|

Rocker Arm

In the context of an internal combustion engine, a rocker arm is a valvetrain component that typically transfers the motion of a pushrod to the corresponding intake/exhaust valve. Rocker arms in automobiles are typically made from stamped steel, or aluminum in higher-revving applications. Some rocker arms (called ''roller rockers'') include a bearing at the contact point, to reduce wear and friction at the contact point. Overview In the typical use-case of an overhead valve (pushrod) engine, the camshaft at the bottom of the engine pushes the pushrod upwards. The top of the pushrod presses upwards on one side of the rocker arm (located at the top of the engine), which causes the rocker arm to rotate. This rotation causes the other end of the rocker arm to press downwards on the top of the valve, which opens the valve by moving it downwards. A ''roller rocker'' is a rocker arm that uses needle bearings (or a single bearing ball in older engines) at the contact point between the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Škoda 120

The Škoda 105, Škoda 120 and Škoda 125 were three variations of a rear-engined, rear-wheel drive small family car that was produced by Czechoslovakian car manufacturer AZNP in Mladá Boleslav, Czechoslovakia between 1976 and 1990. Engine sizes were 1.05 and 1.2 liters respectively. The range was face lifted in 1984 with a revised design and engine improvements, together with the introduction of a new 1.3 liter version known as the Škoda 130. The related models followed in 1987 with the Škoda 130/135/136. All 105/120/125 and 130 models known by their Škoda internal reference as Type 742, and the later 135 and 136 models as Type 746. In the UK, the 105/120 models were known as the Super Estelle until 1984, when the face-lifted models were called Estelle Two. Initial design In the early 1970s, Škoda had originally intended to produce their successor to the S100/110 as a front-engined front-wheel drive model. However, because of the lack of funding (Škoda had even appl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford Modular Engine

The Ford Modular engine is Ford Motor Company's overhead camshaft (OHC) V8 and V10 gasoline-powered small block engine family. Despite popular belief that the Modular engine family received its moniker from the sharing of engine parts across numerous Ford vehicle platforms, in reality, the Modular engine family was named as such by Ford Motor Company for the new "modular approach" to the setup of tooling and casting stations in the Windsor and Romeo engine manufacturing plants. Implementing a "modular approach" allowed for significantly faster changeovers when switching from one engine platform to another among the Modular engine family. This also allowed for the existing engine plants, and their supporting offsite production facilities, to handle shorter production runs. Implementing shorter production runs without incurring large shutdown and retooling expenses helped to increase the versatility of those production stations that required tooling or machining setups specific to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pushrod

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poppet Valve

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine. It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usually a disk shape on the end of a shaft known as a valve stem. The working end of this plug, the valve face, is typically ground at a 45┬░ bevel to seal against a corresponding valve seat ground into the rim of the chamber being sealed. The shaft travels through a valve guide to maintain its alignment. A pressure differential on either side of the valve can assist or impair its performance. In exhaust applications higher pressure against the valve helps to seal it, and in intake applications lower pressure helps open it. The poppet valve was invented in 1833 by American E.A.G. Young of the New Castle and Frenchtown Turnpike and Railroad Company, Newcastle and Frenchtown Railroad. Young had patented his idea, but the 1836 U.S. Patent Offic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular metal choic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of ironÔÇôcarbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1ÔÇô3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fulcrum (mechanics)

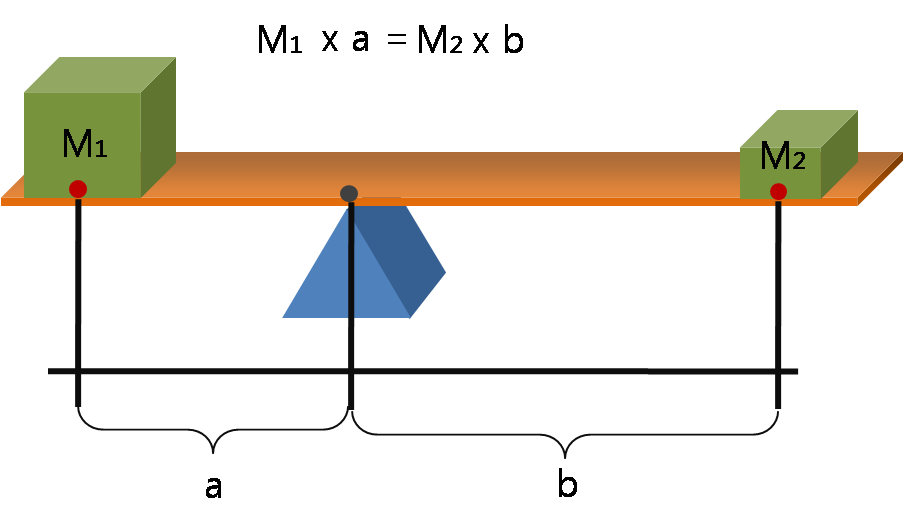

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or ''fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load and effort, the lever is divided into three types. Also, leverage is mechanical advantage gained in a system. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage. The ratio of the output force to the input force is the mechanical advantage of the lever. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English around 1300 from Old French, in which the word was ''levier''. This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to the Latin ''levare'', itself from the adjective ''levis'', meaning "light" (as in "not heavy"). The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reciprocating Weight

The moment of inertia, otherwise known as the mass moment of inertia, angular mass, second moment of mass, or most accurately, rotational inertia, of a rigid body is a quantity that determines the torque needed for a desired angular acceleration about a rotational axis, akin to how mass determines the force needed for a desired acceleration. It depends on the body's mass distribution and the axis chosen, with larger moments requiring more torque to change the body's rate of rotation. It is an extensive (additive) property: for a point mass the moment of inertia is simply the mass times the square of the perpendicular distance to the axis of rotation. The moment of inertia of a rigid composite system is the sum of the moments of inertia of its component subsystems (all taken about the same axis). Its simplest definition is the second moment of mass with respect to distance from an axis. For bodies constrained to rotate in a plane, only their moment of inertia about an axis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. Stamping is usually ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han Dynasty in China, and they were widespread by the medieval period. The camshaft was described in 1206 by engineer Al-Jazari. He employed it as part of his automata, water-raising machines, and water clocks such as the castle clock. Once the rotative version of the steam engine was developed in the late 18th century, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford Zetec Engine

Ford Motor Company used the Zetec name on a variety of inline 4-cylinder automobile engines. It was coined to replace "Zeta" on a range of 1.6 L to 2.0 L multi-valve engines introduced in 1991 because Ford was threatened with legal action by Lancia who owned the Zeta trademark. The company used the name widely in European advertising and later introduced it to the North American market with the Contour. The Zetec name was so recognized that Ford decided to apply it to other high-tech four-cylinder engines. It is used across many engine types in Europe today even though the original Zeta design ended production in 2004. Ford also used the "Zetec" name for a trim level designation in certain markets. A Formula One engine was produced for Ford by Cosworth in 1993. The 3.5-litre Zetec R V8 was used by the Benetton team in 1994, and powered Michael Schumacher to his first World Championship title. Engine reference The Zetec name has been used on many different engines: ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Camshaft Engine

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an OHV en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |