|

Blow Fill Seal

Blow-Fill-Seal, also spelled as Blow/Fill/Seal, in this article abbreviated as BFS, is an automated manufacturing process by which plastic containers, such as bottles or ampoules are, in a continuous operation, blow-formed, filled, and sealed. It takes place in a sterile, enclosed area inside a machine, without human intervention, and thus can be used to aseptically manufacture sterile pharmaceutical or non-pharamceutical liquid/semiliquid unit-dosage forms. BFS is an advanced aseptic processing technology that is typically used for filling and packaging of certain sterile liquid formulations like liquid ophthalmics, inhalational anesthetics, or lavaging agents, but can also be used for injectables, parenteral medicines, and several other liquid or semiliquid medications, with fill volumes ranging from 0.1...1000 cm³. Compared against traditional glass ampoules, BFS ampoules are inexpensive, lightweight, and shatterproof. History BFS was developed in the early 1960s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyethylene

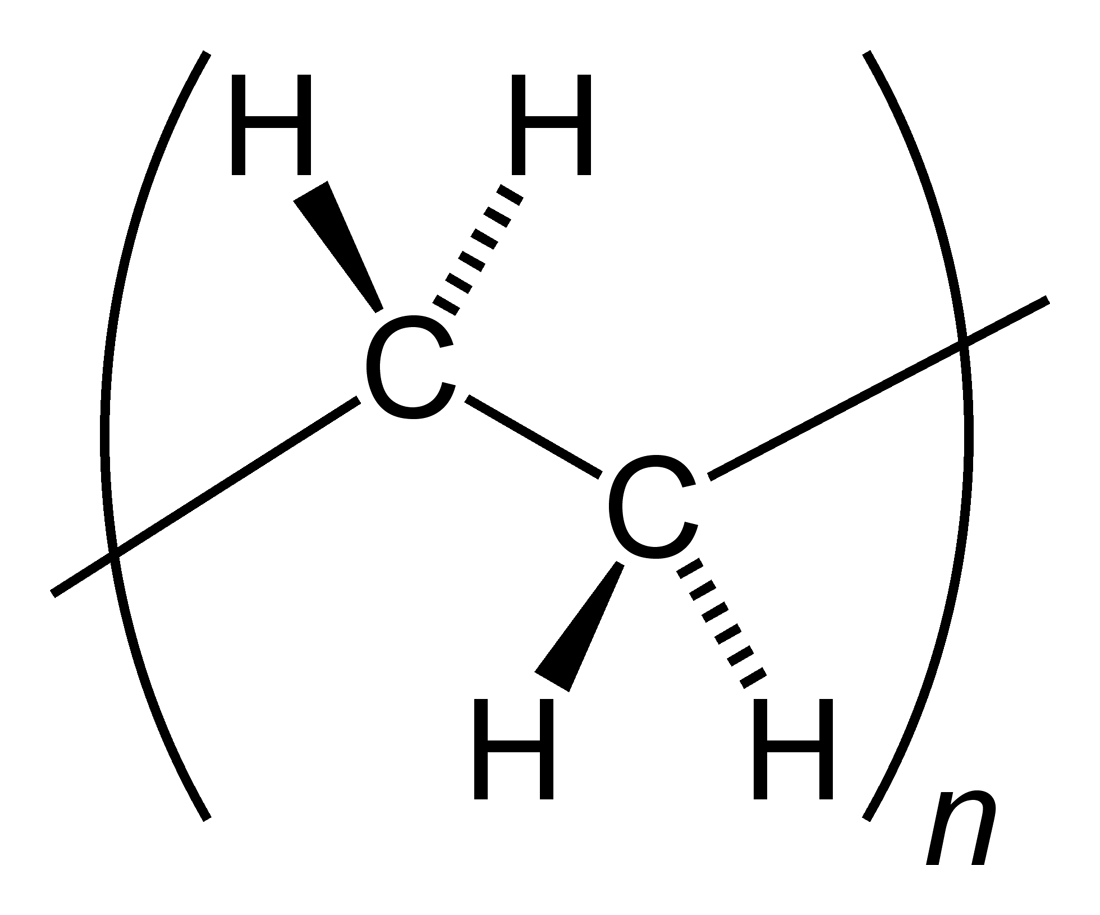

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including bottles, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'': low-density polyethylene is extruded using high pressure () and high temperature (), while high-density polyethylene is extruded using low pressure () and low temperature (). Polyethylene is usually thermoplastic, but it can be modified to become thermosetting instead, for example, in cross-linked polyethylene. History Polyethylene was first synthesized by the German chemist Hans ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Containers

A container is any receptacle or enclosure for holding a product used in storage, packaging, and transportation, including shipping. Things kept inside of a container are protected on several sides by being inside of its structure. The term is most frequently applied to devices made from materials that are durable and are often partly or completely rigid. A container can also be considered as a basic tool, consisting of any device creating a partially or fully enclosed space that can be used to contain, store, and transport objects or materials. History Humans have used containers for at least 100,000 years, and possibly for millions of years.Clive Gamble, ''Origins and Revolutions: Human Identity in Earliest Prehistory'' (2007), p. 204. The first containers were probably invented for storing food, allowing early humans to preserve more of their food for a longer time, to carry it more easily, and also to protect it from other animals. The development of food storage cont ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Purity

In chemistry, chemical purity is the measurement of the amount of impurities found in a sample. Several grades of purity are used by the scientific, pharmaceutical, and industrial communities. Some of the commonly used grades of purity include: * ACS grade is the highest level of purity, and meets the standards set by the American Chemical Society (ACS). The official descriptions of the ACS levels of purity is documented in the ''Reagent Chemicals'' publication, issued by the ACS. It is suitable for food and laboratory uses. * Reagent grade is almost as stringent as the ACS grade. * USP grade meets the purity levels set by the United States Pharmacopeia (USP). USP grade is equivalent to the ACS grade for many drugs. * NF grade is a purity grade set by the National Formulary (NF). NF grade is equivalent to the ACS grade for many drugs. * British Pharmacopoeia: Meets or exceeds requirements set by the British Pharmacopoeia (BP). Can be used for food, drug, and medical purpose ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HDPE

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code. In 2007, the global HDPE market reached a volume of more than 30 million tons. Properties HDPE is known for its high strength-to-density ratio. The density of HDPE ranges from 930 to 970 kg/m3. The standard method to test plastic density is ISO 1183 part 2 (gradient columns), alternatively ISO 1183 part 1MVS2PRO density analyzer. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength (38 MPa versus 21 MPa) than ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

LDPE

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerization. Its manufacture employs the same method today. The EPA estimates 5.7% of LDPE ( resin identification code 4) is recycled in the United States. Despite competition from more modern polymers, LDPE continues to be an important plastic grade. In 2013 the worldwide LDPE market reached a volume of about US$33 billion. Despite its designation with the recycling symbol, it cannot be as commonly recycled as No. 1 (polyethylene terephthalate) or 2 plastics (high-density polyethylene). Properties LDPE is defined by a density range of 917–930 kg/m3. At room temperature it is not reactive, except to strong oxidizers; some solvents cause it to swell. It can withstand temperatures of continuously and for a short time. Made in translucent and opaque v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyolefins

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More specialized polyolefins include polyisobutylene and polymethylpentene. They are all colorless or white oils or solids. Many copolymers are known, such as polybutene, which derives from a mixture of different butene isomers. The name of each polyolefin indicates the olefin from which it is prepared; for example, polyethylene is derived from ethylene, and polymethylpentene is derived from 4-methyl-1-pentene. Polyolefins are not olefins themselves because the double bond of each olefin monomer is opened in order to form the polymer. Monomers having more than one double bond such as butadiene and isoprene yield polymers that contain double bonds ( polybutadiene and polyisoprene) and are usually not considered polyolefins. Polyolefins are the foundati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aseptic Processing

Aseptic processing is a processing technique wherein commercially thermally sterilized liquid products (typically food or pharmaceutical) are packaged into previously sterilized containers under sterile conditions to produce shelf-stable products that do not need refrigeration. Aseptic processing has almost completely replaced in-container sterilization of liquid foods, including milk, fruit juices and concentrates, cream, yogurt, salad dressing, liquid egg, and ice cream mix. There has been an increasing popularity for foods that contain small discrete particles, such as cottage cheese, baby foods, tomato products, fruit and vegetables, soups, and rice desserts. Aseptic processing involves three primary steps: thermal sterilization of the product, sterilization of the packaging material, and conservation of sterility during packaging. To ensure commercial sterility, aseptic processing facilities are required to maintain proper documentation of production operations, showing that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cleanroom

A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. It is well isolated, well-controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientific research, and in industrial production for all nanoscale processes, such as semiconductor manufacturing. A cleanroom is designed to keep everything from dust, to airborne organisms, or vaporised particles, away from it, and so from whatever material is being handled inside it. The other way around, a cleanroom can also help keep materials escaping from it. This is often the primary aim in hazardous biology and nuclear work, in pharmaceutics and in virology. Cleanrooms typically come with a cleanliness level quantified by the number of particles per cubic meter at a predetermined molecule measure. The ambient outdoor air in a typical urban area contains 35,000,000 particles for each cubic meter in the size range 0.5 μm and bigger, equ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Route Of Administration

A route of administration in pharmacology and toxicology is the way by which a medication, drug, fluid, poison, or other substance is taken into the body. Routes of administration are generally classified by the location at which the substance is applied. Common examples include oral administration, oral and intravenous therapy, intravenous administration. Routes can also be classified based on where the target of action is. Action may be topical medication, topical (local), enteral administration, enteral (system-wide effect, but delivered through the gastrointestinal tract), or #Parenteral, parenteral (systemic action, but delivered by routes other than the GI tract). Route of administration and dosage form are aspects of drug delivery. Classification Routes of administration are usually classified by application location (or exposition). The route or course the active substance takes from application location to the location where it has its target effect is usually rather ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)