|

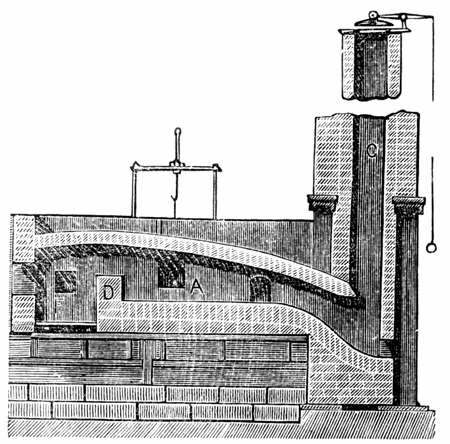

Puddling (metallurgy)

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an oxidizing environment, resulting in wrought iron. It was one of the most important processes of making the first appreciable volumes of valuable and useful bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Industrial Revolution so far as the iron industry is c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

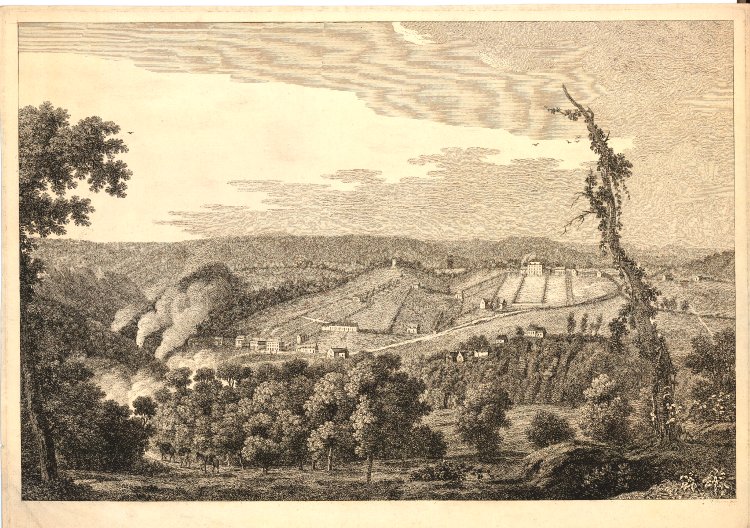

Coalbrookdale

Coalbrookdale is a village in the Ironbridge Gorge in Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge. This is where iron ore was first smelted by Abraham Darby using easily mined "coking coal". The coal was drawn from drift mines in the sides of the valley. As it contained far fewer impurities than normal coal, the iron it produced was of a superior quality. Along with many other industrial developments that were going on in other parts of the country, this discovery was a major factor in the growing industrialisation of Britain, which was to become known as the Industrial Revolution. Today, Coalbrookdale is home to the Ironbridge Institute, a partnership between the University of Birmingham and the Ironbridge Gorge Museum Trust offering postgraduate and professional development courses in heritage. Before Abraham Darby Before the Dissolution of the Monasteries, Made ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applicatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

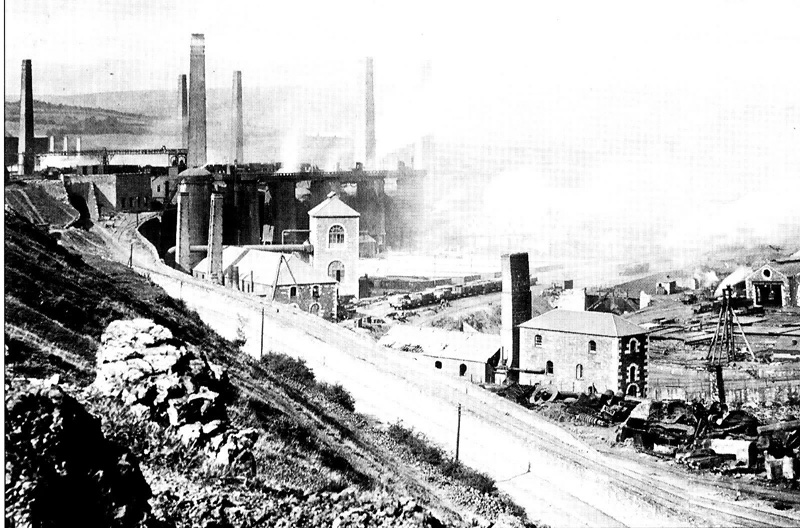

Cyfarthfa Ironworks

The Cyfarthfa Ironworks were major 18th- and 19th-century ironworks in Cyfarthfa, on the north-western edge of Merthyr Tydfil, in South West Wales. The beginning The Cyfarthfa works were begun in 1765 by Anthony Bacon (by then a merchant in London), who in that year with William Brownrigg, a fellow native of Whitehaven, Cumberland, leased the right to mine in a tract of land on the west side of the river Taff at Merthyr Tydfil. They employed Brownrigg's brother-in-law Charles Wood to build a forge there, to use the potting and stamping process, for which he and his brother had a patent. This was powered by water from the river, the race dividing into six to power a clay mill (for making the pots), two stampers, two helve hammers and a chafery. The construction of the first coke blast furnace began in August 1766. This was intended to be 50 feet high with cast iron blowing cylinders, rather than the traditional bellows. It was probably brought into blast in autumn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling Mill

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel ( I-beams, angle stock, channel stock), bar stock, and rails. Most steel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shingling

{{about, the industrial steel manufacturing process, the text mining technique, w-shingling Shingling was a stage in the production of bar iron or steel, in the finery and puddling processes. As with many ironmaking terms, this is derived from the French - ''cinglage''. The product of the finery was a bloom or loop (from old Frankish ''luppa'' or '' lopp'', meaning a shapeless mass); that of the puddling furnace was a puddled ball. In each case, this needed to be consolidated by hammering it into a more regular shape. This was done manually with heavy hammers; later by a waterwheel or steam powered hammers, leading to modern power hammers. The result was an oblong-shaped iron product similar in appearance to shingles used on roofs. In the finery, this was part of the work of the finer; during puddling, it was done by a special workman called the shingler. The iron (or steel) then had to be further shaped (drawn out) under the hammer or rolled in a rolling mill In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fontley

Funtley – from the Anglo-Saxon, "Funtaleg", "spring field (clearing)", is a hamlet or exurb north of Fareham, Hampshire, England. It forms a projection towards the South Downs National Park and is generally included within Fareham's population as it is within its built-up area. At present the village is unparished, although the creation of a parish council has been discussed. The village grew from the development of a clay quarry, the clay used to make chimney pots and bricks — acclaimed Fareham red (bricks) used to build premium Victorian buildings such as the Royal Albert Hall in London, and Knowle Hospital near Fareham. Sometimes known as Fontley by locals (reflecting its probable longstanding alternate pronunciation, as it appears in church use and many other place names such as Mottisfont) the village is no longer a discrete settlement owing to post- World War II growth of Fareham, it is an exurb in rural surrounds separated from the town by the M27 motorw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henry Cort

Henry Cort (c. 1740 – 23 May 1800) was an English ironware producer although formerly a Navy pay agent. During the Industrial Revolution in England, Cort began refining iron from pig iron to wrought iron (or bar iron) using innovative production systems. In 1784, he patented an improved version of the puddling process for refining cast iron although its commercial viability was only accomplished by innovations introduced by the Merthyr Tydfil ironmasters Crawshay and Homfray. Biography Little is known of Cort's early life other than that he was possibly born into a family coming from Lancaster, England although his parents are unknown. Although his date of birth is traditionally given as 1740, this can not be confirmed and his early life remains an enigma. By 1765, Cort had become a Royal Navy pay agent, acting on commission collecting half pay and widows' pensions from an office in Crutched Friars near Aldgate in London. At that time, despite Abraham Darby's improvement ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dowlais Ironworks

The Dowlais Ironworks was a major ironworks and steelworks located at Dowlais near Merthyr Tydfil, in Wales. Founded in the 18th century, it operated until the end of the 20th, at one time in the 19th century being the largest steel producer in the UK. Dowlais Ironworks were the first business to license the Bessemer process, using it to produce steel in 1865. Dowlais Ironworks was one of the four principal ironworks in Merthyr. The other three were Cyfarthfa, Plymouth, and Penydarren Ironworks. In 1936 Dowlais played a part in the events leading to the abdication crisis of Edward VIII, when the King visited the steelworks and was reported as saying that "these works brought these men here. Something must be done to get them back to work", a statement which was seen as political interference. The steelworks finally closed in 1987. Beginnings (1759–1807) The works was founded as a partnership on 19 September 1759. There were nine original partners including Thomas Le ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Peter Onions

Peter Onions (1724 – 1798) was an English ironmaster and the inventor of an early puddling process used for the refining of pig iron into wrought iron. Biography Onions was born in Broseley, Shropshire, later moving to Merthyr Tydfil in Wales. He married Elizabeth Guest, sister of John Guest, a founder of Guest, Keen and Nettlefold, which is today the British conglomerate GKN In 1783, Onions received patent number 1370 for his invention. Henry Cort Henry Cort (c. 1740 – 23 May 1800) was an English ironware producer although formerly a Navy pay agent. During the Industrial Revolution in England, Cort began refining iron from pig iron to wrought iron (or bar iron) using innovative producti ... later improved on Onion's process during the development of his puddling furnace. References cc 1724 births 1798 deaths Businesspeople from Shropshire Foundrymen British ironmasters Engineers from Shropshire People from Broseley People of the Industrial Revolution [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reverbatory Furnace

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is used here in a generic sense of ''rebounding'' or '' reflecting'', not in the acoustic sense of ''echoing''. Operation Chemistry determines the optimum relationship between the fuel and the material, among other variables. The reverberatory furnace can be contrasted on the one hand with the blast furnace, in which fuel and material are mixed in a single chamber, and, on the other hand, with crucible, muffling, or retort furnaces, in which the subject material is isolated from the fuel and all of the products of combustion including gases and flying ash. There are, however, a great many furnace designs, and the terminology of metallurgy has not been very consistently defined, so it is difficult to categorically contradict other views. Applications and comparison wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

River Severn

, name_etymology = , image = SevernFromCastleCB.JPG , image_size = 288 , image_caption = The river seen from Shrewsbury Castle , map = RiverSevernMap.jpg , map_size = 288 , map_caption = Tributaries (light blue) and major settlements on and near the Severn (bold blue) , pushpin_map = , pushpin_map_size = 288 , pushpin_map_caption= , subdivision_type1 = Country , subdivision_name1 = England and Wales , subdivision_type2 = , subdivision_name2 = , subdivision_type3 = Region , subdivision_name3 = Mid Wales, West Midlands, South West , subdivision_type4 = Counties , subdivision_name4 = Powys, Shropshire, Worcestershire, Gloucestershire , subdivision_type5 = Cities , subdivision_name5 = Shrewsbury, Worcester, Gloucester, Bristol , length = , width_min = , width_avg = , width_max = , depth_min = , depth_avg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |