|

Paperboard Packaging

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply. Paperboard can be easily cut and formed, is lightweight, and because it is strong, is used in packaging. Another end-use is high quality graphic printing, such as book and magazine covers or postcards. Paperboard is also used in fine arts for creating sculptures. Sometimes it is referred to as ''cardboard'', which is a generic, lay term used to refer to any heavy paper pulp–based board, however this usage is deprecated in the paper, printing and packaging industries as it does not adequately describe each product type. History In 1817, the first paperbo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cardboard All Flutes

Cardboard is a generic term for heavy paper, paper-based products. The construction can range from a thick paper known as paperboard to corrugated fiberboard which is made of multiple plies of material. Natural cardboards can range from grey to light brown in color, depending of the specific product; dyes, pigments, printing, and coatings are available. The term "cardboard" has general use in English and French, but the term cardboard is deprecated in commerce and industry as not adequately defining a specific product. Material producers, container manufacturers, packaging engineers, and standards organizations, use more specific terminology. Statistics In 2020, the United States hit a record high in its yearly use of one of the most ubiquitous manufactured materials on earth, cardboard. With around 80 per cent of all the products sold in the United States being packaged in cardboard, over 120 billion pieces were used that year. In the same year, over 13,000 separate pieces o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Folding Carton

The folding carton created the packaging industry as it is known today, beginning in the late 19th century. The process involves folding carton made of paperboard that is printed, laminated, cut, then folded and glued. The cartons are shipped flat to a packager, which has its own machinery to fold the carton into its final shape as a container for a product. An example of such a carton is a cereal box. Some styles of folding cartons can be made of E-flute or micro-flute corrugated fiberboard. Invention and development In the 1840s, cartons were made by hand and held together with tacks and string, and used only for expensive items (such as jewellery). Although Charles Henry Foyle is described by some as the "inventor" of the paper carton, mass production of the cartons was invented, partly by accident, at the Robert Gair Company in Brooklyn, New York. Machinery at the end of the press had been set up carelessly by a pressman, and machinery cut through the material. This ruined t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Timber

Lumber is wood that has been processed into dimensional lumber, including beams and planks or boards, a stage in the process of wood production. Lumber is mainly used for construction framing, as well as finishing (floors, wall panels, window frames). Lumber has many uses beyond home building. Lumber is sometimes referred to as timber as an archaic term and still in England, while in most parts of the world (especially the United States and Canada) the term timber refers specifically to unprocessed wood fiber, such as cut logs or standing trees that have yet to be cut. Lumber may be supplied either rough- sawn, or surfaced on one or more of its faces. Beside pulpwood, ''rough lumber'' is the raw material for furniture-making, and manufacture of other items requiring cutting and shaping. It is available in many species, including hardwoods and softwoods, such as white pine and red pine, because of their low cost. ''Finished lumber'' is supplied in standard sizes, mostly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper Recycling

The recycling of paper is the process by which waste paper is turned into new paper products. It has a number of important benefits: It saves waste paper from occupying homes of people and producing methane as it breaks down. Because paper fibre contains carbon (originally absorbed by the tree from which it was produced), recycling keeps the carbon locked up for longer and out of the atmosphere. Around two-thirds of all paper products in the US are now recovered and recycled, although it does not all become new paper. After repeated processing the fibres become too short for the production of new paper, which is why virgin fibre (from sustainably farmed trees) is frequently added to the pulp recipe. There are three categories of paper that can be used as feedstocks for making ''recycled paper'': mill broke, pre-consumer waste, and post-consumer waste. ''Mill broke'' is paper trimmings and other paper scrap from the manufacture of paper, and is recycled in a paper mill. ''Pre-c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

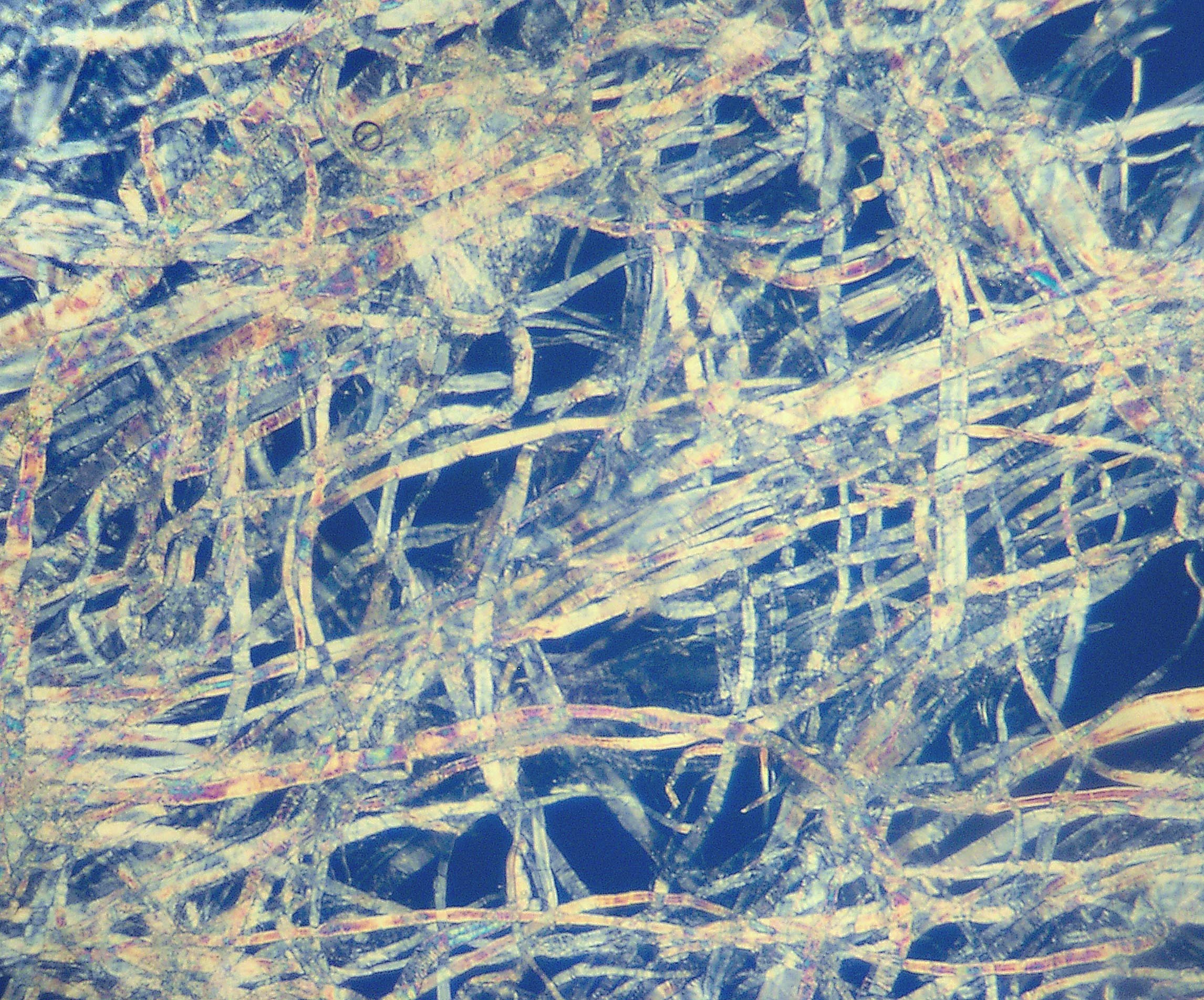

Pulp (paper)

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulberr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Takon Kartonkitehdas Tammerkoski

Takon is an arrondissement in the Plateau department of Benin. It is an administrative division under the jurisdiction of the commune of Sakété. According to the population census conducted by the Institut National de la Statistique Benin An institute is an organisational body created for a certain purpose. They are often research organisations (research institutes) created to do research on specific topics, or can also be a professional body. In some countries, institutes can ... on February 15, 2002, the arrondissement had a total population of 10,424. accessed b Geohive accessed 4 June 2012 References [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bookbinding

Bookbinding is the process of physically assembling a book of codex format from an ordered stack of ''signatures'', sheets of paper folded together into sections that are bound, along one edge, with a thick needle and strong thread. Cheaper, but less permanent, methods for binding books include loose-leaf rings, individual screw-posts (binding posts), twin loop spine coils, plastic spiral coils, and plastic spine combs. For protection, the bound stack of signatures is wrapped in a flexible cover or is attached to stiffened boards. Finally, an attractive cover is placed onto the boards, which includes the publisher's information, and artistic decorations. The trade of binding books is in two parts; (i) stationery binding (vellum binding) for books intended for handwritten entries, such as accounting ledgers, business journals, blank-page books, and guest logbooks, and notebooks, manifold books, day books, diaries, and portfolios. (ii) letterpress printing and binding deals with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrugated Fiberboard

Corrugated fiberboard or corrugated cardboard is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over thick. History Corrugated (also called pleated) paper was patented in England in 1856, and used as a liner for tall hats, but corrugated boxboard was not patented and used as a shipping material until 20 December 1871. The patent was issued to Albert Jones of New York City for single-sided (single-face) corrugated board. Jones used the corrugated board for wrapping bottles and glass lantern chimneys. The first machine for producing large quantities of corrugated board was built in 1874 by G. Smyth, and in the same year Oliver Long improved upon Jones' design by inventing corrugated board with liner sheets on both ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Containerboard

Containerboard or corrugated case material (CCM) is a type of paperboard specially manufactured for the production of corrugated board. It includes both linerboard and corrugating medium (or fluting), the two types of paper that make up corrugated board. Since containerboard is made mainly out of natural unbleached wood fibers, it is generally brown, although its shade may vary depending on the type of wood, pulping process, recycling rate and impurities content. For certain boxes that demand good presentation, white bleached pulp or coating is used on the top ply of the linerboard that goes outside the box. Manufacture Containerboard is made on modified paper machines that can handle higher grammages. The production of containerboard is the highest of all kinds of paper in the world. More than 100 million tons are produced annually. It is made in specialized paper machines from virgin as well as recycled fibers. Linerboard made of virgin pulp is called ''kraftliner'', whereas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid Unbleached Board

Solid unbleached board, also known as SUB, is a grade of paperboard typically made of unbleached chemical pulp. Most often it comes with two to three layers of mineral or synthetic pigment coating on the top and one layer on the reverse side. Recycled fibres are sometimes used to replace the unbleached chemical pulp. The main end use for this type of board is for packaging of frozen or chilled food, beverage carriers, detergent cereals, shoes, toys and others. See also *Folding boxboard *Solid bleached board *White lined chipboard White-lined chipboard (also referred to as WLC, GD, GT or UD) is a grade of paperboard typically made from layers of Paper recycling, waste paper or Recycling, recycled fibers. Most often it comes with two to three layers of coated paper, coating o ... References Paperboard Coated paper Paper {{Material-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid Bleached Board

Solid bleached board (SBB) or solid bleached sulphate (SBS) is a virgin fibre grade of paperboard. This grade is made purely from bleached chemical pulp and usually has a mineral or synthetic pigment coated top surface in one or more layers (C1S) and often also a coating on the reverse side (C2S). It is a medium density board with good printing properties for graphical and packaging end uses and is perfectly white both inside and out. It can easily be cut, creased, hot foil stamped and embossed. Its other properties, such as being hygienic and pure with no smell and taste, make it usable for packaging aroma and flavour sensitive products such as chocolate, cigarettes and cosmetics. See also *Folding boxboard *Solid unbleached board *White lined chipboard White-lined chipboard (also referred to as WLC, GD, GT or UD) is a grade of paperboard typically made from layers of Paper recycling, waste paper or Recycling, recycled fibers. Most often it comes with two to three layers of coat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquid Packaging Board

Liquid packaging board is a multi-ply paperboard with high stiffness, strong wet sizing and a high barrier coating, e.g. plastic. Only virgin paper fibers are used. The barrier coating must hold the liquid and prevent migration of air and flavors through the paperboard. Manufacture A liquid packaging board might be up to five plies and is formed on a multi-ply paper machine with online coating. The most common is to use three plies with a basis weight of about 300 g/m2. The base or middle ply is normally made of pulp from bleached or unbleached chemical pulp, CTMP or ''broke'' (waste paper from a paper machine). CTMP gives more bulk and stiffness. The top ply (inside) is made of bleached chemical pulp. The barrier coating depends on the application and might be applied on both sides. When induction welding is employed an aluminum foil layer is used for barrier protection and for heating. The back side of the board is the printing side and might have an extra ply made from chemic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |