|

MV Agusta 350 Racers

The MV Agusta 350 cc racers were motorcycles produced by MV Agusta between 1954 and 1976 and raced in the 350 cc Grand Prix motorcycle racing, motorcycle GP championships. 10 world titles were achieved by riders John Surtees, Gary Hocking and Giacomo Agostini on these machines. MV Agusta 350 4C 1954–1964 Domenico Agusta, Count Domenico Agusta never released technical data of his machines and personnel, technical staff and riders were forbidden to divulge anything about the machines. Because a number of newer machines were later sold through auctions, data is known about these, but the machines from the early years sometimes remain a mystery. Of the original 350 4C is really only known that it was a reduced version of the MV Agusta 500 4C. Designer Piero Remor initially provided that machine with experimental and often useless technology, but rider Leslie Graham made some improvements. In 1953 that machine had a telescopic forks and a Motorcycle frame#Full duplex cradle, double c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angelo Bergamonti

Angelo Bergamonti (18 March 1939 - 4 April 1971) was an Italian Grand Prix motorcycle racing, Grand Prix motorcycle road racing, road racer. Bergamonti was born in Gussola. His best year was in 1970 Grand Prix motorcycle racing season, 1970 when he finished third in the 500cc world championship, behind his MV Agusta teammate Giacomo Agostini and Ginger Molloy. Bergamonti was killed in 1971 during a race held on the city streets of Riccione. References 1939 births 1971 deaths Sportspeople from the Province of Cremona Italian motorcycle racers 125cc World Championship riders 250cc World Championship riders 350cc World Championship riders 500cc World Championship riders Motorcycle racers who died while racing Sport deaths in Italy 20th-century Italian people {{Italy-motorcycle-sport-bio-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valvetrain

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

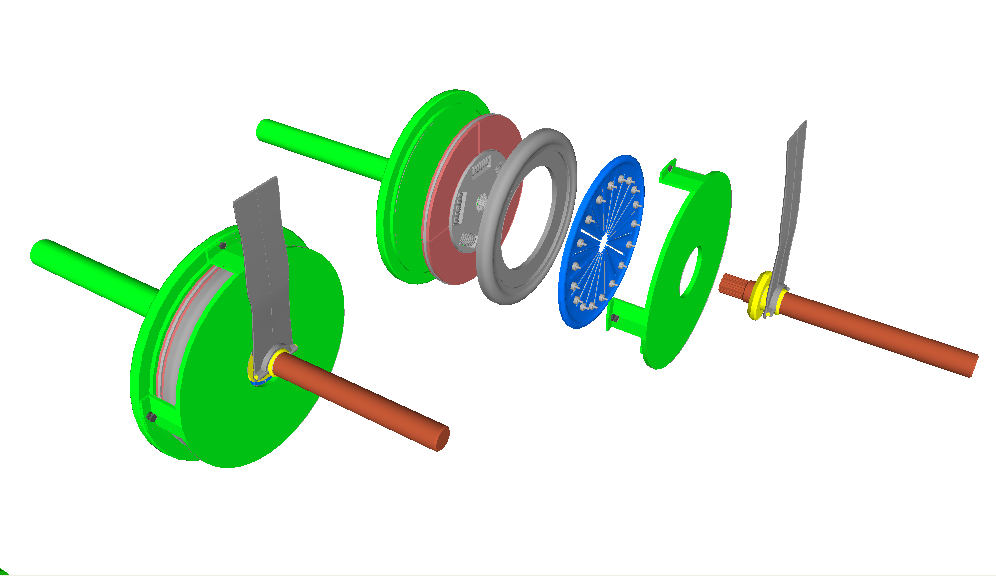

Clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine or other power unit (the driving member), while the other shaft (the driven member) provides output power for work. Typically the motions involved are rotary, but linear clutches also exist. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission, and briefly disconnects, or separates the engine from the transmission system. This disconnects the drive wheels whenever the clutch pedal is depressed, allowing the driver to smoothly change gears. In a torque-controlled drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so they may be locked together and spin at the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Primary Drive (motorcycle)

A drivetrain (also frequently spelled as drive train or sometimes drive-train) is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components of a motor vehicle that deliver power to the drive wheels. This excludes the engine or motor that generates the power. In marine applications, the drive shaft will drive a propeller, thruster, or waterjet rather than a drive axle, while the actual engine might be similar to an automotive engine. Other machinery, equipment and vehicles may also use a drivetrain to deliver power from the engine(s) to the driven components. In contrast, the powertrain is considered to include both the engine and/or motor(s) as well as the drivetrain. Function The function of the drivetrain is to couple the engine that produces the power to the driving wheels that use this mechanical power to rotate the axle. This connection involves physically linking the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Power

Engine power is the power that an engine can put out. It can be expressed in power units, most commonly kilowatt, pferdestärke (metric horsepower), or horsepower. In terms of internal combustion engines, the engine power usually describes the ''rated power'', which is a power output that the engine can maintain over a long period of time according to a certain testing method, for example ISO 1585. In general though, an internal combustion engine has a power take-off shaft (the crankshaft), therefore, the rule for shaft power applies to internal combustion engines: Engine power is the product of the engine torque and the crankshaft's angular velocity. Definition Power is the product of torque and angular velocity:. p 233 Let: *P= Power in Watt (W) *M= Torque in Newton-metre (N·m) *n= Crankshaft speed per Second (s−1) *\omega= Angular velocity = 2\pi n Power is then: :P= M \cdot \omega In internal combustion engines, the crankshaft speed n is a more common figure than ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dell'Orto

Dell'Orto is an Italian company, headquartered in Cabiate, specialized in the construction of carburetors and electronic injection systems. The company was founded in 1933 as "Società anonima Gaetano Dell'Orto e figli" (Gaetano Dell’Orto and Sons) but actually only founded by Gaetano's sons, Luigi Piero and Giuseppe. The first production was carburetors for motorbikes. Right before World War II the company started producing carburetors with aluminum body, for competitive racing. Under the second Dell'Orto generation, towards the end of the 60s, the company began producing OEM carburetors for the Fiat group, as well as other Italian and foreign manufacturers (i.e. Flandria, Belgium). At the end of the 1980s, under the supervision of Luigi Dell'Orto (son of Gaetano), the company's first injection systems were released. In 2006, the company expanded on the Indian market, opening Dell'Orto India. In September 2009, Dell’Orto India Private Limited, founded in 2006 with the coope ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

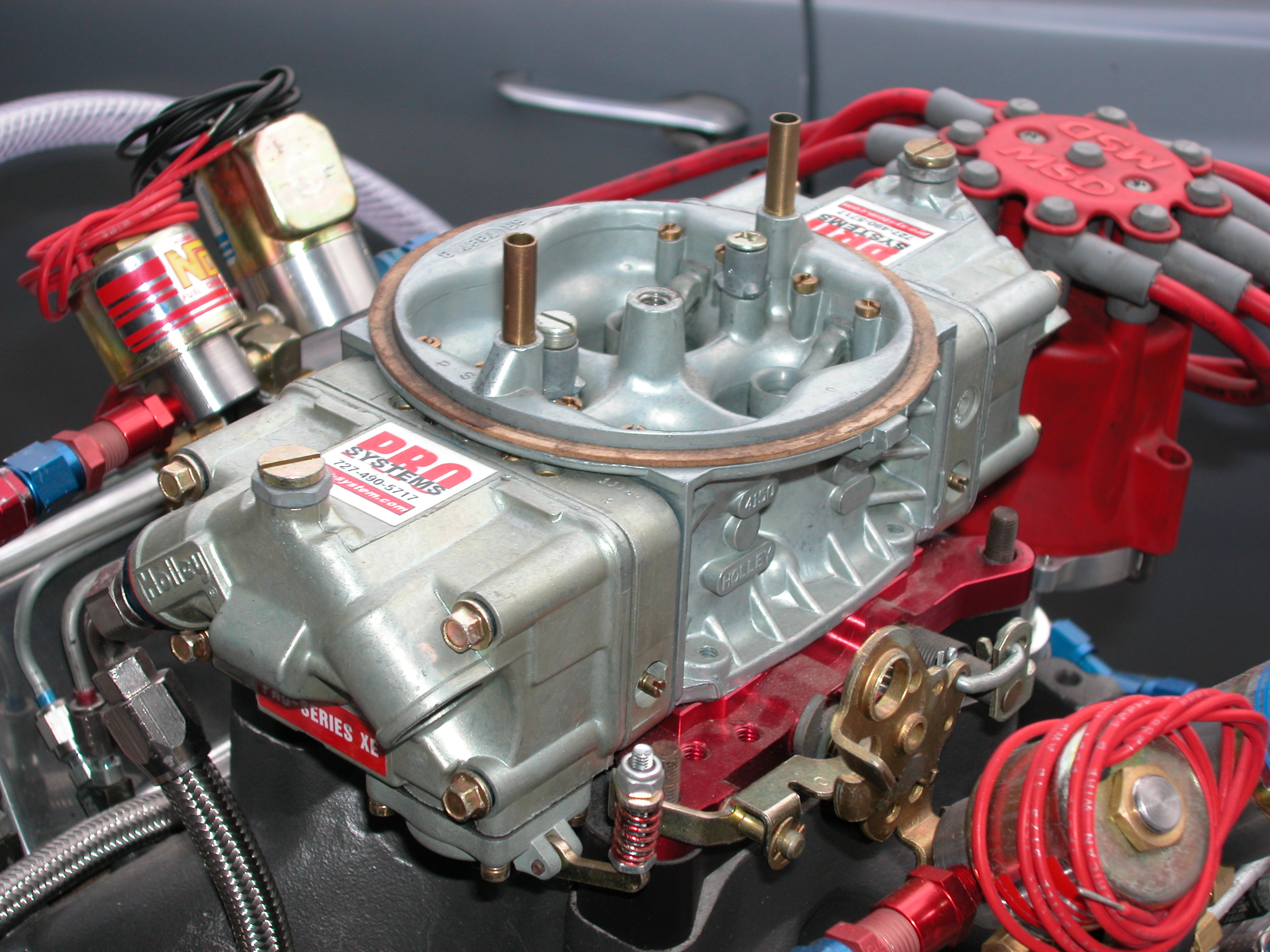

Carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wet Sump

Within piston engines, a wet sump is part of a lubrication system whereby the crankcase sump is used as an integral oil reservoir. An alternative system is the dry sump, whereby oil is pumped from a shallow sump into an external reservoir.Wet sump and dry sump compared - https://www.knowyourparts.com/technical-resources/engine/oil-system-differences/#:~:text=Dry%20Oil%20Systems%20Wet%20sump%20systems%20store%20the,is%20used%20to%20pump%20oil%20from%20the%20motor. Piston engines are lubricated by oil which is pumped into various bearings, and thereafter allowed to drain to the base of the engine under gravity. In most production automobiles and motorcycles, which use a wet sump system, the oil is collected in a capacity pan at the base of the engine, known as the sump or oil pan, where it is pumped back up to the bearings by the internal oil pump. A wet sump offers the advantage of a simple design, using a single pump and no external reservoir. Since the sump is internal, th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology. Lubrication mechanisms such as fluid-lubricated systems are designed so that the applied load is partially or completely carried by hydrodynamic or hydrostatic pressure, which reduces solid body interactions (and consequently friction and wear). Depending on the degree of surface separation, different lubrication regimes can be distinguished. Adequate lubrication allows smooth, continuous operation of machine elements, reduces the rate of wear, and prevents excessive stresses or seizures at bearings. When lubrication breaks down, components can rub destructively against each other, causing heat, local welding, destructive damage and failure. Lubrication mechanisms Fluid-lubricated systems As the load increases on the contacting surfaces, distinct situations can be observed wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Displacement

Engine displacement is the measure of the cylinder volume swept by all of the pistons of a piston engine, excluding the combustion chambers. It is commonly used as an expression of an engine's size, and by extension as a loose indicator of the power an engine might be capable of producing and the amount of fuel it should be expected to consume. For this reason displacement is one of the measures often used in advertising, as well as regulating, motor vehicles. It is usually expressed using the metric units of cubic centimetres (cc or cm3, equivalent to millilitres) or litres (l or L), orparticularly in the United States cubic inches (CID, cu in, or in3). Definition The overall displacement for a typical reciprocating piston engine is calculated by multiplying together three values; the distance travelled by the piston (the stroke length), the circular area of the cylinder, and the number of cylinders in the whole engine. The formula is: : \text = \text \times \frac \times ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stroke (engine)

In the context of an internal combustion engine, the term stroke has the following related meanings: * A phase of the engine's cycle (e.g. compression stroke, exhaust stroke), during which the piston travels from top to bottom or vice versa. * The type of power cycle used by a piston engine (e.g. two-stroke engine, four-stroke engine). * "Stroke length", the distance travelled by the piston during each cycle. The stroke length––along with bore diameter––determines the engine's displacement. Phases in the power cycle Commonly used engine phases or strokes (i.e. those used in a four-stroke engine) are described below. Other types of engines can have very different phases. Induction-intake stroke The induction stroke is the first phase in a four-stroke (e.g. Otto cycle or Diesel cycle) engine. It involves the downward movement of the piston, creating a partial vacuum that draws a air-fuel mixture (or air alone, in the case of a direct injection engine) into the combus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bore (engine)

In a piston engine, the bore (or cylinder bore) is the diameter of each cylinder. Engine displacement is calculated based on bore, stroke length and the number of cylinders: displacement = The stroke ratio, determined by dividing the bore by the stroke, traditionally indicated whether an engine was designed for power at high engine speeds (rpm) or torque at lower engine speeds. The term "bore" can also be applied to the bore of a locomotive cylinder or steam engine pistons. Steam locomotive The term bore also applies to the cylinder of a steam locomotive or steam engine. See also * Bore pitch * Compression ratio * Engine displacement Engine displacement is the measure of the cylinder volume swept by all of the pistons of a piston engine, excluding the combustion chambers. It is commonly used as an expression of an engine's size, and by extension as a loose indicator of the ... References {{Steam engine configurations Engine technology ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |