|

Parison

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or wikt:parison, parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a molding (process), mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Wheel Blow Molding Systems

Rotary wheel blow molding systems are used for the high-output production of a wide variety of plastic extrusion blow molded articles. Containers may be produced from small, single serve bottles to large containers up to 20-30 liters in volume - but wheel machines are often sized for the volume and dimensional demands of a specific container, and are typically dedicated to a narrow range of bottle sizes once built. Multiple parison machines, with high numbers of molds are capable of producing over one million bottles per day in some configurations. Description Rotary blow molding "wheels" are targeted to the high output production of containers. They are used to produce containers from one to seven layers. View stripe and In Mold Labeling (IML) options are available in some configurations. Rotary wheels, which may contain from six to thirty molds, feature continuously extruded parisons. Revolving sets of blow molds capture the parison or parisons as they pass over the extr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parison

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or wikt:parison, parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a molding (process), mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Fill Seal

Blow-Fill-Seal, also spelled as Blow/Fill/Seal, in this article abbreviated as BFS, is an automated manufacturing process by which plastic containers, such as bottles or ampoules are, in a continuous operation, blow-formed, filled, and sealed. It takes place in a sterile, enclosed area inside a machine, without human intervention, and thus can be used to aseptically manufacture sterile pharmaceutical or non-pharamceutical liquid/semiliquid unit-dosage forms. BFS is an advanced aseptic processing technology that is typically used for filling and packaging of certain sterile liquid formulations like liquid ophthalmics, inhalational anesthetics, or lavaging agents, but can also be used for injectables, parenteral medicines, and several other liquid or semiliquid medications, with fill volumes ranging from 0.1...1000 cm³. Compared against traditional glass ampoules, BFS ampoules are inexpensive, lightweight, and shatterproof. History BFS was developed in the early 1960s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Readability

Readability is the ease with which a reader can understand a written text. In natural language, the readability of text depends on its content (the complexity of its vocabulary and syntax) and its presentation (such as typographic aspects that affect legibility, like font size, line height, character spacing, and line length). Researchers have used various factors to measure readability, such as: * Speed of perception * Perceptibility at a distance * Perceptibility in peripheral vision * Visibility * Reflex blink technique * Rate of work (reading speed) * Eye movements * Fatigue in reading * Cognitively-motivated features * Word difficulty * N-gram analysis * Semantic Richness Higher readability eases reading effort and speed for any reader, but it makes a larger difference for those who do not have high reading comprehension. Readability exists in both natural language and programming languages though in different forms. In programming, things such as programmer comments, c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glassblowing

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble (or parison) with the aid of a Blowpipe (tool), blowpipe (or blow tube). A person who blows glass is called a ''glassblower'', ''glassmith'', or ''gaffer''. A ''lampworking, lampworker'' (often also called a glassblower or glassworker) manipulates glass with the use of a torch on a smaller scale, such as in producing precision laboratory glassware out of borosilicate glass. Technology Principles As a novel glass forming technique created in the middle of the 1st century BC, glassblowing exploited a working property of glass that was previously unknown to glassworkers; inflation, which is the expansion of a molten blob of glass by introducing a small amount of air into it. That is based on the liquid structure of glass where the atoms are held together by strong chemical bonds in a disordered and random network,Frank, S 1982. Glass and Archaeology. Academic Press: London. Freestone, I. (1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Forming Machine

Plastic forming machines, or plastic molding machines, were developed on the basis of rubber machinery and metal die-casting machines. After the inception of the polymer injection molding process in the 1870s, plastic-forming machines were rapidly developed up until the 1930s. With the gradual commercialization of plastic molding equipment, injection molding and extrusion molding became the most common industrialized processes. Blow molding is the third-largest plastic molding method after the injection molding and extrusion blow molding methods. Types of plastic forming machine Plastic injection molding machine A plastic injection molding machine injects melted plastic into a mold to make solid plastic parts. Plastic extrusion machine A plastic extrusion machine extrudes plastic in a continuous profile. The main machine is usually called the host, and its accompanying equipment are called the plastic auxiliary equipment. Plastic extruders can make plastic film/wrapping, packi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer

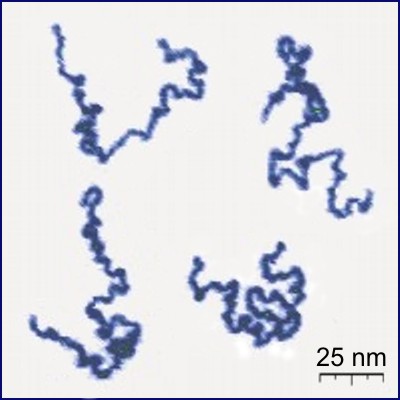

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of the molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured glass are "silicate glasses" based on the chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. Soda–lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. The term ''glass'', in popular usage, is often used to refer only to this type of material, although silica-free glasses often have desirable properties for applications in modern communications technology. Some objects, such as drinking glasses and eyeglasses, are so commonly made of silicate-based glass that they are simply called by the name of the material. Despite bei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass Bottles

A glass bottle is a bottle made from glass. Glass bottles can vary in size considerably, but are most commonly found in sizes ranging between about 200 millilitres and 1.5 litres. Common uses for glass bottles include food condiments, soda, liquor, cosmetics, pickling and preservatives; they are occasionally also notably used for the informal distribution of notes. These types of bottles are utilitarian and serve a purpose in commercial industries. History Glass bottles and glass jars are found in many households worldwide. The first glass bottles were produced in Mesopotamia around 1500 B.C., and in the Roman Empire around 1 AD. America's glass bottle and glass jar industry was born in the early 1600s, when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle-blowing machine in 1903 industrialized the process of making bottles. Manufacture The earliest bottles or vessels were made by ancient man. Ingredients were melte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Accumulator Head Machinery

Accumulator may refer to: * Accumulator (bet), a parlay bet * Accumulator (computing), in a CPU, a processor register for storing intermediate results * Accumulator (computer vision), discrete cell structure to count votes, standard component of the Hough transform * Accumulator (cryptography), a value, determined by a set of values, that allows one to verify if any one of the original values is a member of the set * Accumulator (energy), an apparatus for storing energy or power ** Capacitor, in electrical engineering, also known by the obsolete term ''accumulator'' ** Electrochemical cell, a cell that stores electrical energy, typically used in rechargeable batteries ** Hydraulic accumulator, an energy storage device using hydraulic fluid under pressure ** Thermal accumulator, a device or system that provides thermal energy storage as from concentrated solar power and storage heaters or heat banks in buildings * Accumulator (structured product), a financial contract used by client ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Packaging

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and personal use. Package labeling (American English) or labelling (British English) is any written, electronic, or graphic communication on the package or on a separate but associated label. History of packaging Ancient era The first packages used the natural materials available at the time: baskets of reeds, wineskins (bota bags), wooden boxes, pottery vases, ceramic amphorae, wooden barrels, woven bags, etc. Processed materials were used to form packages as they were develope ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |