|

Reactive Bonding

Reactive bonding describes a wafer bonding procedure using highly reactive nanoscale multilayer systems as an intermediate layer between the bonding substrates. The multilayer system consists of two alternating different thin metallic films. The self-propagating exothermic reaction within the multilayer system contributes the local heat to bond the solder films. Based on the limited temperature the substrate material is exposed, temperature-sensitive components and materials with different CTEs, i.e. metals, polymers and ceramics, can be used without thermal damage. Overview ] The bonding is based on reactive nano scale multilayers providing an internal heat source. These foils are combined with additional solder layers to achieve bonding. The heat that is required for the bonding is created by a self-propagating exothermic reaction of the multilayer system. This reaction is ignited by an energy pulse, i.e. temperature, mechanical pressure, electrical spark or laser pulse. The g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wafer Bonding

Wafer bonding is a packaging technology on Wafer (electronics), wafer-level for the fabrication of microelectromechanical systems (MEMS), nanoelectromechanical systems (NEMS), microelectronics and optoelectronics, ensuring a mechanically stable and hermetically sealed encapsulation. The wafers' diameter range from 100 mm to 200 mm (4 inch to 8 inch) for MEMS/NEMS and up to 300 mm (12 inch) for the production of microelectronic devices. Smaller wafers were used in the early days of the microelectronics industry, with wafers being just 1 inch in diameter in the 1950s. Overview In microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS), the package protects the sensitive internal structures from environmental influences such as temperature, moisture, high pressure and oxidizing species. The long-term stability and reliability of the functional elements depend on the encapsulation process, as does the overall device cost. The package has to fulfil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other types of material. As a method of printmaking, it is, along with engraving, the most important technique for old master prints, and remains in wide use today. In a number of modern variants such as microfabrication etching and photochemical milling it is a crucial technique in much modern technology, including circuit boards. In traditional pure etching, a metal plate (usually of copper, zinc or steel) is covered with a waxy ground which is resistant to acid. The artist then scratches off the ground with a pointed etching needle where the artist wants a line to appear in the finished piece, exposing the bare metal. The échoppe, a tool with a slanted oval section, is also used for "swelling" lines. The plate is then dipped in a bath of aci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diffusion

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical potential. It is possible to diffuse "uphill" from a region of lower concentration to a region of higher concentration, like in spinodal decomposition. The concept of diffusion is widely used in many fields, including physics (particle diffusion), chemistry, biology, sociology, economics, and finance (diffusion of people, ideas, and price values). The central idea of diffusion, however, is common to all of these: a substance or collection undergoing diffusion spreads out from a point or location at which there is a higher concentration of that substance or collection. A gradient is the change in the value of a quantity, for example, concentration, pressure, or temperature with the change in another variable, usually distance. A change in c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intermetallic Compound

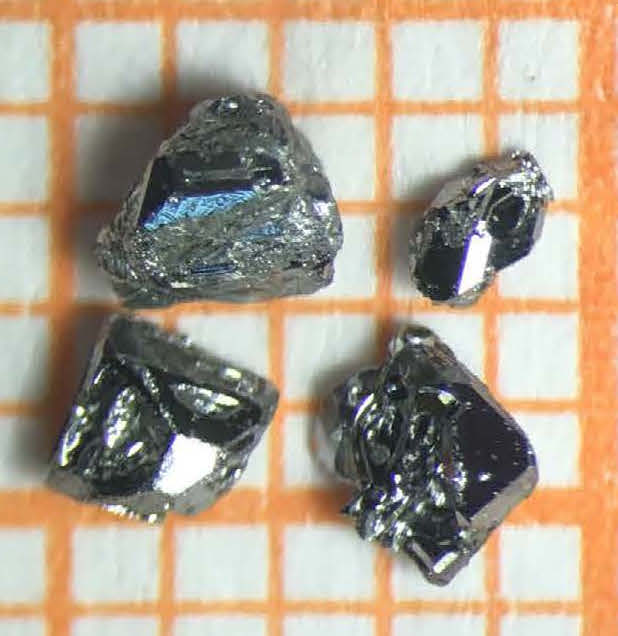

An intermetallic (also called an intermetallic compound, intermetallic alloy, ordered intermetallic alloy, and a long-range-ordered alloy) is a type of metallic alloy that forms an ordered solid-state compound between two or more metallic elements. Intermetallics are generally hard and brittle, with good high-temperature mechanical properties. They can be classified as stoichiometric or nonstoichiometic intermetallic compounds. Although the term "intermetallic compounds", as it applies to solid phases, has been in use for many years, its introduction was regretted, for example by Hume-Rothery in 1955. Definitions Research definition Schulze in 1967 defined intermetallic compounds as ''solid phases containing two or more metallic elements, with optionally one or more non-metallic elements, whose crystal structure differs from that of the other constituents''. Under this definition, the following are included: #Electron (or Hume-Rothery) compounds #Size packing phases. e.g. Lav ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity (optics), opacity, and lustre (mineralogy), luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in Atomic ratio, atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Bond

A chemical bond is a lasting attraction between atoms or ions that enables the formation of molecules and crystals. The bond may result from the electrostatic force between oppositely charged ions as in ionic bonds, or through the sharing of electrons as in covalent bonds. The strength of chemical bonds varies considerably; there are "strong bonds" or "primary bonds" such as covalent, ionic and metallic bonds, and "weak bonds" or "secondary bonds" such as dipole–dipole interactions, the London dispersion force and hydrogen bonding. Strong chemical bonding arises from the sharing or transfer of electrons between the participating atoms. Since opposite electric charges attract, the negatively charged electrons surrounding the nucleus and the positively charged protons within a nucleus attract each other. An electron positioned between two nuclei will be attracted to both of them, and the nuclei will be attracted toward electrons in this position. This attraction constitu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrochemical Machining

Electrochemical machining (ECM) is a method of removing metal by an electrochemical process. It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods.Todd, H. Robert; Allen, K. Dell; Alting, Leo (1994), Manufacturing Processes Reference Guide (1st ed.), Industrial Press Inc., pp. 198–199, . Its use is limited to electrically conductive materials. ECM can cut small or odd-shaped angles, intricate contours or cavities in hard and exotic metals, such as titanium aluminides, Inconel, Waspaloy, and high nickel, cobalt, and rhenium alloys.Valenti, Michael, "Making the Cut." Mechanical Engineering, American Society of Mechanical Engineers, 2001. http://www.memagazine.org/backissues/membersonly/nov01/features/makcut/makcut.html accessed 2/23/2010 Both external and internal geometries can be machined. ECM is often characterized as "reverse electroplating", in that it removes material i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dry Etching

Dry etching refers to the removal of material, typically a masked pattern of semiconductor material, by exposing the material to a bombardment of ions (usually a plasma of reactive gases such as fluorocarbons, oxygen, chlorine, boron trichloride; sometimes with addition of nitrogen, argon, helium and other gases) that dislodge portions of the material from the exposed surface. A common type of dry etching is reactive-ion etching. Unlike with many (but not all, see isotropic etching) of the wet chemical etchants used in wet etching, the dry etching process typically etches directionally or anisotropically. Applications Dry etching is used in conjunction with photolithographic techniques to attack certain areas of a semiconductor surface in order to form recesses in material. Applications include contact holes (which are contacts to the underlying semiconductor substrate), via holes (which are holes that are formed to provide an interconnect path between conductive layers in th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanostructure

A nanostructure is a structure of intermediate size between microscopic and molecular structures. Nanostructural detail is microstructure at nanoscale. In describing nanostructures, it is necessary to differentiate between the number of dimensions in the volume of an object which are on the nanoscale. Nanotextured surfaces have ''one dimension'' on the nanoscale, i.e., only the thickness of the surface of an object is between 0.1 and 100 nm. Nanotubes have ''two dimensions'' on the nanoscale, i.e., the diameter of the tube is between 0.1 and 100 nm; its length can be far more. Finally, spherical nanoparticles have ''three dimensions'' on the nanoscale, i.e., the particle is between 0.1 and 100 nm in each spatial dimension. The terms nanoparticles and ultrafine particles (UFP) are often used synonymously although UFP can reach into the micrometre range. The term ''nanostructure'' is often used when referring to magnetic technology. Nanoscale structure in biology i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrochemical

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference, as a measurable and quantitative phenomenon, and identifiable chemical change, with the potential difference as an outcome of a particular chemical change, or vice versa. These reactions involve electrons moving via an electronically-conducting phase (typically an external electrical circuit, but not necessarily, as in electroless plating) between electrodes separated by an ionically conducting and electronically insulating electrolyte (or ionic species in a solution). When a chemical reaction is driven by an electrical potential difference, as in electrolysis, or if a potential difference results from a chemical reaction as in an electric battery or fuel cell, it is called an ''electrochemical'' reaction. Unlike in other chemical reactions, in electrochemical reactions electrons are not transferred directly between atoms, ions, or molecules, but via the af ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |