|

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. Usually the term "turning" is reserved for the generation of ''external'' surfaces by this cutting action, whereas this same essential cutting action when applied to ''internal'' surfaces (holes, of one kind or another) is called " boring". Thus the phrase "turning and boring" categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called "facing", and may be lumped into either category as a subset. Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Collet

A collet is a segmented sleeve, band or ''collar''. One of the two radial surfaces of a collet is usually tapered (i.e a truncated cone) and the other is cylindrical. The term ''collet'' commonly refers to a type of chuck that uses collets to hold either a workpiece or a tool (such as a drill) but has other mechanical applications. An external collet is a sleeve with a cylindrical inner surface and a conical outer surface. The collet can be squeezed against a matching taper such that its inner surface contracts to a slightly smaller diameter, squeezing the tool or workpiece to hold it securely. Most often the collet is made of spring steel, with one or more kerf cuts along its length to allow it to expand and contract. This type of collet holds the external surface of the tool or workpiece being clamped. This is the most usual type of collet chuck. An external collet clamps against the internal surface or bore of a hollow cylinder. The collet's taper is internal and the c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dog (engineering)

In engineering, a dog is a tool or part of a tool, such as a pawl, that prevents or imparts movement through physical engagement. It may hold another object in place by blocking it, clamping it, or otherwise obstructing its movement. Or it may couple various parts together so that they move in unison – the primary example of this being a flexible drive to mate two shafts in order to transmit torque. Some devices use dog clutches to lock together two spinning components. In a manual transmission, the dog clutches, or "dogs" lock the selected gear to the shaft it rotates on. Unless the dog is engaged, the gear will simply freewheel on the shaft. This word usage is a metaphor derived from the idea of a dog (animal) biting and holding on, the "dog" name derived from the basic idea of how a dog jaw locks on, by the movement of the jaw, or by the presence of many teeth. In engineering the "dog" device has some special engineering work when making it – it is not a simple part to ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

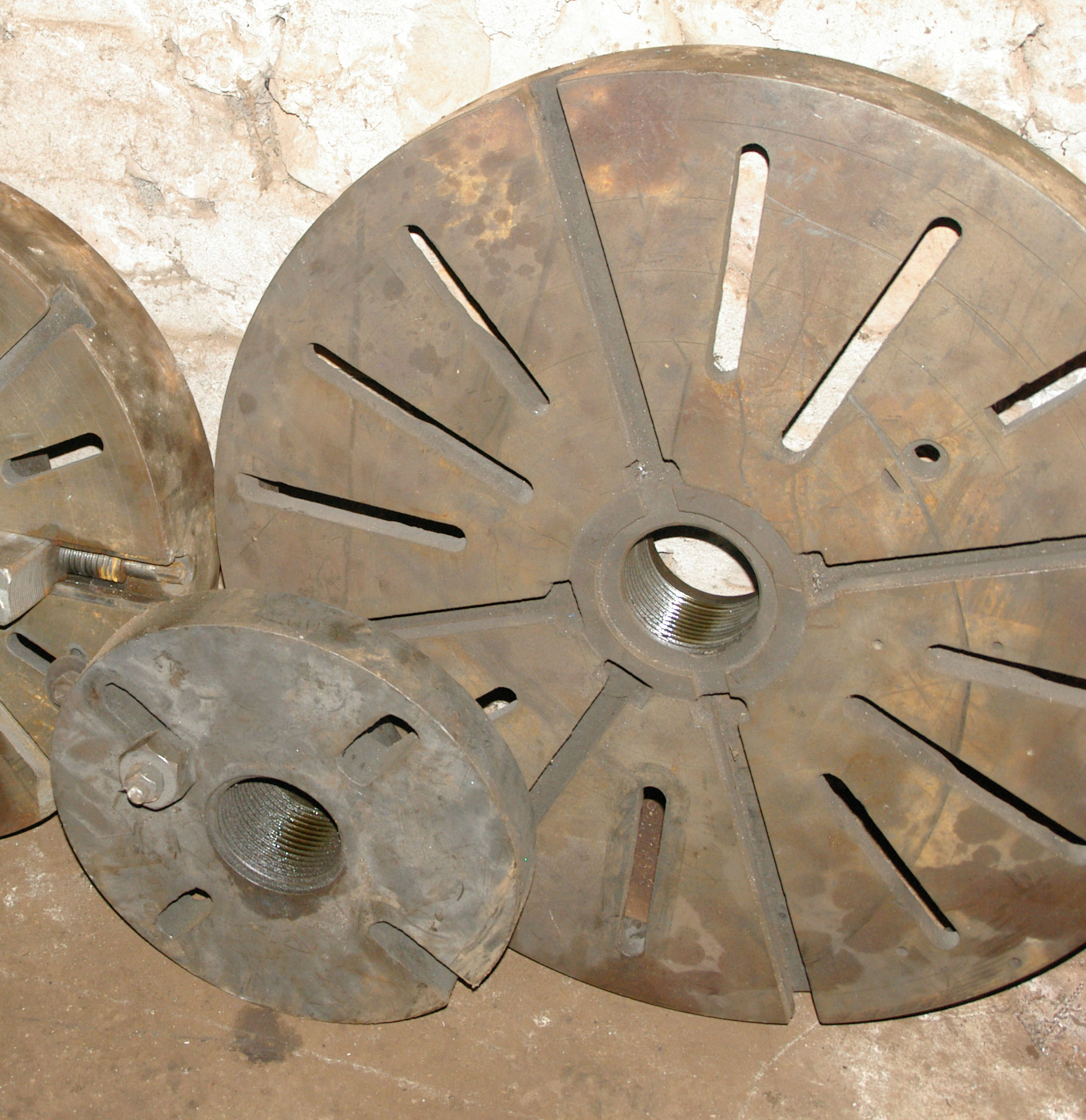

Lathe Faceplate

A lathe faceplate is a basic workholding accessory for a wood or metal turning lathe. It is a circular metal (usually cast iron) plate which fixes to the end of the lathe spindle. The workpiece A workpiece is a piece, often made of a single material, that is being processed into another desired shape (such as building blocks). The workpiece is usually a piece of relatively rigid material such as wood, metal, plastic, or stone. After a ... is then clamped to the faceplate, typically using t-slot nuts in slots in the faceplate, or less commonly threaded holes in the faceplate itself. The faceplate may be attached to the lathe in several ways: the two most common are a thread and a precision cone arrangement, and threaded studs and a circular recess fitting a flange on the end of the spindle. Increasingly common is the camlock arrangement, in which shaped studs and cams replace threaded studs for rapid exchanging of the faceplate with other accessories, such as three or fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodturning

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a simple mechanism that can generate a variety of forms. The operator is known as a turner, and the skills needed to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known as 'the misterie' of the turners guild. The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinist's lathe, or metal-working lathe. Items made on the lathe include tool handles, candlesticks, egg cups, knobs, lamps, rolling pins, cylindrical boxes, Christmas ornaments, bodkins, knitting needles, needle cases, thimbles, pens, chessmen, spinning tops; legs, spindles, and pegs for furniture; balusters and newel posts for architecture; baseball bats, hollow forms such as wood ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining proc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Facing (machining)

Facing in machining can be used in two different areas: facing on a milling machine and facing on a lathe. Facing on the milling machine involves various milling operations, but primarily face milling. On the lathe, facing is commonly used in turning and boring operations. Other operations remove material in ways similar to facing, for example, planing, shaping, and grinding, but these processes are not labeled by the term "facing." Facing lathe operation Facing on the lathe uses a facing tool to cut a flat surface perpendicular to the work piece's rotational axis. A facing tool is mounted into a tool holder that rests on the carriage of the lathe. The tool will then feed perpendicularly across the part's rotational axis as it spins in the jaws of the chuck. A user will have the option to hand feed the machine while facing, or use the power feed option. For a smoother surface, using the power feed option is optimal due to a constant feed rate. Facing will take the work piece ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips (swarf) from the hole as it is drilled. In rock drilling, the hole is usually not made through a circular cutting motion, though the bit is usually rotated. Instead, the hole is usually made by hammering a drill bit into the hole with quickly repeated short movements. The hammering action can be performed from outside the hole ( top-hammer drill) or within the hole ( down-the-hole drill, DTH). Drills used for horizontal drilling are called drifter drills. In rare cases, specially-shaped bits are used to cut holes of non-circular cross-section; a square cross-section is possible. Process Drilled holes ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knurling

Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Etymology The terms ''knurl'' and ''knurled'' are from an earlier ''knur'' ‘knot in wood’ and the diminutive ''-le'', from Middle English ''knaur'' or ''knarre'' ‘knot in wood; twisted rock; crag’. This descends from Old English ''cnearra'' but the vowel in Middle English may have been influenced by Old Norse ''knǫrr'' ‘merchant ship’ which was known as ''cnearr'' in Old English. The modern ''gnarl'' is a back-formation of ''gnarled'' which itself is first attested in Shakespeare’s works and is apparently a variant of ''knurled''. Uses The operation is performed for producing indentations on a part of a workpiece. Knurling allows hands or fingers to get a better grip on the knurled object than would be provided by the originally smooth metal surface. Occasionally, the knurled pattern is a series of straight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to fasten materials by the engagement of the screw thread with a similar ''female thread'' (internal thread) in a matching part. Screws are often self-threading (also known as self-tapping) where the thread cuts into the material when the screw is turned, creating an internal thread that helps pull fastened materials together and prevents pull-out. There are many screws for a variety of materials; materials commonly fastened by screws include wood, sheet metal, and plastic. Explanation A screw is a combination of simple machines: it is, in essence, an inclined plane wrapped around a central shaft, but the inclined plane (thread) also comes to a sharp edge around the outside, which acts as a wedge as it pushes into the fastened material, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |