Chuck (engineering) on:

[Wikipedia]

[Google]

[Amazon]

A chuck is a specialized type of clamp used to hold an object with

A chuck is a specialized type of clamp used to hold an object with

A ''drill chuck'' is a specialised self-centering, three-jaw chuck, usually with capacity of or less, and rarely greater than , used to hold

A ''drill chuck'' is a specialised self-centering, three-jaw chuck, usually with capacity of or less, and rarely greater than , used to hold

On an ', each jaw can be moved independently. Because they most often have four jaws, the term ''four-jaw chuck'' without other qualification is understood by machinists to mean a chuck with four independent jaws. The independence of the jaws makes these chucks ideal for (a) gripping non-circular cross sections and (b) gripping circular cross sections with extreme precision (when the last few hundredths of a millimeter r thousandths of an inchof runout must be manually eliminated). The non-self-centering action of the independent jaws makes centering highly controllable (for an experienced user), but at the expense of speed and ease. Four-jaw chucks are almost never used for tool holding. Four-jaw chucks can be found on lathes and indexing heads.

Self-centering chucks with four jaws also can be obtained. Although these are often said to suffer from two disadvantages: inability to hold hex stock, and poor gripping on stock which is oval, only the latter is true. Even with three jaw self centering chucks, work which is not of uniform section along the work (and which is not free of spiral or 'wind') should not be gripped, as the jaws can be strained and the accuracy permanently impaired.

Four-jaw chucks can easily hold a workpiece eccentrically if eccentric features need to be machined.

On an ', each jaw can be moved independently. Because they most often have four jaws, the term ''four-jaw chuck'' without other qualification is understood by machinists to mean a chuck with four independent jaws. The independence of the jaws makes these chucks ideal for (a) gripping non-circular cross sections and (b) gripping circular cross sections with extreme precision (when the last few hundredths of a millimeter r thousandths of an inchof runout must be manually eliminated). The non-self-centering action of the independent jaws makes centering highly controllable (for an experienced user), but at the expense of speed and ease. Four-jaw chucks are almost never used for tool holding. Four-jaw chucks can be found on lathes and indexing heads.

Self-centering chucks with four jaws also can be obtained. Although these are often said to suffer from two disadvantages: inability to hold hex stock, and poor gripping on stock which is oval, only the latter is true. Even with three jaw self centering chucks, work which is not of uniform section along the work (and which is not free of spiral or 'wind') should not be gripped, as the jaws can be strained and the accuracy permanently impaired.

Four-jaw chucks can easily hold a workpiece eccentrically if eccentric features need to be machined.

For special purposes, chucks are available with ''six'' or ''eight'' jaws. These are usually of the self-centering design, and may be built to very high standards of accuracy. However, it is a misconception that such chucks necessarily offer more precision in holding solid workpieces than conventional three-jawed self-centering chucks. Indeed, hot-rolled or other imperfectly round workpieces may "teeter" insecurely between opposing jaws of scroll chucks having even numbers of jaws, in the same manner that a four-legged stool teeters on a rough floor while a three-legged stool never does. The primary purpose of six- and eight-jawed chucks is to hold thin-walled tubing with minimum deformation. By having twice as many clamping points, a six-jaw chuck induces less than half as much clamping distortion in a thin-walled workpiece, compared to a three-jawed chuck.

''Two-jaw chucks'' are available and can be used with

For special purposes, chucks are available with ''six'' or ''eight'' jaws. These are usually of the self-centering design, and may be built to very high standards of accuracy. However, it is a misconception that such chucks necessarily offer more precision in holding solid workpieces than conventional three-jawed self-centering chucks. Indeed, hot-rolled or other imperfectly round workpieces may "teeter" insecurely between opposing jaws of scroll chucks having even numbers of jaws, in the same manner that a four-legged stool teeters on a rough floor while a three-legged stool never does. The primary purpose of six- and eight-jawed chucks is to hold thin-walled tubing with minimum deformation. By having twice as many clamping points, a six-jaw chuck induces less than half as much clamping distortion in a thin-walled workpiece, compared to a three-jawed chuck.

''Two-jaw chucks'' are available and can be used with

Developed by Bosch in 1975 for

Developed by Bosch in 1975 for

* A backplate with threads may screw onto a threaded spindle nose (for lathe work) or onto an adapter plate with the same nose, to be mounted on the table of

* A backplate with threads may screw onto a threaded spindle nose (for lathe work) or onto an adapter plate with the same nose, to be mounted on the table of

The original forms of workholding on lathes were between-centers holding and ''ad hoc'' fastenings to the headstock spindle. The spike-style centers still used on wood lathes represent an ancient method. ''Ad hoc'' fastening methods in centuries past included anything from pinning with clenching or wedging; nailing; lashing with cords of leather or fiber; dogging down (again involving pinning/wedging/clenching); or other types. Faceplates have probably been around at least since the era of medieval clock-makers.

Tooling similar to today's chucks seems likely to have evolved from faceplate work, as workers using faceplates for repetitive work began to envision types of clamps or dogs for the faceplate that could be opened and closed in more convenient ways than repeated total disassembly and reassembly.

A ''chock'' was originally just a lump of wood. However, by 1703 it could be "… Chocks, belonging to the Screw-Mandrel". By 1807 the word had changed to the more familiar chuck'': "On the end of the spindle … is screwed … a universal Chuck for holding any kind of work".

In late 1818 or early 1819 the Society for the Encouragement of Arts, Manufactures and Commerce awarded its silver medal and 10 guineas (£10.50 – ) to Mr. Alexander Bell for a three jaw lathe chuck: It is not clear how they were moved "equably" whether by a scroll or some other means. Later in 1819 the same body awarded a further silver medal to Mr. T. Hack for a four jaw chuck. In the United States

The original forms of workholding on lathes were between-centers holding and ''ad hoc'' fastenings to the headstock spindle. The spike-style centers still used on wood lathes represent an ancient method. ''Ad hoc'' fastening methods in centuries past included anything from pinning with clenching or wedging; nailing; lashing with cords of leather or fiber; dogging down (again involving pinning/wedging/clenching); or other types. Faceplates have probably been around at least since the era of medieval clock-makers.

Tooling similar to today's chucks seems likely to have evolved from faceplate work, as workers using faceplates for repetitive work began to envision types of clamps or dogs for the faceplate that could be opened and closed in more convenient ways than repeated total disassembly and reassembly.

A ''chock'' was originally just a lump of wood. However, by 1703 it could be "… Chocks, belonging to the Screw-Mandrel". By 1807 the word had changed to the more familiar chuck'': "On the end of the spindle … is screwed … a universal Chuck for holding any kind of work".

In late 1818 or early 1819 the Society for the Encouragement of Arts, Manufactures and Commerce awarded its silver medal and 10 guineas (£10.50 – ) to Mr. Alexander Bell for a three jaw lathe chuck: It is not clear how they were moved "equably" whether by a scroll or some other means. Later in 1819 the same body awarded a further silver medal to Mr. T. Hack for a four jaw chuck. In the United States

At the start of the 20th century, Arthur Irving Jacobs developed the modern drill chuck. After bruising his knuckles on one of the old-fashioned spanner adjusted drill chucks, he developed a chuck in which the jaws moved axially in inclined slots. His details the mechanism. The term clearly did not originate with him, but his new type of drill chuck long ago displaced any earlier types that lacked the angled jaw movement and outer sleeve now found on all common drill chucks.

At the start of the 20th century, Arthur Irving Jacobs developed the modern drill chuck. After bruising his knuckles on one of the old-fashioned spanner adjusted drill chucks, he developed a chuck in which the jaws moved axially in inclined slots. His details the mechanism. The term clearly did not originate with him, but his new type of drill chuck long ago displaced any earlier types that lacked the angled jaw movement and outer sleeve now found on all common drill chucks.

A chuck is a specialized type of clamp used to hold an object with

A chuck is a specialized type of clamp used to hold an object with radial symmetry

Symmetry in biology refers to the symmetry observed in organisms, including plants, animals, fungi, and bacteria. External symmetry can be easily seen by just looking at an organism. For example, take the face of a human being which has a pla ...

, especially a cylinder

A cylinder (from ) has traditionally been a three-dimensional solid, one of the most basic of curvilinear geometric shapes. In elementary geometry, it is considered a prism with a circle as its base.

A cylinder may also be defined as an infin ...

. In a drill, a mill

Mill may refer to:

Science and technology

*

* Mill (grinding)

* Milling (machining)

* Millwork

* Textile mill

* Steel mill, a factory for the manufacture of steel

* List of types of mill

* Mill, the arithmetic unit of the Analytical Engine early ...

and a transmission, a chuck holds the rotating tool

A tool is an object that can extend an individual's ability to modify features of the surrounding environment or help them accomplish a particular task. Although many animals use simple tools, only human beings, whose use of stone tools dates ba ...

; in a lathe, it holds the rotating workpiece.

Chucks commonly use jaws to hold the tool or workpiece. The jaws (sometimes called dogs) are typically arranged in a radially symmetrical pattern like the points of a star. Jawed chucks may require a wrench

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning.

In the UK, Ireland, Australia, and New Zeala ...

-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms.

Instead of jaws, a chuck may use magnetism, vacuum

A vacuum is a space devoid of matter. The word is derived from the Latin adjective ''vacuus'' for "vacant" or " void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressure. Physicists often di ...

, or collets, which are flexible collars or sleeves that fit closely around the tool or workpiece and grip it when squeezed.

Types

Jawed chucks

Self-centering

A ''self-centering chuck'', also known as a ', usesdog

The dog (''Canis familiaris'' or ''Canis lupus familiaris'') is a domesticated descendant of the wolf. Also called the domestic dog, it is derived from the extinct Pleistocene wolf, and the modern wolf is the dog's nearest living relative. Do ...

s (usually called ''jaws''), interconnected via a ''scroll gear'' (scroll plate), to hold onto a tool or workpiece. Because they most often have three jaws, the term ''three-jaw chuck'' without other qualification is understood by machinists to mean a self-centering three-jaw chuck. The term ''universal chuck'' also refers to this type. These chucks are best suited to grip circular or hexagonal cross-sections when very fast, reasonably accurate (±0.005 inch .125 mm TIR) centering is desired.

Sometimes this type of chuck has four or six jaws instead of three. Four-jawed chucks are primarily useful for gripping square or octagon material, while six-jawed chucks hold thin-walled tubing and plastic materials with minimum distortion.

There are also independent-jaw (non-self-centering) chucks with three jaws, but they offer few advantages and are very rare.

There are hybrid self-centering chucks that have adjustment screws that can be used to further improve the concentricity after the workpiece has been gripped by the scroll jaws. This feature is meant to combine the speed and ease of the scroll plate's self-centering with the run-out

Run-out or runout is an inaccuracy of rotating mechanical systems, specifically that the tool or shaft does not rotate exactly in line with the main axis. For example; when drilling, run-out will result in a larger hole than the drill's nomina ...

eliminating controllability of an independent-jaw chuck. The most commonly used name for this type is a brand name, Set-Tru. To avoid undue genericization

A generic trademark, also known as a genericized trademark or proprietary eponym, is a trademark or brand name that, because of its popularity or significance, has become the generic term for, or synonymous with, a general class of products or ...

of that brand name, suggestions for a generic name have included "exact-adjust".

Three-jaw chucks are often used on lathes and indexing head

An indexing head, also known as a dividing head or spiral head, is a specialized tool that allows a workpiece to be circularly indexed; that is, easily and precisely rotated to preset angles or circular divisions. Indexing heads are usually use ...

s.

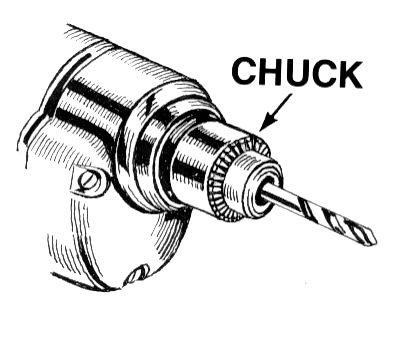

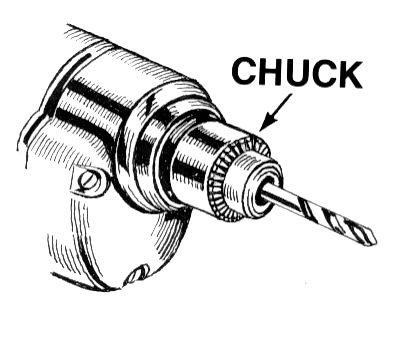

= Drill chuck

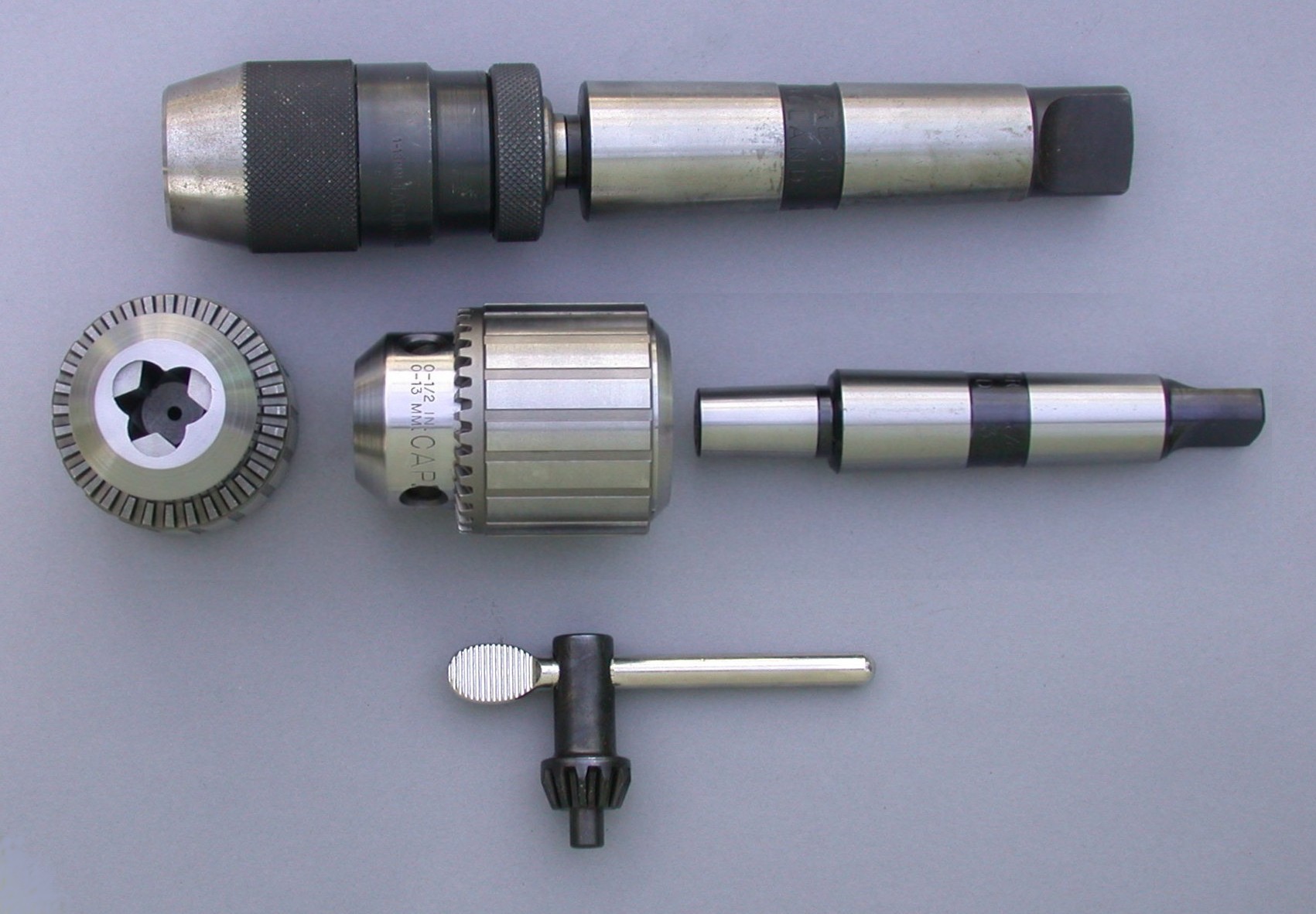

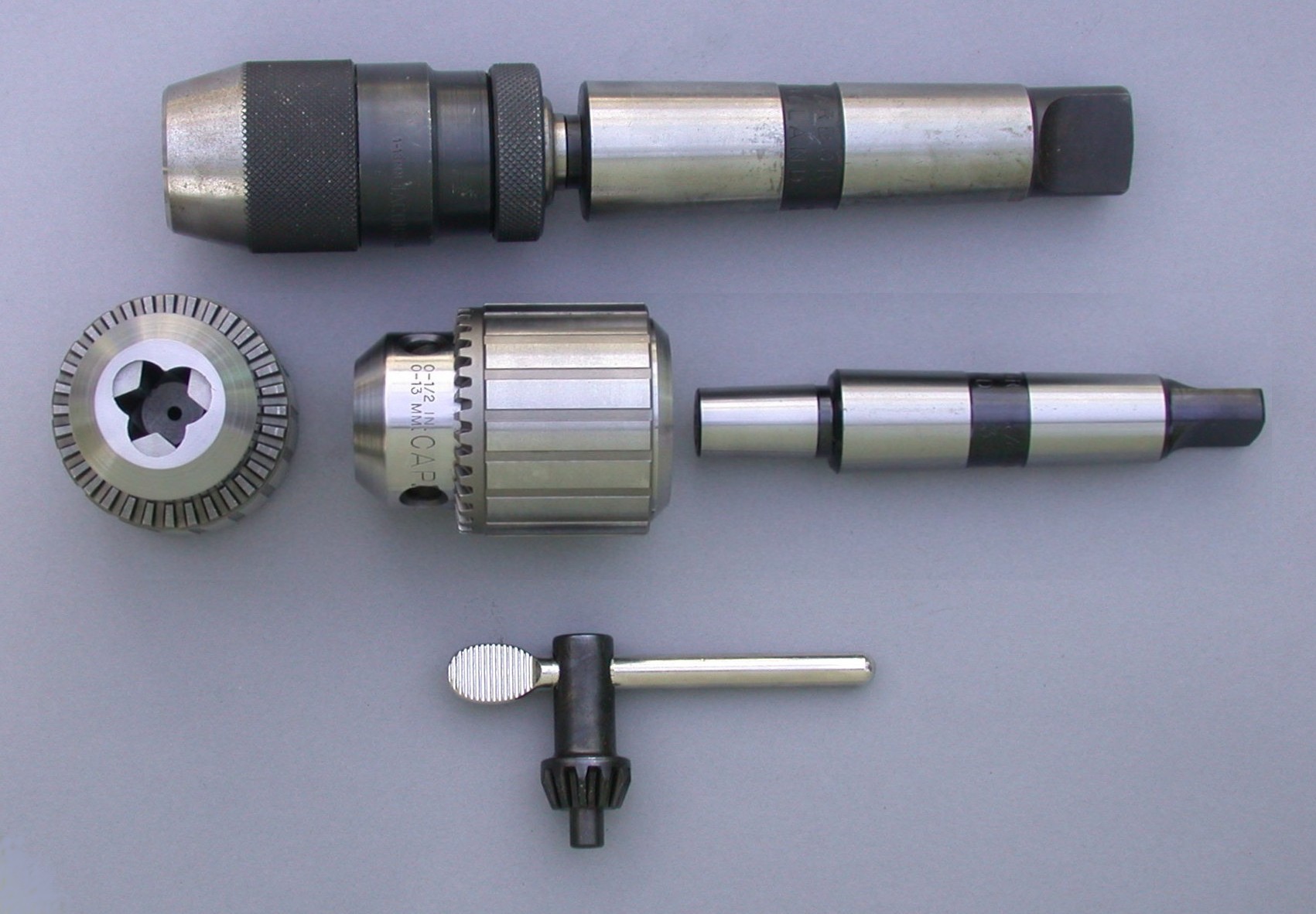

= A ''drill chuck'' is a specialised self-centering, three-jaw chuck, usually with capacity of or less, and rarely greater than , used to hold

A ''drill chuck'' is a specialised self-centering, three-jaw chuck, usually with capacity of or less, and rarely greater than , used to hold drill bit

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order ...

s or other rotary tools. This type of chuck is used on tools ranging from professional equipment to inexpensive hand and power drills for domestic use.

Some high-precision chucks use ball thrust bearings to reduce friction in the closing mechanism and maximize drilling torque. One brand name for this type of chuck, which is often genericized in colloquial use although not in catalogs, is ''Super Chuck''.

A ''pin chuck'' is a specialized chuck designed to hold small drills (less than in diameter) that could not be held securely in a normal drill chuck. The drill is inserted into the pin chuck and tightened; the pin chuck has a shaft which is then inserted into the larger drill chuck to hold the drill securely. Pin chucks are also used with high-speed rotary tools other than drills, such as die grinders and jig grinder

A jig grinder is a machine tool used for grinding complex shapes and holes where the highest degrees of accuracy and finish are required.

The jig grinder is very similar to a jig borer, in that the table positioning and spindles are very accu ...

s.

Independent-jaw

On an ', each jaw can be moved independently. Because they most often have four jaws, the term ''four-jaw chuck'' without other qualification is understood by machinists to mean a chuck with four independent jaws. The independence of the jaws makes these chucks ideal for (a) gripping non-circular cross sections and (b) gripping circular cross sections with extreme precision (when the last few hundredths of a millimeter r thousandths of an inchof runout must be manually eliminated). The non-self-centering action of the independent jaws makes centering highly controllable (for an experienced user), but at the expense of speed and ease. Four-jaw chucks are almost never used for tool holding. Four-jaw chucks can be found on lathes and indexing heads.

Self-centering chucks with four jaws also can be obtained. Although these are often said to suffer from two disadvantages: inability to hold hex stock, and poor gripping on stock which is oval, only the latter is true. Even with three jaw self centering chucks, work which is not of uniform section along the work (and which is not free of spiral or 'wind') should not be gripped, as the jaws can be strained and the accuracy permanently impaired.

Four-jaw chucks can easily hold a workpiece eccentrically if eccentric features need to be machined.

On an ', each jaw can be moved independently. Because they most often have four jaws, the term ''four-jaw chuck'' without other qualification is understood by machinists to mean a chuck with four independent jaws. The independence of the jaws makes these chucks ideal for (a) gripping non-circular cross sections and (b) gripping circular cross sections with extreme precision (when the last few hundredths of a millimeter r thousandths of an inchof runout must be manually eliminated). The non-self-centering action of the independent jaws makes centering highly controllable (for an experienced user), but at the expense of speed and ease. Four-jaw chucks are almost never used for tool holding. Four-jaw chucks can be found on lathes and indexing heads.

Self-centering chucks with four jaws also can be obtained. Although these are often said to suffer from two disadvantages: inability to hold hex stock, and poor gripping on stock which is oval, only the latter is true. Even with three jaw self centering chucks, work which is not of uniform section along the work (and which is not free of spiral or 'wind') should not be gripped, as the jaws can be strained and the accuracy permanently impaired.

Four-jaw chucks can easily hold a workpiece eccentrically if eccentric features need to be machined.

= Spiders

= A spider is a simple, relatively inexpensive, limited-capability version of an independent-jaw chuck. It typically consists of a ring of metal with screw threads tapped radially into it, in which screws (hex cap, socket hex cap, or set screws) serve as independent jaws. Spiders can serve various purposes: * As auxiliary features that complement the main lathe chuck: ** To hold the bar or workpiece at the back end of the spindle bore and support it concentrically, so that it resists wobbling or whipping while the spindle is turning. Gun barrels and oil pipes are examples of workpieces that benefit. ** To hold the bar or workpiece at the tailstock end (thus serving as a steady rest) or following the tool (thus serving as a follower rest). * In place of the main lathe chuck (for particular workpieces that can benefit—for example, in somegunsmithing

A gunsmith is a person who repairs, modifies, designs, or builds guns. The occupation differs from an armorer, who usually replaces only worn parts in standard firearms. Gunsmiths do modifications and changes to a firearm that may require a very ...

work)

Specialty jawed types (two-, six-, eight-jaw; other)

For special purposes, chucks are available with ''six'' or ''eight'' jaws. These are usually of the self-centering design, and may be built to very high standards of accuracy. However, it is a misconception that such chucks necessarily offer more precision in holding solid workpieces than conventional three-jawed self-centering chucks. Indeed, hot-rolled or other imperfectly round workpieces may "teeter" insecurely between opposing jaws of scroll chucks having even numbers of jaws, in the same manner that a four-legged stool teeters on a rough floor while a three-legged stool never does. The primary purpose of six- and eight-jawed chucks is to hold thin-walled tubing with minimum deformation. By having twice as many clamping points, a six-jaw chuck induces less than half as much clamping distortion in a thin-walled workpiece, compared to a three-jawed chuck.

''Two-jaw chucks'' are available and can be used with

For special purposes, chucks are available with ''six'' or ''eight'' jaws. These are usually of the self-centering design, and may be built to very high standards of accuracy. However, it is a misconception that such chucks necessarily offer more precision in holding solid workpieces than conventional three-jawed self-centering chucks. Indeed, hot-rolled or other imperfectly round workpieces may "teeter" insecurely between opposing jaws of scroll chucks having even numbers of jaws, in the same manner that a four-legged stool teeters on a rough floor while a three-legged stool never does. The primary purpose of six- and eight-jawed chucks is to hold thin-walled tubing with minimum deformation. By having twice as many clamping points, a six-jaw chuck induces less than half as much clamping distortion in a thin-walled workpiece, compared to a three-jawed chuck.

''Two-jaw chucks'' are available and can be used with soft jaw

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever.

A vise grip is n ...

s (typically an aluminium alloy) that can be machined to conform to a particular workpiece. It is a short conceptual leap from these to faceplate

Faceplate (face plate, face-plate) is a plate, cover, or bezel on the front of a device, such as:

Computers and electronics

* Electrical outlet, also referred to as a wall plate, outlet cover, or socket cover

* Front panel, of computers

* Head ...

s holding custom fixtures, wherein the part is located against fixed stops and held there with toggle clamps or toe clamps.

Jaw construction

Many chucks have removable jaws (often the top part is removable leaving the base or 'master jaw' assembled with the scroll), which allows the user to replace them with new jaws, specialised jaws, or soft jaws. Soft jaws are made of soft materials such as soft (unhardened) metal, plastic, or wood. They can be machined as needed for particular setups. The typical interface between the master jaw and the removable jaw is a matching pair of serrated surfaces, which, once clamped by the mounting screws, cannot allow relative slipping between the two parts.Collet

A collet, one type of chuck, is a sleeve with a (normally) cylindrical inner surface and a conical outer surface. The collet can be squeezed against a matching taper such that its inner surface contracts to a slightly smaller diameter, squeezing the tool or workpiece whose secure holding is desired. Most often this is achieved with a spring collet, made ofspring steel

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon stee ...

, with one or more kerf

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and mo ...

cuts along its length to allow it to expand and contract. An alternative collet design is one that has several tapered steel blocks (essentially tapered gauge block

Gauge blocks (also known as gage blocks, Johansson gauges, slip gauges, or Jo blocks) are a system for producing precision lengths. The individual gauge block is a metal or ceramic block that has been precision ground and lapped to a specific ...

s) held in circular position (like the points of a star, or indeed the jaws of a jawed chuck) by a flexible binding medium (typically synthetic or natural

Nature, in the broadest sense, is the physical world or universe. "Nature" can refer to the phenomena of the physical world, and also to life in general. The study of nature is a large, if not the only, part of science. Although humans are ...

rubber). The Jacobs Rubber-Flex brand is a name that most machinists would recognize for this type of collet chuck system.

Regardless of the collet design, the operating principle is the same: squeeze the collet radially against the tool or workpiece to be held, resulting in high static friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of t ...

. Under correct conditions, it holds quite securely. Almost all collet chucks achieve the radial squeezing motion via moving one or more male-female pairs of tapered (conical) surfaces axially, which produces the radial squeezing in a highly concentric manner. Depending on the collet design, it can be either pulled (via a threaded section at the rear of the collet) or pushed (via a threaded cap with a second taper) into a matching conical socket to achieve the clamping action. As the collet is forced into the tapered socket, the collet will contract, gripping the contents of the inner cylinder. (The axial movement of cones is not mandatory, however; a split bushing squeezed radially with a linear force—e.g., set screw, solenoid, spring clamp, pneumatic or hydraulic cylinder—achieves the same principle without the cones; but concentricity can only be had to the extent that the bushing's diameters are perfect for the particular object being held. Thus only in toolroom contexts, such as machine tool tooling creation and setup, is this common.)

One of the corollaries of the conical action is that collets may draw the work axially a slight amount as they close. Collet chuck systems that make no provision to prevent this draw-in are often called draw-in collet chucks, in contrast to systems which circumvent this movement, usually by pushing the tapered closing ring toward the collet rather than pulling the collet into the ring. Such non-draw-in types are often called "dead-length" or "non-draw-in" collet chucks. Draw-in is not always a problem, but avoiding it can be helpful on some work where failing to account for it might result in inaccuracy on part overall length, shoulder lengths, etc.

Collets are most commonly found on milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

s, lathes, wood router

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs (hollows out) an area in hard material, such as wood or plastic. Rout ...

s, precision grinders

Grinder may refer to:

Machinery

*Various types of grinding machine, used in a machining operation to refine the surface of materials

*Food grinders

**Blade grinder, includes food processors, blenders, electric coffee and spice grinders, etc.

**Co ...

, and certain handheld power tools such as die grinders and rotary tool

Die grinders and rotary tools are handheld power tools used for grinding, sanding, honing, polishing, or machining material (typically metal, but also plastic or wood). All such tools are conceptually similar, with no bright dividing line bet ...

s. There are many different systems, common examples being the ''ER'', ''5C'', and ''R8'' systems. Collets can also be obtained to fit ''Morse'' or ''Brown and Sharpe'' taper

Taper may refer to:

* Part of an object in the shape of a cone (conical)

* Taper (transmission line), a transmission line gradually increasing or decreasing in size

* Fishing rod taper, a measure of the flexibility of a fishing rod

* Conically t ...

sockets.

Typically collets offer higher levels of precision

Precision, precise or precisely may refer to:

Science, and technology, and mathematics Mathematics and computing (general)

* Accuracy and precision, measurement deviation from true value and its scatter

* Significant figures, the number of digit ...

and accuracy

Accuracy and precision are two measures of ''observational error''.

''Accuracy'' is how close a given set of measurements ( observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each oth ...

than self-centering chucks, and have a shorter setting up time than independent-jaw chucks. The penalty is that most collets can only accommodate a single size of workpiece. An exception is the ER collet which typically has a working range of 1 mm (about 0.04 in).

Collets usually are made to hold cylindrical work, but are available to hold square, hexagonal or octagonal workpieces. While most collets are hardened, "emergency" collets are available that can be machined to special sizes or shapes by the user. These collets can be obtained in steel, brass, or nylon. Step collets are available that are machinable to allow holding of short workpieces that are larger than the capacity of normal collets.

Special Direct System (SDS)

Developed by Bosch in 1975 for

Developed by Bosch in 1975 for hammer drill

A hammer drill, also known as a percussion drill or impact drill, is a power tool used chiefly for drilling in hard materials. It is a type of rotary drill with an impact mechanism that generates a hammering motion. The percussive mechanism prov ...

s, the ''SDS System'' uses an SDS Shank which is a cylindrical shank with indentations to be held by the chuck. A tool is inserted into the chuck, and is locked in place until the lock is released. The rotary force is transmitted through wedges that fit into two or three open grooves. The bit is free to move a short distance and the hammer action moves the bit up and down within the chuck. Two sprung balls fit into closed grooves, allowing movement whilst retaining the bit. There are four standard sizes with varying shank diameters:

; SDS Quick: A 6 mm shank with two open grooves interacting with the driving wedges and two closed grooves held by locking balls. This is the newest size introduced in 2011 for the Bosch Uneo series and takes concrete drills up to 10 mm diameter.

SDS-Plus

: A 10 mm shank with two open grooves interacting with the driving wedges and two closed grooves held by locking balls. This is the most common size and takes a hammer up to 4 kg. The wedges grip an area of and the shank is inserted 40 mm into the chuck. ; SDS-top: A 14 mm shank similar to SDS-plus, designed for hammers from 2 to 5 kg. The grip area is increased to and the shank is inserted 70 mm. This size remained uncommon and was discontinued in 2009. ; SDS-max: An 18 mm shank with three open grooves and locking segments rather than balls. It is designed for hammers over 5 kg. The wedges grip an area of and the shank is inserted 90 mm. Many SDS drills have a "rotation off" setting, which allows the drill to be used for chiselling. The name SDS comes from the German ''Steck-Dreh-Sitz'' (''insert-drill-attachment''). In German-speaking countries the acronym ''Spannen durch System'' (Clamping System) was also used, though Bosch now uses ''Special Direct System'' internationally. (German language)Chucks with both indexable positioning and indexable clamping

Commercial production machining now makes use of increasingly advanced chucks which have not only indexable positioning but also indexable clamping.. Both functions are typically hydraulically controlled. The clamping is often done with each pair of jaws consisting of one fixed jaw and one movable jaw (hydraulically actuated), thematically similar to advanced millingvise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever.

A vise grip is n ...

s. This method of clamping brings the high precision and repeatability of such vises to a chucking application. Such chucks offer the centering precision of traditional independent-jaw chucks with the chucking speed and ease of traditional three-jaw self-centering scroll chucks. They have expensive initial cost (compared with traditional chucks), but such initial cost pays for itself and then lowers ongoing marginal costs in commercial production-run environments.

It is also possible nowadays to build CNC chucks in which the position and clamping pressure of each jaw can be precisely controlled with CNC, via closed-loop positioning and load monitoring. In essence, each jaw is one independent CNC axis, a machine slide with a leadscrew, and all four or six of them can act in concert with each other. Although this idea is conceptually interesting, the simpler chucking systems mentioned in the previous paragraph are probably a marketplace winner over this alternative for most applications, because they supply the same capabilities via a simpler, less expensive solution.

Magnetic

Used for holding ferromagnetic workpieces, a ''magnetic chuck'' consists of an accurately centred permanentmagnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nicke ...

face. Electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in ...

s or permanent magnets are brought into contact with fixed ferrous plates, or ''pole pieces'', contained within a housing. These pole pieces are usually flush with the housing surface. The part (workpiece) to be held forms the closing of the magnetic loop or path, onto those fixed plates, providing a secure anchor for the workpiece.

Electrostatic

Commonly used for holding silicon wafers during lithography processes, an ''electrostatic chuck'' comprises a metal base-plate and a thin dielectric layer; the metal base-plate is maintained at a high-voltage relative to the wafer, and so an electrostatic force clamps the wafer to it. Electrostatic chucks may have pins, or mesas, the height of which is included in the reported dielectric thickness; a design bySandia National Laboratory

Sandia National Laboratories (SNL), also known as Sandia, is one of three research and development laboratories of the United States Department of Energy's National Nuclear Security Administration (NNSA). Headquartered in Kirtland Air Force Bas ...

uses a patterned silicon-dioxide dielectric to form the pins.

Vacuum

A vacuum chuck is primarily used on non-ferrous materials, such as copper, bronze, aluminium, titanium, plastics, and stone. In a vacuum chuck, air is pumped from a cavity behind the workpiece, and atmospheric pressure provides the holding force. Vacuum produces a hold down pressure of at sea level, decreasing at higher elevations where the atmospheric pressure is lower. The decrease in holding pressure is roughly 0.5 psi per 1000' above sea level.Mounting methods

Connecting chucks to the spindles or tables ofmachine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All ...

s or power tool

A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labor used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed ...

s has been accomplished in many ways over the years.

Mounting of drill chucks

* A may screw into the chuck body. * A (with a self-holding taper) may be pressed into the chuck body. ** Removal and insertion may involve various tools or methods: *** Tools:vise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever.

A vise grip is n ...

(especially with a wooden jig or soft jaw made for this purpose); hammer (especially nonmarring hammer or rubber mallet); arbor press

An arbor press is a small hand-operated press. It is typically used to perform smaller jobs, such as staking, riveting, installing, configuring and removing bearings and other press fit work. Punches, inserters, or other tools/dies may be add ...

or shop press (the latter two require skill to avoid damaging the chuck).

*** Methods: heating (via heat gun

A heat gun is a device used to emit a stream of hot air, usually at temperatures between 100 °C and 550 °C (200-1000 °F), with some hotter models running around 760 °C (1400 °F), which can be held by hand. Heat ...

s, blow torch

A blowtorch, also referred to as a blowlamp, is an ambient air fuel-burning gas lamp used for applying flame and heat to various applications, usually metalworking.

Early blowtorches used liquid fuel, carried in a refillable reservoir attach ...

es, or ovens) and cooling (via kitchen freezers, winter weather, or decompression of compressed air or nitrogen).

* A drill chuck may have a hollow body that threads directly onto a lathe's threaded spindle nose. (These are fairly rare, especially nowadays.)

Mounting of large jawed chucks

* A backplate with threads may screw onto a threaded spindle nose (for lathe work) or onto an adapter plate with the same nose, to be mounted on the table of

* A backplate with threads may screw onto a threaded spindle nose (for lathe work) or onto an adapter plate with the same nose, to be mounted on the table of milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

s or surface grinding machines. This "threaded spindle nose" type of mounting was the typical method in the 19th century through 1930s. It is simple and useful, but the degree of control of concentricity is not quite good enough to be foolproof for high-speed, high-precision work (high precision can be achieved, but the time and skill involved in the setups makes it a poor choice now that better options exist, such as the cam-lock spindle noses described below). Threaded spindle noses are still built on new machine tools, but only of the low-end variety (hobbyist, least-expense MRO, etc.). High-capital manufacturing (where high upfront expense yields lowest possible unit expense for mid- to high-volume part counts of high-precision parts) has moved away from this type of mounting. The exact-adjust (Set-Tru) concept is one way to chase high concentricity on threaded spindle noses with some relative degree of ease.

* A common solution on smaller lathes is a broad flanged end to the spindle with a concentric raised circular register matching a recess in the chuck or its backplate. The register is normally shallow and parallel sided and a light push fit in the female register of the chuck. The chuck is held in place with bolts through clearance holes that do not affect the alignment which is entirely provided by the register. This arrangement has excellent repeatability but is slow in a production situation.

* A backplate with a female (self-releasing) taper may seat on the matching male taper of the tapered spindle nose (for lathe work) or of an adapter plate with the same nose, to be mounted on a table. This system improves the repeatability of the mounting concentricity down to a very small total indicated runout (TIR) value. Subtypes:

** The chuck may be held against the taper with a threaded retainer ring (large thin nut

Nut often refers to:

* Nut (fruit), fruit composed of a hard shell and a seed, or a collective noun for dry and edible fruits or seeds

* Nut (hardware), fastener used with a bolt

Nut or Nuts may also refer to:

Arts, entertainment, and media Co ...

), typically wrenched with a spanner wrench of the pin or hook variety. The peak of popularity for building this type of spindle nose was the 1940s and 1950s.

** The chuck may be held against the taper with cam-lock posts that wedge into a stuck-fast position. Industry-standard spindle nose designs allow wide interchangeability

Interchangeability can refer to:

*Interchangeable parts

Interchangeable parts are parts (components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into ...

. This cam lock spindle nose system replaced the earlier systems on most machine tools in the 1960s.

Mounting of collet chucks

* For collet chucks mounted on backplates, all of the same methods above are applicable. * Many lathes that run collet chucks have dedicated collet-closer setups whereby there is no backplate, and the spindle nose contains the female taper for either the collet's male outer taper, or a sleeve that will hold it. A hollow drawbar passes back through the headstock to its back side, where a closer mechanism is mounted. The latter allows easy, rapid opening and closing of the collet. The drawbar's inner diameter determines the through-the-spindlebar

Bar or BAR may refer to:

Food and drink

* Bar (establishment), selling alcoholic beverages

* Candy bar

* Chocolate bar

Science and technology

* Bar (river morphology), a deposit of sediment

* Bar (tropical cyclone), a layer of cloud

* Bar (u ...

diameter capacity of the lathe. Some collet-closer systems even allow opening and closing without stopping the spindle rotation. The closer on a manual lathe is either lever-style or handwheel-style. The closer on a CNC lathe is powered (electric, hydraulic, or pneumatic), and it may be controlled by various means: a foot pedal that the operator steps on when desired; a line in the program (for opening and closing under program control); or a button on the control panel.

History

The original forms of workholding on lathes were between-centers holding and ''ad hoc'' fastenings to the headstock spindle. The spike-style centers still used on wood lathes represent an ancient method. ''Ad hoc'' fastening methods in centuries past included anything from pinning with clenching or wedging; nailing; lashing with cords of leather or fiber; dogging down (again involving pinning/wedging/clenching); or other types. Faceplates have probably been around at least since the era of medieval clock-makers.

Tooling similar to today's chucks seems likely to have evolved from faceplate work, as workers using faceplates for repetitive work began to envision types of clamps or dogs for the faceplate that could be opened and closed in more convenient ways than repeated total disassembly and reassembly.

A ''chock'' was originally just a lump of wood. However, by 1703 it could be "… Chocks, belonging to the Screw-Mandrel". By 1807 the word had changed to the more familiar chuck'': "On the end of the spindle … is screwed … a universal Chuck for holding any kind of work".

In late 1818 or early 1819 the Society for the Encouragement of Arts, Manufactures and Commerce awarded its silver medal and 10 guineas (£10.50 – ) to Mr. Alexander Bell for a three jaw lathe chuck: It is not clear how they were moved "equably" whether by a scroll or some other means. Later in 1819 the same body awarded a further silver medal to Mr. T. Hack for a four jaw chuck. In the United States

The original forms of workholding on lathes were between-centers holding and ''ad hoc'' fastenings to the headstock spindle. The spike-style centers still used on wood lathes represent an ancient method. ''Ad hoc'' fastening methods in centuries past included anything from pinning with clenching or wedging; nailing; lashing with cords of leather or fiber; dogging down (again involving pinning/wedging/clenching); or other types. Faceplates have probably been around at least since the era of medieval clock-makers.

Tooling similar to today's chucks seems likely to have evolved from faceplate work, as workers using faceplates for repetitive work began to envision types of clamps or dogs for the faceplate that could be opened and closed in more convenient ways than repeated total disassembly and reassembly.

A ''chock'' was originally just a lump of wood. However, by 1703 it could be "… Chocks, belonging to the Screw-Mandrel". By 1807 the word had changed to the more familiar chuck'': "On the end of the spindle … is screwed … a universal Chuck for holding any kind of work".

In late 1818 or early 1819 the Society for the Encouragement of Arts, Manufactures and Commerce awarded its silver medal and 10 guineas (£10.50 – ) to Mr. Alexander Bell for a three jaw lathe chuck: It is not clear how they were moved "equably" whether by a scroll or some other means. Later in 1819 the same body awarded a further silver medal to Mr. T. Hack for a four jaw chuck. In the United States Simon Fairman

Simon Fairman (1792–1857) of West Stafford, Connecticut, is credited as having invented the scroll-type lathe chuck

Chuck is a masculine given name or a nickname for Charles or Charlie. It may refer to:

People

Arts and entertainment

* Chuck ...

(1792–1857) developed a recognisable modern scroll chuck as used on lathes. The patent refers to the technicalities of assembly, he does not claim invention of the scroll ("convolute grooves"). His son-in-law Austin F. Cushman (1830–1914) developed the ideas and sold chucks through his business, Cushman Industries.

Jacobs Chuck

At the start of the 20th century, Arthur Irving Jacobs developed the modern drill chuck. After bruising his knuckles on one of the old-fashioned spanner adjusted drill chucks, he developed a chuck in which the jaws moved axially in inclined slots. His details the mechanism. The term clearly did not originate with him, but his new type of drill chuck long ago displaced any earlier types that lacked the angled jaw movement and outer sleeve now found on all common drill chucks.

At the start of the 20th century, Arthur Irving Jacobs developed the modern drill chuck. After bruising his knuckles on one of the old-fashioned spanner adjusted drill chucks, he developed a chuck in which the jaws moved axially in inclined slots. His details the mechanism. The term clearly did not originate with him, but his new type of drill chuck long ago displaced any earlier types that lacked the angled jaw movement and outer sleeve now found on all common drill chucks.

Performance evaluation

National and international standards are used to standardize the definitions, requirements, and test methods used for the performance evaluation of chucks. Selection of the standard to be used is an agreement between the supplier and the user and has some significance in the design of the chuck. In the United States,ASME

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

has developed the B5.60 Standard entitled Workholding Chucks: Jaw-Type Chucks, which establishes requirements and methods for specifying and testing the performance of workholding chucks used primarily in turning operations.

See also

* Collet *Drill bit shank

The shank is the end of a drill bit grasped by the chuck of a drill. The cutting edges of the drill bit contact the workpiece, and are connected via the shaft with the shank, which fits into the chuck. In many cases a general-purpose arrangement ...

* Lathe faceplate

A lathe faceplate is a basic workholding accessory for a wood or metal turning lathe. It is a circular metal (usually cast iron) plate which fixes to the end of the lathe spindle. The workpiece

A workpiece is a piece, often made of a single ...

* Mandrel

* Mechanical pencil

A mechanical pencil, also clutch pencil, is a pencil with a replaceable and mechanically extendable solid pigment core called a "lead" . The lead, often made of graphite, is not bonded to the outer casing, and can be mechanically extended as its ...

* Woodturning

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a simple mechanism that can generate a variety of forms. The operator ...

* Wrench

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning.

In the UK, Ireland, Australia, and New Zeala ...

References

Bibliography

* {{DEFAULTSORT:Chuck (Engineering) Clamps (tool) Lathes Machine tools Woodworking clamps