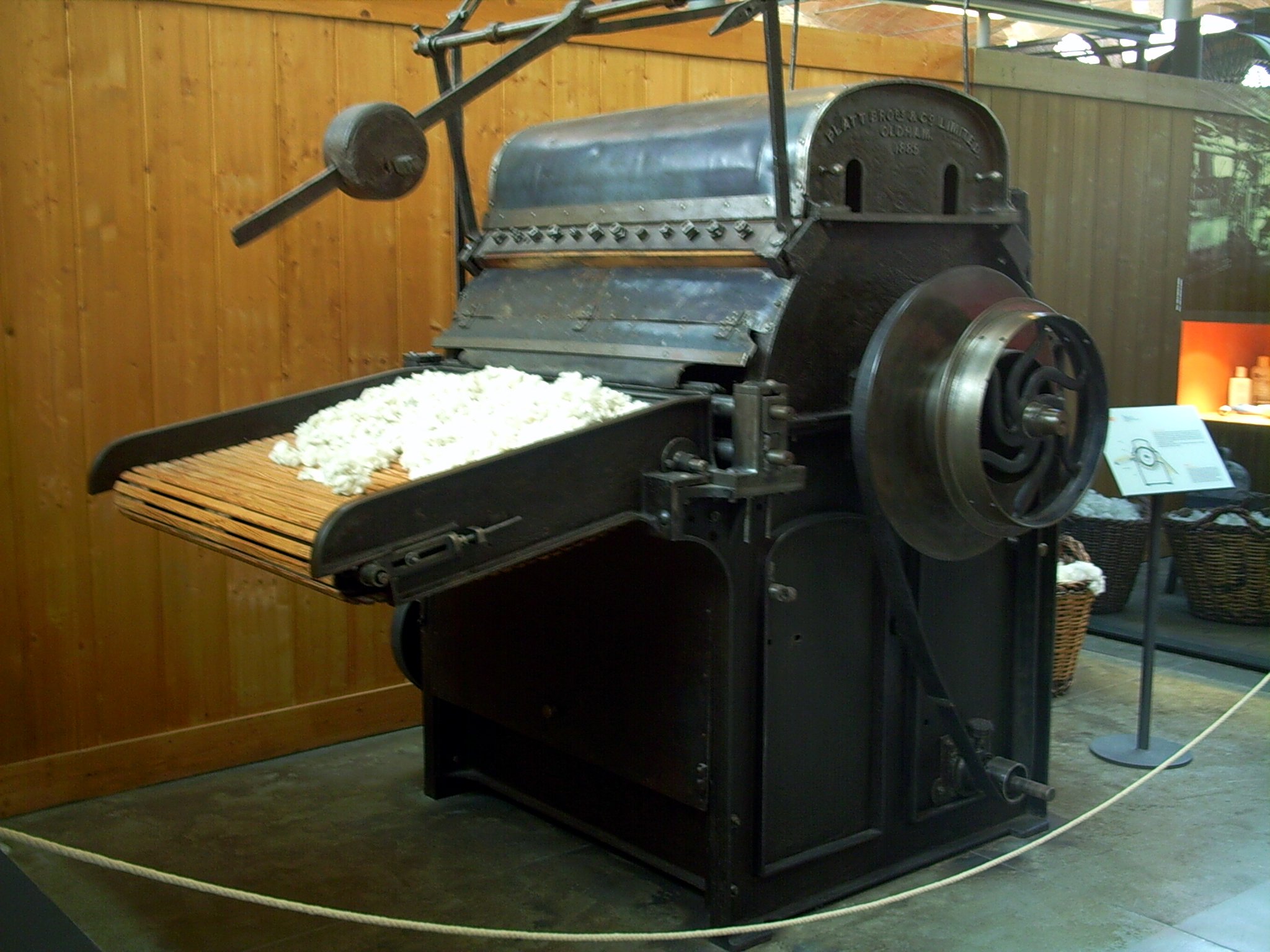

Roberts Loom

The Roberts loom was a cast-iron power loom introduced by Richard Roberts in 1830. It was the first loom that was more viable than a hand loom and was easily adjustable and reliable, which led to its widespread use in the Lancashire cotton industry. Richard Roberts Roberts was born at Llanymynech, on the border between England and Wales. He was the son of William Roberts, a shoemaker, who also kept the New Bridge tollgate. Roberts was educated by the parish priest, and early found employment with a boatman on the Ellesmere Canal and later at the local limestone quarries. He received some instruction in drawing from Robert Bough, a road surveyor, who was working under Thomas Telford. He was responsible for developing ever more precise machine tools, working eventually from 15 Deansgate, Manchester. Here he worked on improving textile machinery. He patented the cast-iron loom in 1822 and in 1830 patented the self-acting mule thus revolutionising the production of both the sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roberts Loom-marsden Front

Roberts may refer to: People * Roberts (given name), a Latvian masculine given name * Roberts (surname), a popular surname, especially among the Welsh Places * Roberts (crater), a lunar impact crater on the far side of the Moon ;United States * Roberts, Idaho * Roberts, Illinois * Roberts, Indiana * Roberts, West Virginia * Roberts, Wisconsin * Roberts County, South Dakota * Roberts County, Texas * Mount Roberts (New Hampshire), a summit in the Ossipee Mountains Facilities and structures * The old name of Brandeis/Roberts (MBTA station) * Roberts Stadium (other) Other uses * Roberts class monitor, a class of British warship * USS ''Samuel B. Roberts'' (FFG-58), a U.S. Navy frigate * Roberts Cycles, a cycle manufacturer (also known as Chas. Roberts) * Roberts Radio, a radio manufacturer * .257 Roberts, a medium-powered .25 caliber cartridge * Roberts (company), a Swedish soft drinks manufacturer See also * * * Strebor, a lock manufacturer (Roberts ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manchester

Manchester () is a city in Greater Manchester, England. It had a population of 552,000 in 2021. It is bordered by the Cheshire Plain to the south, the Pennines to the north and east, and the neighbouring city of Salford to the west. The two cities and the surrounding towns form one of the United Kingdom's most populous conurbations, the Greater Manchester Built-up Area, which has a population of 2.87 million. The history of Manchester began with the civilian settlement associated with the Roman fort ('' castra'') of ''Mamucium'' or ''Mancunium'', established in about AD 79 on a sandstone bluff near the confluence of the rivers Medlock and Irwell. Historically part of Lancashire, areas of Cheshire south of the River Mersey were incorporated into Manchester in the 20th century, including Wythenshawe in 1931. Throughout the Middle Ages Manchester remained a manorial township, but began to expand "at an astonishing rate" around the turn of the 19th century. Manchest ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution In England

Industrial may refer to: Industry * Industrial archaeology, the study of the history of the industry * Industrial engineering, engineering dealing with the optimization of complex industrial processes or systems * Industrial city, a city dominated by one or more industries * Industrial loan company, a financial institution in the United States that lends money, and may be owned by non-financial institutions * Industrial organization, a field that builds on the theory of the firm by examining the structure and boundaries between firms and markets * Industrial Revolution, the development of industry in the 18th and 19th centuries * Industrial society, a society that has undergone industrialization * Industrial technology, a broad field that includes designing, building, optimizing, managing and operating industrial equipment, and predesignated as acceptable for industrial uses, like factories * Industrial video, a video that targets “industry” as its primary audience * Industrial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

History Of The Textile Industry

History (derived ) is the systematic study and the documentation of the human activity. The time period of event before the invention of writing systems is considered prehistory. "History" is an umbrella term comprising past events as well as the memory, discovery, collection, organization, presentation, and interpretation of these events. Historians seek knowledge of the past using historical sources such as written documents, oral accounts, art and material artifacts, and ecological markers. History is not complete and still has debatable mysteries. History is also an academic discipline which uses narrative to describe, examine, question, and analyze past events, and investigate their patterns of cause and effect. Historians often debate which narrative best explains an event, as well as the significance of different causes and effects. Historians also debate the nature of history as an end in itself, as well as its usefulness to give perspective on the problems of the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weaving Equipment

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. (''Weft'' is an Old English word meaning "that which is woven"; compare ''leave'' and ''left''.) The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms. The way the warp and filling threads interlace with each other is called the weave. The majority of woven products ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile Machinery

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household work. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heddle

A heddle is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." ''The Oxford English Dictionary''. 2nd ed. 1989. The typical heddle is made of cord or wire and is suspended on a shaft of a loom. Each heddle has an eye in the center where the warp is threaded through. As there is one heddle for each thread of the warp, there can be near a thousand heddles used for fine or wide warps. A handwoven tea-towel will generally have between 300 and 400 warp threads and thus use that many heddles. In weaving, the warp threads are moved up or down by the shaft. This is achieved because each thread of the warp goes through a heddle on a shaft. When the shaft is raised the heddles are too, and thus the warp threads threaded through the heddles are raised. Heddles can be either equally or unequally distributed on the shafts, dep ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. (''Weft'' is an Old English word meaning "that which is woven"; compare ''leave'' and ''left''.) The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms. The way the warp and filling threads interlace with each other is called the weave. The majority of woven products a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spinning (textiles)

Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton, which is the most popular, are viscose (the most common form of rayon), and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel became the predominant spinning tool across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution. Process The yarn issuing from the drafting rollers passes through a thread-guide, round a Ring spinning#How it works, traveller that is free to rotate around a ring, and then onto a tube or bobbin, which is carried on to a Spindle (textiles), spindle, the axis of which passes through a center of the ring. The spin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

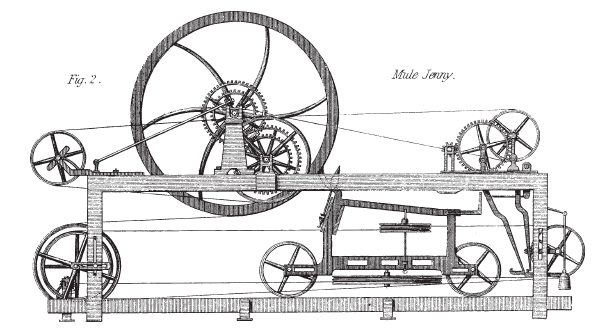

Spinning Mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be long, and would move forward and back a distance of four times a minute. It was invented between 1775 and 1779 by Samuel Crompton. The self-acting (automatic) mule was patented by Richard Roberts in 1825. At its peak there were 50,000,000 mule spindles in Lancashire alone. Modern versions are still in niche production and are used to spin woollen yarns from noble fibres such as cashmere, ultra-fine merino and alpaca for the knitware market. The spinning mule spins textile fibres into yarn by an intermittent process. In the draw stroke, the roving is pulled through rollers and twisted; on the return it is wrapped onto the spindle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tools

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

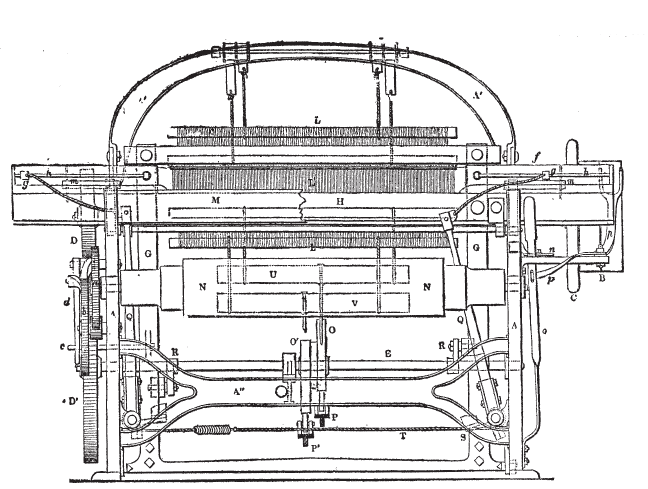

Power Loom

A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1786 by Edmund Cartwright and first built that same year. It was refined over the next 47 years until a design by the Howard and Bullough company made the operation completely automatic. This device was designed in 1834 by James Bullough and William Kenworthy, and was named the Lancashire loom. By the year 1850, there were a total of around 260,000 power loom operations in England. Two years later came the Northrop loom which replenished the shuttle when it was empty. This replaced the Lancashire loom. Shuttle looms The main components of the loom are the warp beam, heddles, harnesses, shuttle, reed, and takeup roll. In the loom, yarn processing includes shedding, picking, battening and taking-up operations. * ''Shedding''. Shedding is the raising of the warp yarns to form a loop through whi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)