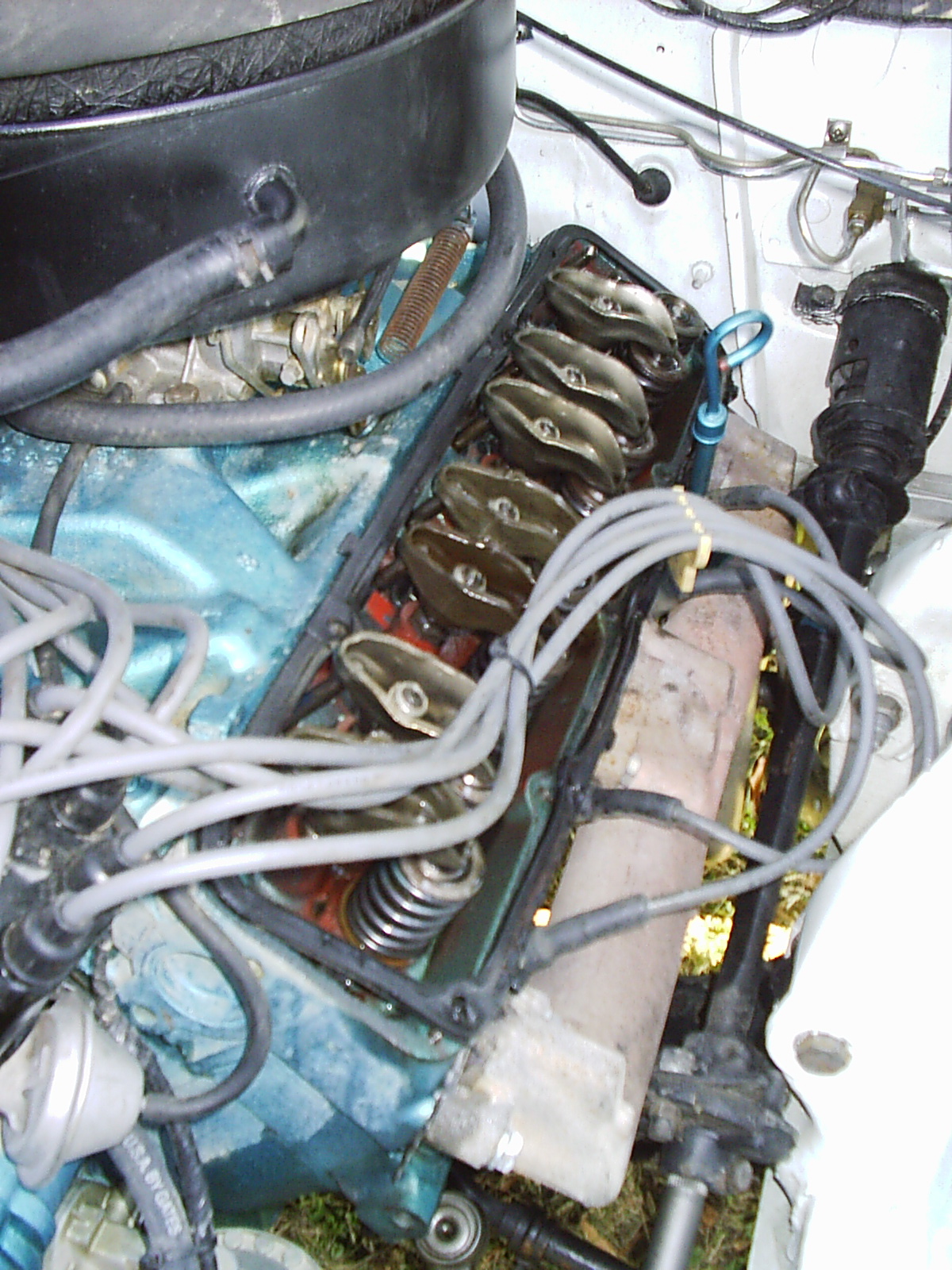

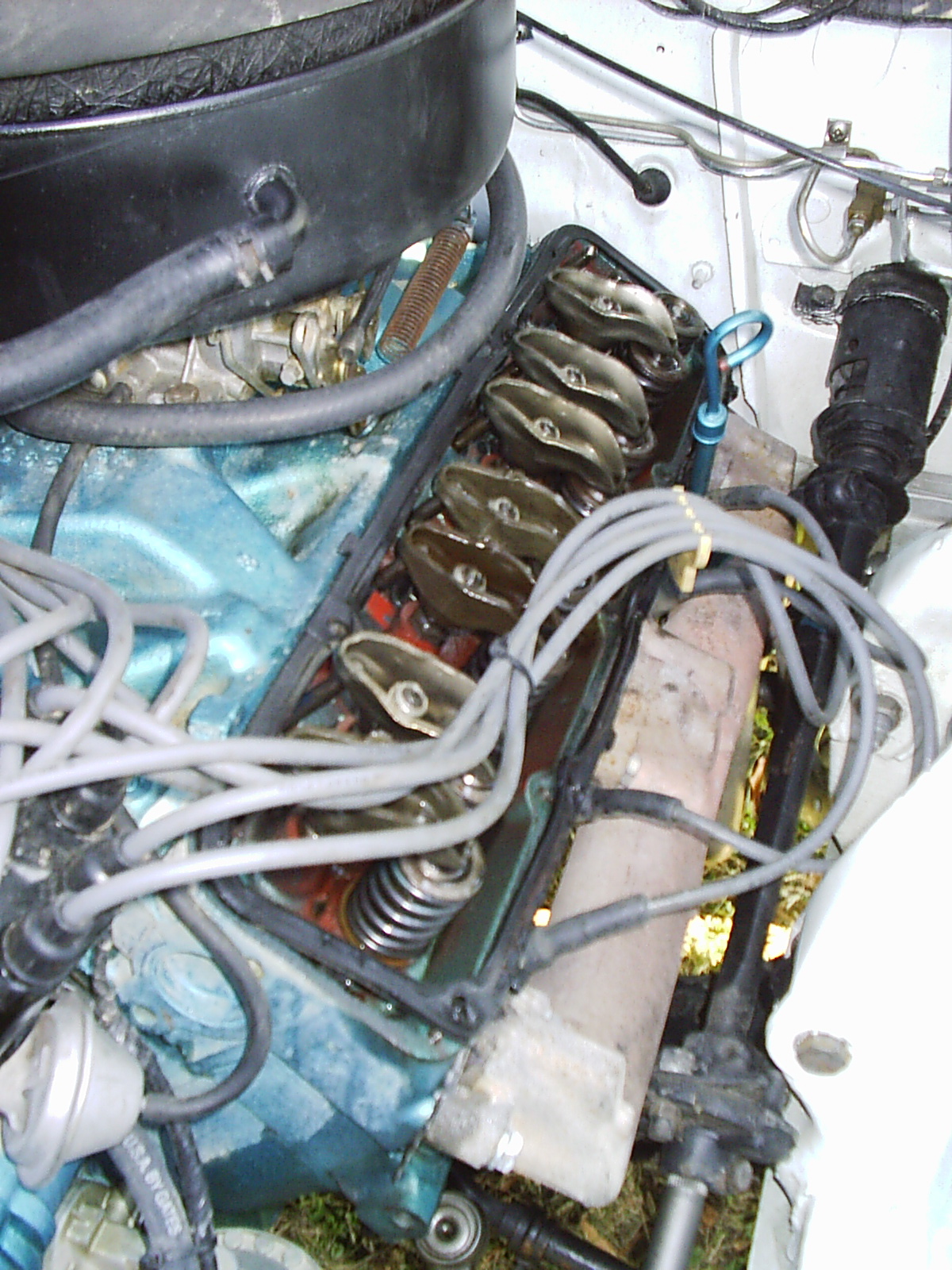

Valvetrain on:

[Wikipedia]

[Google]

[Amazon]

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combus ...

. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed.

Layout

The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: *Flathead engine

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as ...

: The camshaft and the valves are located in the engine block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attac ...

below the combustion chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

Intern ...

.

* Overhead valve engine

An overhead valve (OHV) engine, sometimes called a ''pushrod engine'', is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with earlier flathead engines, where the valves were located b ...

: The camshaft remains in the block, however the valves are located in the cylinder head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber.

In sidevalve engines, the head is a simple sheet of metal; whereas in more modern ...

above the combustion chamber.

* Overhead camshaft engine

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion ...

: The valves and camshaft(s) are in the cylinder head above the combustion chamber.

Components

The valvetrain consists of all the components responsible for transferring the rotational movement of the camshaft into the opening and closing of the intake and exhaust valves. Typical components are listed below in order from the crankshaft to the valves.Camshaft

The timing and lift profile of the valve opening events are controlled by thecamshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems ...

(s), through use of a carefully shaped lobe on a rotating shaft. The camshaft is driven by the crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting ...

and— in the case of a four-stroke engine— rotates at half the speed of the crankshaft.

Motion is transferred from the crankshaft to the camshaft most commonly by a rubber timing belt, a metallic ''timing chain'' or a set of gears.

Pushrod

Pushrod

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) ...

s are long, slender metal rods that are used in overhead valve engines to transfer motion from the camshaft (located in the engine block) to the valves (located in the cylinder head). The bottom end of a pushrod is fitted with a lifter, upon which the camshaft makes contact. The camshaft lobe moves the lifter upwards, which moves the pushrod. The top end of the pushrod pushes on the rocker arm, which opens the valve.

Rocker arm / Finger / Bucket tappet

Depending on the design used, the valves are actuated by arocker arm

In the context of an internal combustion engine, a rocker arm is a valvetrain component that typically transfers the motion of a pushrod to the corresponding intake/exhaust valve.

Rocker arms in automobiles are typically made from stamped steel ...

, finger

A finger is a limb of the body and a type of digit, an organ of manipulation and sensation found in the hands of most of the Tetrapods, so also with humans and other primates. Most land vertebrates have five fingers ( Pentadactyly). Chambers ...

or bucket tappet

A tappet is most commonly a component in an internal combustion engine which converts the rotating motion of the camshaft into linear motion of the valves, either directly or indirectly.

An earlier use of the term was for part of the valve gear ...

. Overhead valve engines use rocker arms, which are actuated from below indirectly (through the pushrods) by the cam lobe

Calmodulin (CaM) (an abbreviation for calcium-modulated protein) is a multifunctional intermediate calcium-binding messenger protein expressed in all eukaryotic cells. It is an intracellular target of the secondary messenger Ca2+, and the bind ...

s. Overhead camshaft engines use fingers or bucket tappets, which are actuated from above directly by the cam lobes.

Valves

Most modern engines usepoppet valves

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine.

It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usual ...

, although sleeve valve

The sleeve valve is a type of valve mechanism for piston engines, distinct from the usual poppet valve. Sleeve valve engines saw use in a number of pre-World War II luxury cars and in the United States in the Willys-Knight car and light truck. ...

s, slide valves and rotary valve

A rotary valve (also called rotary-motion valve) is a type of valve in which the rotation of a passage or passages in a transverse plug regulates the flow of liquid or gas through the attached pipes. The common stopcock is the simplest form of rot ...

s have also been used at times. Poppet valves are typically opened by the camshaft lobe or rocker arm, and closed by a coiled spring called a ''valve spring''.

Valve float Valve float is an adverse condition which can occur at high engine speeds when the poppet valves in an internal combustion engine valvetrain do not properly follow the closure phase of the cam lobe profile. This reduces engine efficiency and perform ...

occurs when the valve spring is unable to control the inertia of the valvetrain at high engine speeds (RPM).

See also

*Cam-in-block A cam-in-block engine is where the camshaft is located in the engine block. Types of cam-in-block engines are:

* F-Head Engine

* Flathead engine

* Overhead valve engine (the only type where the valves are above the combustion chamber)

* T-head eng ...

* Camless piston engine

A camless or free-valve piston engine is an engine that has poppet valves operated by means of electromagnetic, hydraulic, or pneumatic actuators instead of conventional cams. Actuators can be used to both open and close valves, or to open valves ...

References

{{Internal combustion engine , state=expanded Engine components