|

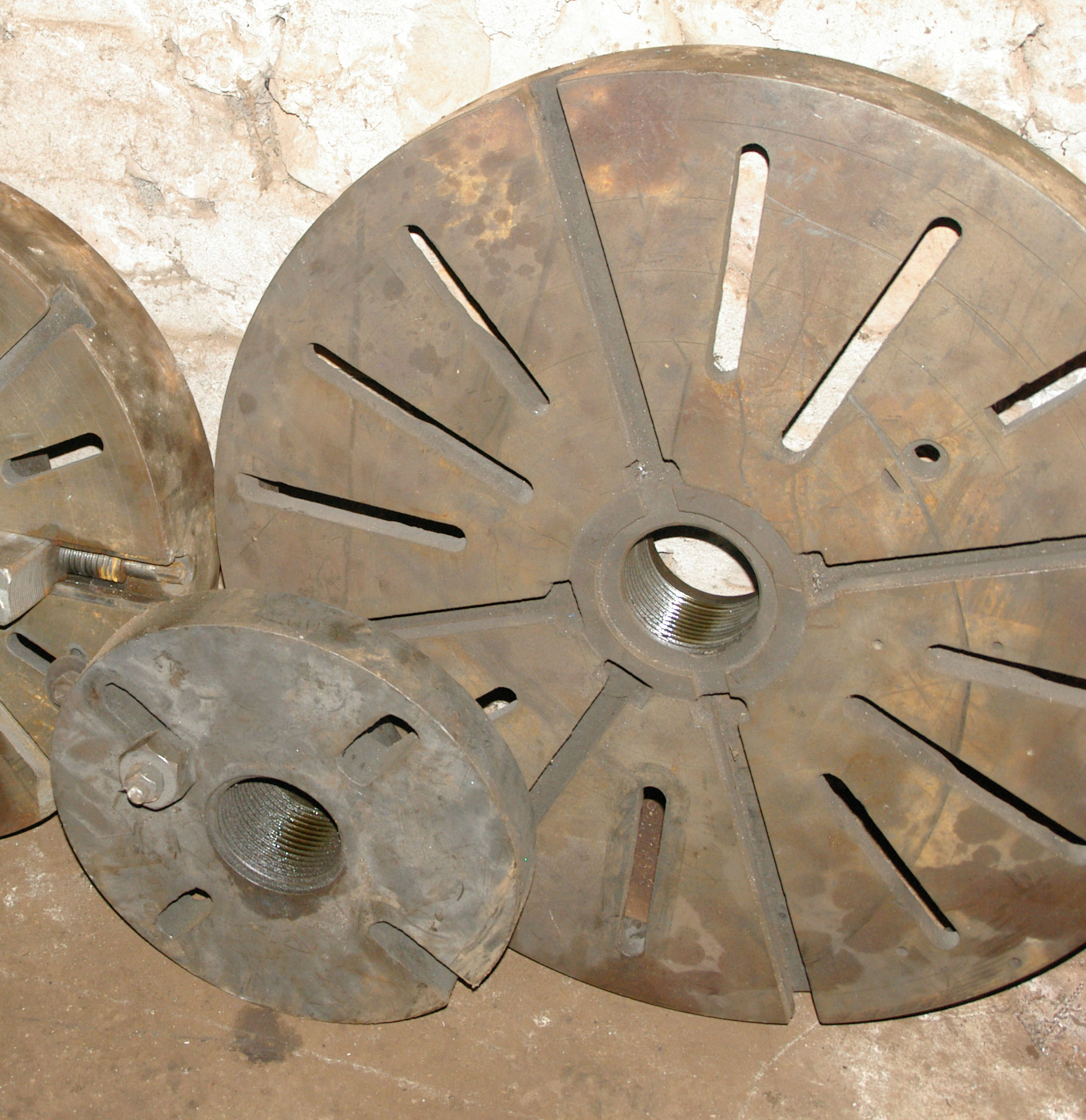

Lathe Faceplate

A lathe faceplate is a basic workholding accessory for a wood or metal turning lathe. It is a circular metal (usually cast iron) plate which fixes to the end of the lathe spindle. The workpiece A workpiece is a piece, often made of a single material, that is being processed into another desired shape (such as building blocks). The workpiece is usually a piece of relatively rigid material such as wood, metal, plastic, or stone. After a ... is then clamped to the faceplate, typically using t-slot nuts in slots in the faceplate, or less commonly threaded holes in the faceplate itself. The faceplate may be attached to the lathe in several ways: the two most common are a thread and a precision cone arrangement, and threaded studs and a circular recess fitting a flange on the end of the spindle. Increasingly common is the camlock arrangement, in which shaped studs and cams replace threaded studs for rapid exchanging of the faceplate with other accessories, such as three or fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Faceplate2

Faceplate (face plate, face-plate) is a plate, cover, or bezel on the front of a device, such as: Computers and electronics * Electrical outlet, also referred to as a wall plate, outlet cover, or socket cover * Front panel, of computers * Head unit, stereo system component * Motherboard, input/output port panel such as on an ATX * Cover (container) * Faceplate (housing), decorative elements of housing ** Nokia 5110, mobile phone with interchangeable faceplates ** Interchangeable bezels for Game Boy Micro ** Interchangeable bezels for Nintendo 3DS ** Interchangeable bezels for Nintendo 2DS ** Interchangeable decorative front plates for Nintendo Wii Remote musical instrument controllers ** Interchangeable decorative front plates for PlayStation 3 rhythm game peripherals ** Interchangeable decorative front case panels for Xbox 360 Other uses * Lathe faceplate, accessory for a wood or metal turning lathe * Lockset, components that make up the locking or latching mechanism * St ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spindle (tool)

In machine tools, a spindle is a rotating axis of the machine, which often has a shaft at its heart. The shaft itself is called a spindle, but also, in shop-floor practice, the word often is used metonymically to refer to the entire rotary unit, including not only the shaft itself, but its bearings and anything attached to it ( chuck, etc.). A machine tool may have several spindles, such as the headstock and tailstock spindles on a bench lathe. The main spindle is usually the biggest one. References to "the spindle" without further qualification imply the main spindle. Some machine tools that specialize in high-volume mass production have a group of 4, 6, or even more main spindles. These are called multispindle machines. For example, gang drills and many screw machines are multispindle machines. Although a bench lathe has more than one spindle (counting the tailstock), it is not called a multispindle machine; it has one main spindle. Examples of spindles include * On a la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workpiece

A workpiece is a piece, often made of a single material, that is being processed into another desired shape (such as building blocks). The workpiece is usually a piece of relatively rigid material such as wood, metal, plastic, or stone. After a processing step, the workpiece may be moved on to further steps of processing. For example, a part can made out of bar stock and later become part of a semi-finished product. The workpiece is often attached to the tool being used via a jig or fixture, like for example to a milling machine via an angle plate, or to a lathe via a lathe faceplate. A vise is another example of a simple type of fixture used to fix workpieces. A workpiece may be subjected to various cutting operations, like truing, making fillets, chamfers, countersinking, counterboring, etc. It may also receive various surface treatments and finishes. The term "workpiece" has established itself within crafts and the manufacturing industry, and connects the work o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

T-slot Nut

A T-slot nut is used with a threaded clamp to position and secure pieces being worked on in a workshop. The T-slot nut slides along a T-slot track, which is set in workbench or table for a router, drill press, or bandsaw. T-slot nuts are also used with T-slot structural framing to build a variety of industrial structures and machines. A T-slot bolt is generally stronger than a T-slot nut and hex-head cap screw. A heavy-duty T-slot nut with a M12 bolt is rated to support 10000 N (about 1 imperial ton at rest). and the T-slot nuts to fit into them comprised the first modular system developed for use in mechanical engineering in 1980 by item Industrietechnik. item Industrietechnik GmbH"timeline: 1980" The item aluminum framing system has since been expanded to include a variety of t-slot nuts that have been designed for specific applications. The item system is very similar to the "channel-and-groove design" used in some toys. File:CAD model of a T-Nut 1.png, CAD mode ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cam Lock (latch)

A latch or catch (called sneck in Northern England and Scotland) is a type of mechanical fastener that joins two (or more) objects or surfaces while allowing for their regular separation. A latch typically engages another piece of hardware on the other mounting surface. Depending upon the type and design of the latch, this engaged bit of hardware may be known as a ''keeper'' or ''strike''. A latch is not the same as the locking mechanism of a door or window, although often they are found together in the same product. Latches range in complexity from flexible one-piece flat springs of metal or plastic, such as are used to keep blow molded plastic power tool cases closed, to multi-point cammed latches used to keep large doors closed. Common types Deadbolt latch A single-throw bolt. The bolt can be engaged in its strike plate only after the door is closed. The locking mechanism typically prevents the bolt from being retracted by force. Spring latches * Latch bolt An extrem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chuck (engineering)

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws (sometimes called dogs) are typically arranged in a radially symmetrical pattern like the points of a star. Jawed chucks may require a wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a chuck may use magnetism, vacuum, or collets, which are flexible collars or sleeves that fit closely around the tool or workpiece ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: *The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe Carrier

A lathe dog is a mechanical device typically made of cast iron, steel or aluminum that transmits rotary motion from a faceplate to a workpiece mounted between centers in a lathe. The tail of the dog is rotated by a slot in a driving faceplate, a stud mounted on a faceplate, or sometimes a side of a chuck jaw. The workpiece passes through an aperture in the dog into which the work is secured by one or more setscrews or a clamp arrangement. The maximum cross sectional dimension of the workpiece is limited by the dimensions of the dog aperture. Lathe dogs are provided in ''straight tail'' or ''bent tail'' form, and may be ''single tail'' or ''double tail''. A lathe dog designed to hold square, rectangular or odd-shaped work and having a moveable portion secured typically by two cap screws is called a ''clamp dog''. Bent tail dogs are able to engage directly with a driving faceplate slot or a chuck jaw but can crowd work off centre if clearance is not present between the dog tail and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angle Plate

An angle plate is a work holding device used as a fixture in metalworking. Angle plates are used to hold workpieces square to the table during marking out operations. Adjustable angle plates are also available for workpieces that need to be inclined, usually towards a milling cutter. Angle plates are made from high quality material (generally spheroidal cast iron) that has been stabilized to prevent further movement or distortion. Slotted holes or "T" bolt slots are machined into the surfaces to enable the secure attachment or clamping of workpieces to the plate, and the plate to the worktable. See also * Lathe faceplate A lathe faceplate is a basic workholding accessory for a wood or metal turning lathe. It is a circular metal (usually cast iron) plate which fixes to the end of the lathe spindle. The workpiece A workpiece is a piece, often made of a single ... {{DEFAULTSORT:Angle Plate Machine tools Metalworking measuring instruments ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)